Perspective

pubs.acs.org/Macromolecules

Controlled Depolymerization: Stimuli-Responsive Self-Immolative

Polymers

Gregory I. Peterson,† Michael B. Larsen,† and Andrew J. Boydston*

Department of Chemistry, University of Washington, Box 351700, Seattle, Washington 98195-1700, United States

ABSTRACT: Self-immolative polymers (SIPs) are unique

macromolecules that are able to react to multiple types of

environmental influences by giving amplified response outputs.

When triggering moieties installed at SIP chain ends are

activated by their corresponding stimuli, a spontaneous headto-tail depolymerization ensues, often involving multitopic

release of small molecules. SIP designs have evolved a high

degree of modularity in each of their functional components,

enabling a broad range of utility and applications-driven

tuning. In this Perspective, we summarize and discuss recent

progress in this nascent area of research, including (i) synthesis of different types of SIPs, (ii) design and evaluation of triggering

moieties, (iii) depolymerization mechanisms and kinetics, (iv) applications of SIPs, and (v) outlook and challenges facing the

field.

1. INTRODUCTION

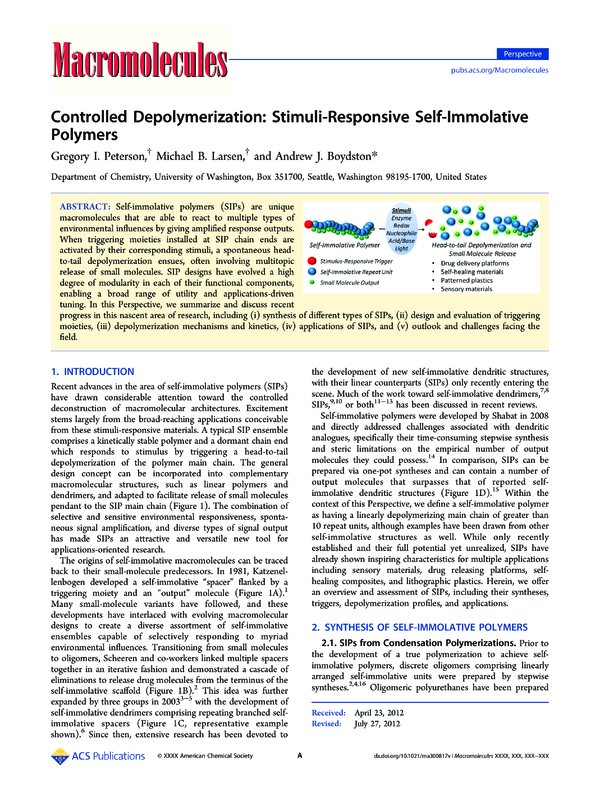

Recent advances in the area of self-immolative polymers (SIPs)

have drawn considerable attention toward the controlled

deconstruction of macromolecular architectures. Excitement

stems largely from the broad-reaching applications conceivable

from these stimuli-responsive materials. A typical SIP ensemble

comprises a kinetically stable polymer and a dormant chain end

which responds to stimulus by triggering a head-to-tail

depolymerization of the polymer main chain. The general

design concept can be incorporated into complementary

macromolecular structures, such as linear polymers and

dendrimers, and adapted to facilitate release of small molecules

pendant to the SIP main chain (Figure 1). The combination of

selective and sensitive environmental responsiveness, spontaneous signal amplification, and diverse types of signal output

has made SIPs an attractive and versatile new tool for

applications-oriented research.

The origins of self-immolative macromolecules can be traced

back to their small-molecule predecessors. In 1981, Katzenellenbogen developed a self-immolative “spacer” flanked by a

triggering moiety and an “output” molecule (Figure 1A).1

Many small-molecule variants have followed, and these

developments have interlaced with evolving macromolecular

designs to create a diverse assortment of self-immolative

ensembles capable of selectively responding to myriad

environmental influences. Transitioning from small molecules

to oligomers, Scheeren and co-workers linked multiple spacers

together in an iterative fashion and demonstrated a cascade of

eliminations to release drug molecules from the terminus of the

self-immolative scaffold (Figure 1B).2 This idea was further

expanded by three groups in 20033−5 with the development of

self-immolative dendrimers comprising repeating branched selfimmolative spacers (Figure 1C, representative example

shown).6 Since then, extensive research has been devoted to

© XXXX American Chemical Society

the development of new self-immolative dendritic structures,

with their linear counterparts (SIPs) only recently entering the

scene. Much of the work toward self-immolative dendrimers,7,8

SIPs,9,10 or both11−13 has been discussed in recent reviews.

Self-immolative polymers were developed by Shabat in 2008

and directly addressed challenges associated with dendritic

analogues, specifically their time-consuming stepwise synthesis

and steric limitations on the empirical number of output

molecules they could possess.14 In comparison, SIPs can be

prepared via one-pot syntheses and can contain a number of

output molecules that surpasses that of reported selfimmolative dendritic structures (Figure 1D).15 Within the

context of this Perspective, we define a self-immolative polymer

as having a linearly depolymerizing main chain of greater than

10 repeat units, although examples have been drawn from other

self-immolative structures as well. While only recently

established and their full potential yet unrealized, SIPs have

already shown inspiring characteristics for multiple applications

including sensory materials, drug releasing platforms, selfhealing composites, and lithographic plastics. Herein, we offer

an overview and assessment of SIPs, including their syntheses,

triggers, depolymerization profiles, and applications.

2. SYNTHESIS OF SELF-IMMOLATIVE POLYMERS

2.1. SIPs from Condensation Polymerizations. Prior to

the development of a true polymerization to achieve selfimmolative polymers, discrete oligomers comprising linearly

arranged self-immolative units were prepared by stepwise

syntheses.2,4,16 Oligomeric polyurethanes have been prepared

Received: April 23, 2012

Revised: July 27, 2012

A

dx.doi.org/10.1021/ma300817v | Macromolecules XXXX, XXX, XXX−XXX

�Macromolecules

Perspective

Figure 1. Specific examples and general models of a self-immolative (A) spacer, (B) oligomer/polymer, (C) G2 dendrimer, and (D) polymer with

self-immolative side chains. Reproduced with permission from ref 15. Copyright 2008 Wiley-VCH Verlag GmbH & Co. KGaA.

