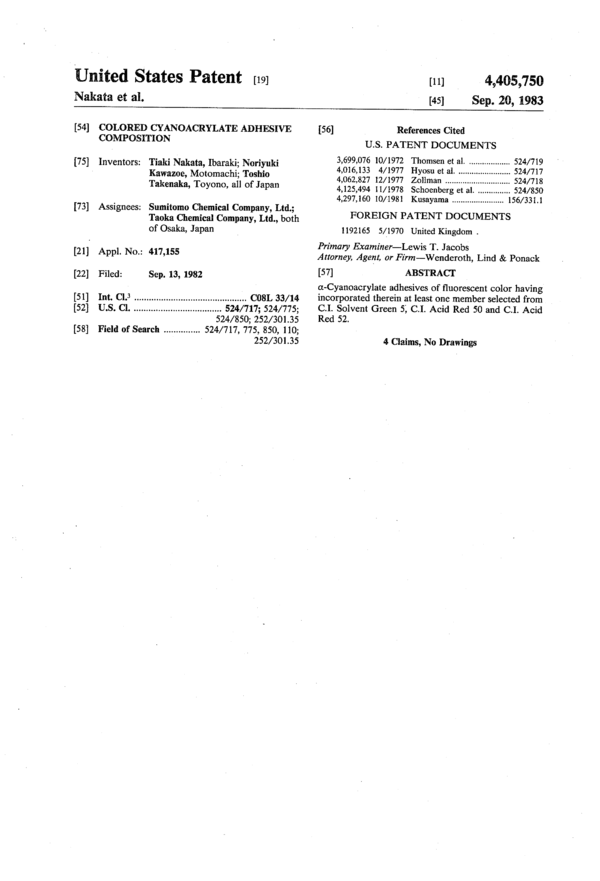

Colored Cyanoacrylate Adhesive composition

Folder:

Year:

Abstract:

Alpha-cyanoacrylate adhesives of fluorescent color having incorporated therein at least one member selected from C.I. Solvent Green 5; C.I. Acid Red 50 and C.I. Acid Red 52.

Type of document:

Language:

United States Patent [19]

Nakata et al.

[54]

[75]

[73]

[211]

[22]

[51]

[52]

[58]

COLORED CY ANOACRYLATE ADHESIVE

COMPOSITION

Inventors: Tiaki Nakata, Ibaraki; Noriyuki

Kawazoe, Motomachi; Toshio

Takenaka, Toyono, all of Japan

Assignees: Sumitomo Chemical Company, Ltd.;

Taoka Chemical Company, Ltd., both

of Osaka, Japan

Appl. No.: 417,155

Filed: Sep. 13, 1982

Int. Cl.3 ............................................ .. C08L 33/14

U.S. Cl. .................................. .. 524/717; 524/775;

524/850; 252/301.35

Field of Search ............. .. 524/717, 775, 850, 110;

252/ 301.35

[11] 4,405,750

[45] Sep. 20, 1983

[56] References Cited

U.S. PATENT DOCUMENTS

3,699,076 10/1972 Thomsen at al. ................. .. 524/719

4,016,133 4/1977 Hyosu et al. . . . . . . . . . . .. 524/717

4,062,827 12/1977 Zollman ........................ .. 524/718

4,125,494 11/1978 Schoenberg et al. . . . . . . . . . .. 524/850

4,297,160 I0/-1981 Kusayama ...................... .. 156/331.1

FOREIGN PATENT DOCUMENTS

1192165 5/1970 United Kingdom.

Primary Examiner—Lewis T. Ja.cobs

Attorney, Agent, or Firm-—Wenderoth, Lind & Ponack

[5 7] ABSTRACT

a-Cyanoacrylate adhesives of fluorescent color having

incorporated therein at least one member selected from

C.I. Solvent Green 5; C.I. Acid Red 50 and C.I. Acid

Red 52.

4 Claims, No Drawings

4,405,750

1

COLORED CY ANOACRYLATE ADHESIVE

COMPOSITION

The present invention relates to novel a-cyanoacry-

late adhesives. More particularly, it relates to cyanoac-

rylate adhesives colored with particular fluorescent

dyes.

