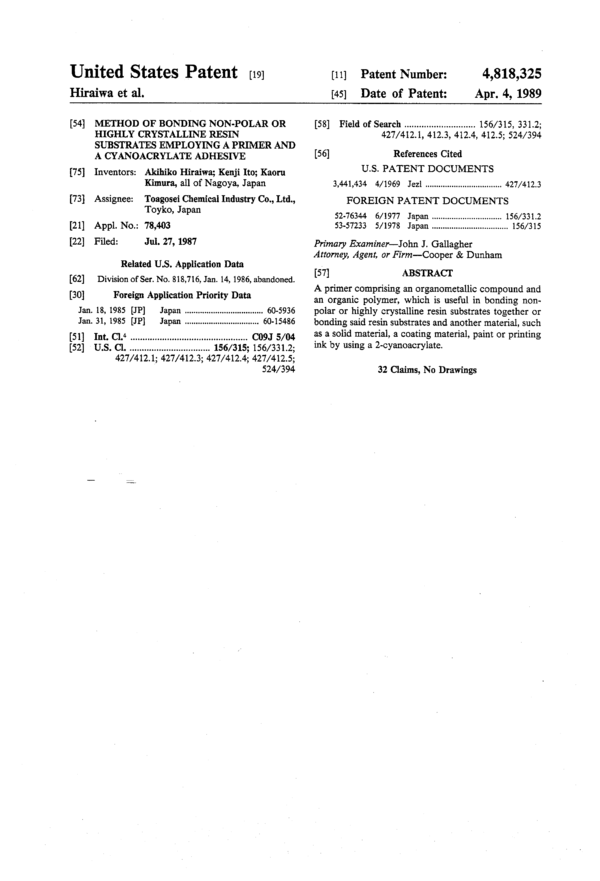

Method of Bonding Non-Polar or Highly Crystalline Resin Substrates Employing a Primer and a Cyanoacrylate Adhesive

Method of Bonding Non-Polar or Highly Crystalline Resin Substrates Employing a Primer and a Cyanoacrylate Adhesive

US4818325

Company:

Folder:

Year:

Abstract:

A primer comprising an organometallic compound and an organic polymer, which is useful in bonding non-polar or highly crystalline resin substrates together or bonding said resin substrates and another material, such as a solid material, a coating material, paint or printing ink by using a 2-cyanoacrylate.

Type of document:

Language:

United States Patent [19]

Hiraiwa et al.

[54] METHOD OF BONDING NON-POLAR OR

HIGHLY CRYSTALLINE RESIN

SUBSTRATES EMPLOYING A PRIMER AND

A CY ANOACRYLATE ADHESIVE

[75] Inventors: Akihiko Hiraiwa; Kenji Ito; Kaoru

Kimura, all of Nagoya, Japan

Toagosei Chemical Industry Co., Ltd.,

Toyko, Japan

[21] Appl. No.: 78,403

[22] Filed: Jul. 27, 1987

[73] Assignee:

Related U.S. Application Data

[62] Division of Ser. No. 818,716, Jan. 14, 1986, abandoned.

[30] Foreign Application Priority Data

Jan. 18,1985 [JP] Japan .................................. .. 60-5936

Jan. 31, 1985 [JP] Japan ................................ .. 60-15486

[51] Int. Cl.4 .............................................. .. C09J 5/04

[52] U.S. Cl. ............................... .. 156/315; 156/331.2;

427/412.1; 427/412.3; 427/412.4; 427/412.5;

524/394

J 1

[11] Patent Number: 4,818,325

[45] Date of Patent: Apr. 4, 1989

[58] Field of Search ........................... .. 156/315, 331.2;

427/4121, 412.3, 412.4, 412.5; 524/394

[56] References Cited

U.S. PATENT DOCUMENTS

3,441,434 4/1969 Jezl ................................. .. 427/412.3

FOREIGN PATENT DOCUMENTS

52-76344 6/1977 Japan .............................. .. 156/331.2

53-57233 5/1978 Japan ................................. .. 156/315

Primary Exam1'ner—John J. Gallagher

Attomey, Agent, or Fz'rm—Cooper & Dunham

[57] ABSTRACI‘

A primer comprising an organometallic compound and

an organic polymer, which is useful in bonding non-

polar or highly crystalline resin substrates together or

bonding said resi.n substrates and another material, such

as a solid material, a coating material, paint or printing

ink by using a 2-cyanoacrylate.

32 Claims, No Drawings

4,818,325

1

METHOD OF BONDING NON-POLAR OR

HIGHLY CRYSTALLINE RESIN SUBSTRATES

EMPLOYING A PRINIER AND A

CYANOACRYLATE ADHESIVE

This is a division of application Ser. No. 818,716 filed

Jan. 14, 1986, now abandoned.

