�����������United States Patent [191

Forage et al.

[54] BEVERAGE PACKAGE AND A METHOD OF

PACKAGING A BEVERAGE CONTAINING

GAS IN SOLUTION

[75] Inventors: Alan J. Forage, Seer Green, Great

Britain; William J. Byrne, Mount

Merrion, Ireland

[73] Assignee: Arthur Guinness Son & Company

Limited, Dublin, Ireland

[21] Appl. No.: 916,656

[22] Filed: Oct. 3, 1986

[30] Foreign Application Priority Data

Nov. 29, 1985 [GB] United Kingdom ............... .. 8529441

[51] Int. Cl.4 ............................................ .. B65D 85/72

[52] U.S. Cl. ................................. 426/112; 426/115;

426/124; 426/131; 426/394; 426/ 398; 426/407;

53/79; 53/127

[58] Field of Search ............. .. 426/112, 115, 124, 131,

426/316, 474, 477, 394, 398; 53/79, 127

[56] References Cited

U.S. PATENT DOCUMENTS

3,085,714 4/1963 Lighter .

3,513,886 5/1970 Easter et al. ...................... .. 426/115

4,147,808’ 4/1979 Liepa et al. . . . . . . . .. 426/477

4,186,215 1/1980 Buchel ............. .. . 426/477 X

4,399,158 8/1983 Bardsley et al. 426/124 X

4,518,082 5/1985 Ye ........................ .. . 426/124 X

4,693,902 9/1987 Richmond et al. . .............. .. 426/521

[11] Patent Number:

[45] Date of Patent:

4,832,968

May 23, 1989

FOREIGN PATENT DOCUMENTS

1266351 3/1972 United Kingdom .

1588624 4/1981 United Kingdom.

Primary Examiner—Barry S. Richman

Assistant Examiner-—Timothy M. McMahon

[57] ABSTRACI‘

A beverage package and a method of packaging a bev-

erage having gas (preferably at least one of carbon

dioxide and inert (nitrogen gases) in solution has a non-

resealable container 1 within which is located a hollow

pod 4 having a restricted aperture 7 in a side wall. The

container is charged with the beverage 8 and sealed.

Beverage from the main chamber of the container en-

ters the pod 4 (shown at 8a) by way of the aperture 7 to

provide headspaces la in the container and 4a in the

pod 4. Gas within the headspaces la and 4a is at greater

than atmospheric pressure. Preferably the beverage is

drawn into the hollow pod by subjecting the package to

a heating and cooling cycle. Upon opening the con-

tainer 1 by draw ring/region 13, the headspace la is

vented to atmosphere and the pressure differential re-

sulting from the pressure in the pod headspace 4a causes

gas/beverage to be ejected from the pod (by way of the

aperture 7) into the beverage 8. Said ejection causes gas

to be evolved from solution in the beverage in the main

container chamber to form a head of froth on the bever-

age. The pod 4 is preferably formed by blow moulding

and located as a press fit within the container 1 which

latter is preferably a can, carton or bottle.

35 Claims, 2 Drawing Sheets

U.S. Patent May 23,1989 Sheet 1 of2 4,832,968

U.S. Patent May 23,1989 Sheet 2 of 2 4,832,968

4,832,968

1

BEVERAGE PACKAGE AND A METHOD OF

PACKAGING A BEVERAGE CONTAINING GAS IN

SOLUTION

TECHNICAL FIELD AND BACKGROUND ART

This invention relates to a beverage package and a

method of packaging a beverage containing gas in solu-

tion. The invention more particularly concerns bever-

ages containing gas in solution and packaged in a sealed,

non-resealable, container which, when opened for dis-

pensing or consumption, permits gas to be evolved or

liberated from the beverage to form, or assist in the

formation of, a head or froth on the beverage. The

beverages to which the invention relates may be alco-

holic or non-alcoholic; primarily the invention was

developed for fermented beverages such as beer, stout,

ale, lager and cider but may be applied with advantage

to so-called soft drinks and beverages (for example fruit

juices, squashes, colas, lemonades, milk and milk based

drinks and similar type drinks) and to alcoholic drinks

(for example spirits, liqueurs, wine or wine based drinks

and similar).

It is recognised in the beverage dispensing and pack-

aging art that the characteristics of the head of froth

which is provided on the beverage by the liberation of

gas from the beverage immediately prior to consump-

tion are an important consideration to the consumers

enjoyment of the product and are therefore of commer-

cial importance. Conventionally beverages of the type

discussed above containing gas in solution and pack-

aged in a non-resealable container (such as a can, bottle

or carton) provide a headspace in the container within

which gas is maintained under pressure. Upon opening

of the package, the headspace gas is vented to atmo-

sphere and the beverage is usually poured into a drink-

ing vessel. During such dispensing of the beverage it is

usual for gas in solution to be liberated to create the

froth or head. It is generally recognised that when dis-

pensing a beverage as aforementioned, the gas is liber-

ated as a result of the movement of the beverage over a

surface having so-called gas nucleation or active sites

which may be the wall of the drinking vessel into which

the beverage is poured. There is therefore a distinct

possibility with conventional beverage packages that

upon opening of the container after storage and until the

beverage is poured therefrom, the beverage will have

little or no froth or head—such a headless beverage is

usually regarded by the consumer as somewhat unat-

tractive and unappealing especially where the beverage

is to be drunk directly from the container. Admittedly it

may be possible to develop a head or froth within the

container by agitating or shaking the package (so that

the movement of the beverage over the interior surface

of the container causes the liberation of the gas in solu-

tion) but this is clearly inconvenient once the container

is opened and is inadvisable if the package is shaken

immediately prior to opening as the contents tend to

spray or spurt on opening.