An a-cyanoacrylate having the following formula (I)

CN

I

CI-I;_=C—CO—OR

(1)

wherein R is a C1—C;5 alkyl, C2-C5 alkenyl, C1-C5

alkoxy C2-C4 alkyl, tetrahydrofurfuryl, phenyl or cy-

clohexyl group, is a colorless and transparent liquid of a

high fluidity at room temperature, and when coated in

a thin film on the surface of substrate body and exposed

to ambient atmosphere for several seconds, it rapidly

hardens to form a strong solid film. Taking advantage of

these properties, the compound described above is rap-

idly applied between two materials, whereby the mate-

rials are very strongly bonded in several to several ten

seconds without applying pressure or heat. Because of

such properties of a-cyanoacrylate, adhesives compris-

ing this compound have been used as instantaneous

adhesives for producing precision apparatus, electrical

and electronic apparatus, etc. Further in recent years,

their demand for domestic use is increasing, and they

are in use for bonding various metallic articles, ceram-

ics, glass articles, rubber articles, plastic articles and the

like.

While various performances including viscosity,

bonding strength, setting time and so on are required for

this type of adhesive depending upon intended uses, for

example the kind of materials to be bonded, the form of

bonding, a period of time necessary for bonding, the

property of bonded materials and the like, and for satis-

fying these requirements, a different kind of this type of

adhesive composition is now placed on the market.

For satisfying these requirements, for example, this

type of adhesive comprises 10 to 50 ppm of sulfur diox-

ide and 50 to 500 ppm of hydroquinone to elevate stor-

age stability, and also comprises other stabilizers, poly-

merization inhibitors, thickeners, diluents, plasticizers,

etc. It is therefore very desirable to have a means to

distinguish various kinds of these adhesive compositions

at a glance.

The well-known methods intended to distinguish the

kind of these cyanoacrylate adhesives is to color the

adhesives by the addition of particular dyes, for exam-

ple 1-hydroxy-4-amino (or 4-arylamino)anthraquinones

(British Pat. No. 1,192,165 and U.S. Pat. Nos. 3,699,076

and 4,062,827). These dyes, however, lower the bond-

ing strength and storage stability of the cyanoacrylate

adhesives.

Generally speaking, a deep coloration is favorable for

discrimination or distinction but causes the staining of

materials to be bonded as well as lowering of the bond-

ing strength and storage stability. Whereas, a light col-

oration makes discrimination between coated "area and

uncoated one impossible, so that parts to be coated

remain uncoated in part, or more parts than required are

coated, thereby impairing the bonding strength or caus-

ing the staining of materials to be bonded.

The present inventors extensively studied to improve

the foregoing defects of the conventional coloration of

5

10

15

20

2

cyanoacrylate adhesives, and as a result, found that

particular dyes having fluorescence well color the cya-

noacrylate adhesives without impairing the bonding

performances and storage stability thereof, and exhibit a

very good visible distinguishabillity even in a light col-

oration.

An object of the present invention is to provide col-

ored cyanoacrylate adhesives. Another object of the

present invention is to provide cyanoacrylate adhesives

which are easy to distinguish their kindsand coated

areas from uncoated ones even in a light coloration. A

further object of the present invention is to provide a

method for giving fluorescence to cyanoacrylate adhe-

sives and cyanoacrylate adhesives having fluorescence.

According to the present invention, there is provided

an adhesive composition comprising an a-cyanoacry-

late having the formula,

CN

I

CH2=C-C0---OR

wherein R is a C1—C15 alkyl, C2-C5 alkenyl, C1-C5

alkoxy C2-C4 alkyl, tetrahydrofurfuryl, phenyl or cy-

5 clohexyl group, and at least one dye selected from the

30

35

40

45

50

55

60

65

group consisting of C.I. Solvent Green 5, C.I. Acid Red

50 and C.I. Acid Red 52.