This invention relates to a primer which is used as

such in bonding non-polar or highly crystalline resin

substrates together or bonding other material thereto

with use of a 2-cyanoacrylate.

This invention has its object to provide a primer

satisfactorily useful in bonding together easily, speedily

and surely non-polar or highly crystalline resin sub-

strates or so bonding another material to the resin sub-

strate with use of a 2-cyanoacrylate, the resin substrates

having heretofore been considered as difficult to bond

together, bond the other material thereto, coat, paint

and print thereon and being typified by polyethylene,

polypropylene, polybutene, polyfluoroethylene, their

copolymer and other polyolefm substrates as well as

polyethylene terephthalate, polyacetal, nylon and soft

PVC (having a high content of a plasticizer) substrates.

This invention has its another object to solve the

problems that the primers earlier proposed by the pres-

ent inventors are unsatisfactory in operativeness and

must be severely controlled as to their film thickness to

prevent their performances or properties from being

degraded.

To render these substrates or materials improved in

adhesiveness, there has heretofore been proposed a

surface treating method which comprises subjecting the

substrates, for example polyethylene or polypropylene,

to flame treatment, corona discharge treatment, irradia-

tion treatment or oxidizing treatment with a bichro-

mate, sulfate or the like so as to produce polar groups

such“as a carbonyl group on the surface of the sub-

strates. In addition, to make a resin, such as polyfluoro-

ethylene, which is impossible to oxidize on the surface,

improved in adhesiveness, there has been proposed a

special chemical treatment such as lithium vapor treat-

ment, heating treatment with an alkali in a helium

stream or treatment of metallic sodium with liquid am-

monia.

However, the proposed method and treatments need

special equipments, are complicated to carry out, are

unable to uniformly treat every part of the surface of a

substrate having a complicated shape and require great

expenses, these being disadvantageous.

Various primers also have been proposed. For exam-

ple, Japanese Patent Appln. Laid-Open Gazettes Nos.

52-98062, 56-141328 and 57-119929 have proposed

primers prepared by dissolving a chlorinated polyethyl-

ene or chlorinated polypropylene or a fatty acid-modi-

fied acrylated alkyd resin in an organic acid.

According to Japanese Pat. Appln. Laid-Open Ga-

zette No. 58-8734, however, the primers so proposed

are unsatisfactory in adhesiveness to a paint although

they are satisfactory in adhesiveness to a polyolefm

substrate, or, even if the paint and the polyolefin are

satisfactory in adhesion to each other, the adhesiveness

there between will undesirably decrease due to repeti-

tion of the cold/hot cycle.

Japanese Pat. Appln. Laid-Open Gazettes Nos.

54-124048, 54-124049 and 54-124095 have proposed a

modified polyolefin prepared by incorporating solid

rubber, an unsaturated carboxylic acid or the derivative

l0

l5

20

25

30

35

45

50

55

65

2

thereof, and a radical generator in a polyolefm, how-

ever, according to Japanese Pat. Appln. Laid-Open

Gazette No. 57-38827, the modified polyolefin will have

undesirable effects on the adhesiveness of a paint

formed thereon since the unreacted unsaturated carbox-

ylic acid and the radical generator remain in the modi-

fied polyolefin.

Further, Japanese Pat. Appln. Laid-Open Gazettes

Nos. 54-124050, 55-34270 and 55-84271 have proposed

an improved resin composed essentially of a propyle-

ne/styrene/butadiene block copolymer and an inor-

ganic filler, however, the improved resin so proposed

seems to raise various problems as to poor weather-

proofness of unpainted parts and low-temperature fra-

gility due to the incorporation of the filler.

If non-polar or highly crystalline resins such as poly-

olefm can be improved in adhesiveness or they can

allow a coating, painting or print to be satisfactorily

formed on the surface thereof, they would be very

conductive to various fields such as the automobile

industry and electric appliance industry since they have

many merits such as excellent properties, light weight,

rust-proof and low cost as compared with metallic ma-

terial.

In attempts to develop a surface treating method

which is simple and speedy as compared with the con-

ventional methods, in view of the above-mentioned

situations, the present inventors made intensive studies

and, as the result of their studies, they developed de-

sired primers which enable satisfactory adhesion, coat-

ing, painting and printing.

The present inventors previously filed a U.S. patent

application Ser. No. 611,691 in which is disclosed a

primer comprising an organometallic compound as an

effective ingredient.

