Curable Compositions

Folder:

Year:

Abstract:

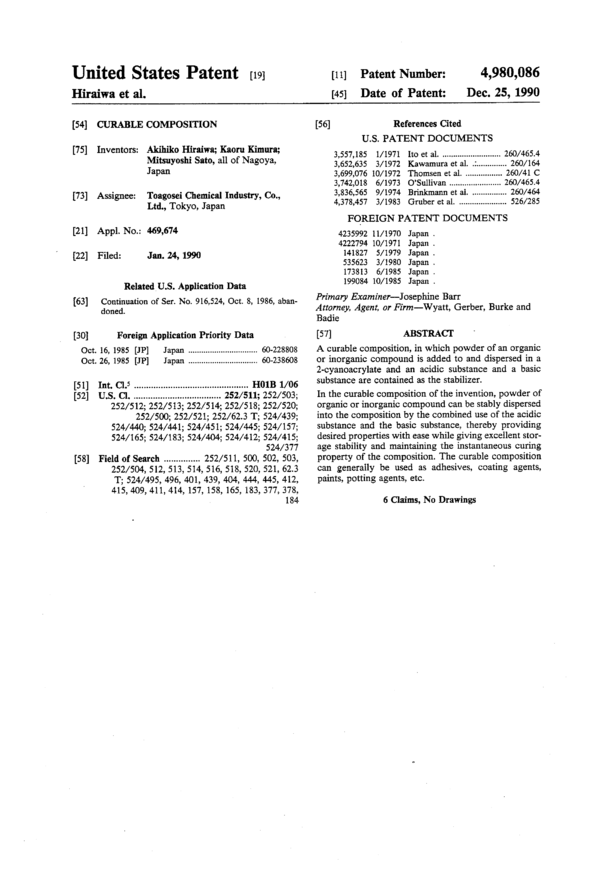

A curable composition, in which powder of an organic or inorganic compound is added to and dispersed in a 2-cyanoacrylate and an acidic substance and a basic substance are contained as the stabilizer. In the curable composition of the invention, powder of organic or inorganic compound can be stably dispersed into the composition by the combined use of the acidic substance and the basic substance, thereby providing desired properties with ease while giving excellent storage stability and maintaing the instantaneous curing property of the composition. The curable composition can genereally be used as adhesive, coating agents, paints, potting agents, etc.

Type of document:

Language:

United States Patent [191

Hiraiwa et al.

[54] CURABLE COMPOSITION

[75] Inventors: Akihiko Hiraiwa; Kaoru Kimura;

Mitsuyoshi Sato, all of Nagoya,

Japan

[73] Assignee: Toagosei Chemical Industry, Co.,

Ltd., Tokyo, Japan

[21] Appl. No.: 469,674

[22] Filed: Jan. 24, 1990

Related_U.S. Application Data

[63] Continuation of Ser. No. 916,524, Oct. 8, 1986, aban-

doned.

[30] Foreign Application Priority Data

Oct. 16, 1985 [JP] Japan .............................. .. 60-228808

Oct. 26, 1985 [JP] Japan .............................. .. 60-238608

[51] Int. Cl.5 ............................................. .. H01B 1/06

[52] U.S. Cl. .................................. .. 252/511; 252/503;

252/512; 252/513; 252/514; 252/518; 252/520;

252/500; 252/521; 252/62.3 T; 524/439;

524/440; 524/441; 524/451; 524/445; 524/157;

524/165; 524/183; 524/404; 524/412; 524/415;

524/377

[58] Field of Search ............. .. 252/511, 500, 502, 503,

252/504, 512, 513, 514, 516, 518, 520, 521, 62.3

T; 524/495, 496, 401, 439, 404, 444, 445, 412,

415, 409, 411, 414, 157, 158, 165, 183, 377, 378,

184

[11] Patent Number: 4,980,086

[45] Date of Patent: Dec. 25, 1990

[56] References Cited

U.S. PATENT DOCUMENTS

3,557,185 1/1971 Ito et a1. ....... .. 260/465.4

3,652,635 3/1972 Kawamura et a . 260/164

3,699,076 10/1972 Thomsen et al. .. 260/41 C

3,742,018 6/1973 O’Su1livan ....... .. 260/465.4

3,836,565 9/1974 Brinkmann et al. 260/464

4,378,457 3/1983 Gruber et al. .................... .. 526/285

FOREIGN PATENT DOCUMENTS

4235992 11/1970 Japan .

4222794 10/1971 Japan .

141827 5/1979 Japan.

535623 3/1980 Japan .

173813 6/1985 Japan .

199084 10/1985 Japan .

Primary Examiner—Josephine Barr

Attorney, Agent, or F1'rm—Wyatt, Gerber, Burke and

Badie

[57] ABSTRACT

A curable composition, in which powder of an organic

or inorganic compound is added to and dispersed in a

2-cyanoacrylate and an acidic substance and a basic

substance are contained as the stabilizer.

In the curable composition of the invention, powder of

organic or inorganic compound can be stably dispersed

into the composition by the combined use of the acidic

substance and the basic substance, thereby providing

desired properties with ease while giving excellent stor-

age stability and maintaining the instantaneous curing

property of the composition. The curable composition

can generally be used as adhesives, coating agents,

paints, potting agents, etc.

6 Claims, No Drawings

4,980,086

1

CURABLE COMPOSITION

This is a continuation of 06/916,524 filed Oct. 8, 1986,

now abandoned.

BACKGROUND OF THE INVENTION

1. Field of the Invention

This invention relates curable compositions and,

more specifically, compositions containing 2-cyanoa—

crylic acid esters which are main ingredients of 2-

cyanoacrylic ester type instant curing adhesives utilized

broadly for bonding, repairing and covering of prod-

ucts in various field of industries. Curable composition

can be utilized in those fields of industries where such

instant adhesives have been used broadly, as well as in

beauty parlor or like other service area and further in

home uses.

