����������������������������������������������������������������������

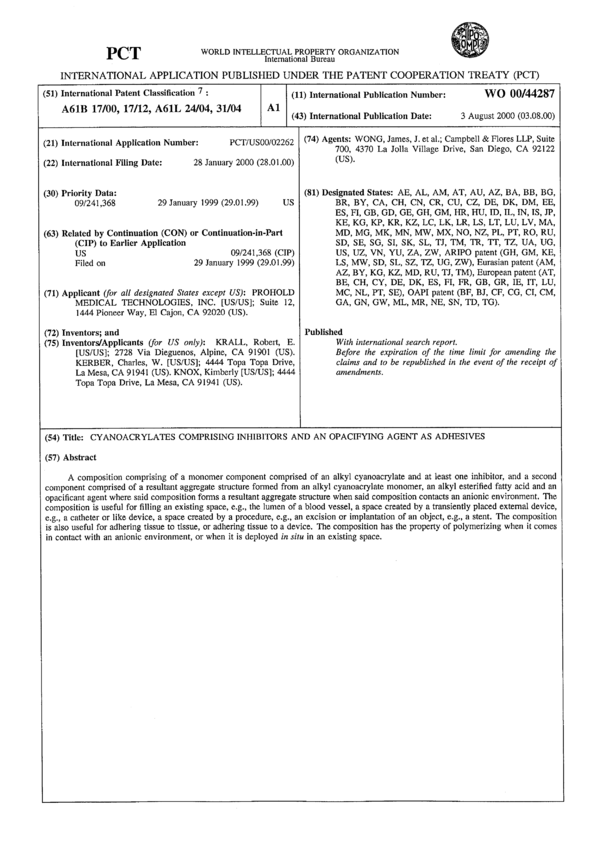

WORLD INTELLECTUAL PROPERTY ORGANIZATION

Intemational Bureau

INTERNATIONAL APPLICATION PUBLISHED UNDER THE PATENT COOPERATION TREATY (PCT)

(51) International Patent Classification 7 1 (11) International Publication Number: WO 00/44287

A61B 17/00, 17/12, A61L 24/04, 31/04 _ _ .

(43) International Publication Date: 3 August 2000 (03.08.00)

(21) International Application Number: PCT/USO0/02262 (74) Agents‘ WONG: James» J- et 31-9 Ca"‘Pb6“ & Flores LU’: Suite

700, 4370 La Jolla Village Drive, San Diego, CA 92122

(22) International Filing Date: 28 January 2000 (28.01.00) (US)-

(30) Priority Data: (81) Designated States: AE, AL, AM, AT, AU, AZ, BA, BB, BG,

09/241,368 29 January 1999 (29.01.99) US BR, BY, CA, CH, CN, CR, CU, CZ, DE, DK, DM, EE,

ES, FI, GB, GD, GE, GH, GM, HR, HU, ID, IL, IN, IS, JP,

KE, KG, KP, KR, KZ, LC, LK, LR, LS, LT, LU, LV, MA,

(63) Related by Continuation (CON) or Continuation-in-Part MD, MG, MK, MN, MW, MX, NO, NZ, PL, PT, RO, RU,

(CIP) to Earlier Application SD, SE, SG, SI, SK, SL, TJ, TM, TR, "IT, TZ, UA, UG,

US 09/241,368 (CIP) US, UZ, VN, YU, ZA, ZW, ARIPO patent (GH, GM, KE,

Filed on 29 January 1999 (29.0l.99) LS, MW, SD, SL, SZ, TZ, UG, ZW), Eurasian patent (AM,

AZ, BY, KG, KZ, MD, RU, TJ, TM), European patent (AT,

BE, CH, CY, DE, DK, ES, FI, FR, GB, GR, IE, IT, LU,

(71) Applicant (for all designated States except US): PROHOLD MC, NL, PT, SE), OAPI patent (BF, BJ, CF, CG, CI, CM,

MEDICAL TECHNOLOGIES, INC. [US/US]; Suite 12, GA, GN, GW, ML, MR, NE, SN, TD, TG).

1444 Pioneer Way, El Cajon, CA 92020 (US).

(72) Inventors; and Published

(75) Inventors/Applicants (for US only): KRALL, Robert, E. With international search report.

[US/US]; 2728 Via Dieguenos, Alpine, CA 91901 (US). Before the expiration of the time limit for amending the

KERBER, Charles, W. [US/US]; 4444 Topa Topa Drive, claims and to be republished in the event of the receipt of

La Mesa, CA 91941 (US). KNOX, Kimberly [US/US]; 4444 amendments.

Topa Topa Drive, La Mesa, CA 91941 (US).

(54) Title: CYANOACRYLATES COMPRISING INHIBITORS AND AN OPACIFYING AGENT AS ADHESIVES

(57) Abstract

A composition comprising of a monomer component comprised of an alkyl cyanoacrylate and at least one inhibitor, and a second

component comprised of a resultant aggregate structure formed from an alkyl cyanoacrylate monomer, an alkyl esterified fatty acid and an

opacificant agent where said composition forms a resultant aggregate structure when said composition contacts an anionic environment. The

composition is useful for filling an existing space, e.g., the lumen of a blood vessel, a space created by a transiently placed extemal device,

e.g., a catheter or like device, a space created by a procedure, e.g., an excision or implantation of an object, e.g., a stent. The composition

is also useful for adhering tissue to tissue, or adhering tissue to a device. The composition has the property of polymerizing when it comes

in contact with an anionic environment, or when it is deployed in situ in an existing space.

FOR THE PURPOSES OF INFORMATION ONLY

Codes used to identify States party to the PCT on the front pages of pamphlets publishing intemational applications under the PCT.

Albania ES Spain LS Lesotho SI Slovenia

Armenia FI Finland LT Lithuania SK Slovakia

Austria FR France LU Luxembourg SN Senegal

Australia GA Gabon LV Latvia SZ Swaziland

Azerbaijan GB United Kingdom MC Monaco TD Chad

Bosnia and Herzegovina GE Georgia MD Republic of Moldova TG Togo

Barbados GH Ghana MG Madagascar TJ Tajikistan

Belgium GN Guinea MK The former Yugoslav TM Turkmenistan

Burkina Faso GR Greece Republic of Macedonia TR Turkey

Bulgaria I-IU Hungary ML Mali TT Trinidad and Tobago

Benin IE Ireland MN Mongolia UA Ukraine

Brazil IL Israel MR Mauritania UG Uganda

Belarus IS Iceland MW Malawi US United States of America

Canada IT Italy MX Mexico UZ Uzbekistan

Central African Republic JP Japan NE Niger VN Viet Nam

Congo KE Kenya NL Netherlands YU Yugoslavia

Switzerland KG Kyrgyzstan N0 Norway ZW Zimbabwe

Cote d’Ivoire KP Democratic People’s NZ New Zealand

Cameroon Republic of Korea PL Poland

China KR Republic of Korea PT Portugal

Cuba KZ Kazakstan R0 Romania

Czech Republic LC Saint Lucia RU Russian Federation

Germany LI Liechtenstein SD Sudan

Denmark LK Sri Lanka SE Sweden

Estonia LR Liberia SG Singapore

WO 00/44287 PCT/US00/02262

CYANOACRYLATES COMPRISING INHIBITORS AND AN OPACIFYING AGENT AS

ADHESIVES

FIELD OF THE INVENTION

This invention relates to cyanoacrylate

compositions useful as medical devices.

