Sterilization using high-pressure carbon dioxide

Year:

Abstract:

Disclosed are compositions and methods for the biocompatible sterilization of materials, in particular, of medical devices and implants. Sterilization is achieved by deactivation of microorganisms through treatment of the material with a mixture of at least one microbiocidal additive and a high-pressure or supercritical fluid, for example, high-pressure carbon dioxide or supercritical carbon dioxide. This abstract is intended as a scanning tool for purposes of searching in the particular art and is not intended to be limiting of the present invention.

Type of document:

Language:

(19) United States

US 20 1 00080790A1

(12) Patent Application Publication (10) Pub. No.: US 2010/0080790 A1

Matthews et al.

(43) Pub. Date: Apr. 1, 2010

(54) STERILIZATION USING HIGH-PRESSURE

CARBON DIOXIDE

(75) Inventors: Michael A. Matthews,

Blythewood, SC (U S); Jian Zhang,

West Columbia, SC (U S)

Correspondence Address:

Ballard Spahr LLP

SUITE 1000, 999 PEACHTREE STREET

ATLANTA, GA 30309-3915 (US)

(73) Assignee: University of South Carolina

(21) Appl. No.: 11/995,654

(22) PCT Filed: Jul. 7, 2006

(86) PCT No.: PCT/US06/26412

§ 371 (OX1),

(2), (4) Date: Apr. 26, 2009

Ltzegg 9.}

Related U.S. Application Data

(60) Provisional application No. 60/699,007, filed on Jul.

13, 2005.

Publication Classification

(51) Int. Cl.

A61L 2/18 (2006.01)

A01N 59/04 (2006.01)

A01N 63/00 (2006.01)

A01P 1/00 (2006.01)

A61L 2/00 (2006.01)

(52) U.S. Cl. ....................... .. 424/94.61; 424/700; 422/33

(57) ABSTRACT

Disclosed are compositions and methods for the biocompat-

ible sterilization of materials, in particular, of medical devices

and implants. Sterilization is achieved by deactivation of

microorganisms through treatment of the material with a

mixture of at least one microbiocidal additive and a high-

pressure or supercritical fluid, for example, high-pressure

carbon dioxide or supercritical carbon dioxide. This abstract

is intended as a scarming tool for purposes of searching in the

particular art and is not intended to be limiting of the present

invention.

Patent Application Publication Apr. 1, 2010 US 2010/0080790 A1

?“‘.“*

$n'u'(

.-W *"‘

3 ~$§

«>1-Tr.

,....u...-.........w......m«...,

5

1.

,‘, ‘f

, ‘*3? _ ~ x V _i

’25»=T§:Qi:§2.§;. :2

US 2010/0080790 A1

STERILIZATION USING HIGH-PRESSURE

CARBON DIOXIDE

CROSS-REFERENCE TO RELATED

APPLICATIONS

[0001] This application claims the benefit of U.S. Applica-

tion No. 60/699,007, filed Jul. 13, 2005, which is hereby

incorporated herein by reference in its entirety.

ACKNOWLEDGEMENT

[0002] This invention was made with government support

under Grant R01 EB 055201 awarded by the National Insti-

tutes of Health. The government has certain rights in the

invention.

BACKGROUND

[0003] Sterilization of medical devices that are used in

intimate contact with the human body is crucial to aid in

prevention of patient infection. Sterilization of medical

devices and implants is a serious issue for surgical wards and

hospitals. For example, in the United States, over 600,000

arthroplasties are performed each year, of which 0.6-2.3%

result in infection. These infections can cause substantial

physical injury or even death to the patient. Some other

widely used medical devices, such as endoscopes, can also

cause infection if not properly sterilized. Disinfection of heat-

sensitive biomaterials, especially polymers, presents a chal-

lenge to the currently used techniques of microorganism

destruction. There is increasing interest in the use ofbiopoly-

mers, autograft tissue, and allograft tissue in, for example,

regenerative medicine, and these materials generally require

sterilization prior to implantation.

[0004] Current methods of sterilization typically employ

high temperatures, toxic chemicals, strong radiation, or

strongly oxidizing chemical additives that are detrimental to

such materials and that may corrode or damage the materials

of construction of biomedical devices and sterilization equip-

ment.

