����������������(19) United States

US 20030164222A1

(12) Patent Application Publication (10) Pub. No.: US 2003/0164222 A1

Kneafsey et al.

(43) Pub. Date: Sep. 4, 2003

(54) SEMI-SOLID PRIMER COMPOSITIONS

(76) Inventors: Brendan J. Kneafsey, Dublin (IE);

John Guthrie, Kildare (IE)

Correspondence Address:

Henkel Loctite Corporation

1001 Trout Brook Crossing

Rocky Hill, CT 06067 (US)

(21) Appl. No.: 10/276,421

(22) PCT Filed: May 30, 2001

(86) PCT No.: PCT/IE01/00070

(30) Foreign Application Priority Data

May 31, 2000 (IE) ......................................... .. 2000/0439

Publication Classification

(51) Int. Cl.7 ...................................................... .. C09J 5/04

(52) U.S. Cl. ........................... .. 156/314; 524/387; 401/55

(57) ABSTRACT

A composition comprising at least one carrier solvent, at

least one primer component and at least one gelling or

solidifying agent is provided. The composition according to

the invention may he provided in the form of a soft solid, for

example, in the form of a stick. A two-part adhesive system

is also provided, comprising at least one anaerobic product

and a composition comprising at least one carrier solvent, at

least one primer component Where the primer component is

a cure promoting agent and at least one gelling or solidifying

agent. A two-part adhesive system comprising a cyanoacry-

late adhesive and a composition having at least one carrier

solvent, at least one primer component and at least one

gelling or solidifying agent is also provided. A pack is

provided comprising a shaped mass of a composition which

includes at least one carrier solvent, at least one primer

component and at least one gelling or solidifying agent, and

a container (1) for the composition which has a mechanism

for expelling the shaped mass.

Patent Application Publication Sep. 4, 2003 US 2003/0164222 A1

US 2003/0164222 A1

SEMI-SOLID PRIMER COMPOSITIONS

FIELD OF THE INVENTION

[0001] The present invention relates to semi-solid primer

compositions, particularly well suited to promoting the

bonding of substrates, such as those constructed of non-

polar or highly crystalline materials or for promoting the

cure of otherwise slow curing products.

BRIEF DESCRIPTION OF RELATED

TECHNOLOGY

[0002] Primers have long been used to promote the bond-

ing of substrates which otherwise are not readily bonded

together to a satisfactory extent by adhesive alone. The

primer promotes adhesion to the surface. Materials which do

not bond satisfactorily with adhesive alone are often referred

to as “difficult-to-bond”. Where both surfaces to be bonded

are difficult-to-bond, both may be primed prior to attempted

adhesion. Primer is applied to the surfaces to be bonded, to

“activate” or “prime” the surface for reception of later

applied adhesive. Certain primer components are thus often

referred to as adhesion-promoting agents” or “adhesion-

promoting primers” as they can promote subsequent adhe-

sion of substrates with a conventional adhesive.

[0003] The types of surface (substrate) which are difficult-

to-bond with adhesives, especially with cyanoacrylate adhe-

sives, are widely recognised and include non-polar or highly

crystalline substrates.

[0004] Non-polar substrates typically have low surface

energy which is due to an absence of polar groups on the

surface to be bonded. Polar groups are generally thought to

raise the surface energy to the level needed to give satis-

factory adhesion with conventional adhesives.

[0005] Non-polar substrates are often constructed of poly-

olefins in particular linear polymers of simple olefins, such

as polyethylene, polypropylene, polybutene, polytetrafluo-

roethylene and the like, including their copolymers; poly-

acetals, plasticised PVC (polyvinyl chloride), polyurethane,

EPDM (ethylene-propylene diamine monomer) rubber, ther-

moplastic rubbers based on vulcanised polyolefins and the

like.

[0006] Difficult-to-bond materials which are widely rec-

ognised include those with a waxy or paraffin-like surface

character; a low critical surface tension of wetting; and

which may have at their surface a weak boundary layer.

[0007] It will be appreciated therefore, that the main

function of an adhesion-promoting primer is to promote

adhesion in cases where curing (polymerization) occurs

readily but where adhesion may not take place at all or to a

desired extent. As stated above this a scenario typical of

cyanoacrylate adhesives.

[0008] A second function of a primer composition may be

to promote cure of the curable composition. Primer compo-

nents which have this function are referred to herein as

“cure-promoting”. In some instances curable compositions

may provide a desired degree of adhesion but achieve

adhesion at an undesired rate. For example the curable

composition may cure to give sufficient adhesion but may do

so only very slowly so that [text missing or illegible

when filed] bonded must be kept in contact over a period

of hours or even longer. While relatively long cure times are

Sep. 4, 2003

desirable in some instances, a shorter cure time without

deleteriously affecting bond strength is desirable for many

other purposes. Slow cure is a property associated with

many products including those termed “anaerobic” products.