2. Description of Related Art Including Information

Disclosed under 1.97—1.99

Upon contact with the moisture in the atmosphere or

a trace quantity of water adsorbed to the surface of a

material to be coated with adhesives, 2-cyanoacrylic

acid esters rapidly polymerize to cure and show excel-

lent adhesive performance under ambient temperature

and, accordingly, they have been widely used for in-

stant adhesiveness for the bonding of plastic, rubber,

glass and metal.

Meanwhile, various attempts have been made for the

addition of powdered organic or inorganic compounds

in order to improve the properties of curing products of

2-cyanoacrylic acid esters to increase the number of

uses of adhesives and also of paints and coating or pot-

ting agents by utilizing the above-mentioned properties

of 2-cyanoacrylic acid ester.

For instance, it has been attempted to utilize the in-

stant curing property of 2-cyanoacrylic acid esters as

electroconductive adhesives, or as substitutes for sol-

dering and electroconductive paints for use in the fixing

of lead wires to contacts, manufacturing of circuits or

painting for electromagnetic wave shields in electronic

or electrical industries by the addition of electrocon-

ductive powder to 2-cyanoacrylic acid ester.

Further, attempts have been made to add a pigment-

ing agent, for coloration, to 2-cyanoacrylic acid ester to

facilitate the identification of various kinds of adhesives

thereby preventing errors in coating them and, further,

utilize them as paints and, particularly, rapid curing

paint (refer to Japanese Patent Publication No. Sho

46-35250, Japanese Patent Laid-Open No. Sho 52-65531

and Japanese Patent Publication No. Sho 55-11685).

Furthermore, it has also been tried to add various

kinds of powders of high polymers or inorganic com-

pounds in order to improve the peeling-strength and

impact shocks which are important as the properties of

the adhesives (refer to Japanese Patent Laid-Open No.

Sho 60-19908-1»).

However, the instantaneous curing property of 2-

cyanoacrylate esters improves as the purity and such

improves instantaneous curability is reduced as addi-

tives are added. Further, the storage stability often

becomes poor. Accordingly, it has been extremely diffi-

cult and rarely successful to improve the properties of

2-cyanoacrylic acid ester by adding additives.

While on the other hand, various kinds of stabilizers

have been studied for providing satisfactory storage

stability without damaging the instantaneous curability

of 2-cyanoacrylic acid ester. For such stabilizers, there

10

15

20

25

30

35

45

50

55'

65

2

have been proposed, for example, acidic gases such as

S02, NO and HF or solid acids such as phosphor pen-

toxide, antimony pentoxide, picric acid and ferric chlo-

ride (refer to U.S. Pat. Nos. 2,467,926, 2,467,927,

2,721,858, 2,756,251, 2,763,677, 2,765,332 and

2,794,788), phosphor pentoxide, acetic acid, acrylic

acid, methacrylic acid, itaconic acid, SnC14, complex

salts of boron trifluoride with ether, carboxylic acids,

ketones and other similar oxygen atom-containing com-

pounds, ferric chloride and other Lewis acids (refer to

U.S. Pat. Nos. 2,912,454 and 2,926,188), anhydrous

sulfuric acid or benzene sulfmic acid (Japanese Patent

Publication No. Sho 45-2010), sulfuryl chloride (Japa-

nese Patent Publication No. Sho 45-35291), sultone

(Japanese Patent Publication No. Sho 45-41520,

47-50213), aromatic sulfonic acid (Japanese Patent Pub-

lication Nos. Sho 46-13729, 48-10379, British Patent No.

1301645 and U.S. Pat. No. 3,652,635), non-volatile acid

with pKa less than 3 (Japanese Patent Publication No.

Sho 46-37278), combination of aromatic sulfonic acid

with acidic gas such as S02, NO and HF (Japanese

Patent Publication Nos. Sho 48-13334 and 48-16904),

boron trifluoride——pheno1 complex salt, boron tri-

fluoride—carboxylic acid complex salt, boron trifluo-

ride—-ether complex salt (Japanese Patent Publication

No. Sho 56-52949), trichloro acetic acid (Japanese Pa-

tent Laid-Open No. Sho 49-31619), oxonium com-

pounds and phosphonium compounds (Japanese Patent

Publication No. Sho 56-53593), etc. as well as various

other compounds.

The present inventors have made various studies of

stabilizers, including those as described above, capable

of attaining satisfactory storage stability of curable com-

positions, in which organic or inorganic powder is

added and dispersed in order to improve the properties

of 2-cyanoacrylic acid esters, without damaging the

instantaneous curability thereof and have accomplished

this invention based on the findings that the foregoing

purpose can be attained by the combination of specific

stabilizers, that is, by the combined use of an acidic

substance and a basic substance as the stabilizer.

SUMMARY OF THE INVENTION

The foregoing object can be attained in accordance

with this invention by a curable composition in which a

powder of an organic or inorganic compound is added

and dispersed in 2-cyanoacrylic acid ester and an acidic

substance and a basic substance are contained as a stabi-

lizer.

DETAILED DESCRIPTION OF THE

INVENTION

2-cyanoacrylic acid ester

2-cyanoacrylic acid esters (hereinafter referred to as

2-cyanoacrylate) used in this invention are used as the

main ingredient for cyanoacrylate type adhesives which

have been generally used as rapidly or instantaneous

curing adhesives (hereinafter referred to as instant adhe-

sives).

“The 2-cyanoacrylates useful in this invention” in-

clude the following esters which can be used alone or in

combinations containing two or more methyl, ethyl,

chloroethyl, n-propyl, i-propyl, allyl, propargyl, n-

butyl, i-butyl t-butyl, n-pentyl, n-hexyl, cyclohexyl,

phenyl, tetrahydrofurfuryl, heptyl, 2-ethylhexyl, n-

octyl, nonyl, oxononyl, decyl, n-dodecyl, ethoxyethyl,

4,980,086

3

3-methoxybutyl, ethoxyethoxyethyl,

hexafluoroisopropyl and the like.

trifluoroethyl,

Powder of organic or inorganic compounds

The powder of organic or inorga.nic compounds 5

added and dispersed for improving the properties of

2—cyanoacrylate can include, for example, electrocon-

ductive powder, pigment powder, heat conductive

powder, flame retardant powder, high polymer powder

and like other additive powder, and they specifically

include the types of compounds mentioned below. The

powder may be in the form of particulates, filaments,

whiskers and the like.

