Improvement of the thermal stability of cyanoacrylate adhesives

Improvement of the thermal stability of cyanoacrylate adhesives

Journal:

Year:

Abstract:

The results of studies of the effect of synthesized modifiers based on cyanosorbic acid on the ther- mal properties of cyanoacrylate adhesives have been presented.

DOI:

10.1134/S1995421209010055

Type of document:

Language:

ISSN 1995-4212, Polymer Science, Series D. Glues and Sealing Materials, 2009, Vol. 2, No. 1, pp. 27–30. © Pleiades Publishing, Ltd., 2009.

Original Russian Text © A.M. Vetrova, D.A. Aronovich, G.N. Chervyakova, A.P. Sineokov, 2007, published in Klei. Germetiki. Tekhnologii, 2007, No. 8, pp. 22–25.

Improvement of the Thermal Stability

of Cyanoacrylate Adhesives

A. M. Vetrova, D. A. Aronovich, G. N. Chervyakova, and A. P. Sineokov

Federal State Unitary Enterprise Kargin Scientific Research Institue of Polymers (FGUP NIIP),

Dzerzhinsk, Nizhegorodskoi oblast, 60600 Russia

e-mail: niip@kis.ru

Received on 12 April 2007

Abstract—The results of studies of the effect of synthesized modifiers based on cyanosorbic acid on the thermal properties of cyanoacrylate adhesives have been presented.

DOI: 10.1134/S1995421209010055

cyanoacrylates that are easily copolymerized with

α-cyanoacrylates in the process of gluing and form

structured polymers with higher thermostability. At the

same time, the synthesis of β-vinyl-α-cyanoacrylates,

as a rule, takes place with low yield and involves the

application of high-toxicity acrolein.

At room temperature, cyanoacrylate monomers,

which are widely used as binders for fast-setting adhesives in the polymerization on the anion mechanism,

form linear thermoplastic polymers with low stability at

high temperatures. The problem of improving the thermal stability of cyanoacrylate compositions is solved

mainly in two ways, i.e., by the use of cyanoacrylate

monomers with multiple bonds in alcohol radical and

by structuring the polymer chain with various modifying additives [1–3].

In light of this, derivatives of α-cyanosorbic

(cyanopentadine, crotolidencyanacetic) acids, which

are synthesized by the condensation of respective

cyanoacetate with crotonic or cinnamic aldehyde in

aqueous and alcohol solutions with a zinc chloride catalyst [7] are of particular interest. The compositions

One of the most efficient methods is the introduction

into adhesive compositions [4-6] of various β-vinyl-α-

1

2

3

4

5

6

7

8

9

10

Modifier formula

[XCH=CH–CH=C(CN)–COO]nR

Tensile strength*,

MPa, at the temperature, °C

Base of adhesive composition

X

n

R

20

150

200

250

7.2

11.0

9.3

3.1

10.0

12.0

11.5

9.8

7.8

1.7

7.0

6.8

3.5

3.5

5.2

4.5

1.1

4.5

1.8

7.6

6.4

4.1

6.8

4.2

3.8

2.4

4.6

9.2

5.0

4.0

Unmodified allyl-α-cyanoacrylate

Allylcyanosorbinate

Propargylcyanosorbinate

Etoxyethylcyanosorbinate

Diallyloxyisopropilcyanosorbinate

Dicyanosorbinate of ethylene glycol

Tetracyansorbinate pentaerithrytol

Allylcyanomilidencyanoacetate

Dicynnamilidencyanoacetate

ethylene glycol

CH3

CH3

CH3

CH3

CH3

CH3

C6H5

C6H5

1

1

1

1

2

4

1

2

–CH2CH=CH2

–CH2C≡CH

–C2H4OC2H5

–CH(CH2OCH2CH=CH2)2

–CH2CH2–

=(CH2)2C(CH2)2=

–CH2CH=CH2

–CH2CH2–

26.2

29.0

28.0

35.0

26.0

25.6

29.0

21.0

23.2

Tris-(cyanomilidencyanacetate)

glycerin

C6H5

3

–CH 2 –CH–CH 2 –

26.5

–

Composition no.