5 BACKGROUND OF THE INVENTION

Cyanoacrylate tissue adhesives have been in

clinical endovascular use since the 1970's. Liquid

acrylics are extremely useful as endovascular embolic

agents because of their ability to create permanent

10 vascular occlusion. They may, however, be difficult to

use technically as they have a variable and sometime

unpredictable polymerization time based on the operator

selection of an acrylic mix with either iodinated oil or

glacial acetic acid. The appropriate choice of

15 polymerization time depends on a number of variables,

including the transit time between arterial and venous

elements in the embolic target, the target volume, the

architecture of the target, for example, a fistula versus

nidus, which affects the relative endovascular

20 turbulence, and the method of injection (bolus, full

column, or wedge—flow arrest). Typical complications

associated with the use of liquid acrylics for

embolization occur when there is occlusion of normal

arterial branches or acrylic penetration into critical

25 venous outflow channels. Additionally, reflux of acrylic

around the delivery catheter tip can result in permanent

endovascular catheter adhesion, which may require

permanent catheter implantation. Overzealous attempts at

withdrawal can produce catheter fracture (and resultant

30 embolization of flow-directable distal catheter segment),

vascular damage with resultant dissection/occlusion, or

WO 00/44287

10

15

20

25

30

PCT/US00/02262

2

avulsion of the involved vascular pedicle (with resultant

subarachnoid hemorrhage).

Alkyl alpha cyanoacrylates are a homologous

series of organic molecules which polymerize and can

adhere to moist living tissues. The methyl homolog has

been used in homeostasis and non—suture closure since

1960,

usefulness.

but its histoxicity severely limited its clinical

The synthesis of longer alkyl chain homologs

and the evaluation of these in various animal species

have shown that the histoxicity of cyanoacrylates could

be diminished without sacrificing their hemostatic and

tissue bonding properties. Extensive animal studies have

been completed using n-butyl and isobutyl homologs, and

preliminary human trials have been undertaken.

Polymerization speed is another function of

chain length. It has been reported that homologs with

six or more carbon atoms on the alkyl chain polymerize

almost immediately upon contact with moist tissues. The

n—butyl and isobutyl monomers require from four to 15

while the methyl homolog remains as a monomer

The

seconds,

for 30 to 55 seconds. ability to wet and spread

easily over the surface of an anticoagulated blood film

is common to homologs with alkyl chains containing four

The ethyl and propyl derivatives

or ITIOIE carbon atoms.

wet and spread poorly, and the methyl not at all.

Since the advent of NBCA (n—butyl—2—

cyanoacrylate), there has been very little advancement in

the science of "superglue" embolization of vascular

structures, primarily arteriovenous malformations (AVMs).

Certain properties of superglue are advantageous for

embolization, such as adhesion, the ability transform

from a liquid or solid state and rapid polymerization.

WO 00/44287

10

15

20

25

30

PCT/US00/02262

3

However, these properties can be detrimental when present

to an excessive degree, in particular, adhesion which can

result in permanent catheter fixation. Rapid

polymerization allows the material to set in flowing

blood without passing through small channels into venous

structures. However, rapid polymerization may also

release amounts of heat that can cause damage to the

brain tissue.

surrounding tissue, for example,

Hydrophilic catheter coatings have been

developed in the hope of reducingthe risk of inadvertent

catheter

endovascular fixation during embolization due to

reduced bond strength between the hydrophillically coated

catheter and the adhesive. However, micro catheter

cyanoacrylate adhesion remains a problem during

intravascular embolization. Inadvertent gluing of the

catheter tip onto the artery is a well recognized and

distressing complication. Vessel rupture or occlusive

embolization of a detached catheter tip may occur if

excessive force is used to attempt to retrieve the

catheter. permanent intra vascular catheter

Fortunately,

fixation is usually well tolerated, nonetheless this

remains a highly undesirable event. An in vitro study

has shown that recently available hydrophilic micro

catheter coatings decrease catheter adhesion of both pure

normal butyl cyanoacrylate and mixtures of normal butyl

cyanoacrylate and ethiodized oil. Although

hydrophilically coated catheters have the potential of

decreasing the occurrence of inadvertent endovascular

the level of operator proficiency and

the actual

catheter fixation,

experience, and perhaps most importantly,

adhesive composition that is used stills play a major

role in these events.

WO 00/44287 PCT/US00/02262

4

There exists a continuing unmet need for a

composition that has the correct amount of cohesiveness,

produces a robust rubbery casting, is tolerated by the

body, can trigger the appropriate amount of tissue

5 inflammation response and is radiopaque.

It has now been surprisingly found that such a

composition exists that has the requisite combination of

properties in cohesion, stability, body tolerance, low

catheter adhesion and radiopacity.

10 SUMMARY OF THE INVENTION

A composition comprising of a monomer component

comprised of an alkyl cyanoacrylate and at least one

inhibitor, and a second component comprised of a

resultant aggregate structure formed from an alkyl

15 cyanoacrylate monomer, an alkyl esterified fatty acid and

an opacificant agent where said composition forms a

resultant aggregate structure when said composition

contacts an anionic environment. the composition is

useful for filling an existing space, e.g., the lumen of

20 a blood vessel, or the sac of an aneurysm, a space

created by a transiently placed external device, e.g., a

catheter or like device, a space created by a procedure,

e.g., an excision or like procedure or implantation of an

object, e.g., a stent or like device, or a space created

25 by the composition; the composition is also useful for

adhering tissue to tissue, or adhering tissue to a

device. The composition has the property of polymerizing

when it comes in contact with an anionic environment, or

when it is deployed in situ in an existing space, e.g.,

30 the lumen of a blood vessel, or the sac of an aneurysm, a

space created by a transiently placed external device,

e.g., a catheter or like device, a space created by a

WO 00/44287 ’ PCT/US00/02262

5

procedure, e.g., an excision or like procedure or

implantation of an object, e.g., a stent or like device,

or a space created by the composition.

BRIEF DESCRIPTION OF THE DRAWINGS

5 No drawing are included.

DETAILED DESCRIPTION OF THE INVENTION

The present invention provides a composition

comprising of a monomer component comprised of an alkyl

cyanoacrylate, at least one inhibitor and a second

10 component that functions as a opacificant agent and

polymerization retardant. The composition is useful for

filling, occluding, partially filling or partially

occluding an unfilled volume or space in a mass (“a

space”). In particular, the composition is useful for

15 filling an existing space, e.g., the lumen of a blood

vessel, or the sac of an aneurysm, a space created by a

transiently placed external device, e.g., a catheter or

like device, a space created by a procedure, e.g., an

excision or like procedure or implantation of an object,

20 e.g., a stent or like device, or a space created by the

composition; the composition is also useful for adhering

tissue to tissue, or adhering tissue to a device. The

composition has the property of polymerizing when it

comes in contact with an anionic environment, or when it

25 is deployed in situ in an existing space, e.g., the lumen

of a blood vessel, or the sac of an aneurysm, a space

created by a transiently placed external device, e.g., a

catheter or like device, a space created by a procedure,

e.g., an excision or like procedure or implantation of an

30 object, e.g., a stent or like device, or a space created

by the composition.

WO 00/44287

10

15

2O

25

30

PCT/US00/02262

6

Another aspect of the present embodiment is

where the second component is comprised of a halogenated

oil. Preferred are iodinated and brominated oils, such

as Ethiodol, Lipiodol and Pantopaque. Most preferred is

Ethiodol.

One embodiment of the present invention is

where the second component is Ethiodol.

Another aspect of the present embodiment is

where the second component is comprised of a resultant

aggregate structure, i.e., an oligomer or polymer, formed

from a composition of alkyl cyanoacrylate monomer, an

alkyl esterified fatty acid and an opacificant agent.

Another aspect of the present embodiment is

where the monomer component is comprised of an alkyl

cyanoacrylate monomer, and at least two inhibitors, a

preferred aspect is where the monomer component is

comprised of an alkyl cyanoacrylate and at least three

inhibitors, an especially preferred aspect is where the

monomer component is comprised of 2—hexyl cyanoacrylate

and at least one inhibitor. An especially preferred

aspect is where the monomer component is comprised of

2—hexyl cyanoacrylate and at least two inhibitors. A

most especially preferred aspect is where the monomer

component is comprised of 2—hexyl cyanoacrylate, and

three inhibitors, particularly, most especially preferred

is the aspect where one of the inhibitors is selected

from hydroquinone, p—methoxyphenol or phosphoric acid. A

most especially preferred aspect is where the monomer

component is comprised of 2—hexyl cyanoacrylate, and

three inhibitors, where the three inhibitors are

hydroquinone, p-methoxyphenol and phosphoric acid. The

quantity of inhibitors used is measured in terms of parts

WO 00/44287

10

15

20

25

30

PCT/US00/02262

7

per million of alkyl cyanoacrylate. Preferably,

hydroquinone is in the range of about 50 to 150 parts per

million (PPM), p—methoxyphenol in the range of about 50

to 150 PPM, and phosphoric acid in the range of about 125

to 375 PPM, more preferred is hydroquinone in the range

of about 75 to 125 PPM, p~methoxyphenol in the range of

about 75 to 125 PPM, and phosphoric acid in the range of

about 187.5 to 312.5 PPM,

hydroquinone in the range of about 95 to 105 PPM,

and most preferred is

p—methoxyphenol in the range of about 95 to lO5 PPM, and

phosphoric acid in the range of about 200 to 300 PPM.