10

Electroconductive powder 15

Electroconductive powders of various compounds of

silver, copper, nickel, aluminum, gold, palladium, plati-

num, ruthenium and graphite, as well as composite

powder containing them can be employed.

For improving the 2—cyanoacrylate with the electro-

conductive powders, it is desired that the amount of

powder be from 10 to 400 parts by weight and, more

preferably, from 100 to 300 parts by weight based on

100 parts by weight of 2—cyanoacrylate. If the ratio

exceeds 400 parts by weight, the storage stability and

the bonding strength of the composition may be re-

duced to impair the bonding performance. While on the

other hand, insufficient electroconductivity can be at-

tained with less than 10 parts by weight.

20

25

30

Pigment powder

The pigment powder can include those employed

generally as pigments. These include inorganic pig-

ments, for example, powder of titanium oxide, zinc

powder, lithopone, white lead, cadmium yellow, yellow

lead, chrome vermilion, Chrome Orange, loess, amber,

red iron oxide, yellow iron oxide, cadmium red, red

lead, prussian blue, ultramarine, cobalt blue, chromium

oxide, carbon black and iron black; as well as organic

pigments for example, Benzidine Yellow, Hanza Yellow

G, Permanent Red 4G, Para Red, Phthalocyanine Blue,

Aniline Black, Permanent Yellow HR, Violet BL,

quinacridone and Fast Orange GRL, lake pigments, for

example, Alizarine Lake, Pigment Scarlet, Brilliant

Carmine 6B, Permanent Red FSR, Laked C, Rhoda-

mine Lake B, Rhodamine Lake Y, Peacock Blue Lake,

red No. 3 aluminum lake, yellow No. 5 aluminum lake,

and blue No. 2 aluminum lake.

For pigmenting the 2—cyanoacrylate, it is desirable to

add the above-mentioned powder in a.n amount from

0.001 to 30% by weight, preferably, from 0.05 to 5% by

weight in the composition. If the addition amount ex-

ceeds 30% by weight, the storage stability and the

strength after curing may be reduced. While on the

other hand, the pigmentation of the composition is in-

sufficient if the amount is less than 0.001% by weight.

35

45

50

55

Heat conductive powder

Heat conductive powders which improve the heat

conductivity of the compositions include those powders

of silicon nitride, aluminum nitride, boron nitride, tita-

nium nitride, sialon, silicon carbide, aluminum carbide,

boron carbide, titanium carbide, aluminum oxide, glass

fibers, boron oxide, alumina, talc, silica, beryllia, clay,

and powder of metals.

65

4

Flame retardant powder

The flame retardant powder useful in the invention

include antimony pentoxide, antimony trioxide, alumi-

num hydroxide and red phosphor.

High polymer powder

The high polymer powders useful in the invention

include powders of natural rubber, isoprene rubber,

chloroprene rubber, butadiene rubber, acrylonitrile/-

butadiene rubber, styrene/butadiene rubber, urethane

rubber, acryl rubber/acrylonitrile/styrene copolymer,

EPDM rubber/acrylonitrile/styrene copolymer,

acrylonitrile/styrene/butadiene copolymer, methylme-

thacrylate/acrylic rubber/styrene copolymer, methyl-

methacrylate/butadiene/styrene copolymer, methyl-

methacrylate/acrylic rubber/butadiene/styrene co-

polymer, polyethylene, polypropylene, polystyrene,

polyvinyl chloride, polyester and polyamide.

Other additive powder

Other additive powders include powders of barium

stearate, cadmium stearate, calcium stearate, lead stea-

rate, aluminum stearate, barium laurate, barium.cad-

mium laurate, barium ricinoleate, cadmium ricinoleate,

calciumricinoleate, dibasic lead phosphite, tribasic lead

sulfate, dibasic lead stearate, sodium phosphate and

barium phosphate.

The amount of the heat conductivity providing pow-

der or flame retardant powder to be added to the 2-

cyanoacrylate is determined so that the desired proper-

ties, for example, heat conductivity or flame retardancy

can be attained.

The amounts of high polymer powder or like other

additive powder added to the 2—cyanoacrylate for im-

proving the peeling resistance or impact shock to the

joining portion of the joined materials bonded with

2—cyanoacrylate is from 0.01 to 20 parts by weight and,

preferably, from 0.1 to 5 parts by weight based on 100

parts by weight of the 2—cyanoacrylate. If it exceeds 20

parts by weight, the storage stability of the composition

may be impaired. While on the other hand, it is difficult

to provide substantially satisfactory property with less

than 0.01 parts by weight.

Treatment of powder

The powder of organic or inorganic compound used

in this invention is preferably brought into contact with

an acid or coupling agent (surface treating agent) and

the effect intended in this invention can further be im-

proved by such treated powder.

As the acid capable of improving the effect by being

brought in Contact with the powder, there can be men-

tioned protonic acids or anhydrides thereof and they

can include, specifically, inorganic acids such as hydro-

chloric acid, sulfuric acid and phosphoric acid, as well

as organic acids, organic acid anhydrides and organic

acid esters containing acid groups as exemplified below.

The organic acid can include, for example, acetic

acid, propionic acid, butyric acid, trifluoro acetic acid,

valeric acid, hexanoic acid, malonic acid, succinic acid,

glutaric acid, adipic acid, maleic acid, fumaric acid,

cinnamic acid, benzoic acid, methane sulfonic acid,

toluene sulfonic acid, trifluoromethane sulfonic acid,

toluene disulfonic acid, itaconic acid, aconitic acid,

phthalic acid and trimellitic acid. The organic acid

anhydride can include, for example, acetic anhydride,

propionic anhydride, butyric anhydride, valeric anhy-

4,980,086

5

dride, succinic anhydride, glutaric anhydride, adipic

anhydride, maleic anhydride, itaconic anhydride, aco-

nitic anhydride, phthalic anhydride and trimellitic an-

hydride. The organic acid esters containing acid groups

can include those compounds such as ethylene glycol

ditrimellitate and trimethylene glycol ditrimellitate.