1A).2 This method requires long reaction times and chromatographic separation for each step but is useful for synthesizing

well-defined oligomers with three or fewer repeat units.

by activation of a benzyl alcohol chain end via installation of a

nitrophenyl carbonate and subsequent coupling with aminobenzyl alcohols to extend the chain by one repeat unit (Scheme

B

dx.doi.org/10.1021/ma300817v | Macromolecules XXXX, XXX, XXX−XXX

�Macromolecules

Perspective

Scheme 1. Stepwise Synthesis of Self-Immolative Oligomeric Structures Comprised of (A) Urethane and (B) Benzyl Phenyl

Ether Linkagesa (Reproduced with Permission from Ref 18. Copyright 2012 The Royal Society of Chemistry)

a

The DP of oligomers is equal to the number of times the chain extension cycle is conducted.

(monomer 3).14 It has also been shown that after polymerization the esters on the side chains of monomer 3 can be

converted to carboxylic acids to increase the water solubility of

the polymer.14,15,19 Trigger installation was accomplished by

adding a nucleophilic alcohol or amine to the reaction mixture

after polymerization had ensued. The end-capping agent was

found to react selectively with the phenyl carbamate chain end

to cease polymerization and install functional groups bearing

reactivities specific to triggering depolymerization at a later

time.

Complementary to benzyl alcohol-based SIP main chains,

Gillies has achieved condensation polymerizations of carbamate- and thiocarbamate-based monomers for the production

of two different classes of SIPs (Scheme 2B).20,21 For the

synthesis of each, AB-type monomers were prepared that

Similarly, oligomers containing benzyl phenyl ether linkages

prepared by Mitsunobu couplings17 or SN2 reactions of

phenoxides and benzyl halides4,18 have been reported (Scheme

1B) and provide access to self-immolative structures that do not

require decarboxylation during depolymerization.

As a more direct route to SIPs, Shabat developed a one-pot

Sn(IV)-catalyzed polymerization of “blocked isocyanates”,

yielding polyurethanes with degrees of polymerization (DPs)

reaching ca. 20 within 15 min at 110 °C (Scheme 2A).14 This

polymerization was shown to be successful with monomer 1 as

well as with monomers containing functionalized side chains,

which renders the polymer capable of releasing small molecules

from the side chain during depolymerization (monomer 2)15 or

displaying a “turn-on” response by imparting fluorogenic

properties to the repeat units upon depolymerization

C

dx.doi.org/10.1021/ma300817v | Macromolecules XXXX, XXX, XXX−XXX

�Macromolecules

Perspective

Scheme 2. Synthesis of (A) Polyurethanes and (B) Cyclization Elimination SIPs that are Prepared by Condensation

Polymerizations (Reproduced with Permission from Ref 21. Copyright 2010 Wiley Periodicals, Inc.)

20 to 30 kDa with PDIs of 1.1−1.3 (Scheme 3A).25 With

addition of catalyst 7, the reaction time was decreased to 2 h

and yielded polymers with molecular weights of 70 kDa and

PDIs of 1.6 (Scheme 3B).26 While PPA has traditionally been

depolymerized by acid-catalyzed hydrolysis initiated at random

sites within the polymer main chain,27 Phillips has developed

end groups with functionalities that allow for selective

triggering of head-to-tail depolymerization (see section

4.3).25,28

featured an electrophilic p-nitrophenyl carbonate end group

and a Boc-protected amine at opposite termini. To avoid

coupling of the end groups during and after deprotection, the

amine was maintained as the protonated ammonium salt. Then,

upon addition of DMAP and Et3N, polymers were obtained

with Mn values ranging from 1.8 to 17 kDa. Triggering moieties

were incorporated at the polymer chain ends by conducting the

polymerizations in the presence of a small amount of protected

monomer. In this way, the same protecting group used to

prepare the monomers also functioned as the triggering moiety,

though this is not expected to be an inherent requirement and

other triggers could likely be incorporated. The nitrophenyl

end group was hydrolyzed from polymer 5 during the workup

but was retained in polymer 6 as a usable reporter molecule for

monitoring depolymerization (see section 5.1). Conceivably,

the polymer terminus could be modified for application-specific

outputs, and the aryl groups of the benzyl alcohol repeat units

could be functionalized to facilitate side-chain release.

2.2. SIPs from Addition Polymerizations. To our

knowledge, poly(phthalaldehyde) (PPA) is the only reported

SIP that can be prepared via addition polymerization. This has

been achieved by anionic and cationic polymerizations of 1,2benzenedicarboxyaldehyde.22,23 The polymerization requires

low temperatures, as the ceiling temperature of the polymer is

−40 °C. PPA produced via cationic polymerization was found

to be thermally stable up to 150 °C in the solid state, whereas

the product of anionic polymerization reverts almost

instantaneously after isolation of the polymer if the end groups

are not capped.24 Polymerizations typically required 10−14

days and yielded polymers with molecular weights ranging from

3. STIMULI-RESPONSIVE TRIGGERS

Designing SIP triggers to be selectively responsive to specific

stimuli enables chemists to utilize the general function of SIPs

to address diverse applications. Multiple trigger designs have

been reported, with key examples described in Table 1.

Although not all of the triggers presented have been used in

linear polymeric systems, the modular nature of the triggering

component should facilitate incorporation of triggers reported

for oligomeric or dendritic structures into linear SIPs. The

primary reactivity observed for essentially all known triggering

moieties is the unmasking of an electron-rich functional group

in response to a specific stimulus that is compatible with the

SIP main chain and output units. In many cases, cleavage of the

triggering group liberates a carbamate or carbonate which

undergoes subsequent decarboxylation to reveal an amine or

hydroxyl group, respectively (entries 2, 4, 14−16, and 18).

Alternatively, some systems achieve direct conversion of the

trigger into an electron-donating moiety without an intermediate decarboxylation step (entries 1, 3, and 5−13).