[0005] In medical practice, standard sterilization methods

include steam sterilization, gamrna-irradiation, ethylene

oxide, and hydrogen peroxide sterilization. Most of these

techniques can have serious drawbacks. For example, steam

autoclaving damages heat-sensitive materials and deposits an

oxide layer onto metallic surfaces. Gamma-irradiation

reduces shear and tensile strength, elastic modulus, and trans-

parency of medical polymers by breaking polymer chains and

the resultant reactions of the free radicals produced. Ethylene

oxide not only changes the material properties of polymers

but also requires special safety considerations because of its

flammability and toxicity. Hydrogen peroxide is recognized

as a sterilant only when used in relatively high concentration

in aqueous solution, and with relatively long contact times.

The aqueous solution itself is a strong irritant. Because of the

various drawbacks associated with current sterilization tech-

niques, the next generation of polymeric medical devices and

heat sensitive biomaterials call for the use of new sterilization

methods.

[0006] Treatment with liquid or supercritical carbon diox-

ide (CO2) in the dense state can be an effective way to destroy

certain vegetative bacteria; however, several species of

spores, such as Bacillus sublilis and Geobacillus szearozher—

mophilus, have proven to be highly resistant to sterilization

methods with high-pressure CO2 alone. Due to the high resis-

Apr. 1,2010

tance of spores to treatment with pure CO2, some combina-

tion of elevated pressure, high temperature, or extended treat-

ment time are typically required to achieve a significant

reduction in the number of surviving, active spores. However,

excessively high pressure and/or temperature can damage

heat-sensitive materials and devices, and increase investment

and operating cost. Therefore, it can be desirable to operate

the sterilization process at a relatively low temperature and

pressure, and for a relatively short period of time.

[0007] Therefore, there remains a need for methods and

compositions that overcome these deficiencies and that effec-

tively sterilize bacteria and bacterial spores.

SUMMARY

[0008] Disclosed are methods and compositions related to

sterilization of microorganisms including but not limited to

bacterial spores with compositions comprising the combina-

tion of pressurized carbon dioxide and microbiocidal addi-

tives.

[0009] Also disclosed are methods for sterilizing a material

having microorganisms to be inactivated comprising the steps

of contacting the material with a mixture comprising a non-

oxidative microbiocidal additive and high-pressure carbon

dioxide or supercritical carbon dioxide, and maintaining the

contact for a period of time effective to achieve a degree of

inactivation of the microorganisms exceeding 2 log orders.

[0010] Also disclosed are methods for sterilizing a material

having microorganisms to be inactivated comprising the steps

of contacting the material with a mixture comprising hydro-

gen peroxide and supercritical carbon dioxide, and maintain-

ing the contact for a period of time effective to achieve a

degree of inactivation of the microorganisms exceeding 2 log

orders.

[0011] Also disclosed are compositions for sterilizing a

material, comprising a non-oxidative microbiocidal additive

and high-pressure carbon dioxide or supercritical carbon

dioxide.

[0012] Also disclosed are methods for sterilizing a material

having microorganisms to be inactivated comprising the steps

of contacting the material with a mixture comprising a non-

oxidative microbiocidal additive and a high-pressure or

supercritical fluid, and maintaining the contact for a period of

time effective to achieve a degree of inactivation of the micro-

organisms exceeding 2 log orders.

[0013] Also disclosed are compositions for sterilizing a

material comprising a non-oxidative microbiocidal additive

and a high-pressure or supercritical fluid.

BRIEF DESCRIPTION OF THE DRAWINGS

[0014] The accompanying drawings, which are incorpo-

rated in and constitute a part of this specification, illustrate

several embodiments and together with the description illus-

trate the disclosed compositions and methods.