Preferred acids are organic acids such as toluene

sulfonic acid or organic acid anhydride such as trimel-

litic anhydride.

As the coupling agent (surface treating agent), vari-

ous kinds of agents may be applied and they can include,

specifically,

B-(3,4)-epoxycyclohexylethyltrimethoxysilane,

a-chloropropyltrimethoxysilane,

7-glycidoxypropyltrimethoxysilane,

vinyltriacetoxysilane, vinyltriethoxysilane,

vinyltrichlorosilane, viny1tris(2-methoxyethoxy)si1ane,

vinyltrimethoxysilane, 7-methacryloxypropyltrime-

thoxysilane,

ethyltrimethoxysilane, butyltrimethoxysilane,

octyltrimethoxysilane, phenyltrimethoxysilane,

dimethylsiloxane oil, hexamethylsilazane,

isopropyl isostearoyldiacryl titanate,

isopropyldimethacryl isostearoyl titanate,

isopropyl triisostearoyl titanate, ‘

isopropyl trioctanoyl titanate,

isopropyl tricumyl phenyl titanate,

isopropyl tris(dioctylpyrophosphate)titanate,

isopropyl tri(dioctyl)titanate,

isopropyl tridecelbenzenesulfonyl titanate,

dicumyl phenyloxy acetate titanate,

diisostearoyl ethylene titanate,

tetraisopropyl bis(dioctyl phosphite)titanate,

tetraoctyl bis(ditridecylphosphite)titanate,

tetra(2,2-diallylmethyl- 1-butyl)bis(di-tridecyl)phosphite

titanate, bis(dioctylpyrophosphate) ethylene titanate

and

bis(dioctylpyrophosphate) oxyacetate titanate.

In this invention, it is also possible to use those pow-

ders brought into contact with the acid and the cou-

pling agents as described above simultaneously.

One method of bringing the powder for use in this

invention into contact with the acid or the coupling

agent is to immerse the powder in a solution of the

selected acid or coupling agent. Another is to coat the

powders with the solution. Since these compounds in-

clude strong acids or those which are solid at ambient

temperature, it is preferred to use them as a solution in

the dipping or coating step for simplicity of handling

handling and to avoid damages to the powder.

The solvents for preparing the solution has no partic-

ular restrictions so long as they dissolve the above-men-

tioned compounds. The followings are preferred.

Water, aliphatic alcohols with less than 9 carbon

atoms, for example, methanol, ethanol and cyclohexa-

nol, ketones with less than 9 carbon atoms, for example,

acetone and methyl ethyl ketone, esters of acids with

less than 3 carbon atoms and alcohols with less than 7

carbon atoms, for example, ethyl acetate and butyl ace-

tate, aliphatic ethers, for example, diethyl ether, tet-

rahydrofurane and dioxane, halogenated hydrocarbons,

for example, chloroform, trichloroethane and trichlor-

trifluoroethane.

These solvents may be used alone or as a mixed sol-

vent with no substantial difference in the effect of this

invention.

The concentration of acids in the solution using the

solvent as described above is desirably less than 20% by

l0

15

20

25

30

35

45

50

55

65

6

weight and, more preferably, from 0.5 to 5% by weight.

The concentration of coupling agents in the solution

using the solvent as described above is desirably less

than 5% by weight and, more preferably, from 0.01 to

1% by weight.

As the method of bringing the powder into contact

with the above-mentioned compound, that is, means for

dipping the powder in the solution of the compound or

coating the powder with the solution, conventional

methods may be employed in which the powder is im-

mersed in the solution for about one minute to about

one hour or coating the solution by way of a spray gun

or the like.

The powder immersed in the solution or coated with

the solution is preferably removed with the excess solu-

tion by means of separation by filtration, separation by

settling and centrifugal separation, etc. and further re-

moved with the solvent by drying under ambient or

reduced pressure at an ambient or elevated temperature.

Acidic substance

The acidic substances used in this invention are elec-

tron pair acceptors or coordination complexes thereof.

They can include, for example, boron trifluoride and its

derivatives, sulfonic acids, halogenated aliphatic car-

boxylic acids, antimony pentafluoride and phosphor

hexafluoride. Specific compounds belonging to these

respective groups are as follows.

Boron trifluoride and its derivatives

Boron trifluoride, boron trifluoride—-acetic acid

complex salt, boron trifluoride—formic acid complex

salt, boron trifluoride—propionic acid complex salt,

boron trifluoride—butyric acid complex salt, boron

trifluoride—-benzoic acid complex salt, boron tri-

fluoride—methyl ether complex salt, boron tri-

fluoride—ethyl ether complex salt, boron trifluoride-

—n-propyl ether complex salt, boron trifluoride—i-

propylether complex salt, boron trifluoride—n-butyl

ether complex salt, boron trifluoride—tetrahydrofuran

complex salt, boron trifluoride—ethy1 forrnate complex

salt, boron trifluoride—methyl acetate complex salt,

boron trifluoride—ethyl acetate complex salt, boron

trifluoride—methanol complex salt, boron tri-

fluoride—ethanol complex salt, boron tri-

fluoride-—butanol complex salt, boron trifluoride—-

ethylene glycol complex salt, boron trifluoride—tri-

fluoroethanol complex salt, boron trifluoride—-monoe-

thylamine complex salt, boron trifluoride—phenol com-

plex salt, boron trifluoride—creso1 complex salt, boron

trifluoride—catechol complex salt, boron tri-

fluoride—hydroquinone complex salt, boron tri-

fluoride—hydroquinone monomethyl ether complex

salt, boron trifluoride—piperidine complex salt, boron

trifluoride—benzonitri1e complex salt, trifluoro boric

acid, etc.

Sulfonic aid

Toluene sulfonic acid, trifluoromethane sulfonic acid,

chlorosulfonic acid, fluorosulfonic acid, magic acid,

2-sulfone benzoic anhydride, etc.