There is therefore a need for a beverage package and

a method of packaging a beverage containing gas in

solution by which the beverage is packaged in a non-

resealable container so that when the container is

opened gas is liberated from the beverage to form or

assist in the formation of a head or froth without the

necessity of an external influence being applied to the

package; it is an object of the present invention to sat-

10

15

20

25

30

35

45

50

55

65

2

isfy this need in a simple, economic and commercially

viable manner.

STATEMENTS OF INVENTION AND

ADVANTAGES

According to the present invention there is provided

a beverage package comprising a sealed, non-resealable,

container having a primary chamber containing bever-

age having gas in solution therewith and forming a

primary headspace comprising gas at a pressure greater

than atmospheric; a secondary chamber having a vol-

ume less than said primary chamber and which commu-

nicates with the beverage in said primary chamber

through a restricted orifice, said secondary chamber

containing beverage derived from the primary chamber

and having a secondary headspace therein comprising

gas at a pressure greater than atmospheric so that the

pressures within the primary and secondary chambers

are substantially at equilibrium, and wherein said pack-

age is openable, to open the primary headspace to atmo-

spheric pressure and the secondary chamber is arranged

so that on said opening the pressure differential caused

by the decrease in pressure at the primary headspace

causes at least one of the beverage and gas in the sec-

ondary chamber to be ejected by way of the restricted

orifice into the beverage of the primary chamber and

said ejection causes gas in the solution to be evolved

and form, or assist in the formation of, a head of froth on

the beverage.

Further according to the present invention there is

provided a method of packaging a beverage having gas

in solution therewith which comprises providing a con-

tainer with a primary chamber and a secondary cham-

ber of which the volume of the secondary chamber is

less than that of the primary chamber and with a re-

stricted orifice through which the secondary chamber

communicates with the primary chamber, and charging

and sealing the primary chamber with the beverage to

contain the gas in solution and to form a primary head-

space in the primary chamber, and charging the second-

ary chamber with beverage derived from the primary

chamber by way of said restricted orifice to form a

secondary headspace in the secondary chamber

whereby the pressures in both the primary and second-

ary chambers are at equilibrium and gaseous pressures

in both the primary and secondary headspaces are at a

pressure greater than atmospheric so that, when the

container is broached to open the primary headspace to

atmospheric pressure, the pressure differential caused

by the decrease in pressure at the primary headspace

causes at least one of the beverage and gas in the sec-

ondary chamber to be ejected into the beverage of the

primary chamber by way of said restricted orifice and

the said ejection causes gas to be evolved from solution

in the beverage in the primary chamber to form, or

assist in the formation of, a head of froth on the bever-

age.

The present invention is applicable to a wide range of

beverages of the type as previously discussed and where

those beverages contain gas in solution which gas is

intended to be liberated to form or assist in the forma-

tion of the head or froth on the beverage. Understand-

ably the gas in solution must not detract from, and

should preferably enhance the characteristics required

of the beverage and be acceptable for use with food

products; preferably therefore the gas is at least one of

carbon dioxide and inert gases (by which latter term is

4,832,968

3

included nitrogen) although it is to be realised that other

gases may be appropriate.

The present invention was primarily developed for

the packaging of fermented beverages such as beer, ale,

stout, lager and cider where among the desirable quali-

ties sought in a head are a consistent and regular, rela-

tively fine, bubble size; a bubble structure which is

substantially homogeneous so that the head is not

formed with large irregularly shaped and random gaps;

the ability for the head or bubble structure to endure

during a reasonable period over which it is likely to be

consumed, and a so-called “mouth-feel” and flavour

which may improve the enjoyment of the beverage

during consumption and not detract from the desirable

flavour characteristics required of the beverage. These

desirable qualities are of course equally applicable to

non-fermented beverages, for example with so-called

soft drinks. Conventionally, beverages of the type to

which the invention relates are packaged in a non-

resealable container which when opened totally vents

the headspace to atmosphere, contain carbon dioxide in

solution and it is the liberation of the carbon dioxide on

opening of the package and dispensing of the beverage

into a drinking vessel which creates the froth or head;

however, the head so formed has very few of the afore-

mentioned desirable qualities—in particular it is usually

irregular, lacks homogeneity and has very little endur-

ance so that there is a tendency for it to collapse after a

short period. It has been known for approximately 25

years and as discussed in our G.B. Pat. No. 876,628, that

beverages having in solution a mixture of carbon diox-

ide gas and inert gas (such as nitrogen or argon) will,

when dispensed in a manner whereby the mixed gases

are caused to evolve to develop the head or foam from

small bubbles containing the mixture of carbon dioxide

and, say, nitrogen gases, provide the desirable qualities

for the head as previously discussed. Commercially the

formation of the head by the use of mixed gases as afore-

mentioned has been widely employed in the dispensing

of beverage in a draught system and on demand from a

bulk container (such as a keg or barrel) where the gases

are caused to evolve by subjecting the beverage to

intense shear forces in passing it under pressure through

a set of small holes. Beverages, particularly stout, hav-

ing a mixture of carbon dioxide and nitrogen gases in

solution and dispensed in draught using the aforemen-

tioned technique have met with considerable commer-

cial success and it was soon realised that there was a

10

15

20

25

30

35

45

need to make available for consumption a similar bever- ’

age derived from a small non-resealable container suit-

able for shelf storage and retail purposes.

