Preparation of Iodine Polyvinyl-Pyrrolidone Adducts

Preparation of Iodine Polyvinyl-Pyrrolidone Adducts

US2900305

Company:

Folder:

Year:

Abstract:

This invention relates to the preparation of an adduct of iodine and polymeric 1-vinyl-2-pyrrolidone (hereinafter referred to as polyvinylpyrrolidone) whereby there is fomred a composition which is readily soluble in water to form a stable solution and which provides iodine in readily available germicidally and bactericidally active form which is essentially non-toxic to warm-blooded animals.

Type of document:

Language:

2,900,305

7 Patented Aug. 18, 1959

United States, Patent Ofice

1

2,900,305 -

PREPARATION or IODINE POLYVINYL-H

PYRROLIDONE ADDUCTS

Sidney Siggia, Phillipsburg, N.J., assignor to General Ani-

_ . line & Film Corporation, New-York, N.Y., a corpora-

tion of Delaware

No Drawing. Application August 9,1956

' Serial No. 603,185 ’

13 Claims. (Cl. 167—70)

This invention relates to the preparation of an adduct

of iodine and polymeric 1—vinyl—2-pyrrolidone (herein-

after referred to as polyvinylpyrrolidone) whereby there

is formed a composition which is readily soluble in water

to form a stable solution and which provides iodine in

readily available in germicidally -andbactericidally active

form -which is essentially non-toxic to warm-blooded

animals. :

In U.S. Patent 2,706,701 of Beller and Hosmer there

is described a process for the preparation of a composi-

tion of iodine and polyvinylpyrrolidone. In accordance

with -the process of this patent, compositions of iodine

and polyvinylpyrrolidone can be prepared by thoroughly

mixing dry elemental iodine with dry powdered poly-

vinylpyrrolidone. The iodine and powered polymer may

be mixed until a homogeneous powder is obtained, the

mixing being carried out in materials which are not at-

tacked by iodine so a-s to avoid the introduction of metal

ions into the finished composition. This mixing may be

effected by grinding the iodine and polyvinylpyrrolidone

in a mortar and pestle or more advantageously in a suit-

able mechanical mixer such as a —ball mill. The

time of mixing varies -only with the efliciency there-

of, as the combination of the poly-vinylpyrrolidone with

iodine on its surface is rapid; in fact, such combination

will occur to some extent on dropping iodine ‘crystalson

the dry powdered polymer. . I

’ On completion of the mixing there is obtained a com-

pound in a physical state similar to the polymer alone

but which contains varying proportions of iodine—avail-

able iodine (as distinguished from free iodine), iodide

ion and bound iodine. A distinction between these forms

may be made on an analytical basis, available iodine

being determined directly by dissolving a sample of the

product in water and titrating with 0.1—N sodium thio-

sulfate (Na2S2O3) solution using starch as an indicator.

The amount of iodine present as iodide ion is determined

by reducing the iodine compound in solution with 1-N

sodium acid sulfite (NaHSO3) , adding enough to make the

solution colorless, then adding 0.l—N silver nitrate and

enough nitric acid to make the solution acidic and back-

titrating with ammonium thiocyanate (NH4SCN). The

iodide‘ ion is the difference between this figure and the

available iodine as determined above. The total iodine

may be determined by combustion methods such as that‘

formulated by Hallett in Scott’s Standard Methods of

Chemical Analysis, bound iodine then being determined

by subtracting the sum of available iodine and iodide

ion from the total iodine as determined above.

The product, i.e. the polyvinylpyrrolidone—iodine ad-

duct, PVB—I, obtained in accordance with the process of

the Beller and Hosmer patent suffers from the disadvan-

tage that it is not stable in aqueous solution. The_ sta-

bility is reckoned with «respect to loss of iodine in solution.

(The iodine is reduced to iodide by an unknown factor

in the polyvinylpyrrolidone.) ' p

' It -is, accordingly, an important object of this inven-

tion» to providea process for the preparation of a poly-

’ aforementioned and other disadvantages.

10

15

20

25

30

35

40

50

55

60

65

70

. 2 .

vinylpyrrolidone-iodine adduct which is free from the

Another ob-

ject of this invention is the provision of a polyvinylpyr-

rolidone—iodine adduct, prepared by the process of this

invention, which is stable in aqueous solution. Other

objects and advantages of this invention will appear

from the following detailed description and claims.