Halogenated aliphatic carboxylic acids

Trifluoro acetic acid, trichloro acetic acid, dichloro

acetic acid, etc.

Among the above-mentioned compounds particu-

larly preferred in this invention are boron trifluoride

and its derivatives such as boron trifluoride, boron tri-

4,980,086

7

fluoride—acetic acid complex salt, boron trifluoride—-

ethyl ether complex salt, baron fluoride-methanol

complex salt, boron trifluoride—-phenol complex salt, as

well as sulfonic acids such as toluene sulfonic acid,

trifluoromethane sulfonic acid, chlorosulfonic acid and

fluorosulfonic acid. Particularly preferred compounds

are boron trifluoride—acetic acid complex salt, boron

trifluoride—ethyl ether complex salt, toluene sulfonic

acid, trifluoromethane sulfonic acid and chlorosulfonic

acid.

Blending amount

The amount of the acidic substance in the composi-

tion according to this invention is from 10 to 50000 ppm

and, preferably, from 100 to 5()00 ppm relative to 2-

cyanoacrylate present in the composition. If the amount

is less than 10 ppm, it is difficult to maintain stability of

the powder in the composition. While on the other

hand, if the amount exceeds 50000 ppm, the curing rate

of the composition is retarded and instantaneous cura-

blity cannot be expected.

Basic substance

The basic substances used in this invention are elec-

tron donors including amines, crown ethers, polyalkyl-

ene glycols and their derivative, aliphatic acid amides

and the likes. Specific compounds are as follows.

Amines

Triethylamine, triethanolamine, aniline, N,N-dime-

thylaniline, N,N-diethylaniline, toluidine, N,N-dime-

thyltoluidine, N,N-diethyltoluidine, polyvinylpyridine,

polyvinylcarbazole, polyvinylpyrrolidone and the like.

Crown ethers

18-crown-6, l5»crown-5, 12-crown-4, l,l-dimethyl-

sila-11-crown-4, 1,l-dimethylsila-14-crown-5, l,1-dime-

thylsila-l7-crown-6, keto-l l-crown-4, keto-l4—crown-5,

keto-17-crown-6, l-methylphosphono-1 l-crown-4, l-

ethylphosphono-11-crown-4, 1-phenyl-ll-crown-4, 1-

methylphosphono- 14-crown-5, 1-ethylphosphono- l4-

crown-5, 1-phenyl-14-crown-5, l-methylphosphono-l7-

crown-6, l-ethylphosphono-171crown-6, l-phenylphos-

phono-17-crown-6 and the like.

Polyalkylene glycols and derivatives

Polyethylene glycol, polyethylene glycol methyl

ether, polyethylene glycol ethyl ether, polyethylene

glycol acrylate, polyethylene glycol methacrylate,

polypropylene glycol, amylphenol.decaethylene gly-

col, p-isooctylphenol.decaethylene glycol, polyethyl-

ene glycol 400 monolaurate, polyethylene glycol oleate,

polyethylene glycol tall oil ester, polyethylene glycol

sorbitan monolaurate, alkylpolyethylene glycol thioe-

ther, oleylpolyethylene glycol ether, ethylene glycol——-

propylene glycol block copolymer, (polyoxyethylene)-

polysilanolate, (po1yoxypropylene)polysilanolate, (po-

lyoxyisoprene)polysilanolate, (polyoxytetramethylene)-=

polysilanolate, (plyoxyethylene/succinic acid)polyes-

ter, (polyoxypropylene/succinic acid)polyester, (po-

lyoxyisoprene/succinic acid)polyester, (polyoxytet-

ramethylene/succinic acid)polyester, (polyoxye-

thylene/malonic acid)polyester, (polyoxypropylene/-

malonic acid)polyester, (polyoxyisoprene/malonic

acid)polyester, (polyoxytetramethylene/malonic acid)-

polyester, (polyoxyethylene/phthalic acid)polyester,

(polyoxypropylene/phthalic acid)polyester, (polyox-

yisoprene/phthalic acid)polyester, (polyoxytetrame-

l0

15

20

25

30

35

45

50

55

65

8

thylene/phthalic acid)polyester, (polyoxyethylene)po-

lycarbonate, (polyoxyethylene)polyphosphate, (polyox-

ypropylene)polyphosphate, (polyoxyisoprene)poly-

phosphate, (polyoxytetramethylene)polyphosphate,

(polyoxyethylene)polyphosphonate and the like.

These compounds, when represents by the chemical

formula, have the repeating structure therein shown by

the following formula:

1'11

(970

R2

where R1 and R2, which may be identical or different

represent hydrogen atom, substituted or a non-sub-

stituted alkyl group, alkenyl group, aryl group, aralkyl

group, halogen atom or hydroxy group, n is an inter of

1 or greater, m is an integer of 2 or greater.

n in the formula means the repeating unit of the car-

bon main chain in the main skelton. In the case where

n= 1, the skelton is methylene or substituted methylene

group and corresponds, for example, to formaldehyde

condensate products, acetaldehyde condensate prod-

ucts or the like. In the case where n=2, the skelton is

ethylene or a substituted ethylene group, corresponding

specifically, for example, to those compounds having

the skelton of ethylene, 1,2-propylene, chloroethylene,

2-chlororoethylene-ethylene, all of which may be used.

In the case where n=3, the skelton is trimethylene or

substituted trimethylene group and specific compounds

usable herein can include, for example, those having the

skelton of 1,3-propylene, 2,2,-dichloromethyl-propyl

and the like. In the case where n=4, the skelton is tetra-

methylene or substituted tetramethylene group. In the

case where n=5 or greater, corresponding compounds

are present in the same way as described above, all

which can be used. The compounds preferred in this

invention are those in which n is from 2 to 6.

Then, m in the formula represents the repeating unit

of polyether and those in which m is an integer of 2 or

greater can be used in this invention. In a specific exam-

ple of ethylene glycol where R1 and R2 represent hydro-

gen and n=2, the compound is diethylene glycol for

m=2, triethylene glycol for m=3, tetraethylene glycol

for m=4 and polyethylene glycols of various molecular

weights for m=5 or greater. Those preferred in this

invention are compounds in which m is less than 10,000,

more preferably, from 4 to 3,000.