The primer disclosed in said earlier U.S. Application

have an extremely excellent function and can attain the

desired object, however, it has now been found that

when used, they will raise the following problems. '

The problems are that the primers so disclosed are

not suitable to be stored in aluminum tubes or glass

bottles because of being non-viscous particularly when

in the solution form and they need techniques to be

uniformly applied without sagging thereof, this indicat-

ing their inferiority in capability of application. As is

apparent from the specification of said U.S. Applica-

tion, since said primers vary in performances such as

bond strength depending on the thickness of the primer

to be applied, the performances such as bond strength

will not be stabilized if the thickness of the primer to be

applied is specifically limited; particularly thick primer

layers exhibit their brittleness, cannot be improved in

bond strength and may sometimes be even disadvanta-

geous as a primer layer because of being too thick. Such

inferiority in application operation as above will raise a

serious problem as to the practical use of the primers.

It has further been found that primers will often ex-

hibit different performances as such even though they

are prepared from the same materials, and they will

decrease in performances during their storage or use in

spite of the fact that they exhibit satisfactory perfor-

mances when they have been prepared, the above being

additional problems.

The present inventors made intensive studies in at-

tempts to solve the above-mentioned problems and, as

the result of their studies, accomplished this invention.

The primer of this invention comprises at least one

organometallic compound and at least one organic pol-

4,818,325

3

ymer and is used in bonding non-polar or highly crystal-

line resin substrates together or bonding another mate-

rial to the resin substrate with the use of a 2-cyanoacry-

late.

The expression “bonding another material to the resin

substrate with the use of a 2-cyanoacrylate” used herein

is intended to mean, for example, the use of a 2-cyanoa-

crylate in adhesion of a solid material such as a metal,

glass, a synthetic resin, rubber, leather, stone, cloth,

paper, wood or ceramics to the resin substrate or the use

thereof in coating or printing a resin substrate with a

coating material, paint or printing ink.

The organometallic compounds in which the organic

group is combined with a metal may be used in this

invention irrespective of the kind, structure and the like

thereof.

The organic groups contained in the organometallic

compounds include alkyl, cycloalkyl, haloalkyl, alke-

nyl, cycloalkenyl, alkoxy, cycloalkoxy, aryl, aralkyl,

aralkyloxy, acetylacetate, acyloxy and cycloalk-

enyloxy, aryloxy group, with C3 or higher hydrocarbon

groups being preferred. The metals contained in the

organometallic compounds in this invention are in-

tended to include typical metals, transition metals and

metalloids and further include phosphorus, boron and

silicon. The organometallic compounds are illustrated

by the following structural formulae.

(1) M-0-R (wherein M is a metallic element and R an

organic group; these defmitions apply to the following)

which shows metal alcoholates:

organoaluminum compounds such as aluminum iso-

propylate, aluminum mono-sec.-butoxydiisopropylate,

aluminum ethylacetoacetate diisopropylate, aluminum

oleylacetoacetate diisopropylate; organotitanium com-

pounds such as tetrabutyl titanate and tetraisopropyl

titanate; organoboron compounds such as tri-n-butyl

borate, triphenyl borate, tri-n-octadecyl borate and

monobutyldimethyl borate; phosphoric acid esters such

as trioleyl phosphate, tridecyl phosphate, dibutyl phos-

phite, trisisodecyl phosphite, di-2-ethylhexyl phosphite

and tridecyl phosphite; tetraoctyl silicate; triisobutox-

ygallium; and tetrabutyl zirconate.

(2)

which shows 1,3-dicarbonyl complexes:

complex salts of acetylacetonate such as aluminum

trisacetylacetonate, aluminum monoacetylacetonate

bisethylacetoacetate, aluminum trisethylacetoacetate;

acetylacetone lithium, acetylacetone beryllium, acetyl-

acetone sodium, acetylacetone magnesium, acetylace-

tone calcium, acetylacetone titanium, acetylacetone

strontium, acetylacetone barium, acetylacetone thal-

lium, acetylacetone vanadium, acetylacetone manga-

nese (III), acetylacetone iron (III), acetylacetone tho-

. rium, acetylacetone chromium (III), acetylacetone rho-

dium, acetylacetone cobalt (II), acetylacetone cobalt

(III), acetylacetone nickel, acetylacetone copper, ace-

tylacetone zinc, acetylacetone zirconium, acetylacetone

palladium, acetylacetone indium, acetylacetone tin (IV)

and acetylacetone molybdenum; complex salt of aceto-

10

15

20

25

30

35

45

50

55

65

4

acetic acid ester, trifluoroacetylacetone and benzoy-

lacetone.

(3)

M—O—fi.—R

which shows carboxylates:

magnesium stearate, aluminum stearate, calcium stea-

rate, ferric stearate, zinc stearate, barium stearate, lead

stearate, potassium stearate, copper stearate, manganese

stearate, nickel stearate, nickel naphthenate, cobalt

naphthenate, manganese naphthenate, magnesium naph-

thenate, zinc naphthenate, magnesium palrnitate, cad-

mium palmitate, cobalt palmitate, sodium linoleate,

sodium laurate, barium oleate, aluminum laurate, alumi-

num oleate, potassium oleate, aluminum acetate, stan-

nous acetate, staxmous 2-ethylhexanoate, aluminum

formoacetate, zinc tartrate and basic aluminum thiodi-

glycolate.