The a-cyanoacrylate usable in the present invention

includes, for example, methyl a-cyanoacrylate, ethyl

ct-cyanoacrylate, propyl ct-cyanoacrylate, butyl a-

cyanoacrylate, amyl a-cyanoacrylate, hexyl a-cyanoa-

crylate, cyclohexyl a-cyanoacrylate, benzyl a-cyanoa-

crylate, phenyl a-cyanoacrylate, octyl a-cyanoacrylate,

dodecyl a-cyanoacrylate, allyl a-cyanoacrylate, pro-

pargyl on-cyanoacrylate, methoxyethyl a-cyanoacry-

late, ethoxyethyl a-cyanoacrylate, furfuryl a-cyanoa-

crylate, tetrahydrofurfuryl a-cyanoacrylate, chloro-

ethyl a-cyanoacrylate, fluoroethyl a-cyanoacrylate,

hexachloroethyl a-cyanoacrylate and the like. These

a-cyanoacrylates may be used each alone or in combi-

nation of two or more of them.

The dyes used in the present invention, C.I. Solvent

Green 5, C.I. Acid Red 50 and C.I. Acid Red 52, have

structures represented by the formulae II, III and IV,

respectively. These dyes are well soluble in the ct-

cyanoacrylates in a bright yellow having a greenish

fluorescence, a bright yellowish red having a greenish

fluorescence and a bright bluish red having a greenish

fluorescence; respectively.

C.I. Solvent Green 5:

1 II

0. COOCH2—CH(CH3)2

(CH3)2CI-I--CI-I2OOC Q Q

C.I. Acid Red 50:

+ 111

C2Hs-HN o ¢NH--CZH5

H3C: : :cé: ‘CH3

S03‘ ‘

SO3Na

4,405,750

3

-continued

C.I. Acid Red 52:

+ IV

(C2H5)2N N(C2Hs)2 5

‘(EDT)’

C¢

S03‘

10

SO3Na

These dyes may be used each alone or as a mixture of

two or more.

The amount of these dyes added is 0.1 to 10000 ppm, 15

preferably 0.5 to 2000 ppm, based on the weight of the

cyanoacrylate adhesives. When the amount is less than

0.1 ppm, both coloration and fluorescence show little

effect. When the amount is more than 10000 ppm, the

dissolution of dye becomes difficult, and an adverse

effect is sometimes exerted on the bonding strength.

Other dyes known for coloring cyanoacrylate may be

used together so far as the result of the present inven-

tion is not affected, and also in this case, the fluores-

cence is maintained to effect the objects of discrimina-

tion and visible distinction to a sufficient extent.

In the dyes usable in the present invention are some-

times contained basic substances and other impurities

caused in the course of production, and therefore in

such case, it is preferred to previously wash the dyes

with a very dilute aqueous acid solution (e. g. 1% hydro-

chloric acid), followed by drying and pulverizing.

When such dyes are used without washing, they tend

to affect the storage stability of the adhesives.

The colored cyanoacrylate adhesives having fluores-

cence of the present invention may contain various

additives used in the conventional cyanoacrylate adhe-

sives, for example, radical polymerization inhibitors

such as hydroquinone, hydroquinone monomethyl

ether, catechol, pyrogallol, bisphenol A and the like

(about 1 to about 10000 ppm, preferably 10 to 5000 ppm

based on the weight of the adhesive), anionic polymeri-

zation inhibitors such as S02, SOCl2, SO2Cl2, HF, N02,

p-toluenesulfonic acid, methanesulfonic acid, propane-

sultone, phosphoric acid, sulfuric acid, and the like.

Further, for producing adhesive compositions having

an increased viscosity, viscosity regulators such as

methyl methacrylate polymer, vinyl acetate polymer,

cellulose acetate isobutyrate, acrylic rubber, etc. may be

incorporated in the adhesive. In addition to these, plasti-

cizers may be added to give softness to hardened bond

layer, and modifiers for giving impact strength and

thermal resistance may be added.

The colored cyanoacrylate adhesives having fluores-

cence of the present invention have a beautiful yellow

or red color having a greenish fluorescence, even when

C.I. Solvent Green 5, C.I. Acid Red’ 50 or C.I. Acid

Red 52 is used in small amounts. The adhesives of the

present invention are colored without impairing bond-

ing performances and storage stability, and therefore

they are superior in the bonding performance and stabil-

ity of a-cyanoacrylate itself to the conventional colored

adhesives. Besides, the present adhesives are improved

so that discrimination of their kinds and between coated

areas and uncoated ones can easily be achieved even in

a light coloration.