An especially preferred embodiment of the

present invention is a composition comprised of the

present monomer component, and a second component

comprising of a resultant aggregate structure, i.e., an

oligomer or polymer, formed from 2-hexyl cyanoacrylate

monomer, an alkyl esterified fatty acid and an

opacificant agent, most especially preferred is where the

alkyl esterified fatty acid is ethyl myristate, also most

especially preferred is where the opacificant agent is

gold.

Another embodiment of the present invention

provides a method for filling, occluding, partially

filling or partially occluding an unfilled volume or

space in a mass. The types of unfilled volumes or spaces

within the scope of the present invention includes, but

are not limited to the following instances.

For example, one aspect of the present

embodiment is a method of filling, occluding, partially

filling or partially occluding an existing space, such

as, a lumen of a passageway in the body, e.g., a blood

a duct, or a fistula. Examples of

vessel, an aneurysm,

WO 00/44287

10

15

20

25

3O

35

PCT/US00/02262

8

the types treatments covered by this method of use,

include but are not limited to the following. The

present invention is useful as a method of treating

arteriovenous malformations (AVM) where the blood

vessel(s) that feed the AVM are occluded thereby cutting

off the blood supply to the AVM.

is useful as a method to ablate diseased or undesired

The present invention

tissue by cutting off the tissue’s blood supply. In

particular, the present invention is useful as a method

supply, where

occluded

of treating a tumor having a discrete blood

the blood vessel(s) that feed the tumor are

thereby cutting off the blood supply to the tumor

resulting in diminished growth or death of the tumor.

The present invention is useful as a method of preventing

or mitigating the development of an aneurysm by creating

a partial occlusion at a location in the blood vessel

selected to modify the fluid dynamics within the vessel

to mitigate the formation or development of an aneurysm.

The present invention is useful as a non—surgical method

symptomatic uterine leiomyomas by

This method has

of treating

embolizing/occluding the uterine artery.

been reported using a non alkyl cyanoacrylate composition

in J.Vascular and Intervention Radiology, lO:89l—894,

July—August 1999. The present invention is useful as a

method of sterilizing a female mammal by occluding the

fallopian tubes thereby preventing the passage of the

eggs from the ovaries to the uterus. The use of an

occluding agent to sterilize a female mammal is disclosed

5,989,580 “Method of Sterilizing

in U.S. Patent No.

Female Mammals,” herein incorporated by reference. The

methods disclosed in this patent can be advantageously

applied using the compositions of the present invention,

and are within the scope of the present invention. The

present invention is useful for obliterating the left

atrial appendage. The left atrial appendage is derived

WO 00/44287

10

15

20

25

30

PCT/US00/02262

9

from the left wall of the primary atrium. It has been

observed that patients with atrial fibrillation have a

predilection for thrombus to form in the in the left

atrial appendage. A review of this condition and the

current status of treatment is disclosed in the article,

“Left Atrial Appendage: structure, function, and role in

et. al. The present

thromboembolism” N.M. Al—Saady,

invention provides an advantageous method of obliterating

the left atrial appendage.

Another aspect of the present embodiment is a

method of filling, occluding, partially filling or

partially occluding a space created by an external

device, such as, a catheter balloon. Examples of the

types of treatments covered by this method of use

include, but are not limited to the following. The

present invention is useful as a method of treating an

aneurysm by filling the space within the aneurysm with a

composition of the present invention, where the

composition polymerizes in the space within the aneurysm,

thereby preventing the rupture of the aneurysm. This

treatment can be effected using the present invention

catheter

with any number of catheters, catheter coils,

wires or catheter balloons commercially available.

Examples of such devices are commercially available from

For instance, Micro Therapeutics, Inc., 2

California 92618,

SOUICGS .

markets a line of

Goodyear, Irvine,

medical devices, such as, the Rebarm Micro Catheter,

Equinox“ Occlusion Balloon System and Silverspeedm

guidewires. U.S. 5,882,334

“Balloon/delivery Catheter Assembly with Adjustable

Similarly, Patent No.

Balloon Positioning,” assigned to Target Therapeutics,

Inc., and incorporated herein by reference, is directed

to a catheter assembly for delivering compositions, such

as, those of the present invention.

WO 00/44287

10

15

20

25

30

PCT/US00/02262

10

Another aspect of the present embodiment is a

method of filling, occluding, partially filling or

partially occluding a space created or resulting from a

procedure, such as with the excision of tissue, or

insufflation. Examples of the types of treatments

covered by this method of use include, but are not

limited to the following. The present invention is

useful as a method of treating or mitigating capillary

oozing.

Another aspect of the present embodiment is a

method of filling, occluding, partially filling or

partially occluding a space created by the placement or

implantation of an object,

such as, a medical device.

Examples of the types of uses covered by this method of

use include, The

but are not limited to the following.

present invention is useful as a method of restoring the

normal fluid dynamics at the peripheral edges of a

vascular stent by filling the dead spaces between the

stent and the lumen wall created by the implantation of

the stent.

Another aspect of the present embodiment is a

method of filling, occluding, partially filling or

partially occluding a space created by the composition

itself, such as, where the composition is used as a

bulking agent. Examples of the types of uses covered by

this method of use include, but are not limited to the

following. For example, a method of recreating the

normal contours to skin following an adverse event, such

as, physical trauma.

Another embodiment of the present invention

provides a method of affixing therapeutics,

chemotherapeutics, radiation delivery devices, gene

WO 00/44287

10

15

20

25

30

PCT/US00/02262

ll

therapy compositions to a desired location where the

active agents can be advantageously maintained in

proximity to the desired location. The active agent is

then release gradually as the resultant aggregate

structure from the composition of the present invention

is biodegraded. the composition of the

Alternatively,

present invention can be modified to allow for a specific

rate of delivery. This use is particularly beneficial in

the treatment of tumors that are ideally treated by

localized dosages of chemotherapy or radiation. An

advantage of this method is that the patient would not be

subjected to as large of a dose of the therapeutic or

if the therapeutic or

Another

radiation as would be necessary,

radiation was administered on a systemic basis.

advantageous use the present invention is for the

delivery of DNA compositions used in gene therapy. A

long standing problem in the gene therapy arts has been

the inability of practitioners to deliver the DNA

therapeutic to the locales in the body most ideally

suited for the treatment. The present invention provides

a method of affixing the DNA composition at a desired

site, where the active agent is then slowly released over

a period time as the composition of the present invention

biodegrades. Alternatively, a composition of the present

invention can be modified to release the active agent in

a controlled delivery manner.

Another embodiment of the present invention

provides a method of utilizing magnetically controlled

particles inbedded in a composition of the present

invention to deploy the composition to a desired

“Magnetic Probe for the Stereotaxic Thrombosis

J.F., et. al,

1967 April,

location,

of Intracranial Aneurysms,” Alksne, Journal

of Neurology, Neurosurgery and Psychiatry,

30(2):l59—62; “Magnetically Controlled Focal

WO 00/44287

10

15

20

25

30

PCT/US00/02262

12

Intravascular Thrombosis in Dogs” Alksne, J.F., et. al,

1966 Nov, 25(5):5l6—25;

“Thrombosis of Intracranial Aneurysms - An experimental

Journal of Neurosurgery,

approach utilizing magnetically controlled iron

particles” Alksne, J.F., et. al, Radiology 1966 Feb.