I ‘have found «that when elemental iodine of either

a technical or resublimed grade is added to solid poly-

viuylpyrrolidone, which has a moisture (water) content

from 4 to 15%, as a blend, the blend mixed, ‘with some

grinding action if desired, in a glass or earthenware vessel

as in the Bellar and Hosmer process," and the blend then

heated to a temperature between .90 and 100° C., there

is obtained a polyvinylpyrrolidone-iodine adduct of unique

stability in aqueous solution. ,

I have also found that a polyvinylpyrrolidone-

iodine adduct containing 20% available iodine when made

with polyvinylpyrrolidone having a ‘water content of 4

to 15% yields a more stable aqueous solution than a

polyvinylpyrrolidone-iodine adduct containing 10% avail-

able iodine. '

By “K value,” as employed below, "is meant

Fikentscher K value (1000 k) as defined by H. Fikent-

scher in Cellulosechemie 13, 58-64, 71-4 (1932) and was

determined with aqueous solutions of the polymer using

an Ubbelohdeviscosimeter at 25° C., the concentration

being 1 gram of polymer (anhydrous basis) per 100 ml.

of solution.

The details of the present invention will be apparent

from thefollowing specific examples in which the parts

are by weight. ' I .

Example I

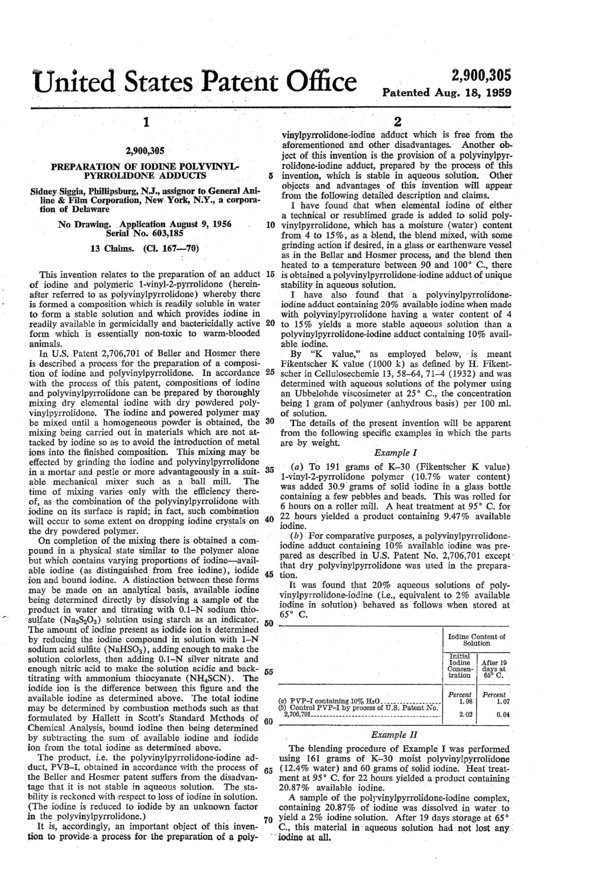

V (a) To 191 grams of K-30 (Fikentscher K value)

1-vinyl-2-pyrrolidone polymer (10.7% water content)

was added 30.9'grams of solid iodine in a glass bottle

containing a few pebbles and beads. This was rolled for

6 hours on a roller mill. A heat treatment at 95° C. for

22 hours yielded a product containing 9.47% available

iodine.

(b) For comparative purposes, a polyvinylpyrrolidone-

iodine adduct containing 10% ‘available’ iodine was pre-

pared as described in U.S. Patent No. 2,706,701 except-

that dry polyvinylpyrrolidone was used in the prepara-

tion. ” -

It was found that 20% aqueous solutions of poly-

; vinylpyrrolidone—iodine (i.e., equivalent to 2% available

iodine in solution) behaved as follows when stored at‘

65° C.

Iodine Content of

Solution

Initial

Iodine After 19

Concen- days at

tration 65° C.

' . - Percent Percent

(42) PV_P—I containing.10% H20 _________________ __ 1. 98 1.07

(12) Control PVP—I by process of U.S. Patent No. .

2,706,701 .......... _-; _______________________ ' 2. 02 0. 04

Example 11

- The blending procedure of Example, I was performed

using 161 grams of K-30 moist polyvinylpyrrolidone

(12.4% water) and 60 grams of solid iodine. Heat treat-

ment at 95 ° C. for 22 hours yielded aproduct containing

20.87% available iodine.