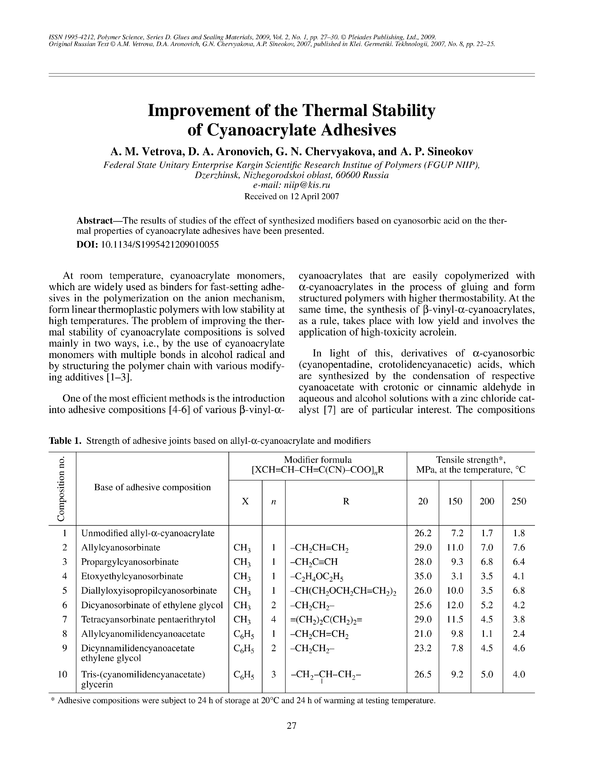

Table 1. Strength of adhesive joints based on allyl-α-cyanoacrylate and modifiers

* Adhesive compositions were subject to 24 h of storage at 20°C and 24 h of warming at testing temperature.

27

28

VETROVA et al.

Table 2. Intensity change of valent fluctuations of double bonds C=C groups of ethyl-α-cyanoacrylate at different temperatures

Optical desity (R)*

at temperature, °C

Polymer

compound

20

190

0.125

0.162

0.179

Poly-ECA

Poly-ECA+ACS

Poly-ECA+PCS**

150

0.095

0.160

0.094

0.291

0.167

0.279

–1

D 1620 cm

* R = --------------------------- .

–1

D 1480 cm

** Propil-α-cyanosorbinate.

synthesized and studied are presented in Table 1; they

turned out to be rather stable during storage. The introduction of these compositions into ethyl (ECA), etoxyethyl (EECA) butyl, and allylic (ACA) ethers of

α-cyanoacrylate acids had no influence on their stability, setting time, and initial strength. At the same time,

we observed a substantial increase in the stability of

adhesive compositions at high temperatures. So, the

introduction of compositions 2, 6, 7 (Table 1) in quantities of 10 wt % into ECA resulted in improved

strength at an even tensile strength of 8–25 MPa after

adhesive joints were warmed at 150°C for two hours.

The test results of steel samples glued together at 150–

250°C by compositions based on ACA [8] that are more

thermal stability than ECA, as well as synthesized

modifiers, are given in Table 1.

Table 1 shows that the introduction of cyanosorbic

acid is more preferable. Allyl-α-cyanosorbinate (ACS)

has the best thermostabilizing properties.

To study the processes that take place in an adhesive

composition based on cyanoacrylate, which contains

ACS modifier, we have used the infrared spectroscopy

method introduced previously [9]. This method enables

us to continually monitor the structural modifications

of the glue matrix during cianoacrylate polymerization.