Currently, there are ∼20 distinct trigger/stimulus combinations

D

dx.doi.org/10.1021/ma300817v | Macromolecules XXXX, XXX, XXX−XXX

�Macromolecules

Perspective

11).19,41,44−49 For example, Phillips adapted the aryl allyl

ether utilized in dendritic and oligomeric systems (entry 8) for

use in linear polymers by installing an allyl carbonate triggering

group at the head of a phthalaldehyde-based SIP (see section

2.2).25 Upon exposure to a Pd0 source, the allyl fragment was

removed and subsequent decarboxylation revealed a hemiacetal,

thereby commencing the depolymerization process. Disulfides

have also been developed as reductive triggers for SIPs having

DPs of ∼35 (Mw ∼3.0 kDa) and offer the potential for

biologically relevant redox triggering (entry 9). As depicted in

Scheme 2B, Gillies incorporated disulfide end groups which

were found to be activated in response to dithiothreitol. The

disulfide linkage is especially attractive for biological

applications as it holds promise for activation under reducing

intracellular environments.50 The use of phenylboronates as

triggers for SIPs introduced a platform for activation under

oxidative conditions (entry 10). Shabat has demonstrated this

class of trigger in dendritic systems (entry 11) to be responsive

to hydrogen peroxide generated from either triacetone

triperoxide44 or enzymatic action45,49 (see section 5.1). In

each of these systems, conversion of the boronate moiety into

an electron-releasing phenol leads to initiation of the selfimmolative cascade.

3.3. Nucleophile-Mediated Cleavage. Although explored

to a lesser extent in comparison with other triggering manifolds,

nucleophilic attack can also serve to liberate electron-releasing

functionalities (entries 12 and 13).20,25,28,51 This is also an

attractive option in cases in which the components of the SIP

are not stable to aqueous conditions, as the use of

tetrabutylammonium fluoride for silyl ether cleavage requires

no adventitious water.25,28 Water itself can also serve as a

nucleophile to hydrolyze labile esters,20 but this method has

seen limited use as more specific trigger/stimulus pairs are

often desired.

3.4. Acid/Base-Mediated Cleavage. Traditional acid- and

base-sensitive protecting groups also provide a facile means of

triggering SIPs (entries 14−16).5,15,19,20,32,36,38,52,53 In particular, the fidelity and familiarity of Boc and Fmoc protecting

groups have essentially established these functionalities as

standards for comparison when developing new triggering

moieties. Their reactivities are ideally suited to SIP applications,

as each strongly diminishes the electron-donating ability of the

amine. The reagents required to install and activate these

triggers are inexpensive and readily available, and pH

modulation is a simple process for on-demand triggering of

SIPs. In a recent example, these triggers were featured in SIPs

that were incorporated into advanced nanoscale materials

capable of on-demand depolymerization of microcapsule shells

(see section 5.3).53

3.5. Photomediated Cleavage. A particularly exciting

advance in the field of SIPs is the development of triggers

capable of remote activation. Photomediated cleavage of

nitrobenzyl carbamates and bromocoumarins (entries 17 and

18)5,18,54 requires only the appropriate wavelength and

intensity of light to initiate the depolymerization process; in

other words, no additional chemical reagents are required to

activate the SIP. This type of remote activation is especially

attractive for drug delivery applications, as it introduces the

potential for spatiotemporal control of release profiles in a

noninvasive manner.55 Toward this end, Almutairi and coworkers developed linear polymers incorporating a lightsensitive o-nitrobenzyl carbamate (entry 17) or bromocoumarin

trigger (entry 18). Upon exposure to the appropriate

Scheme 3. Anionic Polymerization of Phthalaldehyde and

Capping of the Resulting Polymer (A) without a Catalyst

and (B) with a Phosphazene Catalyst

that have been reported, and they can be conveniently grouped

according to the type of stimulus required for their activation.

These classes consist of enzyme, redox, nucleophile, acid/base,

and photomediated cleavage.

3.1. Enzyme-Mediated Cleavage. Enzymatic substrates

(Table 1, entries 1−6) were the first reported triggers in

systems capable of multiple elimination events.2 Research in

this area is strongly motivated by the potential applications of

SIPs in biological systems. Triggering by biological agents that

are native (entries 1, 5, and 6)2,29,30 or foreign (entries 2−

4)14,15,19,31−41 to human physiology has been achieved. Using

linear SIPs, Shabat identified the enzymatic triggering event as

rate-determining in the overall process of SIP depolymerization

involving bovine serum albumin (BSA) as the triggering

enzyme. For these studies, concentrations of 1.0 mg/mL were

used in solutions buffered at pH = 7.4.14 For comparison,

typical serum albumin concentrations in human physiology

range from 0.3 to 0.5 mg/mL.42 Although studies involving

more complex biological systems may require additional SIP

design optimization, foreign and unnatural biological triggering

agents have each been demonstrated in successful in vitro

studies.2,29−32,34 The wealth of kinetic information on enzymemediated cleavage makes enzyme-triggered SIPs attractive

targets for applications in which fine-tuning of initiation

kinetics or highly specific triggering events are required.

3.2. Redox-Mediated Cleavage. The ease of installation

and activation of redox-mediated triggers facilitated their early

introduction into self-immolative scaffolds. Spanning small to

macromolecular systems, examples of redox triggers include

transition metal-mediated reductions (Table 1, entries 7 and

8),3,4,6,16−18,25,43 reduction of disulfide linkages (entry 9),21 and

oxidation of boronates with peroxides (entries 10 and

E

dx.doi.org/10.1021/ma300817v | Macromolecules XXXX, XXX, XXX−XXX

�Macromolecules

Perspective

Table 1. Triggers for SIPs, Grouped According to Triggering Classa

a

E = enzyme, R = redox, N = nucleophile, A = acid/base, and P = photo. R = self-immolative segment, R′ = H or Me.

capsules capable of releasing hydrophobic dye upon triggering

with UV light (o-nitrobenzyl carbamate and bromocoumarin)

or NIR irradiation (o-nitrobenzyl carbamate). Although

bromocoumarin-based triggers were successfully activated via

wavelength of light, the photosensitive moiety was removed,

triggering depolymerization and complete degradation of high

Mw (>35 kDa) polymer in 25 days. Nanoparticles based on

these SIPs were also formulated (see section 5.3), with these

F

dx.doi.org/10.1021/ma300817v | Macromolecules XXXX, XXX, XXX−XXX

�Macromolecules

Perspective

elimination events through both the o- and p-positions gives

rise to multifunctional SIPs designed for main-chain

disassembly and release of side-chain output molecules. In

most cases, complete depolymerization is achieved in 5−10 h in

systems utilizing exclusively elimination via quinone methide

formation. This is usually monitored by observing the

concentration of a specific reporter molecule released from

the output position or monitoring the production of a

fluorogenic monomer unit.14 Under physiological conditions,

Shabat has determined 1,4-elimination to be slower than 1,6elimination, and thus in linear systems backbone depolymerization is expected to occur before side-chain release.39

Preliminary studies of the rates of 1,4-elimination have

shown that the electronic nature of the arene core significantly

affects elimination kinetics.52 Replacement of a methyl group

with an ethyl ester in the position para to the electron-donating

phenoxide increased the rate of elimination 30-fold in both

first- and second-generation self-immolative dendrimers.

