Adhesive Composition

Folder:

Year:

Abstract:

An adhesive composition comprising an .alpha.-cyanoacrylate and about 0.0001% by weight to about 20% by weight, based on the weight of the adhesive composition, of at least one compound selected from the group consisting of (1) polyehtylene glycols having a degree of polymerization of at least 3, and (2) non-ionic surface active agents having a poly(ehtyleneoxy) moiety therein with the poly(ehtyleneoxy) moiety having a degree of polymerization of at least 3.

Type of document:

Language:

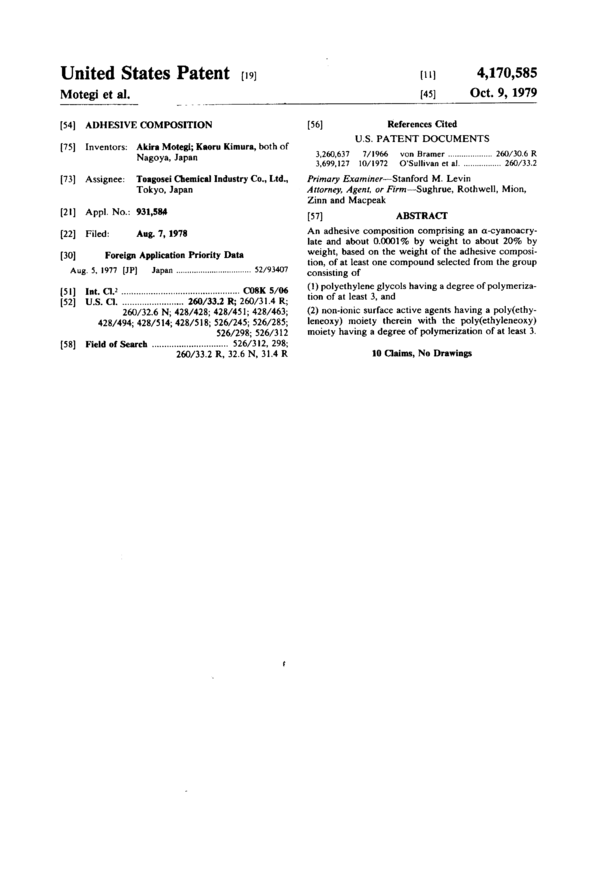

Motegi et al.

United States Patent 1191

[54] ADHESIVE COMPOSITION

[75] Inventors:

Nagoya, Japan

Toagosei Chemical Industry Co., Ltd.,

Tokyo. Japan

[73] Assignee:

[2]] Appl. No.: 931,534

[22] Filed: Aug. 7, 1978

[30] Foreign Application Priority Data

Aug, 5, I977 [JP] Japan 52/93407

[51] Int. CL2 .............................................. .. C08K 5/06

[52] U.S. Cl. ....................... .. 260/33.2 R; 260/31.4 R;

260/32.6 N; 428/428; 423/451; 428/463;

428/494; 428/514; 428/518; 526/245; 526/285;

526/298; 526/312

[58] Field of Search ............................. .. 526/312, 298;

260/33.2 R, 32.6 N, 31.4 R

Akira Motegi; Kaoru Kimura, both of

[11] 4,170,585

[45] Oct. 9, 1979

[56] References Cited

U.S. PATENT DOCUMENTS

3,260,637 7/I966 von Bramer .... .. 260/30.6 R

3,699,l27 10/I972 O‘Sullivan el al. ............... .. 260/331

Primary Examiner——Stanford M. Levin

Attorney, Agent, or Firm——Sughrue, Rothwell, Mion,

Zinn and Macpeak

[57] ABSTRACT

An adhesive composition comprising an a-cyanoacry-

late and about 0.000l% by weight to about 20% by

weight, based on the weight of the adhesive composi-

tion, of at least one compound selected from the group

consisting of

(l) polyethylene glycols having a degree of polymeriza-

tion of at least 3, and

(2) non-ionic surface active agents having a p0ly(ethy-

leneoxy) moiety therein with the poly(ethyleneoxy)

moiety having a degree of polymerization of at least 3.