86(2):342—3

Another embodiment of the present invention

provides a method of adhering, joining, connecting or

affixing a first section of tissue to a second section of

tissue. Examples of the types of uses covered by this

method of use include, but are not limited to the

following. The present invention is useful as a method

of adhering, joining, or connecting two blood vessels,

anastimosis, where blood vessels are quickly and

e.g.,

efficiently adhered, under surgical

The

joined or connected,

conditions without the use of sutures or staples.

present invention is useful as a method of treating

primary wounds or wounds that require immediate

intervention, such as, trauma wounds, where the

compositions of the present invention are used to

temporarily close the wound to minimize the lost of

fluids due to evaporation, and to mitigate infection.

Another embodiment of the present invention

provides a method of adhering, joining, connecting, or

affixing tissue to a non—tissue surface, such as a

medical device. Examples of the types of uses covered by

this method of use include, but are not limited to the

following. The present invention is useful as a method

of implanting or securing venous valves, replacement

heart valves, or stents at their desired location.

The aforementioned uses are possible because

the compositions of the present invention remain in a

WO 00/44287

1O

15

20

25

30

PCT/US00/02262

13

controllable state for a period of time in excess of 1

second after being deployed from an administration

device. This property allows the practitioner to

incrementally maneuver the deployment of the composition

to its most ideal location, even when the composition has

been partially deployed distal the the deployment device.

For instance, the compositions of the present

invention have adequate cohesion to maintain its

continuity once it is outside of the deployment device.

Without adequate cohesion the composition would break

into smaller aggregates dispersing into the blood flow.

For instance, the compositions of the present

invention have appropriate adhesion properties so that

when desired a deployed composition adheres to the

immediate location where it is deployed so that the

resultant aggregate of the monomer is placed where it is

desired.

The compositions of the present invention have

such that, the practitioner can

polymerization rate,

effect the desired amount of penetration of the

composition into a particular type of space. A

composition that polymerizes too quickly would hinder

penetration, conversely a composition that polymerizes

too slowly would make it difficult to precisely place the

polymerized composition resultant aggregate of the

monomer .

Another embodiment of the present invention

provides a method for selectively creating an embolic

duct, fistula or

blockage in the lumen of a blood vessel,

other like body passageways.

WO 00/44287

10

15

20

25

30

PCT/US00/02262

14

Another embodiment of the present invention

provides a method of treating arteriovenous malformation

(AVM)

DEFINITIONS

As used herein the terms "adhesion" or

"adhesive" means the characteristic or tendency of a

material to be attracted to the surface of a second

material. Adhesion occurs as the result of interactions

between two materials. Depending on the characteristics

of the second material relative to the first material,

For a single material,

the

adhesion may or may not occur.

e.g., the composition of the present invention,

presence of adhesion is demonstrated by a material

sticking to the wall of a lumen of blood vessel, i.e.,

there is adhesion between the material and the lumen

wall.

demonstrated for the same material where a micro—catheter

Conversely, the absence of adhesion is

tip used to deposit the material can be removed from the

material, i.e., there is little adhesion between the

material and micro—catheter tip.

As used herein the term "alkyl" refers to a

carbon chain of one to sixteen carbon atoms, where the

carbon atoms can be linear or branched.

As used herein the term “anionic environment”

or “an—ionic environment” refers to an environment that

is non—ionic. This an environment that is devoid of

charged ions, or where the charged ions are complexed

with other molecules which effectively neutralize their

For example, a solution of water and a sugar,

and blood,

charge.

is an anionic environment.

such as, dextrose,

WO 00/44287 PCT/US00/02262

15

As used herein the term "lower—alkyl" refers to

a carbon chain of one to eight carbon atoms, where the

carbon atoms can be linear or branched. Examples of

lower-alkyl moieties include but are not limited to

5 methyl, ethyl, n—butyl, isobutyl, pentyl, n—hexyl,

2—hexyl, n-heptyl, 2-heptyl, n—octyl and 2—octyl.

As used herein the term "branched alkyl" refers

to a carbon chain of one to sixteen carbon atoms where

the carbon chain contains at least one secondary or

10 tertiary substituted carbon atom.

As used herein the term "branched lower—alkyl"

refers to a carbon chain of one to eight carbon atoms

where the carbon chain contains at least one secondary or

tertiary substituted carbon atom, for example, 2—hexyl,

15 isobutyl, 2—heptyl and 2—octyl.

As used herein the term "cohesion" or

"cohesive" means the characteristic or tendency of a

material to stick together to itself. For example, this

characteristic is demonstrated by a material or

20 composition remaining intact as a single mass when

introduced into a stationary fluid, or a fluid stream in

motion, such as, blood. Lack of cohesive integrity

results in the composition breaking up into multiple

smaller subunits.

25 As used herein the term "embolic agent" refers

to a non—naturally occurring composition introduced into

a body cavity or the lumen of a blood vessel, duct,

fistula or other like body passageways for the purpose of

forming an embolic block.

WO 00/44287

10

15

20

25

30

PCT/US00/02262

16

As used herein the term "embolic block" or

"embolic blockage" or occlusion refers to the end result

from the administration of a composition useful as an

embolic agent. The resulting embolic block mechanically

blocks, the lumen of a blood

totally or partially,

duct, fistula or other like body passageways; or

in a like manner forms an occlusion within a cavity,

vessel,

such

as an aneurysm .

As used herein the term "alkyl cyanoacrylate

monomer" refers to the chemical entity of the general

structure H2C=C(CN)—C(O)O—R, where R is an alkyl moiety of

one to sixteen carbon atoms, linear or branched,

saturated or unsaturated, having the physical

characteristic of being able to form the corresponding

alkyl cyanoacrylate.

As used herein the term "alkyl cyanoacrylate

polymer" means an oligomer or polymer resulting from the

polymerization of a alkyl cyanoacrylate monomer.

As used herein the term "alkyl esterified fatty

acid" means a fatty acid derivatized to form an ester

functional group with a alkyl moiety, such as ethyl

These compounds are formed with an alkyl

butyl,

and carboxylic acids with alkyl

myristate.

moiety, such as, methyl, ethyl, propyl, pentyl,

hexyl, heptyl, and octyl;

side chains ranging from l carbon, i.e., acetic acid,

through to and including 17 carbons atoms in length, such

as, proprionic, butyric, isobutyric, valeric, isovaleric,

pivalic, lauric, myristic, palmitic and stearic acids.

As used herein the term "opacificant agent" is

compound or composition which selectively absorbs or

deflects radiation making the material visible under

WO 00/44287

10

15

20

25

30

PCT/US00/02262

l7

x—ray, or any like imaging technique. Typically such

agents include, iodinated oils, and brominated oils, as

well as commercially available compositions, such as

Lipiodol and Ethiodol. These commercially

Pantopaque,

available compositions acts as opacificant agents, and

also dilute the amount of liquid monomer thereby slowing

the rate of polymerization. In addition certain metals,

such as, gold, platinum, tantalum, titanium, tungsten and

barium sulfate and the like, have properties enabling

them to act as opacificant agents.

As used herein the term "polymerization" refers

to the chemical process where identical monomer units

react chemically to form larger aggregates of said

monomeric units as oligomers or polymers.

As used herein the term "polymerization

retardant" means an agent that can stop or slow down the

rate of polymerization. Examples of such agents are pure

phosphoric acid, and 85% phosphoric acid. Certain

opacificant agents, such as Pantopaque, Lipiodol and

Ethiodol can also function as a polymerization retardant

by diluting the amount of liquid monomer and hence

slowing polymerization rate.

As used herein the term “a space” refers to an

unfilled volume or cavity in a mass. Examples of such

spaces, include but are not limited by the following, an

existing space within a mass, such as, the lumen of a

blood vessel, the sac of an aneurysm; a space created by

a transiently placed external device, such as, a catheter

such as,

or like device; a space created by a procedure,

an excision or like procedure; a space created by

implantation of an object, such as, a stent or like

device; or a space created by the composition.

