Study of Thermal Properties of Cyanoacrylate Adhesives Modified with Unsaturated Compounds

Study of Thermal Properties of Cyanoacrylate Adhesives Modified with Unsaturated Compounds

Journal:

Year:

Abstract:

The effect of allyl derivatives of muconic, malonic, and isocyanuric acids, as well as some other unsaturated compounds on the properties of adhesives based on ethyl- and allyl-α-cyanoacrylates, is studied.

DOI:

10.1134/S1995421208040047

Type of document:

Language:

ISSN 1995-4212, Polymer Science, Series D. Glues and Sealing Materials, 2008, Vol. 1, No. 4, pp. 238–240. © Pleiades Publishing, Ltd., 2008.

Original Russian Text © D.A. Aronovich, A.M. Vetrova, A.P. Sineokov, 2008, published in Klei. Germetiki. Tekhnologii, 2008, No. 5, pp. 12–14.

Study of Thermal Properties of Cyanoacrylate Adhesives

Modified with Unsaturated Compounds

D. A. Aronovich, A. M. Vetrova, and A. P. Sineokov

Federal State Unitary Enterprise Kargin Institute of Polymers, Dzerzhinsk, Nizhegorodskaya obl., 60600 Russia

e-mail: niip@kis.ru

Received January 25, 2008

Abstract—The effect of allyl derivatives of muconic, malonic, and isocyanuric acids, as well as some other

unsaturated compounds on the properties of adhesives based on ethyl- and allyl-α-cyanoacrylates, is studied.

DOI: 10.1134/S1995421208040047

Cyanoacrylate adhesives with enhanced thermal stability are of interest for bonding in various fields of

technology. An analysis of the published data [1–5]

demonstrates that the basis for such adhesives is bifunctional cyanoacrylate monomers containing multiple

bonds in the alcohol radical, e.g., allyl-, propargyl-, and

allyloxyethyl cyanoacrylates. Such monomers attract

attention based on the fact that they are first cured by

the anionic mechanism using cyanoacrylate functionality; then, upon heating, multiple bonds of alcohol radical are revealed.

Moreover, thermal properties of adhesives can be

improved by the addition of thermally curing agents,

such as bi- and polyfunctional compounds containing,

e.g., (met)acrylate and allyl groups (dimethacrylate

glycols, diallylisophthalate, tri- and tetraallylpyromellitate, allyl and propargyl esters of dibasic acids, etc.).

As has been shown by us previously [6–8], composi-

tions containing derivatives of β-vinyl-α-cyanoacrylic

and cyanosorbic acids as modifiers of cyanoacrylate

adhesives are characterized by enhanced thermal properties.

In order to further study the heat resistance and

thermal stability of cyanoacrylate adhesives, we tested,

compounds containing unsaturated groups as

structuring agents, such as diallyl muconate

[CH2=CHCH2O(O)CCH=CH–]2 (I), crotolideneallyl

malonate CH3CH=CHCH=C[C(O)OCH2CH=CH2]2 (II),

and cinnamylidene malononitrile C6H5CH=CHCH=

C(CN)2 (III) (Tables 1 and 2). Structurization was performed in both the presence and absence of tert-butyl

peroxide, which can initiate crosslinking at elevated

temperatures.

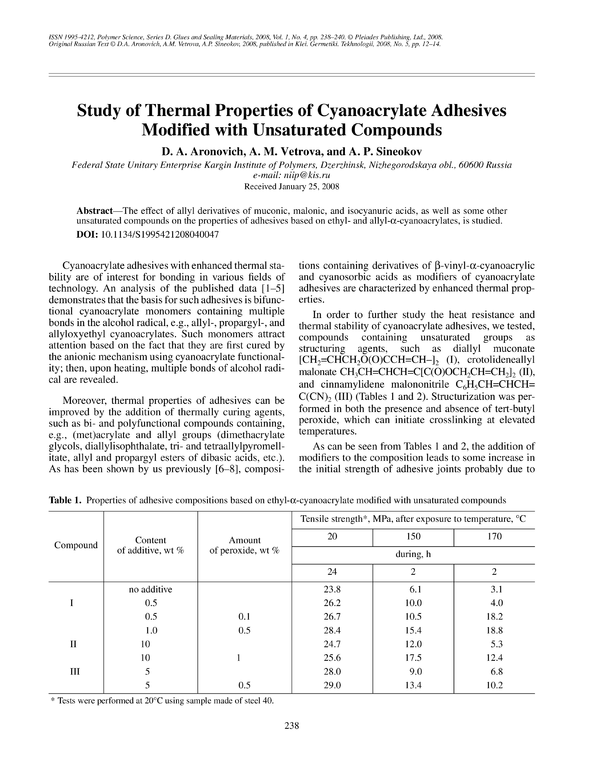

As can be seen from Tables 1 and 2, the addition of

modifiers to the composition leads to some increase in

the initial strength of adhesive joints probably due to

Table 1. Properties of adhesive compositions based on ethyl-α-cyanoacrylate modified with unsaturated compounds