Solvent has also been shown to influence elimination rates.

Both 1,6- and 1,4-eliminations were found to occur more

rapidly in aqueous media than in organic solvents. For example,

depolymerization of SIPs (Figure 1D) in phosphate buffered

saline was found to occur 8 times faster than in MeOH/DMSO

solution.15 In aqueous conditions, the solution is generally

maintained at a slightly basic pH to facilitate elimination to the

quinone methide, and accordingly depolymerization in organic

solvents is aided by exogenous bases.5 When utilizing aprotic

solvents, it has been found that AcOH also accelerates

depolymerization.15

When the immediate product of self-immolation is a highly

reactive quinone methide, these intermediates are rapidly

trapped by adventitious nucleophiles. In most cases the

nucleophile is a solvent molecule such as water; however, in

the presence of more potent nucleophiles other depolymerization products can arise. Such trapping reactions were

investigated by Shabat and co-workers on a single-elimination

model system (Scheme 4).19 In a solution of 90:1 MeOH/

morpholine, they observed trapping by only the more potent

nucleophile, contrasting the usual product and leading the way

toward interesting enzyme-labeling applications (see section

5.4).

4.2. Cyclization−Eliminations. An alternative method of

self-immolative depolymerization is based upon an intramolecular 5-exo-trig cyclization with concurrent release of an

electron-rich leaving group (Figure 2B).20,21,54 This has been

demonstrated to occur in systems forming ureas, carbamates,

and thiocarbonates. The polyurethanes developed by Gillies

(Scheme 2B) are based upon this type of elimination event.

Compared with elimination through an arene monomer,

cyclization−elimination is much slower and appears to be the

rate-limiting step in all reported self-immolative systems in

which it is incorporated. For example, Almutairi and co-workers

synthesized polymers of this type of ∼35 kDa. Upon exposure

NIR irradiation in model SIP systems, the hydrophobic

environment imposed by nanoparticle formation presumably

inhibited efficient NIR triggering.

4. DEPOLYMERIZATION OF SELF-IMMOLATIVE

POLYMERS

Upon removal of the triggering group from the SIP chain end,

three distinct depolymerization mechanisms have been

demonstrated: (1) 1,6- and 1,4-eliminations to form quinone

methides, (2) cyclizations to form imidazolidinones, oxazolidinones, or 1,3-oxathiolan-2-ones, and (3) breakdown of

hemiacetals to dialdehyde monomers (Figure 2). Each

Figure 2. Self-immolative responses of different types of monomer

units: (A) 1,6- and 1,4- elimination to form quinone methides, (B)

cyclization−elimination, and (C) hemiacetal elimination.

mechanism exhibits distinct breakdown kinetics, and the

times for each to reach complete depolymerization are

qualitatively ordered as hemiacetal eliminations < 1,6eliminations < 1,4-eliminations < cyclization−eliminations. As

will be described below, some depolymerization pathways

produce highly reactive monomeric intermediates whereas

others result in more stable small molecule products.

4.1. 1,6- and 1,4-Eliminations. Repeat units containing pbenzylic or o-vinylogous linkages eliminate in a 1,6-fashion,

whereas 1,4-eliminations are observed from repeat units bearing

o-benzylic connectivities (Figure 2A). In each case, a reactive

quinone methide intermediate is formed. The released species

can either be a small molecule output or an activated chain end

poised to continue the depolymerization. Routing the

Scheme 4. Trapping of Single-Elimination Model System by Low Concentrations of Morpholine in MeOH

G

dx.doi.org/10.1021/ma300817v | Macromolecules XXXX, XXX, XXX−XXX

�Macromolecules

Perspective

of SIPs and expanded applications taking advantage of this

characteristic are anticipated.

to triggering conditions, complete depolymerization was

observed over a span of 25 days.54 Shabat synthesized

dendrimers capable of either direct quinone methide

elimination or cyclization−elimination followed by quinone

methide elimination (Figure 3).33 Incorporation of the cyclizing

5. APPLICATIONS OF SELF-IMMOLATIVE POLYMERS

The majority of potential applications for self-immolative

systems take advantage of the amplified release of covalently

bound molecules, as activation of a single triggering moiety

results in release of multiple small molecules. In principle, the

extent of amplification observed with SIPs increases linearly

with the degree of polymerization, and amplification with selfimmolative dendrimers scales exponentially with increasing

generations. Largely due to the steric congestion associated

with the synthesis of higher generation self-immolative

dendrimers, third-generation variants are the largest that have

been reported (8 outputs released per macromolecule).5 Thus,

the amplifying ability of self-immolative dendrimers has

remained synthetically limited and is generally lower when

compared with SIPs achieving high DPs of repeat units

equipped for side-chain release. These amplified responses have

largely been applied to the release of reporter molecules or

therapeutic agents for furthering sensor or drug release

applications, respectively. Additionally, SIP depolymerization

has been targeted for applications that degrade components of

nanoscale materials. It is important to note that in the following

application sections several examples have thus far only been

applied to dendritic systems.

5.1. Sensors. SIPs are well suited for applications as sensory

materials due to their signal amplification ability, which

decreases the detection limit for a particular analyte capable

of trigger activation. Shabat has further increased the amplified

response by modifying dendrimers to release agents that are

converted into the triggering agent under the reaction

conditions (Figure 4).45−47,49 In these systems, the first

deconstruction event initiates a chain reaction that leads to

exponential amplification from activation of a single trigger.