10 Claims, No Drawings

4,170,585

1

ADHESIVE COMPOSITION

BACKGROUND OF THE INVENTION

I. Field of the Invention

This invention relates to an a-cyanoacrylate-type

adhesive composition, and more specifically to an a-

cyanoacrylate-type adhesive composition which has

good storage stability and is rapidly curable with a fast

setting time.

2. Description of the Prior Art

An a-cyanoacrylate monomer, a principal compo-

nent of an a-cyanoacrylate-type adhesive composition,

has unique anionic polymerizability, and begins to poly-

merize in the presence of a weak anion such as the slight

amount of moisture adhering to the surface of an adher-

end. Consequently, an a-cyanoacrylate-type adhesive

composition can be used to bond almost all materials,

except for some inert materials such as polyethylene

and Teflon (trademark for polytetrafluoroethylene res-

ins produced by E. I. du Pont de Nemours), firmly

within several seconds to several minutes. An a-

cyanoacrylate-type adhesive has therefore gained wide-

spread acceptance as an instantaneous adhesive in in-

dustrial, medical and household applications.

The curing of an a-cyanoacrylate-type adhesive is

based on the anionic polymerization of the a-cyanoa-

crylate monomer. The anionic polymerization, how-

ever, is inhibited when bonding a adherend having an

acidic surface, such as a wooden material, a chemically

treated surface (e.g., a chromate-treated surface), or a

surface which has the tendency to permit the formation

of an acidic oxide coating. Frequently, this causes a

retardation in the setting time, and the adhesion

strength obtained is not necessarily sufficient. For ex-

ample, wooden materials generally used have a mois-

ture content of about 10% by weight at a temperature of

about 23° C. and a relative humidity of about 55%.

When a wooden material is bonded with a conventional

a-cyanoacrylate-type adhesive composition, a setting

time of several minutes to more than ten minutes is

required despite the presence of such a large amount of

water in the woody tissue and the surface of the mate-

rial. It has been generally considered to be difficult to

bond wooden materials with a-cyanoacrylate-type ad-

hesive compositions. The reason is believed to be due to

the following. The surface of a wooden material is

acidic with a pH of about 4 to 6 because of the sap

present, and, therefore, in bonding, the anionic poly-

merization of the ct-cyanoacrylate monomer is inhibited

and the rate of curing is slow. Furthermore, during this

time, the adhesive composition penetrates into the po-

rous woody tissue, and adhesive-free portions in the

adhesive layer result.

Various investigations have been made to provide a

method for shortening the setting time of a-cyanoacry-

late-type adhesive compositions. The most common

method is to use a curing agent for promoting the ani-

onic polymerization of the a-cyanoacrylate monomer

as a primer or a post-treating agent (for example, as

disclosed in U.S. Pat. No. 3,260,637). When both the

a-cyanoacrylate monomer and the curing agent are

prepared as a one-package adhesive composition, the

monomer polymerizes during storage. Hence, they

must be stored, and the curing agent described above

must be used as a primer on the job. Thus, two coating

operations are required to apply both the primer and the

10

I5

20

25

30

35

40

45

50

55

65

2

adhesive, and the coating efficiency decreases drasti-

cally.

SUMMARY OF THE INVENTION

In view of this state of art, extensive investigations

have now been made on a method which can accelerate

the setting of an a-cyanoacrylate-type adhesive compo-

sition without adversely affecting the stability and other

properties of the composition, and which can be em-

ployed simply and accurately.

The word led to the discovery that the object de-

scribed above can be achieved by incorporating at least

one compound selected from the group consisting of

polyethylene glycols and nonionic surface active agents

having a poly(ethyleneoxy) moiety into an a-cyanoa-

crylate-type adhesive composition.