These are polymerizable products which are stable and

remain unpolymerized in the presence of air (oxygen in

particular) and which tend to cure rapidly in the absence of

air.

[0009] It is normal for an initiator component of a cure

system to be excluded from the primer composition so that

the primer composition is absent an initiator component.

[0010] It is known to provide cure-promoting primer com-

positions for the purpose of decreasing cure times. In such

cases the cure-promoting primer is applied (usually by

application in solution form as described below) to the

desired substrate and the curable composition is then applied

to the surface treated with primer. The cure-promoting

primer acts to decrease cure times by accelerating the cure

of the composition but without for example diminishing

bond strength of adhesives, or sealing capability of sealants.

[0011] It is possible that any given primer may have dual

functionality i.e. promoting adhesion and promoting cure

though it is usual for primers to be classified as having one

of these main functions.

[0012] The present invention is concerned with primers in

general including both adhesion-promoting, and cure-pro-

moting primers.

[0013] Application of a primer composition which com-

prises a primer component in a solvent to a substrate to be

primed is typically by way of a brush or some such other

applicator, to form a layer or coating on the surface. The

coating is then typically dried, or allowed to dry for a period,

before bonding with adhesive is attempted, and to ensure

that the surface is properly primed. In this respect at least for

adhesion-promotion primers the solvent is normally a vola-

tile one i.e. evaporates readily at room temperature leaving

behind the primer component. The solvent does not there-

fore interfere with the [text missing or illegible when

filed] adhesion process—acting only as an inert carrier

solvent for placing the adhesion-promoting primer compo-

nent on the substrate. For cure-promoting primers the sol-

vent may be a polymerizable monomer or oligomer which

may take part in the polymerization process during bonding.

Accordingly these solvents are not usually considered

“inert” in the sense that the participate in the subsequent

bonding process. They do however act as carrier solvents for

the primer component. Monomeric or oligomeric solvents

do not tend to evaporate to any appreciable extent after

application so that they are not normally considered volatile.

These compositions will most usually be liquid also.

[0014] The nature of such primer compositions can result

in difficult handling for example unwanted spillage, run-on

of the coating applied, and the cumbersome task of having

to use an applicator or brush. It is desirable to provide a more

easily handled and potentially safer form of primer compo-

sition.

[0015] Primer compositions typically include at least one

priming compound or agent which is the primer component

of the composition. Various primer components and primer

compositions are described below.

[0016] It is desirable therefore to provide a primer com-

position in a consumer-friendly manner to allow for ease of

US 2003/0164222 A1

handling etc. Presenting primer compositions in consumer-

friendly forms and/or packages is a difficult task as the

primer component must not have its adhesion- or cure-

promoting capabilities deleteriously affected by the form, or

package, in which it is presented for use.

[0017] Various types of adhesive compositions are avail-

able commercially ranging from low viscosity (liquid) com-

positions to gels and other medium viscosity compositions

to higher viscosity products such as pastes, and soft-solid

products.

[0018] It is known to thicken or gel adhesive such as

cyanoacrylate adhesives with polymethylmethacrylate or

thixotropic agents such as those described in U.S. Pat. Nos.

4,447,607 and 4,533,422 (Litke).

[0019] It is also known for instance to formulate adhesives

as “stick” compositions. The patent literature on stick adhe-

sives is extensive and covers a broad range of adhesive

types, from emulsion adhesives through solvent based adhe-

sives, to contact adhesives, as well as gelling and solidifying

additives for the preparation of the sticks ranging from

thermosetting through natural polymers to inert fillers. A

well known example of one such adhesive stick sold under

the trade name PrittStickTM by Henkel KGaA which is an

emulsion-based adhesive.

[0020] In the patent literature the following patents typify

the type of composition in which adhesive components have

been formulated as soft-solids, and more particularly sticks.

U.S. Pat. No. 5,433,775 discloses an adhesive stick consist-

ing of a water based preparation of starch derivatives and a

soap gel as the shaping gel-forming component. See also

U.S. Pat. No. 5,371,131.

[0021] U.S. Pat. No. 3,846,363 relates to an adhesive

crayon composition containing a sorbitol-benzaldehyde

reaction product as an additive. U.S. Pat. No. 4,639,475

discloses an adhesive stick composed of the reaction product

of sorbitol and/or xylitol and benzaldehyde as the gel-

forming composition together with an adhesive resin which

is the reaction product of methyl vinyl ether/maleic acid

anhydride copolymers with partially neutralised acid phos-

phate esters of non-ionic wetting agents of the lower alky-

lene oxide adduct type.

[0022] Japanese unexamined patent application laid open

(Kokai) 51-103939 describes a stick-like epoxy adhesive

and a stick-like epoxy hardening agent which is used there-

with. The sticks are obtained by suitably compounding

gelling agent or/and water is and/or organic solvent with

liquid or solution type epoxy adhesive and epoxy hardening

agent.