Research has indicated that to achieve the initiation

of a head on a beverage containing carbon dioxide and

inert gas such as nitrogen in solution it is necessary to

provide so-called “active sites” which are regions

where the beverage is subjected to a high local strain

(such a strain being higher than the cohesive force of

the beverage). In these conditions the beverage prefers

to generate a bubble of mixed gases instead of “bending

around” the active site. It was found that an active site

could be solid, liquid or gas such as granules, restrictor

holes, rapid streams of liquid or bubbles and the like. It

was also found that ultrasonics could produce a “ghost”

active site by the formation of extreme pressure gradi-

ents. There has however been a problem in providing an

“active site” in a beverage packaged in a non-resealable

small container in a manner which is commercially and

economically acceptable. During the past 25 years con-

50

55

60

65

4

siderable expenditure has been devoted to research and

development in an attempt to overcome the aforemen-

tioned problem. For example, our G.B. Pat. No.

1,588,624 proposes initiating the evolution of mixed

carbon dioxide and nitrogen gases from a beverage by

subjecting the beverage to ultrasonic excitement, by

injecting a gas, liquid and/ or foam into the beverage by

use of a syringe-type device, or by pouring the beverage

over an excitation surface such as polystyrene granules.

Although these latter proposals were successful in

achieving the desired head formation, the necessity to

use ancilliary apparatus had commercial disadvantages

(for example, it is unreasonable to expect a retail cus-

tomer to have available an ultrasonic signal generator;

also the steps required to effect initiation of the head

following opening of the beverage package involved an

inconvenient discipline and time factor). In a further

example our G.B. Pat. No. 1,266,351 relates to a non-

resealable package containing beverage having mixed

carbon dioxide and inert gases in solution; in this disclo-

sure a can or bottle has two chambers of which a larger

chamber contains the beverage while the smaller cham-

ber is charged under pressure with the mixed gases. On

opening of the can or bottle to expose the larger cham-

ber to atmosphere, its intemal pressure falls to atmo-

spheric permitting the pressurised gas in the small

chamber to jet into the beverage by way of a small

orifice between the two chambers. This jet of gas pro-

vides sufficient energy to initiate the formation of min-

ute bubbles and thereby the head from the evolution of

the mixed gases in the beverage coming out of solution.

By this proposal the small gas chamber is initially press-

urised with the mixed gases to a pressure greater than

atmospheric and from a source remote from the bever-

age; as a consequence it was found necessary, particu-

larly in the case of cans, to provide a special design of

two chambered container and an appropriate means for

sealing the smaller chamber following the charging of

that chamber with the mixed gases (such charging usu-

ally being effected, in the case of cans, by injecting the

mixed gases into the small chamber through a wall of

the can which then had to be sealed). Because of the

inconvenience and high costs involved in the develop-

ment of an appropriate two chambered container and

the special facilities required for charging the mixed

gases and sealing the container, the proposal proved

commercially unacceptable.

The container employed in the present invention will

usually be in the form of a can, bottle or carton capable

-of withstanding the internal pressures of the primary

and secondary chambers and of a size suitable for con-

ventional shelf storage by the retail trade so that, the

overall volume of the container may be, typically, 0.5

liters but is unlikely to be greater than 3 liters.

By the present invention a two chambered container

is employed as broadly proposed in G.B. Pat. No.

1,266,351; however, unlike the prior proposal the sec-

ondary chamber is partly filled with beverage contain-

ing gases in solution and the beverage in the secondary

chamber is derived wholly from the beverage in the

primary chamber so that when the contents of the pri-

mary and secondary chambers are in equilibrium (and

the primary and secondary headspaces are at a pressure

greater than atmospheric) immediately prior to broach-

ing the container to open the primary headspace to

atmosphere, the pressure differential between that in the

secondary headspace and atmospheric pressure causes

beverage in the secondary chamber to be ejected by

4,832,968

5

way of the restricted orifice into the beverage in the

primary chamber to promote the formation of the head

of froth without the necessity of any extemal influence

being applied to the package. The pressurisation of the

headspace gas in the secondary chamber is intended to

result from the evolution of gas in the sealed container

as the contents of the container come into equilibrium at

ambient or dispensing temperature (which should be

greater than the temperature at which the container is

charged and sealed). Consequently the present inven-

tion alleviates the necessity for pressurising the second-

ary chamber from a source extemally of the container

so that the secondary chamber can be formed as a sim-

ple envelope or hollow pod of any convenient shape

(such as cylindrical or spherical) which is located as a

discrete insert within a conventional form of can, bottle

or carton (thereby alleviating the requirement for a

special structure of can or bottle as envisaged in G.B.

Pat. No. 1,266,351).