(4) M-R which shows hydrocarbon group-containing

metals:

alkyl metals such as zinc 2-ethylhexyl, lithium hexa-

decyl, sodium n-hexyl, potassium hexadecyl, aluminum

n-trioctyl, lead n-propylethyl, antimony tri-n-pentyl,

antimony tri-n-decyl and zinc isobutylisoamyl; organo-

tin compounds such as dibutyl tin diacetate, di-n-butyl

tin dimaleate, di-n-butyl tin dioxide, triphenyl tin ace-

tate, tri-n-butyl tin oxide, dioctyl tin dilaurate, tributyl

tin acetate, tributyl tin chloride, tin tetraamyl and dial-

lyl tin dichloride; methylvinyldichlorosilane; octadecyl-

dimethyl[3(trimethoxysilyl)propyl]ammonium chlo-

ride; ferrocene; titanocene dichloride; and nickelocene.

(5) M-X-R (where X is a hetero atom) shows other

organometallic compounds:

metal thioalcoholates such as n-dodecylmercap-

topotassium salt and aluminum trithiobutoxide; thi-

odicarboxylates such as tin 2-ethylhexanemonothioate

and zinc 2-ethylhexanedithioate; dithiocarbamates such

as nickel dimethyldithiocarbamate, copper dimethyldi-

thiocarbamate, iron dimethyldithiocarbamate and zinc

diethyldithiocarbamate; sulfonic acids such as nickel

benzenesulfonate; phosphates such as vanadium dibu-

tylphosphate; and zinc mercaptobenzothiazole.

Among these organometallic compounds, the carbox-

ylates (3) and the hydrocarbon group-containing metals

(4) are preferred, and the metal alcoholates (1) and the

1,3-dicarbonyl complex salts (2) are more preferred.

More particularly, the preferred organometallic com-

pounds include acetylacetone lithium, acetylacetone

sodium, acetylacetone magnesium, acetylacetone tita-

nium, acetylacetone iron (III), acetylacetone palladium,

acetylacetone indium, tri-n-octadecyl borate, sodium

linoleate, magnesium stearate, aluminum stearate, alu-

minum acetate, aluminum laurate, basic _a1uminum thi-

odiglycolate, calcium stearate, ferric stearate, ferro-

cene, copper dimethyldithiocarbamate, zinc stearate,

zinc 2-ethylhexyl, zinc tartrate, stannous acetate, di-n-

butyl tin maleate, di-n-butyl tin oxide, triphenyl tin

acetate, barium stearate, lead stearate, dibutyl phos-

phite, tridecyl phosphate and trioleyl phosphate. The

more preferred organometallic compounds include ace-

tylacetone calcium, acetylacetone zinc, potassium ole-

ate, nickel naphthenate and dioctyl tin dilaurate. The

most preferred organometallic compounds include alu-

minum isopropylate, aluminum mono-sec.-butoxydiiso-

proylate, aluminum ethylacetoacetate diisopropylate,

4,818,325

5

aluminum oleylacetoacetate diisopropylate, aluminum

trisacetylacetonate, aluminum monoacetylacetonate

bisethylacetoacetate, aluminum trisethylacetoacetate,

acetylacetone manganese (III), acetylacetone cobalt

(II), acetylacetone nickel, acetylacetpne zinc, acetylac-

etone zirconium, tetrabutyl titanate, tetraisopropyl tita-

nate, dibutyl tin diacetate, tri-n-butyl tin oxide, tin 2-

ethylhexanoate, octadecyldimethyl[3(trimethoxysilyl)-

propyl]ammonium chloride and trisisodecyl phosphite.

The organic polymers used in- this invention may be

those generally known in the art. It is preferable, how-

ever, that they be soluble in organic solvents since the

primers of this invention are used preferably in the

dispersion or solution form.

The organic polymers used herein include olefinic

copolymers such as ethylene/vinyl acetate copolymers,

ethylene/acrylic acid ester copolymers and a-olefin/-

maleic acid copolymers; chlorinated olefmic polymers

such as chlorinated polyethylene, chlorinated polypro-

pylene, chlorinated ethylene/propylene copolymers

and chlorinated ethylene/vinyl acetate copolymers;

vinylic polymers such as polyvinyl chloride, polyvinyl

acetate, poly(meth)acrylic acid ester, polyvinyl ethers

and vinyl chloride/vinylidene chloride copolymers;

and synthetic rubbers such as polychloroprene, NBR,

SBR and chlorinated rubbers.