A sample of the pol}yinylpyrrolidone-iodine complex,

containing 20.87% of iodine was dissolved in Water to

yield a 2% iodine solution. After 19 days storage at 65°

C., this material inaqueous solution had not lost any"

iodine at all.

it 3

Example III

It has been found, as indicated, that a minimum mois-

ture content of 4% in the polyvinylpyrrolidone, blended

with iodine is’ necessary in order to (have -aqueous solu-

tions, and the resulting product to have acceptable sta-

bility on storage; and it is definitely preferable that the

moisture content of the polyvinylpyrrolidone, blended

with ‘the iodine, have a minimum of about 6% moisture

content. Maximum stability is obtained in '-aqueous solu-

tions of the resulting product. Increasing the amount of

moisture in the polyvinylpyrrolidone used for blending

does not result in further increase in stability, However,

it is not objectionable, since the same maximum stability

is obtained. The maximum -amount of moisture obtained

should be about 15%, since, at higher moisture content,

mechanical difiiculties in processing arise. The eifect of

varying amounts of moisture in the polyvinylpyrrolidone

are shown in the table below. The products listed in the

table were prepared, as in Example In above, using poly-

vinylpyrrolidone having a K value of .30, -and the moisture

content indicated in the table.

Percent loss of available

Percent H20 in iodine in storage of 10%

Original PVP PVP—I solution at 42° C.

for 10 days

1

1. 1

2. 7

4. 9

6. 5

9. 1

13. 2

Example IV

It has been found that the same efiect is obtained with

PVP carrying higher K values. As indicated in the table

below, in which PVP samples of K values of 60 and 90,

respectively, and having moisture contents of 10.5 and

11.3%, respectively, were blended with about 20% by

weight of elemental iodine in the manner described in

Example Ia -above.

Freshly Prepared Stability Per-

Percent cent, Loss 1%

K value of PVP H20 in Available Io-

PVP Percent Percent dine-Aqueous

Available Iodide Solution stored

Iodine I011 10 days at 42° C.

60 __________________ _. 10. 5 12. 95 5. 9 1

90 __________________ __ 11.3 12.66 5.8 1

In practicing the present invention, it has been found

that it is preferable to use a polyvinylpyrrolidone having

a K value of at least 20, and more preferably about 30.

From a preparative standpoint, it has been found that

polyvinylpyrrolidone o-f low K value (and corresponding

low molecular weight) consumes more iodine than does

polyvinylpyrrolidone of higher K value—maximum for

available iodine being reached when the K value of the

polyvinylpyrrolidone is about 30. Also, the -stability of

the polyvinylpyrrolidone-iodine complex obtained when

using polyvinylpyrrolidone of low K value is not as great

as the ‘stability of the polyvinylpyrrolidone-iodine adduct

made from polyvinylpyrrolidone of higher K values.

This is possible, due -to the fact that the low K value

of polyvinylpyrrolidone has more -oxidizable fragments or

end groups. Thus, the polyvinylpyrrolidone-iodine ad-

duct, prepared from polyvinylpyrrolidone having a K

value of 20, or lower, ceases to become commercially

attractive, and the optimum product is obtained when the

polyvinylpyrrolidone has a K value of about 30. Fur-

ther increase in the K value of the polyvinylpyrrolidone

is without substantial effect on the properties of the re-

sulting adduct with iodine, until the K value becomes 90,

at which time the solubility of the polyvinylpyrrolidone,

in water, begins to decrease substantially.

’ 2,900,305

10

15

20

25

30

35

40

45

50

55

60

65

70

375

4

The process of the instant invention makes for a ready

method of combining iodine with polyvinylpyrrolidone to‘

obtain ‘a water solution of the polyvinylpyrrolidone-iodine

-adduct containing appreciable amounts of iodine, which

does not deteriorate on standing as was the case of earlier

aqueous solutions of polyvinylpyrrolidone-iodine adducts.

The instant solution of the adduct is more stable than

tincture of iodine and the complex in solution, does not

give sting or epidermal burn, and on drying forms a pro-

tective coating on the skin. Moreover, the iodine in the

solution of the adduct is less toxic than unreacted iodine.

It is .to be understood that the foregoing detailed de-

scription is merely given by way of illustration and that

many variations may be made ‘therein without departing

from the spirit of my invention.

Having described my invention, what I desire to secure

by Letters Patent is:

1. Process for the preparation of a polyvinylpyrroli-

done-iodine composition which is stable in aqueous solu-

tion, Which comprises thoroughly mixing elemental iodine

and powdered 1-vinyl-2-pyrrolidoiie polymer containing

from 4.9—l3.2% water, and heating the resulting com-

position at a temperature of from about 90 to 100° C,

until a product containing an appreciable amount of

available iodine is obtained.

2. Process for the preparation of a polyvinylpyrroli-

done-iodine composition which is stable in aqueous solu-._

tion, which comprises thoroughly mixing elemental iodine

and powdered 1-vinyl-2-pyrrolidone polymer containing

about 11% of water and heating the resulting composi-

tion at a temperature of 95° C. until a product contain-

ing about 9.5% available iodine is obtained.

3. Process for the preparation of a polyvinylpyrroli-

done-iodine composition which is stable in aqueous solu-

tion, which comprises thoroughly mixing elemental iodine

and powdered 1-vinyl-2-pyrrolidone polymer containing

about 12.5% water and heating the resulting composition

at -a temperature of 95° C. until a product containing

about 21% available iodine is obtained.