Although the head or froth formed by pouring

wholly carbonated beverages tends to lack many of the

desirable qualities required of a head as previously dis-

cussed; our tests have indicated that by use of the pres-

ent invention with wholly carbonated beverages (where

the head is formed by injection of beverage from the

secondary chamber into the primary chamber) the re-

sultant head is considerably tighter or denser than that

achieved solely by pouring and as such will normally

have a greater life expectancy.

The beverage is preferably saturated or supersatu-

rated with the gas (especially if mixed carbon dioxide

and inert gases are employed) and the primary chamber

charged with the beverage under a counterpressure and

at a low temperature (to alleviate gas losses and, say, at

a slightly higher temperature than that at which the

beverage freezes) so that when the container is sealed

(which may be achieved under atmospheric pressure

using conventional systems such as a canning or bot-

tling line), the pressurisation of the primary and second-

ary headspaces is achieved by the evolution of gas from

the beverage within the primary and secondary cham-

bers as the package is handled or stored at an ambient or

dispensing temperature (greater than the charging tem-

perature) and the contents of the container adopt a state

of equilibrium. Following the sealing of the container,

the package may be subjected to a heating and cooling

cycle, conveniently during pasteurisation of the bever-

age.

The restricted orifice through which the primary and

secondary chambers communicate is conveniently

formed by a single aperture in a side wall of the second-

ary chamber and such an aperture should have a size

which is sufficiently great to alleviate “clogging” or its

obturation by particles which may normally be ex-

pected to occur within the beverage and yet be re-

stricted in its dimensions to ensure that there is an ade-

quate jetting effect in the ejection of the beverage there-

through from the secondary chamber into the primary

chamber to promote the head formation upon opening

of the container. The restricted orifice may be of any

profile (such as a slit or a star shape) but will usually be

circular; experiments have indicated that a restricted

orifice having a diameter in the range of 0.02 to 0.25

centimeters is likely to be appropriate for fermented

beverages (the preferred diameter being 0.061 centime-

ters). It is also preferred that when the package is posi-

tioned in an upstanding condition in which it is likely to

be transported, shelf stored or opened, the restricted

5

l0

15

20

25

30

35

45

50

55

60

65

6

orifice is located in an upwardly extending side wall or

in a bottom wall of the secondary chamber and prefera-

bly at a position slightly spaced from the bottom of the

primary chamber. When the contents of the sealed

package are in equilibrium and the package is in an

upstanding condition as aforementioned, the restricted

orifice is located below the depth of the beverage in the

secondary chamber so that on opening of the container

the pressure of gas in the secondary headspace initially

ejects beverage from that chamber into the beverage in

the primary chamber to promote the head formation.

Such ejection of beverage through the restricted orifice

provides a greater efficiency in the development of the

head in a liquid supersaturated with gas than will the

ejection of gas alone through the restricted orifice; the

reason for this is that the restricted orifice provides a

very active site which causes the beverage to “rip itself

apart” generating extremely minute bubbles which

themselves act as active sites for the beverage in the

primary chamber, these extremely minute bubbles leave

“vapour trails” of larger initiated bubbles which in turn

produce the head. Since the extremely minute bubbles

are travelling at relatively high speed during their injec-

tion into the beverage in the primary chamber, they not

only generate shear forces on the beverage in that

chamber but the effect of each such bubble is distributed

over a volume of beverage much larger than the imme-

diate surroundings of ' an otherwise stationary bubble.

A particular advantage of the present invention is

that prior to the container being charged with beverage

both the primary and secondary chambers can be at

atmospheric pressure and indeed may contain air. How-

ever, it is recognized that for many beverages, particu-

larly a fermented beverage, prolonged storage of the

beverage in contact with air, especially oxygen, is unde-

sirable as adversely affecting the characteristics of the

beverage. To alleviate this possibility the secondary

chamber may initially be filled with a “non-contami-

nant” gas such as nitrogen (or other inert gas or carbon

dioxide) which does not adversely affect the character-

istics of the beverage during prolonged contact there-

with. The secondary chamber may be filled with the

non-contaminant gas at atmospheric pressure or slightly

greater (to alleviate the inadvertent intake of air) so that

when the container is charged with the beverage, the

non-contaminant gas will form part of the pressurised

headspace in the secondary chamber. As previously

mentioned, the secondary chamber may be formed by

an envelope or hollow pod which is located as a dis-

crete insert within a conventional form of can, bottle or

carton and such a discrete insert permits the secondary

chamber to be filled with the non-contaminant gas prior

to the envelope or pod being located within the can,

bottle or carton. A convenient means of achieving this

latter effect is by blow moulding the envelope or pod in

a food grade plastics material using the non-contami-

nant gas as the blowing medium and thereafter sealing

‘the envelope or pod to retain the non-contaminant gas

therein; immediately prior to the pod or envelope being

inserted into the can, bottle or carton, the restricted

orifice can be formed in a side wall of the pod or enve-

lope (for example by laser boring). Immediately prior to

the container being sealed it is also preferable to remove

air from the primary headspace and this may be

achieved using conventional techniques such as filling

the headspace with froth or fob developed from a

source remote from the container and having character-

istics similar to those of the head which is to be formed

4,832,968

7

from the beverage in the container; charging the pri-

mary chamber with the beverage in a nitrogen or other

inert gas atmosphere so that the headspace is filled with

that inert gas or nitrogen; dosing the headspace with

liquid nitrogen so that the gas evolved therefrom expels

the air from the headspace, or by use of undercover

gassing or water jetting techniques to exclude air.