In general, monitoring signal output has involved observation

of diagnostic UV−vis or photoluminescence signals from

released reporter molecules. For example, release of pnitrophenol is easily detected and quantified via UV−vis

spectrometry, and release of fluorogenic monomer units or

reporter molecules (e.g., 6-aminoquinoline) can be monitored

via photoluminescence spectrometry.14,38 Shabat has also

recently developed the release of FRET pairs for fluorescent

signal generation.41 Although dose-responsive detection has

only been reported for hydrogen peroxide and triacetone

triperoxide,44,45 most of the SIP models that have been

Figure 3. Use of moieties capable of cyclization−eliminations for

tuning of output release kinetics. Reproduced with permission from ref

33. Copyright 2007 Elsevier.

moiety slowed the degradation process by a factor of 140, with

complete release of reporter molecules occurring after days

instead of hours. Thus, cyclizing units can be used to tune the

degradation kinetics.

4.3. Hemiacetal Eliminations. The head-to-tail selfimmolative breakdown of PPA recently reported by Phillips

(Figure 2C)25,28 occurs much more rapidly than depolymerization observed from other types of SIPs. Upon trigger cleavage

at the head of the polymer, a hemiacetal is revealed. Subsequent

reversion to the free aldehyde eliminates the next hemiacetal,

thus propogating the self-immolative sequence. In solution, this

process has been observed to take place in a matter of seconds,

and depolymerization in solid materials required only 15 min

for complete reversion to phthalaldehyde monomer units.25

The remarkably fast depolymerization of PPA-based SIPs

stands in stark contrast to what is observed from other classes

Figure 4. Representative depiction of a single round of an enzyme-mediated dendritic chain reaction.

H

dx.doi.org/10.1021/ma300817v | Macromolecules XXXX, XXX, XXX−XXX

�Macromolecules

Perspective

exposure to either 4 M HCl or 5% piperidine solution,

respectively, depolymerization of the microcapsule shell

resulted in on-demand release of the core contents. Building

upon previously demonstrated work,57,58 Almutairi prepared

nanoparticles comprising light-activated SIP components via

emulsion formulation.54 Upon exposure to appropriate wavelengths of light, the SIPs were degraded, leading to

deconstruction of the architectures and release of encapsulated

Nile red dye. A notable characteristic about payload release

from these nanoparticles is the observation that quantitative

SIP deconstruction was not necessary for nearly complete

release of the nanoparticle contents. Thus, content release can

be achieved in shorter time spans than those required for

complete SIP depolymerization.

Taking advantage of highly labile PPA-based SIPs, Phillips

was able to achieve triggered depolymerization in the solid

state.25 A patterned plastic film was prepared from two PPAs

with differing end groups. At the center of the film was a

circular region comprised of PPA with fluoride-sensitive silyl

ethers as triggers. After exposure to fluoride and subsequent

depolymerization, the released monomer was rinsed away

yielding plastic films with a cylindrical hole. It is expected that

this method could be evolved to offer new approaches in

lithographic techniques. It is important to note that while other

PPA-based systems have been used for lithographic purposes,59,60 this is the first PPA with end-group functionalization

that triggers controlled head-to-tail depolymerization of the

polymer.

5.4. Other Applications. An interesting utility of SIPs

involves releasing small molecules capable of performing

secondary functions other than reporting or providing

therapeutic effects. Shabat demonstrated the release of

diphenylalanine from self-immolative dendrimers.37 Diphenylalanine forms dipeptide nanotubes in solution but does not do

so when bound to the dendrimer. The triggered release of this

self-assembling molecule enabled the spatiotemporal control of

the formation of the nanostructures. Shabat also demonstrated

the use of SIPs for activity-linked labeling of enzymes.19 The

SIP was capped with an enzymatic trigger which, upon cleavage

in the active site, released reactive azaquinone methide

intermediates which were trapped by nucleophilic amino acid

residues in the protein. This method was also shown to be

highly selective for labeling the triggering enzyme in a

competitive environment, likely due to the production of

high local concentration of reactive azaquinone methide units.

Phillips demonstrated use of the concentration gradient of

monomers released from depolymerizing PPA thin films as the

driving force for single-use microscale pumps.28 The pumping

action was triggered by the presence of fluoride, thus allowing

the pump to be activated by a specific stimulus. Pump action

was able to be sustained for >15 min and was able to push

particles through a 5 mm channel containing a 90° turn.

developed could conceivably be adapted to act as sensors for

their corresponding triggering agents.

5.2. Drug Release. The principle of signal amplification can

also apply to drug delivery platforms in which the reporter

molecules have been replaced by a desired pharmaceutical

agent. Drug release was recognized early in the development of

self-immolative systems but is yet to be realized in a linear SIP.

Scheeren and co-workers demonstrated that the rate of drug

release from self-immolative oligomers (DP = 2 or 3) was 2−3

times greater for doxorubicin prodrugs and 6−10 times greater

for paclitaxel prodrugs than that observed when a single spacer

prodrug was used.2 The increased release rate from the

oligomer was attributed to reduced steric interactions between

the bulky drug molecules and the triggering enzyme. Although

an increased drug release rate is a potential advantage of using

self-immolative systems, the ability to increase drug loading

with SIP platforms is arguably their most attractive feature. This

evolutionary step in SIP design will likely be borne out via

systems capable of side-chain release (e.g., SIPs from monomer

2 in Scheme 2), as opposed to release of drug molecules from

the chain end of a self-immolative sequence. By increasing the

drug loading per trigger, burst release profiles can be achieved

which have been shown to have higher drug efficacy against

cancer cells than the release of a single drug per triggering

event.7 Dimeric and trimeric prodrugs have also been

developed that release 2 and 3 different types of drugs,

respectively, from the same dendrimer.32 Different drug

combinations could have synergistic effects and incorporation

of different ratios of pharmaceuticals could be tuned to specific

types of disease.