4. Process for the preparation of a stable aqueous solu-

tion of a polyvinylpyrrolidone-iodine composition, which

comprises thoroughly mixing elemental iodine and pow-

dered 1-vinyl-2-pyrrolidone polymer containing from 4.9

to‘ 13.2% water, heating the resulting composition at a

temperature. of from about 90 to 100° C. until a product

containing an appreciable amount of available iodine is

obtained, and dissolving said product in water.

5. Process for the preparation of a stable aqueous solu-

tion of a polyvinylpyrrolidonoiodine composition, which

comprises thoroughly mixing elemental iodine and pow-

dered 1-vinyl-2-pyrrolidone polymer containing about 11%

of water, heating the resulting composition at a tempera-

ture of 95° C. until a product containing about 9.5%

‘available iodine is obtained, and dissolving said product

in water.

6. Process for the preparation of a stable aqueous solu-

tion of a polyvinylpyrrolidone-iodine composition, which

comprises thoroughly mixing elemental iodine and pow-

dered 1-vinyl-2-pyrrolidone polymer containing about

12.5% water, heating the resulting composition at a tem-—

perature of 95° C. until a product containing about 21%

available iodine is obtained, and dissolving said product

in water.

7. Process for the preparation of a stable aqueous solu-

tion of a polynvinylpyrrolidone-iodine composition, which

comprises thoroughly mixing elemental iodine and pow-

dered 1-vinyl-2-pyrrolidone polymer having a K value,

as defined, of 30 and containing about 11% of water,

heating the resulting composition at a temperature of

95° C. until a product containing about 9.5 % available

iodine is obtained, and dissolving said product in water.

8. Process for the preparation of a stable aqueous solu-

tion of a polyvinylpyrrolidone-iodine composition, which

comprises thoroughly mixing elemental iodine and pow-

dered 1-vinyl-2-pyrrolidone polymer having. a K value, as

2,900,805

5

defined, of 30 and containing about 12.5% -'water, heating

the resulting composition at a temperature of 95° C. un-

til a product containing about 21% available iodine is

obtained, and dissolving said product in water.

9. Process for the preparation of a stable aqueous solu-

tion of a polyvinylpyrrolidone-iodine composition, which

comprises thoroughly mixing elemental iodine and pow-

dered 1-vinyl-2-pyrrolidone polymer having a K value,

as defined, of 60-and containing about 10.5% of water,

heating the resulting composition at a temperature of

95° C. until a product containing about 12.95% avail-

able iodine is obtained, and dissolving said product in

water.

10. Process for the preparation of a stable aqueous

solution of a polyvinylpyrrolidone—iodine composition,

which comprises thoroughly mixing elemental iodine and

powdered 1-vinyl-2-pyrrolidone polymer having a K value,

as defined, of 90 and containing about 10.5% of water,

heating the resulting composition at a temperature of 95°

C. until a product containing about 12.66% available

iodine is obtained, and dissolving said product in Water.

11. A stable aqueous solution of a polyvinyl-pyrroli-

done-iodine composition, comprising the product of claim

1 dissolved in water, said solution being characterized by

its ability to retain more of its available iodine content

after storage than an aqueous solution of a polyvinyl-

10

15

20

25

6

pyrrolidone-iodine composition produced from elemental

iodine and polyvinylpyrrolidone containing less than 4%

of water. ,

12. A stable aqueous solution of a polyvinylpyrroli-

done-iodine composition, comprising the product of claim

2 dissolved in water, said solution being characterized by

its ability to retain more of its available iodine content

after storage than an aqeous solution of a polyvinyl-

pyrrolidone-iodine composition produced from elemental

iodine and polyvinylpyrrolidone containing less than 4%

of water.

13. A stable aqueous solution of a polyvinylpyrroli-

done-iodine composition, comprising the product of claim

3 dissolved in water, said solution being characterized by

its ability to retain more of its available iodine content

after storage than an aqueous solution of a polyvinyl-

pyrrolidone-iodine composition produced from elemental

iodine and polyvinylpyrrolidone containing less than 4%

of water.

References Cited in the file of this patent

UNITED STATES PATENTS

Beller ............... _- Apr. 19, 1955

Hosmer _____________ __ July 10, 1956

2,706,701

2,754,245

_a

UNITED STATES PATENT OFFICE

CERTIFICATE OF CORRECTION

NO. 23900, ‘ l8’

(SEAL)

Attest:

KARL H. VAXLINE ROBERT C. WATSON

Attesting Oificer’ Commissioner of Patents

Coments go here:

- Log in to post comments