The secondary chamber may be charged with bever-

age from the primary chamber at ambient temperature.

It is possible to ensure that the secondary chamber is

efficiently charged by applying an auxilliary pressure to

the headspace of the primary chamber (relative to the

headspace in the secondary chamber) and allowing the

pressures in the container to equilibriate after the pri-

mary chamber has been sealed. An efficient means of

applying an auxiliary pressure is by use of the aforemen-

tioned liquid nitrogen dosing where a dose of liquid

nitrogen is applied to the headspace of the beverage in

the primary chamber immediately before that chamber

is sealed so that, following sealing, the development of

pressure in the primary headspace (assisted by the evo-

lution of nitrogen gas from the dosing) forces beverage

from the primary chamber into the secondary chamber

(by way of the restricted orifice) until a state of equilib-

rium is reached for the contents of the container.

Although the secondary chamber may be constructed

as an integral part of the container, for the reasons dis-

cussed above and also convenience of manufacture, it is

preferred that the secondary chamber is formed as a

discrete insert which is simply deposited or pushed into

a conventional form of can, bottle or carton. With cans

or cartons such an insert will not be visible to the end

user and many bottled beverages are traditionally mar-

keted in dark coloured glass or plastics so that the insert

is unlikely to adversely affect the aesthetics of the pack-

age. The discrete insert may be suspended or float in the

beverage in the primary chamber provided that the

restricted orifice is maintained below the surface of the

beverage in the primary chamber on opening of the

container; for example the insert may be loaded or

weighted to appropriately orientate the position of the

restricted orifice. Desirably however the insert is re-

strained from displacement within the outer container

of the package and may be retained in position, for

example at the bottom of the outer container, by an

appropriate adhesive or by mechanical means such as

projections on the package which may flex to abut and

grip a side wall of the outer container or which may

engage beneath an intemal abutment on the side wall of

the outer container.

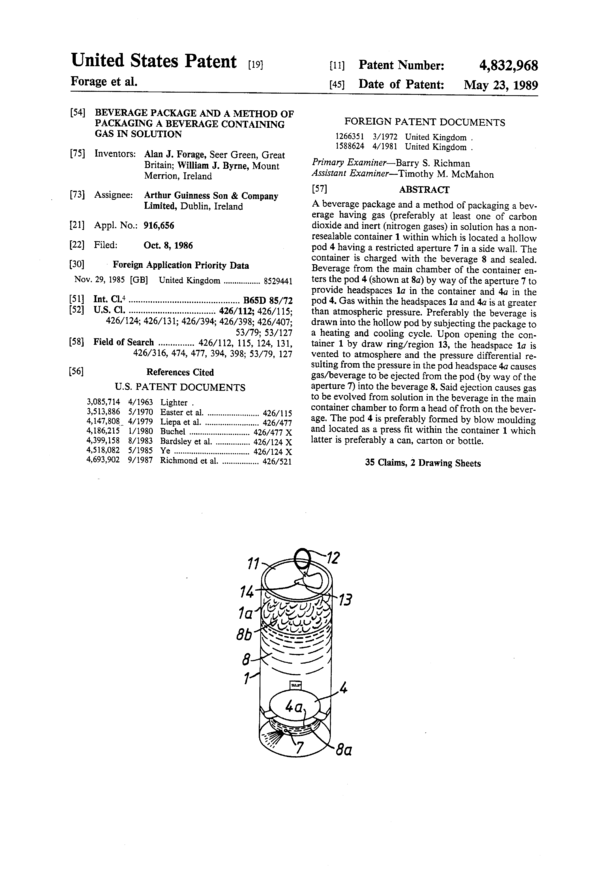

DRAWINGS

One embodiment of the present invention as applied

to the packaging of a fermented beverage such as stout

in a can will now be described, by way of example only,

with reference to the accompanying illustrative draw-

ings, in which:

FIGS. 1 to 4 diagrammatically illustrate the progres-

sive stages in the formation of the beverage package in

a canning line, and

FIG. 5 diagrammatically illustrates the effect on

opening the beverage package prior to consumption of

the beverage and the development of the head of froth

on the beverage.

DETAILED DESCRIPTION OF DRAWINGS

The present embodiment will be considered in rela-

tion to the preparation of a sealed can containing stout

10

15

20

25

30

35

45

50

55

60

65

8

having in solution a mixture of nitrogen and carbon

dioxide gases, the former preferably being present to the

extent of at least 1.5% vols/vol and typically in the

range 1.5% to 3.5% vols/vol and the carbon dioxide

being present at a considerably lower level than the

amount of carbon dioxide which would normally be

present in conventional, wholly carbonated, bottled or

canned stout and typically in the range 0.8 to 1.8 vols/-

vol (1.46 to 3.29 grams/liter). For the avoidance of

doubt, a definition of the term “vols/vol” is to be found

in U.S. Pat. No. 4,279,938 and may be taken as “the

number of volumes of gas which are dissolved in a unit

volume of the beverage, said volumes of gas being de-

termined at a pressure of 760 millimeters of mercury

and at a temperature of 15.6“ C.”.