Of the above-mentioned various organic polymer,

those which are preferred for attaining the objects of

this invention are chlorinated olefinic polymers pre-

pared by chlorination of propylene, ethylene or the like

polymers or copolymers; chlorinated rubbers; olefinic

copolymers such as copolymers of propylene, ethylene

or the like; and methyl methacrylate/chloroprene co-

polymers with chlorinated polypropylene and methyl

methacrylate/chloroprene copolymers being particu-

larly preferred.

The primer gf this invention is used for coating on a

non-polar or highly crystalline resin substrates in bond-

ing the resin substrates together or bonding another

material thereto with use of a 2-cyanoacrylate. In this

case, it is desired to control the thickness of the organo-

metallic compounds coated so that the full effects of this

invention are attained as described later. For this pur-

pose, it is preferred that the compounds be used in solu-

tion.

The solvents used herein are preferably a usual one

which is capable of completely dissolving or dispersing

the organometallic compound and organic polymer

therein, has suitable volatility and is industrially easily

available. The solvents are also preferably such that a

resin, such as polyolefin, can be fully wetted on the

surface therewith, in order to allow the primers to exer-

cise their performance more efficiently. For this pur-

pose, it is further preferable to selectively use an or-

ganic solvent which has a surface tension lower than the

critical surface tension (')'c) of the resin. The following

Table 1 indicates the surface tension and the critical

surface tension of typical solvents to help one skilled in

the art in selecting a solvent to be used.

TABLE I

Critical surface tension

(ye) of resin

(dyne/cm. 20° C.)

Surface tension of

organic solvent

(dyne/cm. 20° C.)

Polytrifluoroethylene 22 1, l,2-trichloro- l,2,2- 19

tiitluoroethane

Polyethylene 3 l Ethanol 22

Polypropylene 3 l Acetone 23

Polyacetal 4-0 Ethyl acetate 24

5

10

15

20

25

30

35

45

50

55

65

6

TABLE I-continued

Critical surface tension

(yo) of resin

(dyne/cm. 20° C.)

Surface tension of

organic solvent

(dyne/cm. 20° C.)

Polyvinylidene chloride 40 1,1,1-trichloroethane 26

Polyethylene terephthalate 43 Tetrahydrofuran 2

6-6 nylon 46 lkdioxane 27

Toluene 28

It is preferable that the organometallic compound in

solution be in a concentration by weight of 0.001-10%

for the reason that the organometallic compound may

be coated to nearly thickness of monomolecular layer

thereof whereby the compound can exhibit its best per-

formance as described later.

The concentration of organic polymer used will vary

depending on the kind of the polymer and is preferably

in the range of 0.1-20% by weight. If the concentration

used is less than 0.1% by weight then it will be difficult

to attain the objects of this invention, whereas the use of

a concentration of more than 20% by weight will hin-

der the action of the organometallic compound, which

plays a principal part as a primer, whereupon the primer

decreases in performance as such. Further, it is pre-

ferred that the amount of kind of the organic polymers

contained in a primer be determined so that when the

primer is made to be a primer solution, the primer solu-

tion will have a viscosity in the range of 2-5000 cp at

25° C. It will be difficult to attain the objects of this

invention when the viscosity of primer solution used is

outside of said range. In addition, when the primer is

used in the solution form, it is possible to add to the

primer solution a small amount of a viscosity improver

such as fused silica in order to use the solution as a

thixotropic one.

It has been found by the present inventors that the

variation of the primer of this invention in quality and

properties as well as the degradation thereof in quality

during its use or storage, is caused by the presence of

water in the primer and that it is desirable to limit the

water content of the primer to a certain amount, that is,

500 ppm or less in order to solve one of the above-men-

tioned problems.

To limit the water content of the primer to within 500

ppm, it is desired to limit not only the water contents of

the organometallic compound and organic polymer as

the ingredients of the primer but also the water content

of an organic solvent used together with said ingredi-

ents if necessary. .

It is also desired to prepare a primer from the above

ingredients in a dehumidified chamber or using 2. mois-

ture-preventing apparatus.

The primer will absorb moisture from air during its

use or storage even if it is free of water just after it has

been prepared. The primer will further absorb moisture

for a‘ long period of time to an extent that the water

content of the primer exceeds 500 ppm, whereby the

primer lowers in primer performance. Thus, it is desir-

able that the primer be treated so that its water content

does not exceed 500 ppm even a long time after its

preparation.

To prevent the primer from absorbing moisture dur-

ing the storage thereof, the primer may be stored in

glass- or metal-made containers as well as in nonperme-

able material-made containers such as plastics-made

containers having a polyvinylidene chloride layer.

However, it is unavoidable that the primer will absorb

4,818,325

7

moisture during its use, and it is undesirable that the

containers for the primer are limited to specific ones.

Therefore, it is preferable to prevent the water content

in the primer from exceeding 500 ppm by moisture

absorption.