Further developments with SIPs may lead to targeted drug

delivery by incorporating triggers that facilitate the release of

therapeutics near diseased tissue. Toward this end, triggers have

been developed that are cleaved by enzymes often overexpressed in many types of tumor tissue (Table 1, entries 5 and

6).30,56 Multisite targeting is also envisioned from recently

developed OR logic gate triggering systems. This concept was

demonstrated in a self-immolative dendrimer in which either of

two orthogonal triggers was activated in the presence of its

corresponding stimuli.34

5.3. Degradable Nanoscale Materials. While many

targeted applications of SIPs have utilized the small molecules

released upon depolymerization, other approaches focus on the

depolymerization event itself as the desired function of the SIP.

Specifically, stimuli-responsive depolymerization has been used

to irreversibly degrade hydrophobic components of micelles,

nanoparticle frameworks, microcapsule shells, and solid

patterned plastics. These degradable platforms may find

application in areas including drug delivery, self-healing

materials (by release of small molecules that promote crosslinking, monomer polymerization, etc.), and lithography. Gillies

demonstrated the hydrolytic degradation of micelles formed

from self-assembly of block copolymers comprising hydrophobic SIP blocks, hydrophilic PEG blocks, and a watersensitive trigger.20 Nile red, a hydrophobic fluorescent dye, was

encapsulated within the hydrophobic core of the micelle and

was released as the micelle was degraded. Such systems are

attractive for applications requiring slow release of a particular

compound.

Small molecule release has also been demonstrated from

degradable capsules. Moore used SIPs as building blocks in

microcapsule shells that were responsive toward acidic or basic

media using either Boc or Fmoc groups, respectively.53 Upon

6. OUTLOOK AND CHALLENGES

Advancements in the field of self-immolative polymers have

collectively resulted in systems capable of side-chain release,

fast deconstruction, and conversion into either functional or

unreactive small molecules. While no single type of SIP

possesses all of these desirable characteristics, the diversity of

trigger structures in combination with differing SIP main chains

combine to make this class of functional polymeric materials

highly versatile. The basic platform has been applied toward

demonstrating the potential use of SIPs in several applications,

I

dx.doi.org/10.1021/ma300817v | Macromolecules XXXX, XXX, XXX−XXX

�Macromolecules

Perspective

While there is considerable opportunity for improvement of

the SIP repeat unit, focus must also be given to expanding

trigger designs. The SIP trigger is the first relay between the

functional macromolecule and the surrounding environment.

The area of sensors is likely to experience the greatest benefit

from trigger developments, as this area requires high fidelity of

analyte/trigger combinations. Development of new triggers that

help target drug release to the sites of disease will also be useful.

For these applications, more in-depth studies also need to be

conducted such as greater exploration into the sensitivity and

selectivity of sensors and in vivo studies of SIPs for drug

delivery. Further expansion of SIPs into solid-state materials

would be accelerated by development of new polymer

structures, as PPA is currently the only demonstrated option

for such roles. The release of monomer units that become

functionally active upon depolymerization is another avenue of

future SIP development. A particularly intriguing application of

this concept would be the development of SIP monomer units

capable of repolymerization under orthogonal triggering

conditions, thus providing a system capable of switching

between covalent polymeric materials and small molecules in

response to different stimuli. Overall, these challenges present

considerable opportunities for the convergence of synthetic

chemistry and materials science with multiple other disciplines,

and we believe the future of stimuli-responsive materials is

likely to see increased focus on self-immolative macromolecules.

often with relatively little augmentation of the SIP architecture.

Although the general modularity of the designs described

herein shows great promise for innovative future technologies,

there remain unanswered challenges and unrealized capabilities

in the area of SIPs.

The ideal SIP would be comprised of monomers that could

be easily obtained and possess the ability for facile side chain

functionalization, both of which have yet to be achieved in

combination. For instance, phthalaldehyde is commercially

available, but side-chain release has not been realized. Similarly,

while p-aminobenzyl alcohol-based monomers with vinylogous

side chains can be readily functionalized with different output

molecules, their preparation requires lengthy syntheses and

purification protocols. More generally, increasing the solubility

of the known polyurethane-based SIPs would also constitute a

significant contribution.

From a synthetic perspective, more powerful approaches

toward accessing SIPs via controlled chain growth polymerization mechanisms are highly desirable. The molecular weights

of SIPs prepared via polycondensation reactions are difficult to

control as their polymerizations proceed through step growth

mechanisms. Thus, SIPs often exhibit characteristics typical of

step growth polymers, such as relatively low molecular weight

ranges and broad PDIs. Higher molecular weights, such as

those achieved with PPA, and low PDIs would not be the only

advantages of a chain growth polymerization, as new SIP

architectures such as block copolymers utilizing different selfimmolative monomers might be obtained. It would be

important that these polymerizations do not detract from the

modular nature of SIPs, as the ability to tune the polymers for

different applications is one of their most attractive features.

Particular attention should also be paid to the mechanism

and kinetics of depolymerization when designing advanced SIP

systems. Collectively, the time to completely depolymerize

from trigger to output varies from seconds to days for known

SIPs. The ability to modulate the depolymerization profile for a

single type of monomer such that variation between rapid and

prolonged depolymerization can be controlled is thus far

unrealized. While Shabat has already reported preliminary

studies of the rates of 1,4-elimination based upon electronic

modification of the arene core (see section 4.1), additional

systematic investigation of the relationship between monomer

structure and depolymerization kinetics would be valuable for

future SIP designs.

Undesired side reactions will continue to be an area of

concern as specialized SIPs are developed for precise

applications. For instance, a particular challenge facing PPAs

is the lack of compatibility of the polymer backbone with protic

conditions, which severely limits the utility of this class of SIPs

in its current iteration. Issues of high reactivity also face SIPs

which operate via quinone methide intermediates, as these are

highly unstable and rapidly react with nucleophiles. As

discussed above, Shabat has demonstrated that reaction of

these quinone methides with biomolecules is possible.

Although the activity of the enzymes studied was not greatly

affected, the formation of highly reactive intermediates in a

more complex biological environment could lead to unwanted

side effects in the application of SIP-based drug release

platforms. Therefore, a logical parameter for the design or

optimization of SIPs is avoidance of reactive species, either in

the pretriggered state or generated as a consequence of polymer

deconstruction.

■

AUTHOR INFORMATION

Corresponding Author

*E-mail boydston@chem.washington.edu, Ph (206) 616-8195,

Fax (206) 685-8665.