WO 00/44287

10

15

20

25

30

PCT/US00/02262

18

As used herein the term "stability" refers to

the ability of a monomer component to resist degradation

or polymerization after preparation but prior to use.

As used herein the term "inhibitor agent"

refers to an agent which stabilizes a monomer composition

by inhibiting polymerization. Within the context of the

current invention, this term refers to agents that

stabilize and inhibit polymerization by various

mechanisms. By altering the amounts of one or more

inhibitor agents, the rate of polymerization can be

controlled. Inhibitor agents have different modes of

activity, for example, hydroquinone acts primarily to

inhibit high energy free radicals; p—methoxyphenol acts

primarily to inhibit low energy free radicals; and

phosphoric acid influences the rate of anionic

polymerization.

As use herein the term “Neuracryl M” refers to

the composition comprising of a monomer component (“Ml”)

comprised of 2—hexyl cyanoacrylate, hydroquinone,

p—methoxyphenol and phosphoric acid, and a second

component (“M2”) comprising of a resultant aggregate

structure formed from 2—hexyl cyanoacrylate monomer,

the term "M1"

and the

ethyl myristate and gold. As noted above,

refers to the monomer component of Neuracryl M,

term "M2" refers to the second component of Neuracryl M.

As used herein the term “deployment device”

refers a device used to deploy compositions, such as,

those of the present invention. Examples of such

devices, include but are not limited to the following.

Irvine, California

the Rebarm Micro

Inc., 2 Goodyear,

Micro Therapeutics,

92618,

Catheter,

markets medical devices, such as,

Equinox” Occlusion Balloon System and

WO 00/44287 PCT/US00/02262

l 9

Silverspeedm guidewires, that are used in conjunction for

treating conditions such as those within the present

invention. The devices disclosed in U.S. Patent No.

5,882,334 “Balloon/delivery Catheter Assembly with

5 Adjustable Balloon Positioning,” incorporated herein by

reference, directed to a catheter assembly for delivering

compositions.

Nomenclature

The compound 2—hexyl cyanoacetate is depicted

10 as follows, and also as Formula 3 in Schemes A and B.

The compound 2—hexyl cyanoacrylate is depicted

as follows, and also as Formula 5 in Scheme B.

O

CH /

zfi/“\O

CN

The present invention is a composition formed

from alkyl cyanoacrylate monomeric units, such as,

15 n-butyl, isobutyl, and 2—hexyl cyanoacrylate with at

least one inhibitor agent, such as hydroquinone,

p—methoxyphenol and phosphoric acid. The composition

forms into its resultant aggregate structure, i.e., an

WO 00/44287

1O

15

20

25

PCT/US00/02262

20

when it comes in contact with an

The

oligomer or polymer,

anionic environment, such as, blood or tissue.

resultant aggregate composition has characteristics which

makes it particularly well suited as an embolic agent.

The composition of the present invention

possess the following properties, which are desirable in

an embolization agent.

1) The composition can be prepared and maintained as a

monomeric component and second component until needed.

2) The composition has the ability to reliably and

predictably change from a liquid state to a solid state,

for its introduction and controlled

duct,

which is essential

placement into the lumen of vessel, fistula or

other like body passageways.

3) The composition has low viscosity, which is essential

for its administration by syringes and micro—catheters or

other like devices.

4) The composition has cohesive characteristics such that

when the composition in administered into an anionic

fluid environment, such as blood, the composition forms a

single aggregate structure.

5) The composition has adhesive characteristic such that

duct,

but not to the degree where

it attaches to the lumen of vessel, fistula or

other like body passageways,

the device depositing the composition will become fixed

to it before the practitioner can remove it.

6) The composition causes mild tissue inflammation,

sufficient to cause scarring, but not so severe to cause

WO 00/44287

l0

15

20

25

30

PCT/US00/02262

21

the formation of pus. Scar formation is necessary to

maintain the functionality of the embolic block after the

composition has biodegraded, or otherwise eliminated from

the lumen.

7) The composition is sufficiently stable to

biodegradation to allow for scarring to occur.

8) The composition is radiopaque. Although not necessary

for its function as an embolic agent, radiopacity allows

the embolic block to be observed with x—ray or other such

imaging techniques.

9) The rate of heat released during polymerization of the

composition is low enough such that the heat does not

adversely effect surrounding tissues that may be heat

sensitive, such as brain tissue.

10) The composition and its biodegradation products are

sufficiently non—histotoxic and non—cytotoxic so that its

presence is well tolerated in the body.

The composition of the present invention is

used by combining the monomer component and second

the invention

duct,

component. Upon mixing of the components,

is administered into the lumen of a blood vessel,

fistula or other like body passageways. The

characteristics of the present invention permit its

accurate placement in the lumen. Contact with an anionic

environment, such as blood, or tissue causes the

composition to polymerize. The size of the resultant

embolic block formed is determined by the amount of

composition administered.

The characteristics of the composition of the

invention can be modified for a specific purpose or

WO 00/44287

10

15

20

25

PCT/US00/02262

22

environment for which the embolic agent is intended to be

utilized. For example, changes in the length and

isomeric configuration of the alkyl side chains can alter

the brittleness of the resultant aggregate of

cyanoacrylate monomers. Alkyl chains that result in the

formation of smaller aggregates tend to be less brittle,

while larger aggregates tend to be less flexible. In

addition, by combining monomers with different alkyl side

chains the characteristics of the resultant polymer can

be modified to what is optimal for a desired application.

Cyanoacrylates generate heat as they change

The amount and rate of

from monomeric to polymeric form.

heat released, if excessive, can have a detrimental

effect on the living tissue proximate to the vessel.

Control of the amount and rate at which heat is release

during polymerization is critical to the utility of

composition.

Preparation of the Monomer Component

The monomer component of the present invention

is prepared by forming the desired precursor ester from

the corresponding alkyl alcohol and cyanoacetic acid

resulting in the desired alkyl cyanoacetate as depicted

in Scheme A. The starting materials for this reaction

are commercially available, for example from Aldrich

Chemical Company, Sigma Chemical Company or Fluka

Chemical Company, or can be prepared following procedures

known to those of ordinary skill in the art.

WO 00/44287 PCT/US00/02262

23

o 0

cN~)J\oH + R-0” ——> CNAO-R

1 2 3

Sdmnelk

The compound of Formula 2 can be any alkyl alcohol, where

R is from one to sixteen carbons, including but not

limited to alcohols based on alkyl groups, such as,

methyl, ethyl, propyl, butyl, pentyl, hexyl, heptyl,

5 heptyl, octyl, nonyl, deca, undeca, dodeca, trideca,

tetradeca, pentadeca and hexadeca, where the preceding

moieties are linear (e.g., n—propyl, n—butyl, n—pentyl)

or variously branched, such as sec—butyl, iso—butyl,

tert-butyl, iso—propyl, 2—butyl, 2—pentyl, 2-hexyl,

10 2—heptyl, 2—octyl and the like. Particularly

advantageous alcohols are those disclosed in U.S. Patent

3,728,375 entitled "Cyanoacrylate Adhesive Compositions",

which is hereby incorporated by reference. Especially

preferred are n—butyl, iso—butyl and 2-hexyl alcohols.

15 About 1 molar equivalents of the compounds of

Formula 1 and Formula 2 are combined in a solvent like

toluene at about 100 ml/molar equivalents. To this

mixture is added a catalytic amount (about 1.0 x 10'4

molar equivalents) of p-toluene sulfonic acid. The

20 mixture is stirred and heated to reflux. The preparation

ideally yields the desired alkyl cyanoacetate at a purity

level of about 95%. The experimental conditions can be

readily modified by one of ordinary skill in the art

without deviating from the present invention. Aspects

WO 00/44287

10

15

20

PCT/US00/02262

24

such as, solvent selection, reaction time,

temperature

and choice of reagents are well within the skill of one

of ordinary skill in the art. If necessary, the material

can be further purified using multiple distillations and

purification techniques and procedures known to those of

such as water extraction,

and the like.

ordinary skill in the art,

vacuum distillation, column chromatography,

Preparation of alkyl cyanoacrylate

The desired alkyl cyanoacrylate monomer

component of the present invention is synthesized from

the alkyl cyanoacetate by reacting the it in a Knoevengel

type reaction as depicted in Scheme B.