In this case, we use monocrystal KBr or NaCl as the

glue substrate and control the hardening kinetics in the

thin glue layer according to the changing intensity of

specific absorption bands –CH=CH– ECA bonds

(1620 cm–1), –CH2=CH–CH=CH2– conjugated ACS

bond (1590 and 1640 cm–1), CH2=CH–CH=CH2–

allylic ACS bond (1655 cm–1). Optical densities R were

measured by the basic line method, which takes the

Table 3. Impact of allyl-α-cyanosorbinate on radical polymerization of α-cyanoacrylates

Polymerization parameters

Oligomer

Concentration

ACS, wt %

Wn × 102, % s–1

Wm × 102, % s–1

Time of reaching Wm ,

min

2.9

1.9

40

0.1

1.8

1.3

48

0.5

1.0

0.7

77

1.0

0.7

0.4

113

5.0

0.4

0.2

300

2.3

1.6

70

0.1

1.6

1.2

85

0.5

1.3

0.8

115

1.0

0.3

0.3

140

5.0

0.2

0.2

340

α-cyanoacrylate

α-cyanoacrylate–EECA

modified α-cyanoacrylate

C2H5–ECA

α-cyanoacrylate

α-cyanoacrylate–EECA

modified α-cyanoacrylate

C2H5OC2H4–EECA

Note: Wn is the initial speed and Wm is the maximum speed.

POLYMER SCIENCE

Series D

Vol. 2

No. 1

2009

IMPROVEMENT OF THE THERMAL STABILITY OF CYANOACRYLATE ADHESIVES

Tensile strength, MPa

Tensile strength, MPa

30

1

30

29

20

20

2

3

10

4

1.5

2.0

2.5

3.0

% mass

~

~

1.0

10

Fig. 1. Influence of tertiary butyl peroxide in allyl-αcyanoacrylate composition with allylcianosorbinate

(5% mass) onto the strength of adhesive joint.

(1) warming at 150°C, testing at 20°C; (2) warming

and testing at 150°C; (3) warming and testing at

200°C; (4) warming and testing at 250°C.

3

~

~

0.5

1

~

~

0

2

~

~

4

0

band at 1480 cm–1 as a standard that is typical for C–H

deformation oscillations.

It was determined that ACSs glued at room temperature do not polymerize according to the anion mechanism. However, in compositions with ECA (5 wt %, for

1–1.5 h, the intensity of double-conjugated bonds

decreases by 15–20% (ECA double bonds are

exhausted by 80–85%), which serves as evidence of the

copolymerization of monomers. The closeness of halfwave potential values for ECA (E1/2 = 1.20) and ACS

(E1/2 = 1.26) determined polarographicly also proves

4

8

12

16

20 30

Time, day

Fig. 2. Influence of thermal aging on adhesive joint

strength. (1) warming at 150°C, testing at 20°C;

(2) warming and testing at 150°C; (3) warming and

testing at 200°C; (4) warming and testing at 250°C.

the possibility of anion copolymerization [10]. Thus, by

the moment that the composition is nearly set, the glue

line turns into a copolymer of ECA and ACS (1.5–2%)

containing unpolymerized ACS and small amount of

Table 4. Strength of various materials joints made by adhesive compositions based on allyl-α-cyanoacrylate*

Tensile strength, MPa

Glued materials

σ20

σ200

σ205

31.2

23.4

28.0

21.8

Steel 12Kh18X10T

Aluminum

Composition metal

Titanium

σ150

20.0

9.5

8.2

6.9

11.2

8.6

9.2

8.5

8.8

6.5

3.5

5.0

Note: Terms of testing are given in the note to Table 1.

* Composition contains 5 wt % ACA and 0.5 wt % peroxide of tert.-butyl.

Table 5. Influence of thermal cycles onto strength of joint made by adhesive compositions based on allyl-α-cyanoacrylate*

Tensile strength, MPa

initial at 20°C

29.5

Strength at displacement, MPa

after thermal cycles**, °C

–60…+150

–60…+200

–60…+250

20.5

4.5

4.0

initial at 20°C

15.0

after thermal cycles**, °C

–60…+150

–60…+200

–60…+250

6.5

4.0

5.0

* Formula of adhesive composition is the same as in Table 4.

** Three thermal cycles were carried out with a 1-h time delay at each temperature and rigorous mode switch.

POLYMER SCIENCE

Series D

Vol. 2

No. 1

2009

30

VETROVA et al.