Author Contributions

†

These authors contributed equally to this work.

Notes

The authors declare no competing financial interest.

Biographies

Gregory I. Peterson received his B.S. in Chemistry from Pacific

Lutheran University in 2010. There he did undergraduate research

with Prof. Dean A. Waldow preparing multiblock copolymers via

anionic polymerizations. He is currently working toward his Ph.D. in

chemistry at the University of Washington, Seattle, under the

supervision of Asst. Prof. Andrew J. Boydston. His research interest

includes the synthesis and application of stimuli-responsive, functional

macromolecules.

J

dx.doi.org/10.1021/ma300817v | Macromolecules XXXX, XXX, XXX−XXX

�Macromolecules

Perspective

(4) Li, S.; Szalai, M. L.; Kevwitch, R. M.; McGrath, D. V. J. Am. Chem.

Soc. 2003, 125, 10516−10517.

(5) Amir, R. J.; Pessah, N.; Shamis, M.; Shabat, D. Angew. Chem., Int.

Ed. 2003, 42, 4494−4499.

(6) Szalai, M. L.; Kevwitch, R. M.; McGrath, D. V. J. Am. Chem. Soc.

2003, 125, 15688−15689.

(7) Shabat, D. J. Polym. Sci., Part A: Polym. Chem. 2006, 44, 1569−

1578.

(8) Wang, R. E.; Costanza, F.; Niu, Y.; Wu, H.; Hu, Y.; Hang, W.;

Sun, Y.; Cai, J. J. Controlled Release 2012, 159, 154−163.

(9) Wang, W.; Alexander, C. Angew. Chem., Int. Ed. 2008, 47, 7804−

7806.

(10) Esser-Kahn, A. P.; Odom, S. A.; Sottos, N. R.; White, S. R.;

Moore, J. S. Macromolecules 2011, 44, 5539−5553.

(11) Avital-Shmilovici, M.; Shabat, D. Soft Matter 2010, 6, 1073−

1080.

(12) Wong, A. D.; DeWit, M. A.; Gillies, E. R. Adv. Drug Delivery Rev.

2011, DOI: 10.1016/j.addr.2011.09.012.

(13) Blencowe, C. A.; Russell, A. T.; Greco, F.; Hayes, W.;

Thornthwaite, D. W. Polym. Chem. 2011, 2, 773−790.

(14) Sagi, A.; Weinstain, R.; Karton, N.; Shabat, D. J. Am. Chem. Soc.

2008, 130, 5434−5435.

(15) Weinstain, R.; Sagi, A.; Karton, N.; Shabat, D. Chem.Eur. J.

2008, 14, 6857−6861.

(16) Warnecke, A.; Kratz, F. J. Org. Chem. 2008, 73, 1546−1552.

(17) Ortiz, A.; Shanahan, C. S.; Sisk, D. T.; Perera, S. C.; Rao, P.;

McGrath, D. V. J. Org. Chem. 2010, 75, 6154−6162.

(18) Kevwitch, R. M.; Shanahan, C. S.; McGrath, D. V. New J. Chem.

2012, 36, 492−505.

(19) Weinstain, R.; Baran, P. S.; Shabat, D. Bioconjugate Chem. 2009,

20, 1783−1791.

(20) DeWit, M. A.; Gillies, E. R. J. Am. Chem. Soc. 2009, 131, 18327−

18334.

(21) DeWit, M. A.; Beaton, A.; Gillies, E. R. J. Polym. Sci., Part A:

Polym. Chem. 2010, 48, 3977−3985.

(22) Ito, H.; Willson, C. G. Polym. Eng. Sci. 1983, 23, 1012−1018.

(23) Aso, C.; Tagami, S.; Kunitake, T. J. Polym. Sci., Part A: Polym.

Chem. 1969, 7, 497−511.

(24) Kostler, S.; Zechner, B.; Trathnigg, B.; Fasl, H.; Kern, W.;

Ribitsch, V. J. Polym. Sci., Part A: Polym. Chem. 2009, 47, 1499−1509.

(25) Seo, W.; Phillips, S. T. J. Am. Chem. Soc. 2010, 132, 9234−9235.

(26) Phillips, S. T.; Seo, W.; Robbins, J.; Olah, M.; Schmid, K.;

Dilauro, A. M. Signal-responsive plastics. W.O. Patent 2012/005806,

Jan 12, 2012.

(27) Tsuda, M.; Hata, M.; Nishida, R.; Oikawa, S. J. Polym. Sci., Part

A: Polym. Chem. 1997, 35, 77−89.

(28) Zheng, H.; Yeung, K.; Robbins, J. S.; Pavlick, R. A.; Wu, M.; Liu,

R.; Sen, A.; Phillips, S. T. Angew. Chem., Int. Ed. 2012, 51, 2400−2404.

(29) Erez, R.; Segal, E.; Miller, K.; Satchi-Fainaro, R.; Shabat, D.

Bioorg. Med. Chem. 2009, 17, 4327−4335.

(30) Grinda, M.; Clarhaut, J.; Renoux, B.; Tranoy-Opalinski, I.;

Papot, S. Med. Chem. Commun. 2012, 3, 68−70.

(31) Shamis, M.; Lode, H. N.; Shabat, D. J. Am. Chem. Soc. 2004,

126, 1726−1731.

(32) Haba, K.; Popkov, M.; Shamis, M.; Lerner, R. A.; Barbas, C. F.,

III; Shabat, D. Angew. Chem., Int. Ed. 2005, 44, 716−720.

(33) Sagi, A.; Segal, E.; Satchi-Fainaro, R.; Shabat, D. Bioorg. Med.

Chem. 2007, 15, 3720−3727.

(34) Amir, R. J.; Popkov, M.; Lerner, R. A.; Barbas, C. F., III; Shabat,

D. Angew. Chem., Int. Ed. 2005, 44, 4378−4381.

(35) Danieli, E.; Shabat, D. Bioorg. Med. Chem. 2007, 15, 7318−7324.

(36) Shamis, M.; Shabat, D. Chem.Eur. J. 2007, 13, 4523−4528.

(37) Adler-Abramovich, L.; Perry, R.; Sagi, A.; Gazit, E.; Shabat, D.