Fatty acid amides

Lauric acid monoethanolamide, lauric acid diethanol-

amide, coconut oil fatty acid monoethanolarnide, coco-

nut oil fatty acid diethanolamide, capryl acid ethanol-

amide, capric acid diethanolamide, myristic acid etha-

nolamide, palmitic acid ethanolamide, stearic acid etha-

nolamide, capryl acid isopropanolamide, capric acid

isopropanolamide, myristic acid isopropanolamide, pal-

mitic acid isopropanolamide and stearic acid iso-

propanolamide.

Among the above-mentioned compounds, those pre-

ferred in this invention are crown ether and polyalkyl-

ene glycol, as well as derivatives thereof. More pre-

ferred compounds are polyethylene glycol ethyl ether,

polypropylene glycol, polyethylene glycol 400 mono-

laurate, polyethylene glycol oleate and alkyl polyethyl-

4,980,086

9

ene glycol thioether. Most preferred compounds are

18-crown-6, polyethylene glycol, polyethylene glycol

methyl ether, polyethylene glycol acrylate, polyethyl-

ene glycol methacrylate, ethylene glycol—propylene

glycol block copolymer and oleylpolyethylene glycol

ether.

As described below, although it has been known that

these compounds are used for improving the curing

rate, etc. of 2-cyanoacrylate, the present inventors have

for the first time found the excellent effect that the

abovementioned compounds can stably disperse the

powders of organic or inorganic compounds in 2-

cyanoacrylate without impairing the instantaneous cur-

ing property of the 2-cyanoacrylate used in combination

with the beforementioned acidic substance.

“The sources of some of the compounds of this inven-

tion are as follows:’’ Polyalkyleneoxide and esters and

ethers thereof (US. Pat. No. 4,170,585), crown ethers

(U .S. Pat. No. 4,171,416), normal or acidic salt or amine

or imine (Japanese Patent Laid-Open No. Sho

54-141827), polyethylene glycol dimethacryl ester (Jap-

anese Patent Laid-Open No. Sho 57-200469), monoa-»

crylate of polyethylene/propyleneoxide (Japanese Pa-

tent Publication No. Sho 60-26513), polyether and its

derivative (U.S. Pat. Nos. 4,307,216 and 4,377,490).

Blending amounts

The amount of the basic substance in the composition

according to this invention is, preferably, 10 to 50,000

ppm and, preferably, from 100 to 5000 ppm based on

2-cyanoacrylate present in the composition. If the

amount is less than 10 ppm, the curing rate of the com-

position is reduced and no instantaneous curability can

be expected. While on the other hand, if it exceeds

50,000 ppm, it becomes difficult to stabilize the powder

in the composition. Thus, neither of the cases are not

preferred since the property as the curing composition

may possibly be hindered.

Referring to the ratio of the acidic substance and the

basic substance in the composition according to this

invention, it is preferred that they are used, generally, in

an equimolar amount or with a slight excess of the

acidic substance, although some variations are tolerable

dependent on the respective substances, by which a

composition excellent in the storage stability and curing

rate can be attained, which is the object of this inven-

tion.

Methods of Preparation

Composition according to this invention can be pre-

pared by merely mixing the ingredients. However, in

view of the stability of 2-cyanoacrylate, a method of

adding and mixing the acidic substance, basic substance

and powder in this sequence to 2-cyanoacrylate is pre-

ferred. When the acidic substance and basic substance

are mixed alone, they partially or entirely form a com-

plex salt and the effect as the purpose of this invention

can sufficiently be attained by using them in such a

form.

As has been described above, it is also possible to use

commercially available cyanoacrylate type adhesives as

the 2-cyanoacrylate, and stabilizer, viscosity improver,

plasticizer and crosslinker, etc., which are usually

added to the cyanoacrylate type adhesives, may also be

10

' added to the composition according to this invention.

10

15

20

25

30

35

45

50

55

The stabilizer include, for example, S02, sultone, lac-

tone, hydroquinone, hydroquinonemonomethyl ether,

catechol and pyrrogarol, which is added by an amount

from 1 to 1000 ppm to 2-cyanoacrylate. The viscosity

improver can include polymer such as methylmethacry-

late polymer, 2-cyanoacrylate polymer and acrylic rub-

ber of which several percent may be added. The plasti-

cizer can include dioctylphthalate, sebacic acid ester,

phosphoric acid ester and the like. The crosslinker can

include, for example, polyfunctional vinyl monomers

such as alkylene diacrylate, alkylenedimethacrylate,

trimethlolpropane triacrylate and triallyl isocyanurate.

Further, thixotropy agent such as fumed ‘silica may be

added up to several percent depending on the case for

improving the viscosity and providing a thixotropic

property.

In the curable composition according to this inven-

tion, the acidic substance and the basic substance, in

combination, give a certain effect to powder thereby

enabling it to disperse stably into the composition, thus

providing the desired properties. Additionally, the com-

position thus obtained is excellent in the storage stability

and, the composition when coated on the surface of a

material can maintain excellent instantaneous curability

due to the moisture at the surface of the material or in

the air. ‘

Accordingly, the curable composition according to

this invention is effective as adhesive, coating agent,

paint and potting agent, etc., which can generally be

used in various field of industries. '

This invention will now be described more specifi-

cally referring to examples and comparative examples.

EXAMPLE 1

Chlorosulfonic acid, polyethylene glycol 1500 and

polymethyl methacrylate were added to ethyl 2-

cyanoacrylate in the blending ratio shown in Table 1, to

which Fast Orange GRL (organic pigment) was further

added and kneaded sufficiently at a room temperature

to obtain a pigmented curable composition. The follow-

ing test was carried out for the thus obtained curable

composition.

For the storage stability, the composition was filled in

a vessel made of polyethylene, left for two weeks under

at 25°:2° C. and 65i5% RH and the state was ob-

served. The setting time was measured according to J IS

K 6861 using test pieces made of ABS resin.