The colored cyanoacrylate adhesives having fluores-

cence of the present invention are suitable for bonding

almost all the materials, i.e. rubbers, plastics, metals,

20

25

30

35

40

45

50

55

60

65

4

woods and the like, to which the conventional instanta-

neous adhesives have been applied, and also preferably

used, for example, in the fields of small-sized parts,

construction of precision apparatus, thread-locking,

sealing, artificial nail and the like.

The present invention will be illustrated in more de-

tail with reference to the following Examples. The test

items and test methods in the Examples are as follows:

VISCOSITY

Measured at 20° C. by means of a Brookfield viscom-

eter (cps).

TENSILE SHEAR STRENGTH

The test was carried out as follows according to

“Test method for cyanoacrylate adhesives” described

in JIS K-6861: A test piece according to JIS G-3141

(SPCC,‘cold-rolled steel sheet), 100 mmX25 mm>< 1.6

mm in size, was polished at the surface with Sand paper

AA-150 and defatted with an acetone/toluene (1:1)

mixed liquor; after coating the adhesive on the surface,

a pair of the test pieces were superposed so that the

bond area was 25 mm>< 12.5 mm, pressed against each‘

other by a force of about 2 kgf and aged as they were

for 24 hours in a room of 20° C. and 60% RH; and then

tensile shear strength was measured on a 5-ton capacity

tensile tester, and a mean value of five tests was taken as

tensile shear strength.

SETTING TIME

Test pieces were prepared for in the same manner as

in the foregoing test method for tensile shear strength.

After coating the adhesive so that the bond area was 25

mm>< 12.5 mm, the test pieces were superposed and

pressed against each other by a force of about 2 kgf.

According to the lapse of time, the bonded test piece

was fixed at the upper end by jig, and a weight of 5 kg

was put on the lower end of the test piece to apply

tensile load. Thus, a period of time from the bonding to

the time when the test piece no longer showed bonding

break, was measured, and taken as a setting time.

STORAGE STABILITY

After storing at 70° C. for 7 days, the viscosity, tensile

shear strength and setting time were measured in the

manner described above.

EXAMPLES 1 TO 5 AND COMPARATIVE

EXAMPLES 1 AND 2

C.I. Solvent Green 5 in an amount (ppm) shown in

Table 1 was dissolved in ethyl a-cyanoacrylate contain-

ing 15 ppm of S02 and 500 ppm of hydroquinone. Ei-

ther of the adhesive compositions obtained had a green-

ish fluorescence and a bright yellow color. These adhe-

sives were examined for bonding performances and

storage stability in comparison with non-colored adhe-

sives, and the results are as shown in Table 1.

During these tests in which the colored adhesives and

non-colored ones were coated on steel plate, each

coated state was observed. With the former ones, the

boundary of coating was clearly recognized irrespec-

tive of the depth of coloration. While with the latter

ones, the boundary of coating was hardly recognized.

In the room of poor illumination, the boundary of coat-

ing was little recognized for both the colored and non-

colored adhesives, but on irradiation with black light, it

4,405,750

5

was able to be recognized very clearly for the colored

adhesives because of a bright greenish fluorescence.

6

ethyl a-cyanoacrylate containing 15 ppm of S02 and

500 ppm of hydroquinone. The adhesives obtained had

TABLE 1

Initial stage Storage stability

Amount ‘Ten- Set- Ten- Set-

of dye sile ting sile ting

added Visco- shear time Visco- shear time

Exp. No. (ppm) sity strength (sec) sity strength (sec)

Example 1 5 2.5 202 45 3.0 196 60

Example 2 100 2.5 211 45 3.0 203 60

Example 3 500 2.5 207 45 3.0 208 60

Example 4‘ 500 60 201 70 110 204 70

Example 5 1000 2.5 212 50 3.0 210 60

Compar- None 2.5 205 45 3.0 219 60

ative

Example 1

Compar- None 60 207 60 100 212 75

ative

Example 2‘

Note:

Each adhesive of Example 4 and Comparative Example 2 additionally comprises 10 parts by

weight based on 100 parts by weight of the adhesive (PHR) of methyl methacrylate polymer.