Tensile strength, MPa

30

20

2

10

1

0

10

20

30

Time, day

Fig. 3. Aging of adhesive materials at 40°C and 98%

humidity. (1) strength at displacement; (2) strength at

even detachment.

unpolymerized ECA. After additional heating at 150°C

for 30–60 min, double-conjugated bonds of ACS disappear, which structures the polymer so as to cause an

increase in thermostability. At a further increase in the

warming temperature to 190°C, the content of the double bonds in pure ECA again grows as a result of polyECA depolymerization. In the presences of ACS, additional double bonds do not form, which is evidence of

the stabilizing effect of ACS on poly-ECA thermodestruction (Table 2).

If we use propyl-α-cyanosorbinat (PCS) that is free

of allyl bonds as a modifier, the IR spectrum of the

polymer in adhesive composition has another character

(Table 2); i.e., there is no thermostabilizing effect at

190°C, which proves the importance of the allylic

group in stabilization. This group, as is known [11],

may serve as a trap for radicals in the radical processes.

In connection with this, the influence of ACS on the

radical polymerization of cyanoacrylate ECA and

EECA at 60°C (Table 3) has been studied. Polymerization was initiated by dicyclohexylperoxidicarbonate

(0.5 wt %). It is clear that even a minor addition of ACS

substantially slows down radical polymerization.

Thus, the obtained data prove that increased thermal

stability of cyanoacrylate adhesive compositions at the

introduction of ACS can be explained as follows. Partial copolymerization and cross-linking during gluing

take place first and, later, at increased temperatures,

radical processes of the destruction of poly-αcyanoacrylate slow down.

Since ACAs and ACSs contain nonsaturated double

bonds, it would be interesting to examine an influence

of peroxide additives on adhesive composition strength

(Fig. 1). The introduction of tertiary butyl peroxide has

no effect on the initial strength, but it does increase the

strength at higher temperatures.

The influence of the nature of glued substrates and

thermocycles on the strength of adhesive compositions

based on ACA is presented in Tables 4 and 5. Thermal

and humidity aging of adhesive compositions at 40°C

and 98% humidity are demonstrated in Figs. 2 and 3.

The results of these studies support the recommendation of cyanoacrylate adhesive compositions modified by cyanosorbinates for use at higher temperatures.

REFERENCES

1. N.N. Trofimov, D.A. Aronovich, V.S. Etlis, N.M. Pivchuk, Plastic masses, 1976, No. 9, p. 55.

2. D.L. Kotzev, T.C. Ward, D.W. Wright. J. Appl. Polym.

Sci., 1981, Vol. 26. No. 6, pp. 1941–1949.

3. V. Vijayalakshmi, J.N. Rupavani, N. Krushnamurti.

J. Appl. Polym. Sci. vol. 49, 1394 (1993).

4. N.N. Trofimov, V.S. Etlis, D.A. Aronovich. Pat.

1415102, Great Britain, 1973.

5. D.A. Aronovich, A.M. Vetrova, Glues. Sealing Materials. Technologies, 2007, No. 4, pp. 10–14.

6. Z.Z. Denchev, V.S. Kabaivanov. J. Appl. Polym. Sci.,

vol. 47, N. 6, pp. 1019–1026 (1993).

7. A.M. Vetrova, N.M. Pinchuk, A.P. Sineokov et al.

A. c. 1089927 USSR, B.I. 1980, N16.

8. A.M. Vetrova, N.M. Pinchuk, N.N. Trofimov et al.

A. c. 730779 USSR, B.I. 1980, N16.

9. E.G. Pomerantseva, D.A. Aronovich, D.A. Meiman,

A.P. Sineokov. Scientific and practical seminar materials

“Glues, metal and plastic sealing”, Leningrad, LDNTP,

1979, pp. 89–91.

10. K. Höfelman, R. Sattelmayer, Macromol. Chem., 1968,

112, pp. 300–302.

11. D. Oudian. Fundamentals of polymer chemistry. Ed. by

acad. V. V. Korshak, Moscow, Mir, 1974, p. 212.

POLYMER SCIENCE

Series D

Vol. 2

No. 1

2009

Coments go here:

- Log in to post comments