[0023] DE 199 57 677 A1, published after the priority date

of the present application, of Henkel KGaA describes a

cyanoacrylate adhesive, coating or sealing material which

also contains at least one condensation product of an alde-

hyde or ketone with a polyol. [text missing or illegible

when filed] may be in stick form.

[0024] While a wide variety of sticks have been described,

no prior publication has suggested that a primer composition

could be made in stick form at all, let alone while main-

taining its primer functionality. It would therefore be advan-

tageous to provide a primer composition in stick form.

SUMMARY OF INVENTION

[0025] The present invention provides a primer composi-

tion suitable for formulation/presentation in stick form. The

Sep. 4, 2003

primer composition may promote subsequent bonding of

non-polar or highly crystalline substrates such as polyole-

fins, or similar plastics substrates with low surface energy,

with adhesive such as cyanoacrylate adhesives. Alterna-

tively or additionally to being adhesion-promoting, the

composition may act as a cure-promoting agent to promote

cure of the curable product depending on the primer com-

ponent chosen. The compositions allow for ease of applica-

tion and/or handling, and allow for accuracy in application

without running on of the primer composition.

[0026]

[0027]

[0028] (a) at least one carrier solvent;

In particular the present invention provides:

a composition including:

[0029] (b) at least one primer component; and

[0030] (c) at least one gelling or solidifying agent.

[0031] The composition is easily cast in stick form and is

very useful in his respect. The present invention thus pro-

vides primer compositions typically for use with an adhe-

sive. In particular the adhesion-promoting primer composi-

tions of the present invention have been demonstrated as

being effective adhesion-promoting agents for example as a

cyanoacrylate primer composition which is particularly use-

ful for promoting adhesion of polyolefins. The cure-promot-

ing compositions within the present invention have been

shown to be effective as cure-promoting agents particularly

with [text missing or illegible when filed] adhesives

and sealants.

[0032] More particularly, the present invention relates to

the preparation and use of primer compositions in stick

form, to promote the bonding of non-polar or highly crys-

talline substrates with adhesives, especially with cyanoacry-

late adhesives or alternatively to promote cure of curable

products in particular to promote the cure of anaerobic

products.

[0033] The curing or polymerization of a film of adhesive

such as cyanoacrylate, between two materials, does not

necessarily result in a strong bond, particularly if the mate-

rials are non-polar, and if the polymerization of the adhesive

is excessively rapid, a very weak bond or no bond will result.

The adhesion-promoting compositions of the present inven-

tion help to alleviate this non-bonding problem. The cure-

promoting compositions of the present invention have been

found to promote (accelerate) curing of otherwise slow

curing products.

[0034] Suitably the composition is the form of a soft-solid.

The composition may be formulated in stick form, for

example by casting.

[0035] Suitably component (a) the carrier solvent com-

prises an organic solvent in which the primer component is

stable. Component (a) may be an organic solvent such as

ethanol, methanol, acetone, methyl ethyl ketone, 1,1,1-

trichloroethane, 1,1,2-trichloro-1,2,2,-trifuoroethane or mix-

tures thereof with each other or with other solvents such as

an azeotropic mixture of 1,1,2-trichloro-1,2,2,-trifluoroet-

hane with acetone. Desirably the solvent is ethanol. The

solvent is desirably an inert carrier solvent where the primer

composition is an adhesion-promoting one.

[0036] The function of the solvent is to provide a suitable

concentration of the primer component so that a coating of

US 2003/0164222 A1

selected thickness can be applied to a surface. Therefore, any

common solvent in which the primer component is stable

will suffice. The solvent will usually dissolve the primer

component though dissolving is not essential provided the

solvent acts to provide a dilute (and thus disperse) form of

the primer component for subsequent application. Certain

active primer components used in this invention [text

missing or illegible when filed] adhesion on non-polar

and highly crystalline substrates While certain others pro-

mote curing of curable products such as anaerobic adhe-

s1ves.

[0037] Component (c) is suitably the condensation prod-

uct of the reaction of at least one aldehyde and/or ketone

with a polyol.