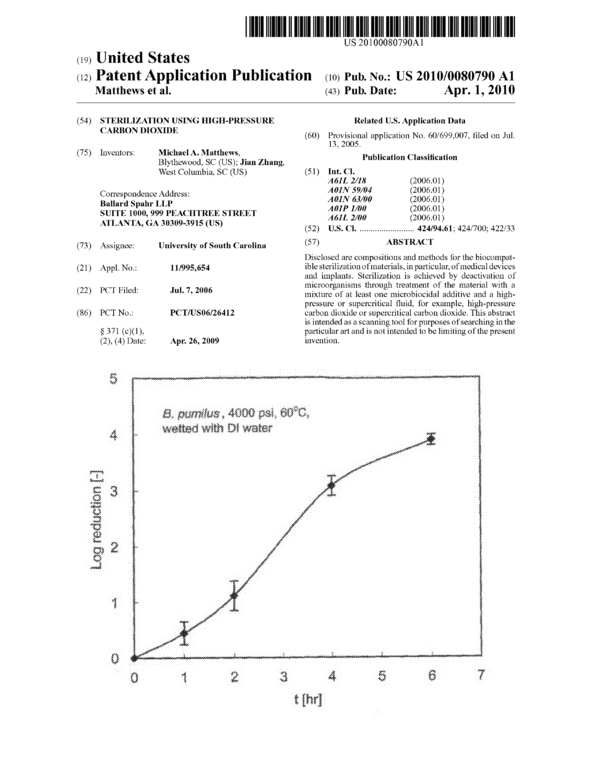

[0015] FIG. 1 shows the effect of treatment time using CO2

on the deactivation of the water-wetted spores.

[0016] FIG. 2 shows a schematic of an exemplary high-

pressure or supercritical fluid apparatus.

DETAILED DESCRIPTION

[0017] Before the present compounds, compositions,

articles, devices, and/ or methods are disclosed and described,

it is to be understood that they are not limited to specific

synthetic methods unless otherwise specified, or to particular

US 2010/0080790 A1

reagents unless otherwise specified, as such may, of course,

vary. It is also to be understood that the terminology used

herein is for the purpose of describing particular embodi-

ments only and is not intended to be limiting.

A. DEFINITIONS

[0018] As used in the specification and the appended

claims, the singular forms “a,” “an” and “the” include plural

referents unless the context clearly dictates otherwise. Thus,

for example, reference to “an additive” includes mixtures of

two or more such additives, and the like.

[0019] Ranges can be expressed herein as from “about” one

particular value, and/or to “about” another particular value.

When such a range is expressed, another embodiment

includes from the one particular value and/or to the other

particular value. Similarly, when values are expressed as

approximations, by use of the antecedent “about,” it will be

understood that the particular value forms another embodi-

ment. It will be further understood that the endpoints of each

of the ranges are significant both in relation to the other

endpoint, and independently of the other endpoint. It is also

understood that there are a number of values disclosed herein,

and that each value is also herein disclosed as “about” that

particular value in addition to the value itself. For example, if

the value “10” is disclosed, then “about 10” is also disclosed.

It is also understood that when a value is disclosed that “less

than or equal to” the value, “greater than or equal to the value”

and possible ranges between values are also disclosed, as

appropriately understood by the skilled artisan. For example,

if the value “10” is disclosed the “less than or equal to 10” as

well as “greater than or equal to 10” is also disclosed. It is also

understood that throughout the application, data are provided

in a number of different formats and that these data represent

endpoints and starting points, and ranges for any combination

of the data points. For example, if a particular data point “10”

and a particular data point “15” are disclosed, it is understood

that greater than, greater than or equal to, less than, less than

or equal to, and equal to 10 and 15 are considered disclosed as

well as between 10 and 15. It is also understood that each unit

between two particular units are also disclosed. For example,

if 10 and 15 are disclosed, then 11, 12, 13, and 14 are also

disclosed.

[0020] “Optional” or “optionally” means that the subse-

quently described event or circumstance may or may not

occur, and that the description includes instances where said

event or circumstance occurs and instances where it does not.

[0021] “High-pressure carbon dioxide,” “high-pressure

CO2,” “dense-phase carbon dioxide,” and “dense-phase CO2”

refer to pressurized, liquid carbon dioxide near but below the

critical temperature and near but below the critical pressure.

For example, in one aspect, the pressure can be from about

400 pounds per square inch (about 27.6 bar) to about 1,070

pounds per square inch (about 73 .7 bar). In another aspect, the

pressure can be from about 500 pounds per square inch (about

34.5 bar) to about 850 pounds per square inch (about 58.6

bar). In a further aspect, the pressure can be from about 600

pounds per square inch (about 41 .36 bar) to about 750 pounds

per square inch (about 51.7 bar).

[0022] “Supercritical CO2” refers to pressurized, fluid car-

bon dioxide at or above the critical temperature (about 31.1°

C.) and at or above the critical pressure (about 73.8 bar).