O Q 0

+ /u\ ____,

CNAO-R H H CH2 0"‘

CN

3 4 5

SdrnbB

About 1 molar equivalents of formaldehyde (Formula 4),

which is prepared from paraformaldehyde, and piperidine

(at about 0.33 ml/molar equivalents) are combined in a

solvent, such as methanol (at about 166 ml/molar

equivalents). To this mixture is added about 1 molar

equivalents of previously prepared alkyl cyanoacetate

(Formula 3) in a dropwise manner. The reaction mixture

is refluxed with stirring yielding the desired alkyl

The reaction mixture

cyanoacrylate polymer (Formula 5).

is further processed with about 0.2 to 0.7 molar

WO 00/44287

10

15

20

25

30

PCT/US00/02262

25

equivalents, preferably about 0.2 to 0.6 molar

equivalents of phosphorous pentoxide yielding the desired

alkyl cyanoacrylate. Care must be taken during

purification steps to prevent the compound of Formula 5

from polymerizing; To this end the system is treated

with trace amounts of sulfur dioxide, and receiver flasks

are treated with hydroquinone and 85% phosphoric acid.

After initial purification, the desired alkyl

cyanoacrylate is further purified using multiple

distillations, or other purification techniques known to

such as,

and the like.

those of ordinary skill in the art, vacuum

distillation, spinning band column,

Formulation

The monomer component of the present invention

comprises of at least one alkyl cyanoacrylate and at

least one inhibitor agent. Typical inhibitors

appropriate for cyanoacrylates are, for example,

hydroquinone, p—methoxyphenol, pure phosphoric acid, and

alkyl carboxylic acids, where the alkyl moiety ranges

from 1 carbon, e.g., acetic acid, through to 15 and 17

carbons atoms in length, palmitic and stearic

i.e.,

acids, respectively; and phosphoric acid at varying

percentage solutions. Preferably hydroquinone,

p—methoxyphenol, and phosphoric acid are used,

individually or in combination.

Different inhibitors have different physical

characteristics and thereby functions to alter the final

hydroquinone

properties of the composition. For example,

is primarily an inhibitor for high energy free radicals;

p—methoxyphenol is primarily an inhibitor for low energy

WO 00/44287

10

15

20

25

30

PCT/US00/02262

26

free radicals; and phosphoric acid acts to control or

inhibit anionic polymerization and the rate of such

polymerization.

The quantity of inhibitors used is measured in

terms of parts per million of alkyl cyanoacrylate. For

for 2—hexyl cyanoacrylate, hydroquinone is in

(PPM),

example,

the range of about 50 to 150 parts per million

p-methoxyphenol in the range of about 50 to 150 PPM, and

phosphoric acid in the range of about 125 to 375 PPM,

more preferred is hydroquinone in the range of about 75

to 125 PPM, p-methoxyphenol in the range of about 75 to

125 PPM,

to 312.5 PPM,

and phosphoric acid in the range of about 187.5

and most preferred is hydroquinone in the

range of about 95 to 105 PPM, p-methoxyphenol in the

range of about 95 to 105 PPM,

range of about 200 to 300 PPM.

and phosphoric acid in the

The second component functions as an

opacificant agent and a polymerization retardant.‘ To

this end, the second component can be an iodinated oil,

such as Ethiodol, or a brominated oil. Typically the

iodinated oil is mixed as some percent of the total

volume of the final composition. The percentage solution

of iodinated oil used will influence the polymerization

rate and opacity of the composition. Generally

advantageous ranges are from about 17% to 66%, preferably

about 33%.

Alternatively, the second component can be a

composition comprising, a opacificant material, such as

gold, platinum, tantalum, titanium, tungsten and barium

sulfate and the like; an alkyl cyanoacrylate polymer

where the.

material, and an alkyl esterified fatty acid,

for example, alkyl butyrate to 17

fatty acids have 3,

wo 00/44237 PCT/US00/02262

27

carbons, for example, alkyl stearate, preferred are,

alkyl laurate, alkyl myristate, alkyl palmatate, and

alkyl stearate, most preferred is alkyl myristate, and

most especially prefereed is ethyl myristate.

5 The opacificant material is used in a fine

powder form, typically, with individual particles sized

no larger than about 7 microns in diameter, preferably

about 5 microns, most preferred about 2 microns and most

especially preferred is 1 micron or smaller.

10 The amount of opacificant material used

relative to alkyl cyanoacrylate polymer will vary

according to the specific materials. Factors that

influence the determination of the ratio include the

amount and size of the particles that are being coated by

15 the alkyl cyanoacrylate polymer. For example, for

2—hexyl cyanoacrylate and gold, 2 g of 2—hexyl

cyanoacrylate is used per 100 g of powdered gold

(particle size of about 5 i 2 microns) being coated. The

amounts vary accordingly with the opacificant material

20 being coated by the alkyl cyanoacrylate. The alkyl

cyanoacrylate and opacificant material are mechanically

mixed by processing the alkyl cyanoacrylate into small

particulate masses, and mixing with the finely powdered

opacificant material. The alkyl cyanoacrylate polymer

25 coated material is then stored in an esterified fatty

acid, which serves as a medium where the alkyl

cyanoacrylate polymer coated material is maintained prior

to use, and as a medium, which when contacted with the

monomer component will not interfere with the

30 polymerization of the composition. The unsealed storage

containers, preferably appropriately sterilized bottles

and caps or the like, with the cyanoacrylate polymer

suspension is then treated with ethylene oxide, or

WO 00/44287 PCT/US00/02262

2 8

alternatively ketene. This treatment should occur no

later than about 48 hours after completion of the coating

process, preferably within 24 hours. The treatment

process provides sterilization and stabilization of the

5 alkyl cyanoacrylate polymer coated material and follows

standard procedures for ethylene oxide use, i.e.,

positioning the containers so that they are amply exposed

to the gas for a sufficient period of time.

Polymer M

10 The characteristics of the composition of the

invention can be modified for a specific application or

environment in which the composition is intended to be

utilized. For example, changes in the length and

isomeric configuration of the alkyl side chains can alter

15 the brittleness of a polymer formed from a cyanoacrylate

monomer. Alkyl chains that result in the formation of

smaller aggregates tend to be less brittle, while larger

aggregates tend to be less flexible. Another method of

modifying the characteristics of a polymer is to use a

20 composition comprising of two or more types of alkyl

cyanoacrylate monomers in combination with the

appropriate inhibitors.

For example, a composition comprised of a

monomer component comprising of 2—hexyl cyanoacrylate,

25 hydroquinone, p—methoxyphenol and phosphoric acid; and a

second component comprising of 2—hexyl cyanoacrylate

polymer, gold, and ethyl myristate results in Polymer M.

A qualitative survey of Polymer M is shown in

Table A. The physical characteristics disclosed are

30 readily recognized by those of ordinary skill in the art

WO 00/44287 PCT/US00/02262

2 9

as being relevant to the applications for which the

polymers are used.

Table A

Characteristics Polymer M

5

polymerization profile polymerizes to semi—solid

to soft—solid on contact

with tissue or blood

10

Polymer M has excellent cohesion properties.

15 When introduced into a stationary fluid, or a fluid

stream in motion, such as, the lumen of a blood vessel or

other like passageway, the composition tend to stick

together to itself remaining intact as a single mass or

aggregate. This permits the composition to be discretely

20 deployed or placed at the desired location without the

hazard of having potions of the composition breaking away

and depositing at undesired locales. Polymer M has

viscosity properties that permit the injection of the

liquid composition into a lumen of a blood vessel, duct,

25 fistula or passageway in the body without using excessive

pressure.