[0038] Suitable polyols include those with at least one of

a 1,2-diol, 1,3 diol or 1,4 diol structure. The diols may

additionally have other groups such as ether, acid, amido,

cyano, hemiacetal or halogen. Examples of suitable polyols

include 1,2-ethandiol, 1,3-propandiol, 1,2-propandiol, 2,3-

butandiol, 1,4-butandiol, 2,2-dimethyl-1,3-propandiol, 2,2-

bis(hydroxymethyl)-1,3-propandiol, 2-(bromomethyl)-2-

(hydroxymethyl)-1,3-propandiol, 1,3,4-butantriol,

1-phenyl-1,2,3-propantriol, 1,2-hexandiol, neopentylglycol,

1,4-bishydroxymethylcyclohexane, 2-methyl-1,3-propan-

diol, hexantriol-(1,2,6), 2-(2-hydroxyethoxy)butan-1,3,4-

triol, glycerine, di and polyglycerine, diglycerindiacetate,

trimethylolpropane, di-(trimethylolpropane), trimethylole-

thane, pentaerythritol, bicyclo [2.2.1] heptane-2,3,5,6-tetrol,

2,2,3,3-tetrahydroxybutandiacid, dipentaerythritol, sorbitol,

formitol, xylitol, inositol, glucitol, glucose, saccharose/su-

crose, starch, cellulose, ascorbic acid, partially or fully

hydrolysed polyvinylacetate, 9,10-dihydroxy stearic acid

methyl ester, diacetylsorbitol and methylglyceride.

[0039] Most suitable polyols are sorbitol, xylitol and man-

nitol especially sorbitol.

[0040] Suitable aldehyde or ketones include those which

have at least one substituted or unsubstituted aromatic,

heteroaromatic or alicylic ring. These polyols may have

additional groups such as ether ester, amide, cyano and

halogen.

[0041] Examples of ketones include cyclopentanone,

cyclohexanone, cycloheptanone, 1-(3,3-dimethylcyclo-

hexyl)-ethanone, 1-cyclopropylethanone, 3-methyl-5-pro-

pylcyclohex-2-en-1-one, dicyclopropylmethanone, 4-tert-

butylcyclohexanone, dicyclohexylmethanone,

4-methylcyclohexanone, 1-(1-methylcyclopropyl)-etha-

none, (4-chlorophenyl)-cyclopropyl-methanone, 1-(1H-pyr-

rol-2-yl)-ethanone, 1-(2,4,6-trimethylphenyl)-ethanone,

1-(2-furanyl)-2-propanone, 1-(2-naphthalenyl)-ethanone,

1-(2-thienyl)-1-propanone, 1-(4-bromophenyl)-ethanone,

1-(4-methoxyphenyl)-ethanone, [text missing or illeg-

ible when filed] alenyl)-ethanone, 1,1-diphenyl-2-pro-

panone, 1,2-diphenylethanone, 1,3-diphenyl-2-propanone,

1-phenyl-1-butanone, 1-phenyl-1-decanone, 1-phenyl-1-

dodecanone, 1-phenyl-1-hexanone, 1-phenyl-1-octanone,

1-phenyl-1-pentanone, 1-phenyl-1-penten-3-one, 1-phenyl-

1-tetradecanone, 1-phenyl-2-butanone, 1-phenyl-2-pro-

panone, 1-pyrazinyl-ethanone, 2,2,2-trifluoro-1-phenyl-

ethanone, 1-(2-furanyl)-ethanone, 1-(2-pyridinyl)-ethanone,

1-(2-thienyl)-ethanone, 4-chloro-1-(4-fluorophenyl)-1-bu-

tanone, 4-phenyl-2-butanone, 1-phenyl-ethanone, bis-(2-hy-

droxyphenyl)-methanone, bis-(4-chlorophenyl)-methanone,

cyclopentylphenylmethanone, cyclopropyl(4-methoxyphe-

Sep. 4, 2003

nyl)-methanone, cyclopropyl-(4-methylphenyl)-methanone,

cyclopropyl-2-thienyl-methanone, cyclopropylphenyl-

methanone, 1,5 -diphenyl-1,4-pentadien-3-one, phenyl-2-py-

ridinyl-methanone, 2-bromo-1-(4-nitrophenyl)-ethanone,

2-naphthalenylphenyl-methanone, 3-chloro-1-phenyl-1-pro-

panone, 4-(4-hydroxyphenyl)-2-butanone, 4-(4-methox-

yphenyl)-3-buten-2-one, 1-(4-pyridinyl)-ethanone, 1-(4-hy-

droxyphenyl)-ethanone, 1-phenyl-1-propanone, 4-phenyl-3-

buten-2-one, diphenylmethanone, 1-phenyl-2-butanone,

1-phenyl-2-buten-1-one, bis-(4-methylphenyl)-methanone,

2-methyl-1-phenyl-1-propanone, 2-chloro-1-phenyl-etha-

none, cyclopropyl-(4-fluorophenyl)-methanone, 1-(p-meth-

oxyphenyl)-2-propanone, cyclohexylphenylmethanone and

phenyl-(2-thienyl)-methanone.