[0023] “High-pressure fluid” and “dense-phase fluid” refer

to any pressurized liquid near but below its critical tempera-

ture and near but below its critical pressure. In one aspect, the

Apr. 1,2010

pressure can be from 35% to 99% of the critical pressure of

the fluid, for example, from 40% to 85% of the critical pres-

sure, for example, from 60% to 75% of the critical pressure.

[0024] “Supercritical fluid” refers to a pressurized fluid at

or above its critical temperature and at or above its critical

pressure.

[0025] “Microbiocidal” refers to having the property of

inactivating pathogens or any microorganisms.

[0026] “Microbiocidal additive” or “microbiocidal agent”

as used herein, refers to having the property of inactivating

pathogens when used as an additive in a high-pressure or

supercritical fluid, in particular carbon dioxide.

[0027] “Microorganisms,” as used herein, refers to and is

understood to include active biological contaminants or

pathogens, including bacteria (including inter- and intracel-

lular bacteria, such as mycoplasmas, ureaplasmas, nanobac-

teria, chlamydia, rickettsias), yeasts, molds, fungi, spores, or

similar agents and/or single or multicellular parasites, and

combinations thereof.

[0028] Disclosed are the components to be used to prepare

the disclosed compositions as well as the compositions them-

selves to be used within the methods disclosed herein. These

and other materials are disclosed herein, and it is understood

that when combinations, subsets, interactions, groups, etc. of

these materials are disclosed that while specific reference of

each various individual and collective combinations and per-

mutation of these compounds may not be explicitly disclosed,

each is specifically contemplated and described herein. For

example, if a particular compound is disclosed and discussed

and a number of modifications that can be made to a number

of molecules including the compounds are discussed, specifi-

cally contemplated is each and every combination and per-

mutation of the compound and the modifications that are

possible unless specifically indicated to the contrary. Thus, if

a class of molecules A, B, and C are disclosed as well as a

class of molecules D, E, and F and an example of a combi-

nation molecule, A-D is disclosed, then even if each is not

individually recited each is individually and collectively con-

templated meaning combinations, A-E, A-F, B-D, B-E, B-F,

C-D, C-E, and C-F are considered disclosed. Likewise, any

subset or combination of these is also disclosed. Thus, for

example, the sub-group of A-E, B-F, and C-E would be con-

sidered disclosed. This concept applies to all aspects of this

application including, but not limited to, steps in methods of

making and using the disclosed compositions. Thus, if there

are a variety of additional steps that can be performed it is

understood that each of these additional steps can be per-

formed with any specific embodiment or combination of

embodiments of the disclosed methods.

[0029] It is understood that the compositions disclosed

herein have certain functions. Disclosed herein are certain

structural requirements for performing the disclosed func-

tions, and it is understood that there are a variety of structures

which can perform the same function which are related to the

disclosed structures, and that these structures will ultimately

achieve the same result.

[0030] Throughout this application, various publications

are referenced. The disclosures of these publications in their

entireties are hereby incorporated by reference into this appli-

cation in order to more fully describe the state of the art to

which this pertains. The references disclosed are also indi-

vidually and specifically incorporated by reference herein for

US 2010/0080790 Al

the material contained in them that is discussed in the sen-

tence in which the reference is relied upon.

B. STERILIZATION METHODS GENERALLY

[0031] The degree of deactivation of microorganisms by a

sterilization method can be characterized by log reduction.

Log reduction can be calculated with the following equation:

Log Reduction =

1 number of untreated microorganisms

o . . . .

number of surviving microorganisms after treatment

[0032] Typically, deactivation methods employing high

pressure CO2 or supercritical CO2 can deactivate B. pumilus

spores by up to three-log. However, at least six-log reduction

is required by the Federal Drug Administration (FDA) to

claim sterilization. Therefore, carbon dioxide and water alone

do not achieve adequate deactivation (Table 1).

TABLE 1

LOG REDUCTION OF B. PUMILUS SPORES ON WETTED

SPORE STRIPS WITH CO2.

DURATION PRESSURE TEMPERATURE

[HR] [BAR] [° C.] LOG REDUCTION

4 276 50 0.58 2 0.04

276 60 3.06 2 0.17

276 80 3.02 2 0.07

103 60 1.91 2 0.23

[0033] The effect of exposure time to CO2 on the deactiva-

tion of the water-wetted spores is shown in FIG. 1. The

nonlinear curve in FIG. 1 can be divided into three stages. In

the first stage (0-2 hours) the log reduction increases slowly

with the treatment time, while in the second stage (2-4 hours)

the deactivation proceeds more rapidly. In the last stage (>4

hours), the log reduction appears to approach a limiting value.