Tensile strength*, MPa, after exposure to temperature, °C

Compound

Content

of additive, wt %

20

Amount

of peroxide, wt %

150

170

during, h

24

I

II

III

no additive

0.5

0.5

1.0

10

10

5

5

1

0.5

* Tests were performed at 20°C using sample made of steel 40.

238

2

23.8

26.2

26.7

28.4

24.7

25.6

28.0

29.0

0.1

0.5

2

6.1

10.0

10.5

15.4

12.0

17.5

9.0

13.4

3.1

4.0

18.2

18.8

5.3

12.4

6.8

10.2

STUDY OF THERMAL PROPERTIES OF CYANOACRYLATE ADHESIVES MODIFIED

239

Table 2. Properties of adhesive compositions based on allyl-α-cyanoacrylate modified with unsaturated compounds

Tensile strength*, MPa, after exposure to temperature, °C

ComContent

Amount

pound of additive, wt % of peroxide, wt %

20

150

170

200

during, h

24

2

6

2

6

1

6

23.0

24.0

9.2

8.4

7.7

4.0

3.2

0.5

23.5

27.4

14.8

12.6

10.0

4.8

3.7

1

0.5

25.4

20.8

12.8

13.0

9.0

9.5

5.0

10

1.0

29.6

16.6

18.8

10.5

14.0

3.0

4.1

1

30.0

28.0

11.6

5.0

30.7

26.0

20.0

16.0

9.2

30.2

28.2

22.1

17.5

10.4

no additive

I

II

5

III

5

5

0.5

3.2**

4.6

Notes: * At 20°C.

** Samples were tested at the temperature of heating.

the plasticization of polymer and the enhancement of

the thermal properties of both alkyl and allyl esters of

poly-α-cyanoacrylate. It was of interest to test unsaturated derivatives of isocyanuric acid, which can be copolymerized with allyl groups of poly-α-cyanoacrylate at

elevated temperatures, as modifiers (Table 3).

In order to synthesize isocyanuric derivatives of

β-vinyl-α-cyanoacrylic and cyanosorbic acids, we conducted the esterification of tris(hyrdoxyethyl) isocyanurate with cyanoacetic acid to form tris(cyanoacetoxyethyl) isocyanurate, which then was condensed with

acrolein or crotonic aldehyde [9]. Tris(allyloxycarboxyethyl) isocyanurate (IV) was synthesized by the

interaction between allylchloroformiate with tris(hyrdoxyethyl) isocyanurate. Prepared compounds of

tris(allyloxycarboxyethyl) (IV), tris(β-vinyl-α-cyanoacryloxyethyl) (V), and tris(cyanosorbiniloxyethyl) (VI) isocyanurates are solid substances with melting points of

63, 127, and 149°C for compounds IV, V, and VI,

respectively, and are well soluble in monomeric

cyanoacrylates. Their structures were confirmed by elemental analysis, the determination of molecular mass,

and the IR spectroscopy.

Note that the addition of compounds VII, VIII, IX,

XI, and XII, in which allyl group is directly bound to

nitrogen of triazene cycle, resulted in the spontaneous

polymerization of cyanoacrylates during storage; therefore, such compounds can be used as activators upon

their deposition onto substrates in the form of solutions

in organic solvents directly prior to bonding.

As can be seen from Table 3, compounds V and VI

increase the initial strength of adhesive joints, which is

probably due to copolymerization during bonding, as

POLYMER SCIENCE

Series D

Vol. 1

No. 4

2008

was shown in [5–7]. In addition, such compounds

increase the stability of adhesive joints to thermal

cyclic treatment at temperatures ranged from –60 to

+200°C. The best strength properties at elevated temperatures are demonstrated by the composition containing compound IV as modifier. The addition of 0.5%

tert-butyl peroxide to such composition increases the

strength of adhesive joints to 12 MPa after heating at

Tensile strength, MPa

35

30

25

1

20

15

10

2

5

3

0

10

20

30

40

50

60

Concentration of modifier, wt %

The effect of the amount of tris(allyloxycarboxyethyl)

isocyanurate (compound IV) in adhesive compositions based on allyl-α-cyanoacrylate on the strength

properties of adhesive joints after exposure for 24 h at

(1) 20, (2) 250, and (3) 300°C.