With these properties Polymer M is ideally

suited for applications where the composition must

penetrate further into anionic environment before

WO 00144287

10

15

20

25

30

PCT/US00/02262

30

arriving at the point of final placement. A preferred

use is the treatment of arteriovenous malformations, also

“AVM”. Polymer M is also ideally suited for the

known as

treatment of longer type urinary fistulas, this is

because preferred treatment requires greater penetration

into cavity space by the liquid composition. Additional

applications suited for Polymer M are creating a tubal

occlusion, For example, a

and surgical adhesions.

composition of the present invention is applied to raw

intraperitoneal tissue to prevent the tissue from

adhering to itself or other tissue.

Administration

The composition of the present invention are

administered with any type of commercially available

needle, catheter devices, or stereotaxic placement

devices, preferably in conjunction with imaging

technology that provides the practitioner with guidance

as to the placement of the composition. Such devices and

methods are readily known to those of ordinary skill in

art. For example in U.S. Patent 5,925,683 “Liquid

Embolic Agents”, herein incorporated by reference, there

is disclosed a method for introducing liquid embolic

agents/solutions into the human body to form precipitated

embolic occlusion masses, and also how this method is

used for treating hepatic tumors using portal vein

embolism. In U.S. Patent 5,702,361 “Method for

Embolizing Blood Vessels”, herein incorporated by

reference, there is disclosed a method of embolizing a

vascular site in a patient’s blood vessel comprising of

introducing, via a catheter, at the vascular site to be

emobolized a non—particulate agent or a plurality of such

via a catheter, to said vascular

agents, and delivering,

site a polymer composition comprising a biocompatible

WO 00/44287

10

15

20

25

PCT/US00/02262

3 1

polymer, a biocompatible solvent and contrast agent,

wherein the delivery is conducted under conditions where

the polymer precipitate forms in situ at the vascular

site resulting in the embolizing of the blood vessel and

where the non—particulate agent is encapsulated within

the precipitate. Additional devices applicable to the

present invention are those disclosed in U.S. Patent No.

5,882,334 “Balloon/delivery Catheter Assembly with

Adjustable Balloon Positioning,” incorporated herein by

reference, directed to a catheter assembly for delivering

Further, Inc.,

Irvine, California 92618,

the Rebarm Micro Catheter,

compositions. Micro Therapeutics,

2 Goodyear, markets medical

devices, such as, Equinox“

Occlusion Balloon System and Silverspeedm guidewires,

that are approved by the U.S. Food and Drug

Administration for use in treating conditions such as

those within the present invention.

The compositions of the present invention can

be used advantageously in conjunction with any

embolization method that employs an embolizing agent,

occluding agent, or such composition that creates an

embolic block, or occlusion.

The compositions of the present are used to

particular advantage in conjunction with commercially

available stereotaxic devices which facilitate the

for

precise deposition of the composition, such as,

forming an occlusion within a cavity that is to be

filled,

that is the source of blood supply for a tumor.

or for forming an occlusion in a blood vessel

WO 00/44287

10

15

20

25

30

PCT/US00/02262

32

Utility

The present invention is useful for filling,

occluding, partially filling or partially occluding an

unfilled volume or space in a mass (“a space”). In

particular, the composition is useful for filling an

existing space, e.g., the lumen of a blood vessel, or the

sac of an aneurysm, a space created by a transiently

placed external device,'e.g., a catheter or like device,

a space created by a procedure, an excision or like

e.g.,

procedure or implantation of an object, a stent or

e.g.,

or a space created by the composition; the

like device,

composition is also useful for adhering tissue to tissue,

or adhering tissue to a device. The composition has the

property of polymerizing when it comes in contact with an

anionic environment, or when it is deployed in situ in an

existing space, e.g., the lumen of a blood vessel, or the

sac of an aneurysm, a space created by a transiently

placed external device, a catheter or like device,

e.g.,

a space created by a procedure, an excision or like

e.g.,

procedure or implantation of an object, a stent or

e.g.,

like device, or a space created by the composition.

The present invention is useful as an embolic

agent that selectively creates an embolic blockage in the

duct, fistula or other like body

lumen of a blood vessel,

passageways.

The present invention can be prepared and

maintained as a monomeric component and second component

until needed. It has the ability to reliably and

predictably change from a liquid state to a solid state,

which is essential for its introduction and controlled

duct, fistula or

placement into the lumen of vessel,

other like body passageways. The composition has low

WO 00/44287

10

15

20

25

PCT/US00/02262

3 3

viscosity, which is essential for its administration by

syringes and micro—catheters or other like devices.

The cohesive characteristics of the invention

are such that when the composition in administered into

an anionic fluid environment, such as blood, the

composition forms a single aggregate structure.

Additionally, the adhesive characteristics are such that

the composition attaches to the lumen of vessel, duct,

fistula or other like body passageways, but not to the

degree where the device depositing the composition will

become fixed to it before the practitioner can remove it.

The present invention causes mild tissue

inflammation, sufficient to cause scarring, but not so

severe to cause the formation of pus. Scar formation is

desirable as the scar tissue is necessary to maintain the

functionality of the embolic block after the composition

has biodegraded, or otherwise eliminated from the lumen.

The composition is sufficiently stable to biodegradation

to allow for scarring to occur.

The present invention is radiopaque. Although

this characteristic is not necessary for its function as

an embolic agent, radiopacity allows the embolic block to

be observed with x—ray or other such imaging techniques.

The rate of heat released during polymerization

of the present invention is low enough such that the heat

does not adversely effect surrounding tissues that may be

heat sensitive, such as brain tissue.

WO 00/44287

10

15

20

25

30

PCT/US00/02262

34

The present invention and its biodegradation

products are sufficiently non—histotoxic and non-

cytotoxic so that its presence is well tolerated in the

body.

The composition of the present invention is

useful for filling, occluding, partially filling or

partially occluding an unfilled volume or space in a mass

(“a space”).

The present invention provides a method for

filling, occluding, partially filling or partially

occluding an unfilled volume or space in a mass. The

types of unfilled volumes or spaces within the scope of

the present invention includes, but are not limited to

the following instances.

For example, the present invention is used as a

method of filling, occluding, partially filling or

partially occluding an existing space, such as, a lumen

of a passageway in the body, a blood vessel, a

duct,

e.g.,

or a fistula. Examples of the types

an aneurysm,

treatments covered by this method of use, include but are

not limited to the following. The present invention is

useful as a method of treating arteriovenous

(AVM)

the AVM are occluded thereby cutting off the blood supply

to the AVM.

to ablate diseased or undesired tissue by cutting off the

malformations where the blood vessel(s) that feed

The present invention is useful as a method

In particular, the present

tissue’s blood supply.

invention is useful as a method of treating a tumor

having a discrete blood supply, where the blood vessel(s)

that feed the tumor are occluded thereby cutting off the

blood supply to the tumor resulting in diminished growth

or death of the tumor. The present invention is useful

WO 00/44287

10

15

20

25

30

PCT/US00/02262

35

as a method of preventing or mitigating the development

of an aneurysm by creating a partial occlusion at a

location in the blood vessel selected to modify the fluid

dynamics within the vessel to mitigate the formation or

development of an aneurysm. The present invention is

useful as a non-surgical method of treating symptomatic

uterine leiomyomas by embolizing/occluding the uterine

artery. This method has been reported using a non alkyl

cyanoacrylate composition in the Journal of Vascular and

Interventional Radiology, 10:89l—894, July-August 1999.

The present invention is useful as a method of

sterilizing a female mammal by occluding the fallopian

tubes thereby preventing the passage of the eggs from the

The use of an occluding agent to

Patent No.

ovaries to the uterus.

sterilize a female mammal is disclosed in U.S.

5,989,580 “Method of Sterilizing Female Mammals,” herein

incorporated by reference. The methods disclosed in this

patent can be advantageously applied using the

compositions of the present invention, and are within the

scope of the present invention.

The present invention is an embolic agent that

provides a method for selectively creating and placing an

embolic blockage which mechanically blocks, totally or

duct, fistula or

partially, the lumen of a blood vessel,

other body passageway. In particular, the current

invention is particularly useful in blocking, totally or

partially, or diverting the flow of blood through the

lumen.

The present invention can be advantageously

used to block blood flow to certain tissues or areas.

the present invention can be used to treat

(AVM).