To this end, a desiccating agent or an adsorbent may

be housed in a space within a container or under the lid

thereof, the space being so defined as to prevent contact

of the primer with the desiccating agent or adsorbent. A

simple method for limiting the water content in the

primer, comprises allowing a solid desiccating agent or

adsorbent to coexist with the primer thereby rendering

it possible to remove the water absorbed or the water

derived from the ingredients of which the primer is

composed and keep the water content in the primer at a

level of not more than 500 ppm.

The desiccating agents used herein include various

kinds of desiccating agents such as phosphorus pentox-

ide, activated alumina, anhydrous calcium sulfate, mag-

nesium oxide, calcium oxide, calcium chloride, magne-

sium sulfate, diatomaceous earth, anhydrous zinc chlo-

ride, anhydrous copper (III) sulfate, silica gel and silica

alumina. The adsorbents used herein include molecular

sieve and activated carbon. The desiccating agents or

adsorbents which are allowed to exist in the primer, are

preferably those which meet the following require-

ments:

(1) They are solid materials,

(2) They are neutral or nearly neutral,

(3) They do not react with the primer,

(4) They are not dissolved in the primer, and

(5) They do not hinder the primer performance or activ-

ity of the primer.

Thus, they include activated alumina, magnesium

oxide, magnesium sulfate, diatomaceous earth, silica

aluminum with silica gel and molecular sieves being

morepreferable

The desiccating agents and adsorbents to be added to

‘the primer are preferably particulate in shape and the

particle size thereof is preferably in the range of about

0.5-10 m. If they have a particle size of smaller than

0.5 mm then they will run out of the primer and be

attached to the surface to be coated during the use of

the primer, whereas if they have too large a particle size

then they will come to be large in volume and unsuit-

able in shape as merchandise. The amount of such desic-

cating agents or adsorbents used may be determined

taking into consideration the expected amount of mois-

ture to be adsorbed and the capability of the agents or

adsorbents to absorb moisture.

The 2-cyanoacrylate used -in this invention is repre-

sented by the following general formula

CN

/

CI-I2=C

COOR

wherein R.is alkyl, alkenyl, cycloalkyl, aryl, alkoxyal-

kyl, aralkyl, haloalkyl or the like and more particularly

it is illustrated by methyl, ethyl, n-propyl, n-butyl, iso-

butyl, n-pentyl, allyl, cyclohexyl, benzyl or methoxy-

propyl.

The 2-cyanoacrylates used herein are the main com-

ponent of commercially available cyanoacrylate-based

instant adhesives which may be used as they are as the

2-cyanoacrylate in this invention.

10

15

20

25

30

35

45

50

55

65

8

The commercially available cyanoacrylate-based

adhesives are composed mainly of a 2-cyanoacrylate

and may be further incorporated with various ingredi-

ents as illustrated below:

(1) Stabilizer

(2) Thickener

(3) Modifier

(4) Dyestuff

The stabilizer is for enhancing the storage stability of

the cyanoacrylate-based adhesives and is illustrated by

sulfur dioxide, an aromatic sulfonic acid or a sultone as

an anion polymerization inhibitor and by hydroquinone

or hydroquinone monomethyl ether as a radical poly-

merization inhibitor.

The thickener used herein is for increasing the viscos-

ity of the cyanoacrylate-based adhesives to several ten

to several thousand cp since usually a 2-cyanoacrylate is

a low viscous liquid having a viscosity of about several

op. The thickener used herein includes a polymethyl-

methacrylate, acryl rubber or cellulose derivative.

The modifier used herein is for improving the impact

resistance or heat resistance which are drawbacks of

conventional cyanoacrylate-based adhesives and is illus-

trated by maleic anhydride or a derivative thereof as an

improver of heat resistance as indicated in Japanese Pat.

Appln. Gazette No.52-12737. To enable a porous and

acidic sap-containing woody material which has hereto-

fore been considered difficult to bond, to be bonded,

crown compounds and the like may be used as indicated

in, for example, Japanese Pat. Appln. Publication Ga-

zette No. 55-2238.

Further, to provide a flexible adhesive layer, the

original adhesive may be incorporated with a plasticizer

such as tricresyl phsphate, dioctyl phthalate or dimethyl

sebacate.

The dyestuff used herein is for, for example, render-

ing a bonded portion easily identifiable, the original

adhesive may be incorporated with, for instance, an

acidic salt of basic dye as indicated in Japanese Pat.

Appln. Laid-Open Gazette No. 53-37260 or the like.

Furthermore, the original adhesive may further be

incorporated with a perfume such as an ester derivative

as indicated in Pat. Appln. Laid-Open Gazette No.

53-58541 or the like, in order to provide the adhesive

with fragrance.