[0042] The following aldehydes are exemplary for use in

the present invention: benzaldehyde, 3-chlorobenzaldehyde,

4-chlorobenzaldehyde, 2,6-dichlorobenzaldehyde, 2,4-dini-

trobenzaldehyde, 3,4-dichlorobenzaldehyde, 3-fluoroben-

zaldehyde, 4-bromobenzaldehyde, 2-methyltetrahydroben-

zaldehyde, tetrahydrobenzaldehyde, 2-methyl-5-

isopropylcyclopenten-1-aldehyde, 2,2,4-

trimethylcyclohexa-4,6-dien-1-aldehyde, 3(4)-methyl-1-

propylcyclohexen-3-aldehyde, 1,3(4)-dimethylcyclohexen-

3-aldehyde, 2-methyl-1-propylcyclohexen-3-aldehyde,

3-cyclohexen-1-aldehyde, 2,3,4,5,6-pentafluorobenzalde-

hyde, 2,4,6-trihydroxybenzaldehyde, 4-tolylacetaldehyde,

2-methylbenzaldehyde, 4-hydroxybenzaldehyde, 3-methyl-

benzaldehyde, 2-hydroxy-1-naphthalaldehyde, 4-methyl-

benzaldehyde, 3,5-dimethoxy-4-hydroxybenzaldehyde, cin-

nam-aldehyde, 3-nitrobenzaldehyde,

2-pentylcinnamaldehyde, 4-diethylaminobenzaldehyde,

4-methoxybenzaldehyde, 2-phenylpropionaldehyde,

2-methoxycinnamaldehyde, 4-methylbenzaldehyde, phe-

noxyacetaldehyde, methylpyrrol-2-aldehyde, 2,5-dimethox-

ytetrahydrofuran-3-aldehyde, 2,5-dipropyl-3,4-dihydropy-

ran-2- , [text missing or illegible when filed] 2,5-

diethyl-3,4-dihydropyran-2-aldehyde, 2,5-diisopropyl-3,4

dihydropyran-2-aldehyde, 2,5-dimethyl-3,4-dihydropyran-

2-aldehyde, 2,5-dibutyl-3,4-dihydropyran-2-aldehyde,

thiophen-3-aldehyde, indol-3-aldehyde, pyridine-3-alde-

hyde, pyridine-4-aldehyde and n-methylpyrrole-2-aldehyde.

[0043] Desirable aldehydes include benzaldehyde, 3-chlo-

robenzaldehyde and 3-fluorobenzaldehyde.

[0044] Particular acetals and ketals include: di-O-ben-

zylidenmannitol, di-O-(2-chlorobenzylidene)mannitol,

di-O-(4-nitrobenzylidene)mannitol, di-O-(3-fluoroben-

zylidene)mannitol, O-benzylidenesorbitol, di-O-benzylide-

nesorbitoldiacetate, di-O-(2-chlorobenzylidene)sorbitoldi-

acetate, tri-O-(4-chlorobenzylidene)sorbitol,

O-benzylidenethreitol, O-benzylidene tartaric acid methyl-

ester, O-cyclohexylidenglycerine, O-cyclohexylidene ascor-

bic acid and O-benzylidene-9, 10-dihydroxy stearic acid

methylester.

[0045] Suitably the aldehyde is benzaldehyde, 3-chlo-

robenzaldehyde or 3-fluorobenzaldehyde especially benzal-

dehyde. Suitably the polyol is sorbitol, xylitol or mannitol

especially sorbitol. The condensation product may be di-O-

benzylidene mannitol; di-O-(3-fluorobenzylidene) mannitol

or di-O-benzylidene sorbitol especially di-O-benzylidene

sorbitol.

[0046] Component (c) the gelling or solidifying agent is

useful for the preparation of a stick from the solutions

containing the adhesion-promoting agent.

[0047] Suitable gelling agents for inclusion as component

(c) include acetals of sugars, particularly acetals of sorbitol,

US 2003/0164222 A1

which are particularly effective as gelling agents. One such

gelling agent includes di-O-dibenzylidene sorbitol (also

referred to simply as dibenzylidene sorbitol) sold by

Roquette Freres, France under the trademark DisorbeneTM.

Other acetals such as those described above have also been

found to be useful.

[0048] Acetals of sugars, particularly natural sugars, for

example acetals of sorbitol, [text missing or illegible

when filed] previously used as gelling agents for the

preparation in stick form and these materials are useful in the

present invention.

[0049] Suitably component (c) the gelling or solidifying

agent has a concentration in the solvent from about 0.01%

to about 20%, such as about 0.01% to about 15%, typically

from about 0.05% to about 10% for example about 0.1% to

about 5% by weight by weight based on the total weight of

the composition.

[0050] It is desirable that a solution of the active primer

component in the solvent should have a concentration of

about 0.001 to about 30% by weight based on the total

weight of the composition for example from about 0.01 to

20% by weight based on the total weight of the composition.