For example,

arteriovenous malformation An AVM is a collection

of abnormal blood vessels which are neither arteries or

WO 00/44287

10

15

20

25

30

PCT/US00/02262

36

These vessels are packed closely together to form

Blood flow into the AVM nidus is

veins.

the nidus of the AVM.

through thinned, enlarged, tortuous vessels and is

rapidly shunted into draining veins because the nidus

contains no arterioles or capillaries to provide high

resistance. Clinical symptoms experienced because of

AVMs are bleeding, re—direction of blood from nearby

or seizures.

normal structures, The primary clinical

problem associated with cerebral AVM is the potential for

lethal hemorrhage. The current standard of care for

treating AVMS is surgical removal, high energy radiation

or embolization with particular devices.

Further, the present invention can be used for

treating cancer by diverting or blocking blood flow to

tumors, the present invention is particularly useful for

treating tumors in areas that are not easily accessible

brain tumors.

for surgical intervention, for example,

Other advantageous uses of the present

invention are for aortopulmonary closure; treatment of

artery pseudoaneursym; hepatic artery vascular occlusion

and for temporary vascular occlusion during co-

treatment of other

administration of cytotoxic drugs;

types of vessels, for example, the composition can be

used for creating tubal occlusions, fallopian tube

occlusions, vas deferens occlusions, and urinary

occlusions.

The present invention provides a method of

filling, occluding, partially filling or partially

occluding a space created by a transiently placed

external device, such as, a catheter balloon. Examples

of the types of treatments covered by this method of use

include, but are not limited to the following. The

WO 00/44287

10

15

20

25

30

PCT/US00/02262

37

present invention is useful as a method of treating an

aneurysm by filling the space within the aneurysm with a

composition of the present invention, where the

composition polymerizes in the space within the aneurysm,

thereby preventing the rupture of the aneurysm. This

treatment can be effected using the present invention

with any number of catheters, catheter coils, catheter

wires or catheter balloons commercially available.

Examples of such devices are commercially available from

For instance, Micro Therapeutics, Inc., 2

California 92618,

the Rebar“ Micro Catheter,

sources .

Goodyear, Irvine, markets a line of

medical devices, such as,

Equinox“ Occlusion Balloon System and Silverspeedm

guidewires. U.S. Patent No. 5,882,334

“Balloon/delivery Catheter Assembly with Adjustable

Similarly,

Balloon Positioning,” assigned to Target Therapeutics,

Inc., and incorporated herein by reference, is directed

to a catheter assembly for delivering compositions, such

as, those of the present invention.

The present invention also provides a method of

filling, occluding, partially filling or partially

occluding a space created or resulting from a procedure,

such as with the excision of tissue, or insufflation.

Examples of the types of treatments covered by this

method of use include, but are not limited to the

following. The present invention is useful as a method

of treating oozing capillaries following an excision

procedure.

The present invention further provides a method

of filling, occluding, partially filling or partially

occluding a space created by the placement or

a medical device.

implantation of an object, such as,

Examples of the types of uses covered by this method of

WO 00/44287

10

15

20

25

30

PCT/US00/02262

38

use include, but are not limited to the following. The

present invention is useful as a method of restoring the

normal fluid dynamics at the peripheral edges of a

vascular stent by filling the dead spaces between the

stent and the lumen wall created by the implantation of

the stent.

Still another advantageous use is the

controlling and smoothing the blood flow around stents.

A major complication from the balloon angioplasty and the

use of stents is disruption of the smooth flow of blood

past and around the stent which can lead to the formation

of blood clots and their associated complications. The

composition of the present invention can be used to

modify and make regular the slip streams of blood through

and adjacent to the stent to mitigate or alleviate the

cause of the turbulence, and such turbulence causing

states.

The present invention further provides a method

of filling, occluding, partially filling or partially

occluding a space created by the composition itself, such

as, where the composition is used as a bulking agent.

Examples of the types of uses covered by this method of

For

use include, but are not limited to the following.

example, a method of recreating normal external contours,

such as following physical trauma.

Administration

The monomer component and second component of

the present invention are combined just prior to use.

The composition of the present invention is administered

using any type of deployment device. The term

“deployment device” refers to a device used to deploy

WO 00/44287

10

15

20

25

30

35

PCT/US00/02262

39

fluids or compositions similar to those of the present

catheter devices, catheter

or the like.

invention, such as, a needle,

balloon, stereotaxic placement devices,

Methods for using these devices are readily known to one

of ordinary skill in the art, and such devices are

commercially available. Such devices and methods are

of ordinary skill in art. For

5,925,683 “Liquid Embolic Agents”,

readily known to those

example in U.S. Patent

herein incorporated by reference, there is disclosed a

method for introducing liquid embolic agents/solutions

into the human body to form precipitated embolic

occlusion masses, and also how this method is used for

treating hepatic tumors using portal vein embolism. In

U.S. Patent 5,702,361 “Method for Embolizing Blood

Vessels”, herein incorporated by reference, there is

disclosed a method of embolizing a vascular site in a

patient’s blood vessel comprising of introducing, via a

catheter, at the vascular site to be emobolized a non-

particulate agent or a plurality of such agents, and

delivering, via a catheter, to said vascular site a

polymer composition comprising a biocompatible polymer, a

biocompatible solvent and contrast agent, wherein the

delivery is conducted under conditions where the polymer

precipitate forms in situ at the vascular site resulting

in the embolizing of the blood vessel and where the non~

particulate agent is encapsulated within the precipitate.

Additional devices applicable to the present invention

5,882,334

“Balloon/delivery Catheter Assembly with Adjustable

are those disclosed in U.S. Patent No.

Balloon Positioning,” incorporated herein by reference,

directed to a catheter assembly for delivering

Further, Micro Therapeutics, Inc.,

Irvine, California 92618,

the Rebarm Micro Catheter,

compositions.

2 Goodyear, markets medical

devices, such as, Equinox“

Occlusion Balloon System and Silverspeedm guidewires,

WO 00/44287

10

15

20

25

PCT/US00/02262

40

that are approved by the U.S. Food and Drug

Administration for use in treating conditions such as

those within the present invention.

The composition of the present invention are

administered with any type of commercially available

catheter devices, or stereotaxic placement

needle,

devices, preferably in conjunction with imaging

technology that provides the practitioner with guidance

as to the placement of the composition. The compositions

of the present invention can be used advantageously in

conjunction with any embolization method that employs an

or such composition

embolizing agent, occluding agent,

that creates an embolic block, or occlusion, or otherwise

in effect is used for filling, occluding, partially

filling or partially occluding an unfilled volume or

space in a mass (“a space").

EXAMPLES

The following examples are given to enable

those of ordinary skill in the art to more clearly

understand and to practice the present invention. The

examples should not be considered as limiting the scope

of the invention, but merely as illustrative and

representative thereof.

EXAMPLE 1

PREPARATION OF 2-HEXYL CYANOACETATE

A 5 liter, 24/40 ground glass jointed flask was

configured with a reflux condenser, Dean—Stark trap, and

The reaction vessel was

(Aldrich

football magnetic stirring bar.

charged with the 1,275.0 g of cyanoacetic acid

WO 00144287

10

15

20

25

30

PCT/US00/02262

41

1,581.5 g of 2-hexanol (Aldrich Chemical

and 3.0 g of p-toluenesulfonic acid (Aldrich

and 1,500 of toluene (Aldrich Chemical

Chemical Co.),

Co.)

Chemical Co.),

Co.). The reaction mixture was stirred and heated to

Water was formed as a byproduct of the reaction

The

reflux.

and was collected during the course of the reaction.

reaction was continued until there was a period of over

30 minutes where no water was produced. The amount of

water collected was 230 ml and indicated that the

reaction had completed with a 85.2% theoretical yield.

The reaction mixture was allowed to cool to room

temperature.

The reaction mixture was stirred and 500 ml of

a saturated baking soda (sodium bicarbonate) solution was

The reaction mixture was

The

gradually added to the mixture.

stirred vigorously until the frothing stopped.