ChemBioChem 2007, 8, 859−862.

(38) Amir, R. J.; Danieli, E.; Shabat, D. Chem.Eur. J. 2007, 13,

812−821.

(39) Erez, R.; Shabat, D. Org. Biomol. Chem. 2008, 6, 2669−2672.

(40) Meyer, Y.; Richard, J.-A.; Delest, B.; Noack, P.; Renard, P.-Y.;

Romieu, A. Org. Biomol. Chem. 2010, 8, 1777−1780.

Michael B. Larsen was born in 1988 in Denver, CO. In 2009 he

obtained his BA in chemistry from the Colorado College, where he

served as department paraprofessional and conducted research under

Asst. Prof. Rongson Pongdee (now at Sewanee). He is currently

working toward his doctorate in chemistry under the supervision of

Asst. Prof. Andrew J. Boydston. His research interests include the

development of novel mechanophores and methods of triggering selfimmolative polymers.

Andrew J. Boydston received his B.S. and M.S. degrees in Chemistry in

2001 and 2002, respectively, both from the University of Oregon

under the mentorship of Professor Michael M. Haley. After

completing his Ph.D. in Chemistry in 2007 at the University of

Texas at Austin under the guidance of Professor Christopher W.

Bielawski, he began postdoctoral studies at the California Institute of

Technology with Professor Robert H. Grubbs. In 2010, he began his

independent career at the University of Washington where he is

currently appointed as an Assistant Professor of Chemistry. His

research focuses on stimuli-responsive macromolecules, polymer

design and synthesis, and electro-organic synthesis.

■

ACKNOWLEDGMENTS

We gratefully acknowledge the University of Washington,

University of Washington Royalty Research Fund, and Army

Research Office Young Investigator Program (W911NF-11-10289) for financial support.

■

REFERENCES

(1) Carl, P. L.; Chakravarty, P. K.; Katzenellenbogen, J. A. J. Med.

Chem. 1981, 24, 479−480.

(2) de Groot, F. M. H.; Loos, W. J.; Kockkock, R.; van Berkom, L. W.

A.; Busscher, G. F.; Seelen, A. E.; Albreccht, C.; de Bruijn, P.;

Scheeren, H. W. J. Org. Chem. 2001, 66, 8815−8830.

(3) de Groot, F. M. H.; Albrecht, C.; Koekkoek, R.; Beusker, P. H.;

Scheeren, H. W. Angew. Chem., Int. Ed. 2003, 42, 4490−4494.

K

dx.doi.org/10.1021/ma300817v | Macromolecules XXXX, XXX, XXX−XXX

�Macromolecules

Perspective

(41) Redy, O.; Kisin-Finfer, E.; Sella, E.; Shabat, D. Org. Biomol.

Chem. 2012, 10, 710−715.

(42) National Library of Medicine: Medline Plus. Albumin - serum.

http://www.nlm.nih.gov/medlineplus/ency/article/003480.htm (accessed 4/2/12).

(43) Polaske, N. W.; Szalai, M. L.; Shanahan, C. S.; McGrath, D. V.

Org. Lett. 2010, 12, 4944−4947.

(44) Sella, E.; Shabat, D. Chem. Commun. 2008, 44, 5701−5703.

(45) Sella, E.; Shabat, D. J. Am. Chem. Soc. 2009, 131, 9934−9936.

(46) Avital-Shmilovici, M.; Shabat, D. Bioorg. Med. Chem. 2010, 18,

3643−3647.

(47) Sella, E.; Lubelski, A.; Klafter, J.; Shabat, D. J. Am. Chem. Soc.

2010, 132, 3945−3952.

(48) Major Jourden, J. L.; Daniel, K. B.; Cohen, S. M. Chem.

Commun. 2011, 47, 7968−7970.

(49) Karton-Lifshin, N.; Shabat, D. New J. Chem. 2012, 36, 386−393.

(50) Zhang, L.; Liu, W.; Lin, L.; Chen, D.; Stenzel, M. H.

Biomacromolecules 2008, 9, 3321−3331.

(51) Perry-Feigenbaum, R.; Sella, E.; Shabat, D. Chem.Eur. J. 2011,

17, 12123−12128.

(52) Perry, R.; Amir, R. J.; Shabat, D. New J. Chem. 2007, 31, 1307−

1312.

(53) Esser-Kahn, A. P.; Sottos, N. R.; White, S. R.; Moore, J. S. J. Am.

Chem. Soc. 2010, 132, 10266−10268.

(54) de Gracia Lux, C.; McFearin, C.; Sankaranarayanan, J.; Fomina,

N.; Almutairi, A. ACS Macro Lett. 2012, 1, 922−926.

(55) Timko, B. P.; Whitehead, K.; Gao, W.; Kohane, D. S.;

Farokzhad, O.; Anderson, D.; Langer, R. Annu. Rev. Mater. Res. 2011,

41, 1−20.

(56) Withana, N. P.; Blum, G.; Sameni, M.; Slaney, C.; Anbalagan,

A.; Olive, M. B.; Bidwell, B. N.; Edgington, L.; Wang, L.; Moin, K.;

Sloane, B. F.; Anderson, R. L.; Bogyo, M. S.; Parker, B. S. Cancer Res.

2012, 72, 1199−1209.

(57) Fomina, N.; McFearin, C.; Sermsakdi, M.; Edigin, O.; Almutairi,

A. J. Am. Chem. Soc. 2010, 132, 9540−9542.

(58) Fomina, N.; McFearin, C.; Sermsakdi, M.; Morachis, J. M.;

Almutairi, A. Macromolecules 2011, 44, 8590−8597.

(59) Knoll, A. W.; Pires, D.; Coulembier, O.; Dubois, P.; Hedrick, J.

L.; Frommer, J.; Duerig, U. Adv. Mater. 2010, 22, 3361−3365.

(60) Coulembier, O.; Knoll, A.; Pires, D.; Gotsmann, B.; Duerig, U.;

Frommer, J.; Miller, R. D.; Dubois, P.; Hedrick, J. L. Macromolecules

2010, 43, 572−574.

L

dx.doi.org/10.1021/ma300817v | Macromolecules XXXX, XXX, XXX−XXX