Suitable concentrations are about 0.005 to about 15% such

as about 0.005 to about 10% by weight based on the total

weight of the composition for example about 0.001 to about

5% by weight based on the total weight of the composition

such as 0.01 to about 2% by weight based on the total weight

of the composition.

[0051] Desirably the primer component is an adhesion-

promoting agent.

[0052] Suitably (where adhesion-promotion is desired) the

primer component is selected from:

[0053] 1,5-diazabicyclo[4.3.0]non-5-ene having the

formula:

/

N

[0054] 1,8-diazabicyclo[5.4.0]undec-7-ene having the for-

mula:

N

/

[0055] or 1,5,7-triazabicyclo[4.4.0]dec-5-ene having the

formula:

NH N

U/J

Sep. 4, 2003

[0056] (ii) triphenyl phosphine, or

[0057] (iii) ethylenediamine or derivatives of ethylenedi-

amine according to the formula:

R R

\ /

N— CH2— CH2—N

/

R R

[0058] wherein each R, which may be the same or differ-

ent, represents hydrogen, an alkyl, alkenyl or alkoxy group

having 1 to 8 carbon atoms, an aryl group having 6 to 8

carbon atoms, a nitrogen-, sulphur-, or silicon-substituted

group having up to 8 carbon atoms or a heterocyclic group

having up to 8 carbon atoms which may be unsubstituted or

substituted with hydroxy, ether oxygen or sulphur; or

[0059] (iv) an imidazole having the formula:

R1

[0060] wherein R1 may be hydrogen; an alkyl group that

is unsubstituted or substituted with an OH group or with an

(alkyl-O)3Si group, wherein the alkyl radical has 1 to 4

carbon atoms; an aryl-alkyl group with 7 to 10 carbon atoms;

or an imidazole-CO group, and R2 may be hydrogen or an

alkyl, aryl, or aryl-alkyl group with up to 17 carbon atoms,

with the condition that one of the substituents R1 or R2 has

an aromatic character and X is one of the groups

CH—CH or CR3R4 CRSR5 wherein R3, R4, R5

and R6 independently of one another represent hydrogen, an

alkyl group with 1 to 4 carbon atoms, or an aryl-alkyl group

with up to 17 carbon atoms.

[0061] Suitably (again particularly where adhesion pro-

motion is sought) the primer component (component

contains at least two nitrogen atoms. Desirably the primer

component is a compound of the group above, in par-

ticular 1,8-diazabicyclo[5.4.0]undec-7-ene.

[0062] From among the ethylenediamines labelled as

primer component (iii) above, suitable ethylenediamines are

those according to the formula give above wherein each R,

which may be the same or different, represents hydrogen, an

alkyl, alkenyl or alkoxy group, having 1 to 8 carbon atoms,

an aryl group having 6 to 8 carbon atoms, a nitrogen- or

sulphur-substituted group having 1 to 8 carbon atoms or a

heterocyclic group having up to 8 carbon atoms which may

be unsubstituted or substituted with hydroxy, ether oxygen

or sulphur.

[0063] Desirably ethylenediamine primer components are

those wherein at least one R is aryl, or each R is other than

hydrogen and at least one R is other than methyl.

[0064] Desirably the composition comprises as primer

components one or more of: N,N,N‘,N'-tetraethylethylene-

diamine and at least one of N‘-benzyl-N,

US 2003/0164222 A1

N‘dimethylethylenediamine,

N‘phenylethylenediamine,

dimethylethylenediamine or

aminopropyl-bis(2-ethylhexoxy)-silane.

N,N-diethyl-

N,N'-dibenzyl-N,N‘-

N-2-aminoethyl-3-

[0065] Examples of the primer component labelled as (iv)

above include the imidazole compounds include: those

derivatives where X is —CR3R4—CR3R6- especially 4,5

dihydroimidazole; these compounds may also be referred to

as imidazolines.

[0066] Desirable primer components include those imida-

zole compounds referred to above where X is —CR3R4—

CR3R6—, R1) R2) R3), R4, R3 and R6 desirably have the

following significance: R1 is hydrogen or a hydroxyalkyl

group, R2 is an aryl or an aryl-alkyl group with to 17 carbon

atoms and R3, R4, R3, and R6 independently are each

hydrogen or an alkyl group with 1 to 4 carbon atoms. More

desirably R1 is hydrogen or a hydroxyethyl group, R2 is a

benzyl or phenyl group, and R3, R4, R3 and R6 are hydrogen.

A particularly advantageous imidazoline derivative for use

in the invention is 2-phenyl-[text missing or illegible

when filed]

[0067] Typical examples of aryl or aralkyl groups that can

be the substituent R2 are phenyl, naphthyl, tolyl, xylyl,

benzyl, and naphthylmethyl groups. Typical examples of

alkyl groups with 1 to 17 carbon atoms that can likewise

form the R2 group are methyl, ethyl, propyl, butyl, pentyl,

heptyl, nonyl, undecyl, tridecyl, pentadecyl, and heptadecyl

groups; straight chain alkyl groups are most useful. In

addition, mixtures of these 2-alkylimidazole derivatives can

also be used, containing alkyl groups of different chain

lengths from the above list. Typical examples of alkyl

groups with 1 to 4 carbon atoms and aryl groups that can

form the substituents R3, R4, R3 and R6 can be obtained from

the above list.