The stout is to be packaged in a conventional form of

cylindrical can (typically of aluminum alloy) which, in

the present example, will be regarded as having a capac-

ity of 500 milliliters and by use of a conventional form

of filling and canning line appropriately modified as will

hereinafter be described. A cylindrical shell for the can

1 having a sealed base 2 and an open top 3 is passed in

an upstanding condition along the line to a station

shown in FIG. 1 to present its open top beneath a stack

of hollow pods 4. Each pod 4 is moulded in a food grade

plastics material such as polypropylene to have a short

(say 5 millimeters) hollow cylindrical housing part 5

and a circumferentially spaced array of radially out-

wardly extending flexible tabs or lugs 6. The pods 4 are

placed in the-stack with the chamber formed by the

housing part 5 sealed and containing nitrogen gas at

atmospheric pressure (or at pressure slightly above

atmospheric); conveniently this is achieved by blow

moulding the housing part 5 using nitrogen gas. The

volume within the housing part 5 is approximately 15

milliliters. At the station shown in FIG. 1 the bottom

pod 4 of the stack is displaced by suitable means (not

shown) into the open topped can 1 as shown. However,

immediately prior to the pod 4 being moved into the can

1 a small (restricted) hole 7 is bored in the cylindrical

side wall of the housing part 5. In the present example,

the hole 7 has a diameter in the order of 0.61 millimeters

and is conveniently bored by a laser beam generated by

device 7a (although the hole could be formed by punch-

ing or drilling). The hole 7 is located towards the bot-

tom of the cylindrical chamber within the housing part

5. Since the hollow pod 4 contains nitrogen gas at atmo-

spheric pressure (or slightly higher) it is unlikely that air

will enter the hollow pod through the hole 7 during the

period between boring the hole 7 and charging of the

can 1 with stout (thereby alleviating contamination of

the stout by an oxygen content within the hollow pod

4).

The hollow pod 4 is pressed into the can 1 to be

seated on the base 2. Conventional cans 1 have a domed

base 2 (shown by the section 2a) which presents a con-

vex internal face so that when the pod 4 abuts this face

a clearance is provided between the hole 7 and the

underlying bottom of the chamber within the can 1. It

will be seen from FIG. 1 that the diameter of the hous-

ing part 5 of the pod 4 is less than the internal diameter

of the can 1 while the diameter of the outermost edges

of the lugs 6 is greater than the diameter of the can 1 so

that as the pod 4 is pressed downwardly into the can,

the lugs 6 abut the side wall of the can and flex up-

wardly as shown to grip the can side wall and thereby

restrain the hollow pod from displacement away from

the base 2.

4,832,968

9

The open topped can with its pod 4 is now displaced

along the canning line to the station shown in FIG. 2

where the can is charged with approximately 4-40 milli-

liters of stout 8 from an appropriate source 9. The stout

8 is supersaturated with the mixed carbon dioxide and

nitrogen gases, typically the carbon dioxide gas being

.present at 1.5 vols/vol (2.74 grams/liter) and the nitro-

gen gas being present at 2% vols/vol. The charging of

the can 1 with the stout may be achieved in conven-

tional manner, that is under a counterpressure and at a

temperature of approximately 0° C. When the can 1 is

charged with the appropriate quantity of stout 8, the

headspace above the stout is purged of air, for example

by use of liquid nitrogen dosing or with nitrogen gas

delivered by means indicated at 10 to alleviate contami-

nation of the stout from oxygen in the headspace.

Following charging of the can 1 with stout and purg-

ing of the headspace, the can moves to the station

shown in FIG. 3 where it is closed and sealed under

atmospheric pressure and in conventional manner by a

lid 11 seamed to the cylindrical side wall of the can. The

lid 11 has a pull-ring 12 attached to a weakened tear-out

region 13 by which the can is intended to be broached

in conventional manner for dispensing of the contents.

Following sealing, the packaged stout is subjected to

a pasteurisation process whereby the package is heated

to approximately 60° C. for about 15-20 minutes and is

thereafter cooled to ambient temperature. Stout flows

from the chamber of the can into the chamber of the

pod so that when the package is at ambient temperature

the hole 7 is located below the depth of stout 8a within

the hollow pod 4.

Following.the pasteurisation process the contents of

the can 1 will stabilise in a condition of equilibrium with

a headspace la over the stout 8 in the primary chamber

of the can and a headspace 4a over the stout 8a in the

secondary chamber forced by the hollow pod 4 and in

the equilibrium condition. With the sealed can at ambi-

ent temperature (or a typical storage or dispensing tem-

perature which may be, say, 8° C.) the pressure of mixed

gases carbon dioxide and nitrogen (which largely re-

sults from the evolution of such gases from the stout) is

substantially the same in the headspaces la and 4a and

this pressure will be greater than atmospheric pressure,

typically in the order of 25lbs per square inch (1.72

bars).

The package in the condition shown in’ FIG. 4 is

typically that which would be made available for stor-

age and retail purposes. During handling it is realised

that the package may be tipped from its upright condi-

tion; in practice however this is unlikely to adversely

affect the contents of the hollow pod 4 because of the

condition of equilibrium within the can.