After six hours of treatment, only a 3.90-log reduction had

been obtained in the water-wetted spores. Such a long process

time is generally not ideal for a commercial sterilizer.

C. IMPROVED STERILIZATION METHODS

[0034] The present invention relates to the sterilization and

disinfection arts. It finds particular application in conjunction

with high-pressure fluids and supercritical fluids associated

with antimicrobial agents, such as sterilants or disinfectants,

for combined cleaning and sterilization or disinfection of

medical instruments, equipment, and supplies, and will be

described with particular reference thereto. It should be

appreciated, however, that the invention is also applicable to

the sterilization or disinfection of other items, including food

processing equipment and packaging and hospital supplies,

such as bed linen and protective clothing, and the like.

[0035] The disclosed compositions and methods can be

used, generally, for any surface having microorganisms. For

example, the disclosed compositions and methods can be

used with medical equipment including, without limitation,

surgical instruments, devices for implants, cannulas, endo-

scopes, syringes, bandages, medical packaging, and vials.

The disclosed compositions and methods can also be used

with tissue. The disclosed compositions and methods can also

Apr. 1,2010

be used with food processing equipment including, without

limitation, eating utensils, cookware, and food and beverage

containers. The disclosed compositions and methods can be

also used with personal items including, without limitation,

clothing, bedding, hospital and institutional bedding and

draperies, hospital and institutional towels, contact lenses,

grooming supplies, and jewelry.

[0036] The disclosed compositions and methods can be

used, generally, with substrates of any material. Materials

suitable for use with the disclosed compositions and methods

include, without limitation, metals such as aluminum, iron,

stainless steel, titanium, gold, silver, platinum, and mixtures

thereof; plastics such as polyesters, nylons, polyolefins, and

mixtures thereof; glass; stone; ceramics; and mixtures

thereof.

[0037] The disclosed compositions and methods can

achieve deactivation of microorganisms, including bacterial

spores, resulting in a log reduction of, for example, greater

than or equal to: l-log, 2-log, 3-log, 4-log, 5-log, 6-log, or

7-log.

[0038] l. Sterilizing Fluids

[0039] a. Carbon Dioxide

[0040] Carbon dioxide can be used in the disclosed method

and compositions as a high-pressure, dense or as a supercriti-

cal fluid. A supercritical fluid is a pure fluid or mixture of

fluids which is at a temperature and pressure at or above its

critical temperature and pressure.

[0041] Hi gh-pres sure sterilization involves temperatures

near but below the critical temperature and pres sures near but

below the critical pressure. Generally, such high-pressure

fluid can be in the liquid state, typically from 35% to 99% of

the critical pressure of the fluids. For carbon dioxide, sufli-

ciently high pressures can be below about 73 .8 bar, the critical

pressure of carbon dioxide.

[0042] Supercritical sterilization employs temperatures at

or above the critical temperature and pressures at or above the

critical pressure. The critical temperature and pressure vary

with the fluid selected. The critical temperature of a fluid is

the temperature above which the fluid can no longer be liq-

uefied, irrespective of the pressure applied. The critical pres-

sure is the pressure at which a substance may exist as a gas in

equilibrium with a liquid at the critical temperature. Thus, the

properties of a dense fluid change appreciably at or above the

critical pressure.

[0043] Carbon dioxide is a particularly advantageous fluid

because it is a non-polar solvent. This allows co-solvents to be

added having a high degree of selectivity. For carbon dioxide,

the critical pressure is 73.8 bar and the critical temperature is

3 1 . 1° C.

[0044] Using CO2 as a fluid to effect sterilization has sev-

eral potential benefits. First, CO2 is not flammable and is

non-toxic; the chief hazard in its use is asphyxiation. Unlike

ethylene oxide, CO2 requires no special handling or ventila-

tion, and leaves no toxic residues. Second, CO2 is inert in

most situations so it does not react with polymers, which

alleviates the aging problem caused by y-irradiation. Also,

CO2 has a low critical temperature (3l.l° C.). This is only

slightly above room temperature, so thermal degradation is

not a problem when a process is operated around the critical

temperature. In a supercritical state, CO2 has low viscosity

(about 3 to 7>X< *

Coments go here:

- Log in to post comments