For the curing time of the thin film, the composition

was coated to a film thickness of 20 um and then the

time until the surface tackiness was eliminated was mea-

sured at of 25°:2° C. and 65i5% RH.

These results are shown Table 1.

EXAMPLES 2-5

Same tests were carried out for the compositions

shown in Table 1 in thesame maxmer as in Example 1.

The results are shown in Table 1.

COMPARATIVE EXAMPLES 1-2

Same tests were carried out for the compositions

shown in Table 1 in the same manner as in Example 1.

TABLE 1

Comflsition ‘1

2-cyanoacrylate Pigment powder

Acidic substance Basic substance

Other

4,980,086

11 12

TABLE 1-continued

Example ethyl Fast Orange chlorosulfonic acid polyethylene polymethylmeth-

1 (84.4) GRL (10) (5000 ppm) glycol 1500 acrylate (5)

(1000 ppm)

Example ethyl Fast Orange boron tri1'luoride- polyethylene polymethylmeth-

2 (84.1) GRL (10) ether complex glycol 1500 acrylate (5)

(8000 ppm) (1000 ppm)

Example ethyl Fast Orange trichloroacetic acie 18-crown-5 polymethylmeth-

3 (92.6) GRL (2) (3CX)0 ppm) (1000 ppm) acrylate (5)

Example ethyl Red No. 2 p-toluene sulfonic 18-crown-6 polymethyl meth-

4 (88.4) aluminum acid (NIX) ppm) acrylate (3)

lake (5) (5000 ppm) Aerosil R805 (3)

Example ethyl Red No. 2 boron trifluoride- polyethylene polymethyl meth-

5 (88.6) aluminum ether complex glycol diacrylate acrylate (3)

lake (5) (3000 ppm) (l0()O ppm) Aerosil R805 (3)

Compara-= ethyl Fast Orange — — polymethyl meth-

tive (90) (5) acrylate (5)

example

1

Compara-= ethyl Red No. 2 — —- polymethyl meth-

tive (93) aluminum acrylate (5)

example lake (2)

Storage stability Setting time

(ABS/ABS) Thin film cure time

120 sec. 15 min. ,

120 sec. 15 min.

15 sec. 5 min.

60 sec. 10 min.

30 sec. 10 min.

‘2

Example 0

g 1

Example 0

2

Example A

3

Example A

4

Example A

5

Compara- X

tive

example

1

Compara— X

tive

example

2

‘I All the units are based on % by weight unless other words specified.

‘2 O: satisfactory;

A: viscosity increased;

X: cured

EXAMPLE 6

Silver powder was immersed for about 10 minutes in

a methanol solution containing p-toluene sulfonic acid

and ‘y-methacryloxypropyl trimethoxysilane each at 5%

by weight, silver powder deposited with the solution

was recovered by filtration and the solvent was re-

moved in vacuum for about 10 hours to obtain silver

powder brought into contact with the acid and the

coupling agent.

The powder was added by 200 parts at weight to 100

parts_ by weight of ethyl 2-cyanoacrylate containing

2000 ppm of boron trifluoride-ethyl ether complex salt,

1000 ppm of polyethylene glycol 1500 and 5% by

weight of polymethyl methacrylate and well kneaded at

a room temperature to obtain an electroconductive

curable composition. The following tests were carried

for the thus obtained composition.

For the storage stability, the composition was filled in

a vessel made of polyethylene, left for one month at

25°:*_-2° C. at 65:5% RH and then the state was ob-

served.

The setting time was measured according to JIS K

6861 using test pieces made of copper.

For the curing time of the thin film, the composition

was coated to a film thickness of 20 pm and the time till

45

50

55

65

the surface tackiness was eliminated was measured at

25°:2° C. and 65:5% RH.

The specific resistance value of the curing product

was measured as the resistance value in the longitudinal

direction of the curing product of 5 mm widthx 50 pm

thickness and 50 mm length one day after the coating.

The results are shown in Table 2.

EXAMPLES 7-14

Same tests were carried out for the compositions

shown in Table 2 in the manner as in Example 6. The

results are shown in Table 2.

COMPARATIVE EXAMPLE 3

When 100 parts by weight of ethyl 2-cyanoacrylate

were added to 100 parts by weight of silver powder,

ethyl 2-cyanoacrylate instantly polymerized while gen-

erating heat failing to serve as the curing composition.

COMPARATIVE EXAMPLE 4

When 100 parts by weight of ethyl 2-cyanoacrylate

were added to 200 parts by weight of silver power

having been treated with a 5 wt % of solution of p—tol-

uene sulfonic acid in methanol, kneaded sufficiently and

the storage stability of the composition was observed,

viscosity increase was resulted in one week and the

4,980,086

13 14

composition was cured substantially completely after

one hour failing to be used as the curing composition. COMPARATIVE EXAMPLES 5"-7

Same tests were carried for the compositions shown

in Table 2 in the matmer as in Example 6. The results are

5 shown in Table 2. '

TABLE 2

Comgsition

' Electroconductive Treatment for electrifflgg pgwder

powder Acidic substance Basic substance Other Acid coupling agent

Example Silver boron trifluoride- Polyethylene Polymethyl p-toluene -y-rnethacryloxy

6 (200 parts ether comples glycol 1500 methacrylate sulfonic acid prolylttimethoxy

by weight) (2000 ppm) (1000 ppm) (5 wt %) ‘2 silane ‘2

Example Silver boron trifluoride— 18-crown-6 polymethyl none none

7 (200 parts ether complex (1000 ppm) methacrylate

by weight) (5000 ppm) (5 wt %)

Example Silver chlorosulfonic triethlamine — hydrochloric 7-methacyloxy

8 (100 parts acid (5000 ppm) acid propyltrimethoxy

by weight) (50()0 ppm) ‘3 silane "2

Example Silver trifluoromethane polyethylene — none none

9 (100 parts sulfonic acid glycol 400

by weight) (200() ppm) monolaurate

(1000 ppm)

Example Silver Magic acid polyvinyl polymethyl none isopropy1dimetha-

10 (200 parts (5000 ppm) pyrrolidone methacrylate cryl isosteararoyl

by weight) (2000 ppm) (5 wt %) titanate

Aerosil R202 '4

(5 wt %)