In the practice of this ‘invention, the 2-cyanoacrylate

-may be used in the form of a diluted solution in a spe-

cific organic solvent. The organic solvent should be

such that it is compatible with the 2-cyanoacrylate and

does not impair the stability thereof, and it includes

toluene, butyl acetate or methylchloroform. It is pre-

ferred that the organic solvent contains none of mois-

ture and other impurities.

In a case where two substrates to be bonded together

are each a non-polar or highly crystalline resin, coating

of the organometallic compound may be effected by

immersing the both of the substrate in a solution of the

primer for several seconds or coating it with the solu-

tion of the use of a brush or spray gun and then air

drying, while in a case where one of substrates to be

bonded together is a non-polar or highly crystalline

resin, the substrate may be treated only in the same

manner as above. '

The primer coated non-polar or highly crystalline

resin substrates together or another material and the

substrate are bonded using the 2-cyanoacrylate by a

usual means, thus obtaining a bonded body having very

excellent bond strength.

4,818,325

9

In the coating method of the primer, there may also

be used a method which comprises ejecting a 2-cyanoa-

crylate and a solution of the organometallic compound

simultaneously by the use of spray gun having two

nozzles.

In a process for forming a coating, painting or print-

ing on a non-polar or highly crystalline resin substrate,

the primer is coated on the resin substrate by the above-

mentioned coating method, and then a 2-cyanoacrylate

is coated and polymerized to form a polymer film

thereof, thus producing a resin substrate having satisfac-

tory receptivity and bond strength to coating materials,

paints and printing ink. The thus produced resin sub-

strates may be coated or printed by a conventional

means to form an excellent coating, painting and print-

ing thereon.

In the coating steps the following steps will show

more excellent effects in coatings.

In a first step, a primer prepared by dissolving the

organometallic compound and organic polymer in an

organic solvent, is coated on a substrate on which a

coating, painting or printing is to be formed by an im-

mersing or spraying method and being laid usually 5-60

minutes at room temperature or several days depending

on the operational steps taken.

In a second step, the 2-cyanoacrylate is coated on the

primer-coated substrate to form a poly-2-cyanoacrylate

film, by a coating method using a preliminarily acid-

treated brush, an immersing method, a spraying

method, or the like. In a case where the spraying

method is used, it is preferred to use a diluted solution of

l0

15

20

25

30

a 2-cyanoacrylate in an organic solvent in order to pre-

vent the nozzles of spray gun from being clogged.

In addition, in a case where a commercially available

cyanoacrylate-based adhesive is used, it is preferable to

choose the low viscosity one.

The substrateon which the 2-cyanoacrylate has been

coated is allowed to stand at room temperature for at

least 12 hours to form a poly-2-cyanoacrylate film.

The poly-2-cyanoacrylate film is not particularly

limited in thickness, but it is preferable that the thick-

ness be in the range of 0.l—lO01.L, preferably 10-50;; to

eliminate defective coated portions.

The substrate on which the primer and a 2-cyanoa-

crylate have been coated as indicated above, is then

coated with a usual coating material, painted with a

paint or printed with a usual printing ink.

There are various kinds of coating materials, paints or

printing inks which may be classified in various ways,

however, they may be enumerated from the view-point

of the kind of vehicle resin used, as follows:

rosin derivatives, nitrocellulose resins, vinylic resins,

acrylic resins, polyester resins, polyamide resins, poly-

urethane resins, phenolic resins, epoxy resins, ami-

noalkyd resins, melamine resins and UV-curable acryl

oligomers.

From the view-point of use, particularly preferred

coating materials, paints or printing inks for use in ap-

plying to a polyolefin substrate are those containing a

polyurethane resin, an epoxy resin, or an alkyd resin.

As to thermosetting coating materials, those which

may be cured at a baking temperature of not higher than

90° C. are preferred.

A coating material or a paint may be applied by a

usual method such as a coating method using a brush, a

bar coater, a roller coater or a spray gun, while a print-

ing ink may be. applied by a usual method such as a silk

35

45

50

55

65

10

screen printing method, a gravure printing method or a

flexographic printing method.

It is not clear why the adhesiveness of a non-polar or

highly crystalline resin to another material is improved

by using the organometallic compound of this invention

as the primer and the 2-cyanoacrylate, however, the

organometallic compounds will exhibit their best

primer performance when they are very thinly coated

to an extent that the amount thereof coated reaches

0.001 to 1 g/m2 although the optimum thickness varies

depending on the kind of the organometallic compound

used.

Bonding tests were made by using a polypropylene

plate (2 mm thick) as the resin substrate, acetylacetone

zirconium (used as solutions of various concentrations

in methylchloroform) as the primer, and a 2-cyanoacry-

late-based adhesive (produced under the tradename of

Aron Alpha No. 201 by Toagosei Chemical Industrial

Co., Ltd.), to obtain bonded products which were mea-

sured for tensile shear strength at the bonded portion.