[0068] When X is —CH=CH—, R1 and R2 desirably

have the following significance; R1 is an aryl group with 7

to 10 carbon atoms or an imidazole-CO group and R2 is

hydrogen or an alkyl group with 1 to 4 carbon atoms. Most

desirably R1 is a methyl or benzyl group and R2 is hydrogen

or a methyl group.

[0069] Other imidazole primer compounds useful in the

present invention include those of the Formula:

[0070] wherein R1 is a C1-C4 alkyl group optionally sub-

stituted with a phenyl group, and R2 is hydrogen or a C1-C4

alkyl group.

[0071] Desirably the composition when solidified has the

consistency of a soft-solid or waxy mass. The Theological

properties of the mass of product should be such that the

mass has a stable geometric shape. It is desirable that the

shaped mass e.g. a stick, is applicable by manual rubbing

against the substrate to which it is to be applied. The soft or

semi-solid mass should be shearable under relatively modest

Sep. 4, 2003

manual pressure to [text missing or illegible when

filed]ease of application. Under shear forces the solid may

liquify to form a film (or smear) of the composition on the

surface. It is desirable that the shaped mass retains its shape,

for example when stored at 20° C. for a number of days for

example at least about 10 days, more desirably for a number

of weeks or months. The composition exemplified herein

have proven to be stable over a number of months in such

conditions. The cast composition has the ease of handling

advantages of a completely solid material yet remains easily

dispensable. PrittStickTM is one commercially available

semi-solid mass sold as an adhesive stick which is well

known as a dispensable adhesive.

[0072] The primer composition composed of one of the

above primer components as a solution in a (solidified)

solvent is normally of such concentration that the thickness

of the coating can be controlled to achieve the full effects of

this invention.

[0073] The present invention also provides a composition

described above wherein the primer component is a cure-

promoting agent. Suitably the cure-promoting primer com-

ponent is selected from substituted thioureas, a compound

having a sulphur-containing free radical source, a compound

containing an oxidisable transition metal or a compound

containing one of the groups

[0074] Most desirable are compositions wherein the

primer component is a compound containing an oxidisable

transition metal. The transition metal is desirably selected

from those elements in the groups (columns) of the Periodic

Tables containing Cr, Mn, Fe, Co or Cu. The transition metal

may be selected from Cu, Cr, Co, Fe, and Mn, more

particularly Cu(I), Cu(II), Co(II), Mn(II), Mn(III) or Cr(II).

Particularly useful are those where the transition metal is

selected from Cu(I) or Cu(II), especially those compounds

which are salts of these particular forms of Cu, for example

salts of carboxylic acids, beta diketones or beta keto esters.

Particular salts are Cu(II) 2-ethylhexanoate or Cu(II) acety-

lacetone.

[0075] Where the primer component is a cure-promoting

primer for anaerobic products [text missing or illegible

when filed] may be a polymerizable monomer or polymer-

izable oligomer for example alkyl methacrylate esters such

as methyl or ethyl methacrylate. In the embodiment the

polymerisable monomer or oligomer may interact with the

polymerization process and thus form part of the cured

product. The monomer or oligomer should provide the

desired concentration of primer component. The solvent

may thus for example be methyl or ethyl methacrylate.

[0076] The invention also provides a two-part adhesive

system comprising at least one cyanoacrylate adhesive

and (ii) an adhesion-promoting primer composition accord-

ing to the present invention as defined above. Suitably the

cyanoacrylate is an alpha cyanoacrylate.

[0077] Suitable cyanoacrylate adhesives for use with the

adhesion-promoting primer of this invention are represented

by the general formula

US 2003/0164222 A1

H2C= C— COOR1

CN

[0078] wherein R1 is alkyl, alkenyl, cycloalkyl, aryl,

alkoxyalkyl, aralkyl, haloalkyl or another suitable group.

The lower alkyl alpha-cyanoacrylates are preferred, and in

particular methyl, ethyl, n-propyl, n-butyl, isobutyl, isopro-

pyl, allyl, cyclohexyl, methoxyethyl or ethoxyethyl

cyanoacrylates are preferred. Many alpha cyanoacrylates

can be obtained commercially as one component instant

adhesives, in which form they may be used in a method of

assembly of this invention.

[0079] The present invention also provides a two-part

adhesive system comprising at least one anaerobic prod-

uct and (ii) a cure-promoting composition as described

above. Suitable anaerobic products are described below.