Accordingly, this invention provides an adhesive

composition comprising an a-cyanoacrylate and about

0.000l% by weight to about 20% by weight, based on

the weight of the adhesive composition, of at least one

compound selected from the group consisting of

(l) polyethylene glycols having a degree of polymeri-

zation of at least 3, and

(2) non-ionic surface active agents having a poly-

(ethyleneoxy) moiety therein, with the poly(ethy-

leneoxy) moiety having a degree of polymerization of at

least 3.

DETAILED DESCRIPTION OF THE

INVENTION

The a-cyanoacrylate-type adhesive composition of

this invention as described above contains an a-cyanoa-

crylate monomer of the formula (1)

CN

/

CHz=C

(I)

COOK’

wherein R‘ represents a straight chain or branched

chain alkyl group having I to 12 carbon atoms (which

may be substituted with a substituent such as a halogen

atom or an alkoxy group) a straight chain or branched

chain alkenyl group having 2 to 12 carbon atoms, a

straight chain or branched chain alkynyl group having

2 to 12 carbon atoms, a cycloalkyl group, an aralkyl

group or an aryl group. Specific examples of the groups

for R‘ are a methyl group, an ethyl group, an n-propyl

group, an isopropyl group, an n-butyl group, an isobutyl

group, a pentyl group, a hexyl group, an allyl group, a

methallyl group, a crotyl group, a propargyl group, a

cyclohexyl group, a benzyl group, a phenyl group, a

cresyl group, a 2-chloroethyl group, a 3-chloropropyl

group, a 2-chlorobutyl group, a trifluoroethyl group, a

2-methoxyethyl group, a 3-methoxybutyl group and a

2-ethoxyethyl group.

A single a-cyanoacrylate monomer or a mixture of

two or more of these a-cyanoacrylate monomers can be

used. Generally, the above a—cyanoacrylate monomer

alone is not sufficient as an adhesive, and the compo-

nents set forth below are sometimes added.

(I) An anionic polymerization inhibitor

(2) A radical polymerization inhibitor

(3) A thickener

(4) Special additives such as plasticizers and heat

stabilizers

(5) Perfumes, dyes, pigments, etc.

4,170,585

3

A suitable amount of the a-cyanoacrylate monomer

present in the adhesive composition is about 80 to

99.9% by weight preferably 90 to 99.9% by weight,

based on the total weight of the adhesive composition.

An anionic polymerization inhibitor is added to the

a-cyanoacrylate-type adhesive composition, e.g., in an

amount of about 1 to 1000 ppm based on the total

weight of the adhesive composition, to increase the

stability of the adhesive composition during storage,

and examples of known inhibitors are sulfur dioxide,

aromatic sulfonic acids, aliphatic sulfonic acids, sul-

tones, and carbon dioxide.

Suitable examples of radical polymerization inhibi-

tors include, for example, hydroquinone and hydroqui-

none monomethyl ether. A radical polymerization in-

hibitor is added, e.g., in amount of about 1 to 5000 ppm

based on the total weight of the adhesive composition,

for the purpose of capturing radicals which are formed

by light during storage.

A thickener is added to increase the viscosity of the

a.-cyanoacrylate-type adhesive composition. The a-

cyanoacrylate monomer generally has a low viscosity

of about several centipoises, and therefore, the adhesive

penetrates into porous materials such as wood and

leather or adherends having a rough surface. Thus,

good adhesion strengths are difficult to obtain. Various

polymers can be used as thickeners, and examples in-

clude poly(methyl methacrylate), methacrylate-type

copolymers, acrylic rubbers, cellulose derivatives, poly-

vinyl acetate and poly(a-cyanoacrylate). A suitable

amount of thickener is generally about 20% by weight

or less based on the total weight of the adhesive compo-

sition.

The plasticizers, perfumes, dyes, pigments, etc., may

be added depending on use purposes in amounts which

do not adversely affect the stability of the a-cyanoa-

cryalte monomer. A suitable amount of the plasticizer is

about 0.1 to 50% by weight, of the heat stabilizer is

about 0.01 to about 5% by weight and of each of the

perfume, the dye and the pigment is about 0.01 to 5% by

weight, based on the total weight of the adhesive com-

position.