When the stout is to be made available for consump-

tion, the can 1 is opened by ripping out the region 13

with the pull-ring 12. On broaching the lid 11 as indi-

cated at 14 the headspace la rapidly depressurises to

atmospheric pressure. As a consequence the pressure

within the headspace 4a of the secondary chamber in

the pod 4 exceeds that in the headspace la and causes

. stout 8a in the hollow pod to be ejected by way of the

hole 7 into the stout 8 in the primary chamber of the

can. The restrictor hole 7 acts as a very “active site” to

the supersaturated stout 8a which passes therethrough

to be injected into the stout 8 and that stout is effec-

tively “ripped apart” to generate extremely minute

bubbles which themselves act as active sites for the

stout 8 into which they are injected. These minute bub-

l0

15

20

25

30

35

45

50

55

65

10

bles leave “vapour trails” of larger initiated bubbles

which develop within the headspace la a head 8b hav-

ing the previously discussed desirable characteristics.

It is appreciated that the headspace la occupies a

larger proportion of the volume of the can 1 than that

which would normally be expected in a 500 milliliter

capacity can; the reason for this is to ensure that there is

adequate volume in the headspace la for the head of

froth 8b to develop efficiently in the event, for example,

that the stout is to be consumed directly from the can

when the tear-out region 13 is removed. Normally how-

ever the stout 8 will first be poured from the can into an

open topped drinking vessel prior to consumption but

this pouring should not adversely affect the desirable

characteristics of the head of froth which will eventu-

ally be presented in the drinking vessel.

In the aforegoing embodiment the can 1 is charged

with stout 8 (from the source 9) having in solution the

required respective volumes of the carbon dioxide and

the nitrogen gases. In a modification the can 1 is

charged with stout (from source 9) having the carbon

dioxide gas only in solution to the required volume; the

2% vols/vol nitrogen gas necessary to achieve the re-

quired solution of mixed gas in the packaged stout is

derived from the liquid nitrogen dosing of the head-

space in the can.

We claim:

1. A beverage package comprising a sealed, non-

resealable, container having a primary chamber con-

taining beverage having gas in solution therewith and

forming a primary headspace comprising gas at a pres-

sure greater than atmospheric; enclosure means defin-

ing a secondary chamber having a volume less than said

primary chamber; restrictor means defining a restricted

orifice, said secondary chamber communicating with

the beverage in said primary chamber through said

restricted orifice; said secondary chamber containing

beverage supplied thereto from the beverage in the

primary chamber and having a secondary headspace

therein comprising gas at a pressure greater than atmo-

spheric so that the pressures within the primary and

secondary chambers are substantially at equilibrium;

said container is openable to expose the primary head-

space to atmospheric pressure, and wherein the second-

ary chamber is arranged so that upon opening of the

container the pressure differential caused by the de-

crease in pressure at the primary headspace causes bev-

erage in the secondary chamber to be ejected by way of

the restricted orifice into the beverage of the primary

chamber and said ejection causes gas in the solution to

be evolved and form, or assist in the formation of, a

head of froth on the beverage.

2. A package as claimed in claim 1 in which the con-

tainer has a base and is upstanding from said base and

has an openable top, and said enclosure means has an

upwardly extending side wall or a bottom wall within

which said restricted orifice is located.

3. A package as claimed in claim 1 in which the con-

tainer has a base on which the enclosure means is lo-

cated and said restricted orifice is located in an up-

wardly extending side wall of the enclosure means

spaced from said base.

4. A package as claimed in claim 1 in which the re-

stricted orifice comprises a circular aperture having a

diameter in the range of 0.02 to 0.25 centimeters.

5. A package as claimed in claim 1, wherein said

gas-containing beverage is a fermented beverage having

in solution therewith carbon dioxide in the range 0.8%

4,832,968

11

to 1.8% vols/vol and nitrogen in the range 1.5% to

3.5% vols/vol.

6. A package as claimed in claim 1 in which the bev-

erage has in solution therewith at least one of carbon

dioxide and nitrogen gas.

7. A package as claimed in claim 6 in which the bev-

erage is supersaturated with said gases.

8. A package as claimed in claim 1 wherein the enclo-

sure means comprises a hollow component inserted in

the container.

9. A package as claimed in claim 8 wherein the hol-

low component comprises a hollow moulding.

10. A package as claimed in claim 8 in which the

enclosure means floats or is suspended in the beverage

in the primary chamber and means is provided for locat-

ing the restricted orifice below the surface of the bever-

age in the primary chamber.

11. A package as claimed in claim 10 wherein said

locating means comprises a load means connected with

the enclosure means and weighted to locate the re-

stricted orifice below the surface of the beverage in the

primary chamber.

12. A package as claimed in claim 8 wherein means is

provided for retaining the enclosure means at a prede-

termined position within the container.

13. A package as claimed in claim 12 wherein the

container has a base and is upstanding from said base

and has an openable top and said enclosure means is

located at or towards the base of said container.

14. A package as claimed in claim 12 wherein the

enclosure means comprises a hollow envelope having

means thereon for retaining it within the container.

15. A package as claimed in claim 14 wherein the

retaining means comprise flexible tab means which en-

gage a side wall of the container to retain the insert.