Example Silver boron trifluoride- dimethyl polymethyl p-toluene 7-methacryloxy

11 (200 parts methanol p-toluene methacrylate sulfonic acid propyltrlmethoxy

by weight) ' complex (10()0 ppm) (5 wt %) ‘2 silane ‘2

(5000 ppm) Aerosil R202

(5 wt %)

Exanple Copper boron trifluoride - polyethylene polymethyl none none

12 (100 parts ether_comp1ex _ glycol 1500 methacrylate

by weight) (5(X)0 ppm) (1000 ppm) (5 wt %)

Example Copper chlorosulfonic polyethylene polymethyl p-toluene none

13 (100 parts acid glycol methacrylate sulfonic acid

by weight) (2000 ppm) . diacrylate (5 wt %) ‘2

(500 ppm)

Example Nickel coat chloro sulfonic ethylene glycol- — none none

14 aluminum acid propylene

powder (2000 ppm) glycol block

(100 parts copolymer

by weight) (500 ppm) '

Compara- Silver -— — polymethyl p-toluene y-methacryloxy

tive (200 parts methacrylate sulfonic acid propyltrimethoxy

example (‘by weight) (5 wt %) ‘2 silane

5 Aerosil R202 '2

(5 wt %)

Compara- Silver boron trifluoride - — polymethyl p-toluene 7-methacryloxy

tive (200 parts ether complex methacrylate sulfonic acid propyltrimethoxy

example by weight) (2000 ppm) (5 wt %) ‘2 silane

6 - "2

Compa.ra- Silver boron trilluoride - — polymethyl none none

tive (200 parts ether complex methacrylate

example by weight) (5000 ppm) (5 wt %)

7

Setting time Specific resistance

Storage stability (copper/ of curing product

‘1 copper) Thin film cure time (.Q- cm)

Example 0 30 sec. 5 min. 1.7 X 10-3

6

Example A 20 sec. 3 min. 3.5 x 10-3

7 .

Example 0 60 sec. 10 min. 2.3 x 10-2

8

Example A 20 sec. 5min. 3.5 x 10-2

9

Example 0 50 sec. 15 min. 4.1 x lo-3

10

Example 0 60sec. 15 min. 3.2 x 10-3

l 1

Example A 15 sec. 5 min. 7.2 x 10-1

12

Example 0 10sec. 5 mi.n. 1.2 x 10-1

13

Example A 45 sec. 15 min. 5.4 x lo-2

14

Compara- X 20 sec. 5 min. 2.3 x lo-3

IIVC

4,980,086

15 16

TABLE 2-continued

example

5

Compara- 0 more than more than cured not

tive 3 min. 30 min. completely

example

6

Compara- A more than more than cured not

tive 3 min. 30 min. completely

example

'1 O: satisfactory,

A: viscosity increased.

X: cured

'2 methanol solution (5 wt %)

'3 aqueous solution (2 wt %)

'4 trichloroethnne solution (2 wt %)

What is claimed is:

1. A composition comprising a 2-cyanoacrylate ester

containing from 10 to 400 parts by weight of the 2-

cyanoacrylate of an electroconductive powder or a heat

conductive powder; the electroconductive powder

being selected from the group consisting of silver, cop-

per, nickel, aluminum, gold, palladium, platinum, ruthe-

nium, graphite, and mixtures thereof; the heat conduc-

tive powder being selected from the group consisting of

silicon nitride, aluminum nitride, boron nitride, titanium

nitride, sialon, silicon carbide, aluminum carbide, boron

carbide, titanium carbide, aluminum oxide, glass fibers,

boron oxide, aluminum, talc, silica, beryllin, clay, metal

powders and mixtures thereof together with an electron

acceptor or a coordination complex thereof selected

from the group consisting of boron trifluoride and de-

rivatives thereof, sulfonic acids, halogenated aliphatic

carboxylic acids, antimony pentafluoride, phosphor

hexafluoride, and mixtures thereof and a substantially

equimolar amount of an electron donor selected from

the group consisting of amines, crown-ethers, polyakly-

lene glycol and derivatives thereof, fatty acid amides

and mixtures thereof.

2. A curable composition as defined in claim 1,

wherein the electron pair acceptor or the coordination

complex thereof is selected from the group consisting of

boron trifluoride, derivatives thereof and sulfonic acids.

3. A curable composition as defined in claim 2

wherein boron trifluoride, derivatives thereof and sul-

20

30

35

50

55

65

fonic acids are selected from the group consisting of

boron trifluoro-acetic acid complex salt, boron trifluo-

ride-ethyl ether complex salt, toluene sulfonic acids,

trifluoromethane sulfonic acid or chlorosulfonic acid.

4. A curable composition as defined in claim 1

wherein the electron donor is selected from the group

consisting of crown-ethers, polyalkylene glycols and

the derivatives thereof.

5. A curable composition as defined in claim 4,

wherein the crown-ether, polyalkylene glycol and the

derivatives thereof are selected from the group consist-

ing of 18-crown-6, polyethylene glycol, polyethylene

glycol methyl ether, polyethylene glycol ethyl ether,

polyethylene glycol acrylate, polyethylene glycol

methacrylate, polypropylene glycol, polyethylene gly-

col 400 monolaurate, polyethylene glycol oleate, alkyl-

polyethylene glycol thioether, ethylene glycol-propy-

lene glycol block copolymer and oleyl polyethylene

glycol ether,

6. A curable composition as defined in claim 4,

wherein the crown-ether, polyalkylene glycol and the

derivatives thereof are selected from the group consist-

ing of 18-crown-6, polyethylene glycol, polyethylene

glycol methyl ether, polyethylene glycol acrylate, poly-

ethylene glycol methacrylate, ethylene glycol-propy-

lene glycol block copolymer and oleyl polyethylene

glycol ether. _‘

# # it * 1

Coments go here:

- Log in to post comments

Comments

Very useful categorisation of

Very useful categorisation of all additives to CA formulation