The accelerating compound also present in the a-

cyanoacrylate adhesive composition of this invention to

accelerate the setting of the adhesive composition, i.e.,

shorten the setting time of the adhesive composition, is

at least one compound selected from the group consist-

ing of

(l) Polyethylene glycols having a degree of polymer-

ization of at least 3, and

(2) non-ionic surface active agents having a poly-

(ethyleneoxy) moiety therein with the poly(ethy-

leneoxy) moiety having a degree of polymerization of at

least 3.

Suitable polyethylene glycols which can be used are

those having a structure of the fonnula (II)

H0-(CH2cH2o),,H (11)

wherein n is the degree of polymerization and n is at

least 3. Usually, they are produced by polymerizing

ethylene oxide. Polythylene glycols are commercially

available in various molecular weights depending on

the degree of polymerization (n). Suitable examples of

polyethylene glycols are polyethylene glycol #200 with

an average degree of polymerization of 4, polyethylene

glycol #300 with an average degree of polymerization

of 6, and polyethylene glycols #400, #600, #1000,

l0

I5

20

25

30

35

45

50

55

65

4

#1250, #1540, #2000. #3600, #4000, #6000, #20000

with various other degrees of polymerization.

The polyethylene glycol used in this invention should

have a degree of polymerization of at least 3, i.e., a

molecular weight of at least I50. If the polyethylene

glycol has a degree of polymerization of less than 3, the

effect of the polyethylene glycol in accelerating the

setting of the adhesive composition is extremely small,

and the adhesive composition of the present invention

can not be obtained. There is no particular upper limit

on the degree of polymerization of the polyethylene

glycol. Preferably, the degree of polymerization of the

polyethylene glycol is about 10,000 or less, more prefer-

ably about 3,000 or less. Polyethylene glycols having a

degree of polymerization greatly exceeding 10,000 tend

to have reduced compatibility with the a-cyanoacrylate

monomer, and it is difficult to use such polyethylene

glycols since they do not dissolve uniformly in the ad-

hesive composition.

Suitable nonionic surface active agents having a poly-

(ethyleneoxy) moiety in the molecule thereof which can

be used in the present invention can be selected, for

example, from the following compounds which are

generally known.

(1) Polyethylene glycol alkyl ether-type nonionic

surface active agents

(2) Polyethylene glycol alkyl phenyl ether-type non-

ionic surface active agents

(3) Polyethylene glycol fatty acid ester-type nonionic

surface active agents

(4) Polyethylene glycol-polypropylene glycol ether-

type nonionic surface active agents

(5) Polyethylene glycol sorbitan fatty acid ester-type

nonionic surface active agents

(6) Ethylene oxide adducts of other active hydrogen-

containing compounds

(7) Polyethylene glycol alkylamine type nonionic

surface active agents

Suitable nonionic surface active agents which are

effective in this invention are those having a poly(ethy-

leneoxy) moiety, -—CHzCH2-0)». in the molecule

thereof. Furthermore, for the same reason as set forth

above for the polyethylene glycol, the degree of poly-

merization of the poly(ethyleneoxy) moiety should be at

least 3. A suitable degree of polymerization (n) for the

poly(ethyleneoxy) moiety is about 3 to 200, preferably 3

to l00.

Specific examples of nonionic surface active agents

having a poly(ethyleneoxy) moiety which can be used

in this invention are listed below. However, these exam-

ples are given merely for the purposes of illustration and

the present invention is not to be construed as being

limited to these examples.

(1) Polyethylene glycol alkyl ether-type nonionic

surface active agents:

Polyethylene glycol lauryl ether,

polyethylene glycol cetyl ether,

polyethylene glycol stearyl ether,

polyethylene glycol oleyl ether, etc.

(2) Polyethylene glycol alkyl phenyl ether-type sur-

face active agents:

Polyethylene glycol octyl phenyl ether,

polyethylene glycol nonyl phenyl ether,

polyethylene glycol dodecyl phenyl ether, etc.