16. A package as claimed in claim 14 in which the

hollow envelope comprises a hollow moulding and in

which ‘the container has a side wall and the moulding is

substantially cylindrical with radially extending tabs

engaging the side wall of the container.

17. A method of packaging a beverage having gas in

solution therewith which comprises providing a con-

tainer with a primary chamber and a secondary cham-

ber of which the volume of the secondary chamber is

less than that of the primary chamber and with the

means defining a restricted orifice through which the

secondary chamber communicates with the primary

chamber, and charging and sealing the primary cham-

ber with the beverage to contain the gas in solution and

to form a primary headspace in the primary chamber,

and charging the secondary chamber with beverage

supplied thereto from the primary chamber by way of

said restricted orifice to form a secondary headspace in

the secondary chamber whereby the pressures in both

the primary and secondary chambers are at equilibrium

and gaseous pressures in both the primary and second-

ary headspaces are at a pressure greater than atmo-

spheric so that, when the container is broached to open

the primary headspace to atmospheric pressure, the

pressure differential caused by the decrease in pressure

at the primary headspace causes beverage in the second-

ary chamber to be ejected into the beverage of the

secondary chamber by way of said restricted orifice and

the said ejection causes gas to be evolved from solution

in the beverage in the primary chamber to form, or

assist in the formation of, a head of froth on the bever-

age.

10

15

20

25

30

35

45

50

55

60

65

12

18. A method as claimed in claim 17 which com-

prises, prior to sealing the primary chamber, purging

the primary head space to exclude air.

19. A method as claimed in claim 17 in which the

container has a base and is upstanding from said base

and has an openable top, and said secondary chamber

has an upwardly extending side wall or a bottom wall

within which said restricted orifice is located.

20. A method as claimed in claim 17 which comprises

subjecting the sealed container to a heating and cooling

cycle.

21. A method as claimed in claim 20 in which the

heating and cooling cycle comprises heating to pasteur-

ization temperatures of the beverage.

22. A method as claimed in claim 17 in which com-

prises applying an auxiliary gas pressure to the head-

space of the primary chamber and allowing the pres-

sures within the container to equilibriate when the pri-

mary chamber is sealed.

23. A method as claimed in claim 22 which further

comprises applying the auxiliary gas pressure to the

headspace of the primary chamber as a result of liquid

nitrogen dosing prior to the primary chamber being

sealed.

24. A method as claimed in claim 17 in which the gas

comprises at least one of carbon dioxide and nitrogen

gas.

25. A method as claimed in claim 24 in which the

beverage is fermented and has in solution carbon diox-

ide in the range 0.8% to 1.8% vols/vol and nitrogen in

the range 1.5% to 3.5% vols/vol.

26. A method a claimed in claim 17 which further

comprises defming the secondary chamber by discrete

hollow enclosure means and locating said enclosure

means within the primary chamber of the container.

27. A method as claimed in claim 26 in which the

enclosure means is floated or suspended in the beverage

in the primary chamber and which further comprises

loading or weighting the enclosure means to locate the

restricted orifice below the surface of the beverage in

the primary chamber.

28. A method as claimed in claim 26 which further

comprises retaining the enclosure means at a predeter-

mined position within the container.

29. A method as claimed in claim 26 which further

comprises forming the restricted orifice in the enclosure

means by the method selected from the group consist-

ing of laser boring, drilling and punching.

30. A method as claimed in claim 26 in which the

container prior to being sealed has a base and is upstand-

ing from said base and has an open top through which

the primary chamber is charged with said beverage and

which further comprises locating the enclosure means

through said open top to provide the secondary cham-

ber within the container.

31. A method as claimed in claim 26 which further

comprises forming the hollow enclosure means having

the restricted orifice’ in a wall thereof and locating the

enclosure means within the primary chamber prior to

the charging and sealing of the primary chamber.

32. A method as claimed in claim 31 which further

comprises press fitting the enclosure means within the

container through an open top thereof so that during its

_ location the enclosure means engages with a side wall of

the container to be retained in position.

33. A method as claimed in claim 26 which further

comprises forming the enclosure means by blow mould-

mg.

4,832,968

13 14

34_ A method as Claimed in Claim 33 which further diately prior to locating the enclosure means in the

comprises blow moulding the enclosure means with gas primary Chamber‘

. . . . . 35. A method as claimed in claim 34 which further

for dissolution m the beverage so that said gas is sealed comprises Sealing Said gas in the Secondary chamber at

within the secondary chamber, and forming said re- 5 least at atmospheric pressure_

stricted orifice in the wall of the enclosure means irnme- * * * * *

10

15

20

25

30

35

45

50

55

65

UNITED STATES PATENT AND TRADEMARK OFFICE

CERTIFICATE OF CORRECTION

PATENTNO. : 4,832,968

DATED : May 23, 1989

INVENTOR(S): Alan J. Forage, et al

It is certified that error appears in the above-identified patent and that said Letters Patent is hereby

corrected as shown below:

On the title page item [73] should read -—Arthur Guinness Son &

Company (Dublin) Limited--

Signed and Sealed this

Twenty-sixth Day of February, 1991

Attest:

HARRY F. MANBECK. JR.

Attesting Oflicer Commissioner of Patents and Trademarks