240

ARONOVICH et al.

Table 3. Strength properties of adhesive compositions based on allyl-α-cyanoacrylate containing derivatives of isocyanuric acid

Tensile strength at 20°C, MPa,

after exposure to temperature, °C

Modifier

Compound

20

R1

R2

R3

250

300

during, h

24

CH2=CHCH2OC–

–(O)OCH2CH2–

CH2=CHCH2OC–

–(O)OCH2CH2–

CH2=CHCH2OC–

–(O)OCH2CH2–

V

CH2=CHCH=C(CN)–

–COOCH2CH2–

CH3CH=CHCH=

=C(CN)–COOCH2CH2–

CH2=CH–CH2–

CH2=CH–CH2–

CH2=CH–CH2–

CH2=CHCH2=C(CN)–

–COOCH2CH2–

CH3CH=CHCH=

=C(CN)–COOCH2CH2–

CH2=CH–CH2–

CH2=CH–CH2–

CH2=CH–CH2–

CH2=CHCH2OCOCH=

=CH–COOCH2CH2–

CH2=CH–CH2–

CH2=CH–CH2–

CH2=CHCH2OCOCH=

=CH–COOCH2CH2–

CH2=CH–CH2–

C7H15OCOCH2CH2–

CH2=CHCH=C(CN)–

–COOCH2CH2–

CH3CH=CHCH=

=C(CN)–COOCH2CH2–

CH2=CH–CH2–

CNCH2CH2–

CH2=

=CHCH2OCOCH2CH2–

CH2=CHCH2OCOCH=

=CH–COOCH2CH2–

C7H15OCOCH2CH2–

C7H15OCOCH2CH2–

VI

VII

VIII

IX

X

XI

XII

3

22.7

27.1

no modifier

IV

24*

1.4

9.6

0

8.4

33.2

7.3

5.0

30.8

8.6

5.3

24.8

24.4

24.3

3.6

7.4

5.6

2.5

5.7

3.5

28.4

4.7

4.0

28.2

28.5

6.9

4.5

4.1

2.1

* Tested at 250°C.

O

R1 N

Note: 1. General formula of isocyanuric acid derivatives is

O C

C

N R2

N

C O

.

R3

2. The amount of modifier is 10 wt %

300°C, which supports the radical mechanism of

crosslinking.

We studied the effect of the content of modifier IV in

the adhesive composition based on allyl-β-cyanoacrylate

on strength properties of adhesive joints at different

temperatures (see figure). The composition containing

10 wt % modifier turned out to be stable to prolonged

thermal aging within a temperature range of 150–

250°C. Residual strength after aging at these temperatures for 500 h was equal to 9–12 MPa.

3. L. M. Pritykin, D. A. Kardashov, and V. L. Vakula,

Monomer Adhesives (Khimiya, Moscow, 1988) [in Russian].

REFERENCES

8. A. M. Vetrova, D. A. Aronovich, and A. P. Sineokov,

Klei. Germet. Tekhnol., No. 8, 22 (2007).

1. Yu. G. Gololobov and V. Gruber, Usp. Khim. 66 (11),

1054 (1997).

2. N. N. Trofimov, D. A. Aronovich, V. S. Etlis, and

N. M. Pinchuk, Plast. Massy, No. 9, 55 (1976).

4. D. L. Kotzev, T. C. Ward, and D. W. Wright, J. Appl.

Polym. Sci. 26 (6), 1941 (1981).

5. K. L. Shantha, S. Thennarasu, and N. Krishnamurti, J.

Adhes. Sci. Technol. 3 (4), 237 (1989).

6. D. A. Aronovich, Candidate’s Dissertation in Chemistry

(Dzerzhinsk, 1977).

7. D. A. Aronovich and A. M. Vetrova, Klei. Germet. Tekhnol., No. 4, 10 (2007).

9. N. M. Pinchuk, A. M. Vetrova, A. P. Sineokov, et al.,

USSR Inventor’s Certificate No. 686292A1, Byull. Izobret., No. 17 (1995).

POLYMER SCIENCE

Series D

Vol. 1

No. 4

2008

Coments go here:

- Log in to post comments