(3) Polyethylene glycol fatty acid ester-type nonionic

surface active agents:

Polyethylene glycol monolaurate,

polyethylene glycol monostearate,

4,170,585

5

polyethylene glycol monooleate,

polyethylene glycol distearate,

polyethylene glycol stearate (mixture of mono- and

di-esters),

polyethylene glycol perfluorolaurate, etc.

(4) Polyethylene glycol-polypropylene glycol ether-

type nonionic surface active agents:

Polyethylene glycol-polypropylene glycol ether, etc.

(5) Polyethylene glycol sorbitan fatty acid ester-type

nonionic surface active agents:

Polyethylene glycol sorbitan monolaurate,

polyethylene glycol sorbitan monostearate.

polyethylene glycol sorbitan monooleate,

polyethylene glycol sorbitan monopalmitate,

polyethylene glycol sorbitan tristearate,

polyethylene glycol sorbitan trioleate. etc.

(6) Ethylene oxide adducts of active hydrogen-con-

taining compounds:

Phenolic resin/polyethylene oxide adducts,

polyacrylate/polyethylene oxide adducts,

3,6-dimethyl~4-octyne-3,6-diol/polyethylene

adducts,

polyethylene glycol lanolin alcohol ether,

polyethylene glycol lanolin fatty acid ester, etc.

(7) Polyethylene glycol alkylamine type nonionic

surface active agents:

Polyethylene glycol alkylamine adducts.

The amount of the above accelerating compound

present in the a-cyanoacrylate adhesive composition is

not particularly limited as long as the setting of the

adhesive composition is accelerated without impairing

the storage stability of the adhesive composition. Gen-

erally, a suitable amount of the accelerating compound

ranges from about 0.001% by weight to about 20% by

weight, preferably from 0.01% by weight to 10% by

weight. Generally, when the amount of the accelerating

compound is small, the effect of accelerating the setting

is small, although this varies somewhat depending on

the type of the accelerating compound used. When the

amount of the accelerating compound exceeds about

20% by weight, there is a tendency for the accelerating

compound to dissolve with difficulty, for the viscosity

of the adhesive composition to increase, or for the adhe-

sive composition to gel during storage. When the

amount of the accelerating compound is within the

range of about 0.01 to about 10% by weight, a very fast

setting time balanced with good storage stability is

achieved.

Suitable adherends which can be bonded using the

adhesive composition of this invention include not only

the wooden materials and chromate-treated metallic

materials as described above but also ordinary metallic

materials, ceramics, plastics, and rubbers. The adhesive

composition of this invention can also be employed in

bonding porous materials such as leather and paper.

The adhesive composition of this invention has an

extremely fast setting time, and the storage stability of

the adhesive composition scarcely changes. The acidifi-

cation phenomenon (i.e., the phenomenon that during

storage, the setting time gradually becomes slower, and

finally the adhesiveness of the adhesive composition is

lost although the adhesive composition is not gelled) of

the adhesive composition can be markedly retarded.

The following Examples and Comparative Examples

are given to illustrate the present invention in more

detail. In these examples, all % and ppm values are by

weight. The properties indicated were measured using

the following methods.

oxide

10

15

20

25

30

35

45

50

55

60

65

6

(1) Setting Time Measurement

The setting time was measured in accordance with

the testing method for setting time set forth in Standards

JAI-4 “Method for Testing a-Cyanoacrylate-Type Ad-

hesive" of the Japan Association of Adhesive Industry.

The adherend sample had a size of 5>< l2.7>< 38 mm, and

the setting time of the adhesive composition at the grain

surface (adhering area: 1.61 m3) parallel to the grain was

measured. The moisture content was measured using a

Kett wood moisture meter.

(2) Compression Shear Adhesion Strength

Compression shear adhesion strength was measured

in accordance with JIS K-6852 “Method for Testing

Compression Shear Adhesion Strength of Adhesives."

The adhered sample had a size of l2.7>

Coments go here:

- Log in to post comments