EXAMPLES 6 TO 12 AND COMPARATIVE

EXAMPLES 3 AND 4

C.I. Acid Red 50 and C.I. Acid Red 52 in amounts as

shown in Table 2 were dissolved in methyl a-cyanoa-

crylate containing 15 ppm of S02 and 200 ppm of hy-

droquinone. Either of the adhesive compositions ob-

tained had a greenish fluorescence and a bright red

color. ‘

The foregoing both dyes were treated before use as

follows: Five grams of the crude product of them was

dispersed in 200 ml of 1% aqueous hydrochloric acid

solution, stirred for 30 minutes for washing, filtered,

dried at 80° C. for 24 hours and then pulverized.

The results about the bonding performances and stor-

age stability are as shown in Table 2.

The coated state on steel plate was observed, and it

was found that either of the colored adhesives was

clearly recognized, but with the non-colored ones, the

boundary of coating was undistinguishable. In a dark

place, both the adhesives were invisible, but on irradia-

tion with black light, the colored ones only emitting a

beautiful greenish fluorescence could clearly be recog-

nized.

a color as shown in Table 3, but fluorescence.

These colored adhesives were examined and the re-

sults are as shown in Table 3.

25 TABLE 3

Storage

Compa- stability

rative Tensile

Example shear Visco-

30 No. Name of dye Color strength sity

1 Non Non 209 105

5 5-Amino-4-anilino— Blue 204 410

1,8—dihydroxy-anthra-

quinone

6 l-Hydroxy-3-bromo-4- Red 151 110

35 amino-anthraquinone

7 2-(3—Hydroxy-2-quino- Yellow 140 105

linyl)-1H-indene-

1,3(2I-I)-dione

8 4-p-Anisidino-1- Purple 186 260

40

hydroxy-anthraquinone

What is claimed is:

1. An adhesive composition comprising an a—cyanoa-

crylate having the formula,

TABLE 2

Amount of dye added Initial stage Storage stability

Tensile Setting Tensile Setting

C.I. Acid C.I. Acid Visco- shear time Visco- shear time

Exp. No. Red 50 Red 52 Vsity strength (sec.) sity strength (sec.)

Example 6 5 -— 2.5 201 45 3.0 196 45

Example 7 500 — 2.5 207 45 3.0 206 45

Example 8 1000 —— 2.5 203 45 3.0 207 45

Example 9 —- 5 2.5 198 45 3.0 g 207 45

Example 10 — 500 2.5 206 45 3.0 206 45

Example 11’ —- 500 60 199 60 130 200 60

Example 12 — 1000 2.5 201 45 3.0 203 45

Compa- — —— 2.5 205 45 3.0 209 45

rative

example 3

Compa- -— — 60 207 60 100 200 60

rative

example 4‘

Note:

Each adhesive of Example 11 and Comparative Example 4 additionally comprises 10 parts by weight based on 100 parts

by weight of the adhesive (PHR) of methyl methacrylate polymer.

COMPARATIVE EXAMPLES 5 TO 8

Two hundred ppm of each of the dyes described in

U.S. Pat. Nos. 3,699,076 and 4,062,827 was dissolved in

65

CN

I

CH2=C—C0-OR

4,405,750

7

wherein R is a C1—C15 alkyl, C2-C5 alkenyl, C1-C5

alkoxy C2-C4 alkyl, tetrahydrofurfuryl, phenyl or cy-

clohexyl group, and at least one dye selected from the

group consisting of C.I. Solvent Green 5, C.I. Acid Red

50 and C.I. Acid Red 52.

2. The adhesive composition according to claim 1,

wherein the content of the dye is 0.1 to 10000 ppm

based on the weight of the adhesive composition.

3. The adhesive composition according to claim 1,

10

15

20

25

30

35

40

45

50

55

60

65

8

wherein the composition additionally comprises atleast

one member selected from the group consisting of poly-

merization inhibitors, viscosity regulators, plasticizers

and impact strength modifiers.

4. Materials bonded with the adhesive composition of

claim 1.

Coments go here:

- Log in to post comments