The following Table A indicates the differences in ten-

sile shear strength due to the differences in amount of

the primer coated. The bonded products were aged at

23° C. under a relative humidity (RH) of 60% for one

day.

TABLE A

Amount of Tensile shear

Cone. of primer primer coated strength

(wt. %) (g/m2) (kgf/cmz)

5 0.5-2.5 3

3 0.3-1.5 10

1 0.1-0.5 15

0.5 0.05-0.25 36

0.25 0.025—O.l25 55*

0.05 0005-0025 60*

0.025 00025-00125 27

0.01 0.001—0.005 11

0.001 0.0001-0.0005 3

Note:

The symbol, ‘, indicates the destruction of plate.

It is seen from the results in Table A that the primer

will exhibit its best performance when it is coated in

nearly the thickness of its monomolecular layer. From

the above results and the fact that the organometallic

compounds have a polar segment and non-polar seg-

ment in structure, it is surmised that the effects of this

invention are produced under the following mecha-

msm. —

The organometallic compound, that is, the primer ‘of

this invention is present in approximately the monomo-

lecular layer between the surface of the non-polar or

highly crystalline resin substrate and the 2-cyanoacry-

late layer (monomer or polymer film layer) whereby the

groups highly compatible with the 2-cyanoacrylate

layer, in other words, the lipophilic groups and the

polar groups are arranged in order and these groups act

as a bonding agent to obtain the effects of this invention.

To obtain the best results in accordance with this

invention, it is necessary to determine an organometal-

lic compound and organic polymer to be used, the con-

centration of the compound, the amount thereof ap-

plied, and the like in view of the nature of the organo-

metallic compound, the organic polymer, a substrate

and a material to be bonded thereto. As to the amount

of the organometallic compound (primer) applied, the

use of the primer in such a small amount that the result-

ing primer layer does not cover all the surface of the

substrate which is needed, will naturally not give good

4,818,325

11

results, whereas the use thereof in such a large amount

that the resulting primer layer is thicker than the mono-

molecular layer, will result in forming a fragile primer

layer whereby the results of this invention are not ob-

tained. Thus, the concentration of an organometallic

compound in solution (primer solution) is preferably

0.001-10% by weight and the amount of the primer

coated is in the-range of preferably 0.00l—l g/m2, more

preferably 0.0l—0.l g/m3.

A secure bond is effected between a non-polar or

highly crystalline resin substrate and a 2-cyanoacrylate

with aid of the organometallic compound present there-

between whereby the resin substrate is much improved

in adhesiveness and, further, a usual coating material or

printing ink can easily be applied to the treated resin

substrate without causing any problems owing to the

presence of a poly-2-cyanoacrylate film formed

thereon.

The excellent effects obtained by the practice of this

invention are those which may be attained by the com-

bined use of the 2-cyanoacrylate, organometallic com-

pound and non-polar or highly crystalline resin sub-

strate. On the other hand, in cases where a bond is

attempted to be effected between polyolefin (such as

polyethylene) and something, an organotitanium com-

pound was once studied to fmd whether it is useful as a

primer or preliminary treatment; in these cases, how-

ever, excellent effects were not appreciated since an

epoxy, urethane, rubber or acrylic adhesive was used.

These conventional means do not anticipate at all the

present invention which will unexpectedly excellent

effects when practiced.

The effects of this invention will be exhibited only

when a non-polar or highly crystalline resin is used as

the substrate, whereas they will not be exhibited when

other materials (such as a metal, wood or porcelain) are

used as the substrate.

TE: primerzof this invention is effective for a non-

polar or highly crystalline resin such as olefinic poly-

mers typified by polyethylene, polypropylene, polybu-

tene and polymethylpentene; composite materials com-

posed of the olefinic polymers incorporated with talc,

alumina, mica, glass fibers and the like; polyethylene

terephthalate; polyacetal; polyurethane; silicone rub-

bers; and soft-type PVC (polyvinyl chloride). It is for

olefmic polymers such as polyethylene and polypropyl-

ene that the primer of this invention is the most effec-

tive.

This invention will be better understood by the fol-

lowing Examples and Comparative Examples wherein

all parts and percentages are by weight unless otherwise

specified.

EXAMPLE 1

0.5 parts of Manganese (III) acetylacetonate and 2

parts of chlorinated polypropylene (produced under the

tradename of SUPERCHLON l06H by Sanyo

Kokusaku Pulp Co., Ltd.) were dissolved in 97.5 parts

of toluene to obtain a primer. In accordance with JIS

10

20

25

30

35

45

50

55

12

K6861-1977, the thus obtained primer was applied to

polypropylene resin-made test pieces (25X l0O>

Coments go here:

- Log in to post comments