[0080] The invention also relates to the solidified product

of a composition as described above. Suitably the compo-

sition is solidified in a desired geometric form, for example

in a cylindrical shape. Any suitable shape which allows for

ease or handling is desired and such shapes are typically

referred to as sticks. One method of preparing a soft-solid or

semi solid mass of the composition includes the steps of:

[0081] heating a composition comprising (a) at least

one carrier solvent; (b) at least one primer component; and

(c) at least one gelling or solidifying agent, to a desired

temperature; and

[0082] (ii) allowing the composition to cool or cooling the

composition sufficiently to set the composition.

[0083] Typically the composition will set (solidify to a

soft-solid) at a temperature of below about 30° C. for

example at about 15-22° C.

[0084] The invention also relates to a shaped mass pre-

pared by the method just described and particularly a mass

shaped in a stick form.

[0085] While these commercially available cyanoacry-

lates are composed principally of alpha cyanoacrylate mono-

mer, the formulation may contain stabilisers, thickeners,

adhesion-promoters, plasticizers, dyes, heat resistant addi-

tives, impact resistance modifiers, perfumes, diluents and

such like. These adjustments may also be used with anaero-

bic products.

[0086] It will be appreciated that if the composition is cast

before cooling to its set temperature then it will take the

shape of the container or mould in which it is cast. It is

desirable that the composition be cast in a desired geometric

shape for example as a stick for example a stick of a

generally cylindrical shape. The person skilled in the art will

appreciate that the pre-and post-casting composition will

have essentially the same compositional make-up, with

mainly physical changes from liquid to solid occurring

during casting. Little or no solvent will be lost during the

casting process. The amounts of the various components

thus remains essentially unchanged as between the liquid

and solidified compositions. No appreciable volume change

occurs during casting.

Sep. 4, 2003

[0087] In a further aspect the invention provides a method

of bonding a first (non-polar) [text missing or illegible

when filed] to a second substrate (which may be polar or

non-polar), which comprises treating (by priming) the first

(non-polar) substrate(s) by applications of a composition

according to the present invention, applying a cyanoacrylate

(suitably an alpha cyanoacrylate) adhesive to the treated

surface(s) and contacting the substrates for sufficient time

(and with sufficient pressure) to allow them to bond to each

other. In this way a bonded assembly is created. In the case

where the substrates to be bonded are both non-polar or

otherwise difficult-to-bond materials of that type, both sub-

strates may be primed with a composition of the invention.

The composition may suitably be applied by (manually)

rubbing the primer stick on the substrate. If the non-polar

substrate is to be bonded to a polar or more active substrate,

only the non-polar substrate needs to have applied the

primer. Following application of the primer to the non-polar

substrate(s), the bond may be completed using cyanoacry-

late adhesive in the normal manner. This method is espe-

cially useful for priming polyolefin substrates. This method

may also be used with anaerobic products where the sub-

strate to which the product is applied is not necessarily a

non-polar one. Anaerobic products may seal between rather

than bond together two substrates.

[0088] The invention relates also to a bonded assembly

created by this method. The invention thus discloses the use

of a primer composition in the manufacture of a castable

primer stick composition for example a primer stick for

priming substrates (for subsequent bonding with adhesive).

The adhesion-promoting compositions of the invention may

be used to prime non-polar or highly crystalline substrates.

[0089] The invention also provides an easy to use and

consumer-friendly pack comprising:

[0090] a shaped mass of a composition according to the

invention (a cast composition); and

[0091] (ii) a container for the composition, the container

having a mechanism for expelling the shaped mass. Desir-

ably the shaped mass is moveable between a position where

the shaped mass projects from the container, and a position

where the shaped mass is substantially located (retracted)

within the container.

[0092] The composition may be cast directly in the con-

tainer. Normally the container [text missing or illegible

when filed]bular and most often of cylindrical shape. The

container may be of the type having a displaceable mecha-

nism for example a carrier for displacing the mass of the

composition relative to the container. The carrier may move

the mass so that it projects from the container, or retract the

mass so that it is housed within the container. In this way the

mass may be extended for application to a substrate or

retracted for storage. The container may comprise a cap for

protection of the mass when the composition is not in use.

Desirably the container has means for manual adjustment of

the position of the mass or carrier, for example where the

carrier is reciprocally threaded on a winding mechanism and

can thus be extended or retracted by rotation of the winding

mechanism in one of two directions.

[0093] It will be appreciated by those skilled in the art that

a multitude of suitable containers may be used with the

shapes masses or sticks of the present invention. Typically

used containers are those with propulsion mechanisms to

propel the stick out of the container. Many such containers

are known for example for deodorants/anti-perspirants, and

make-up such as lipstick etc.

US 2003/0164222 A1

BRIEF DESCRIPTION OF THE FIGURES

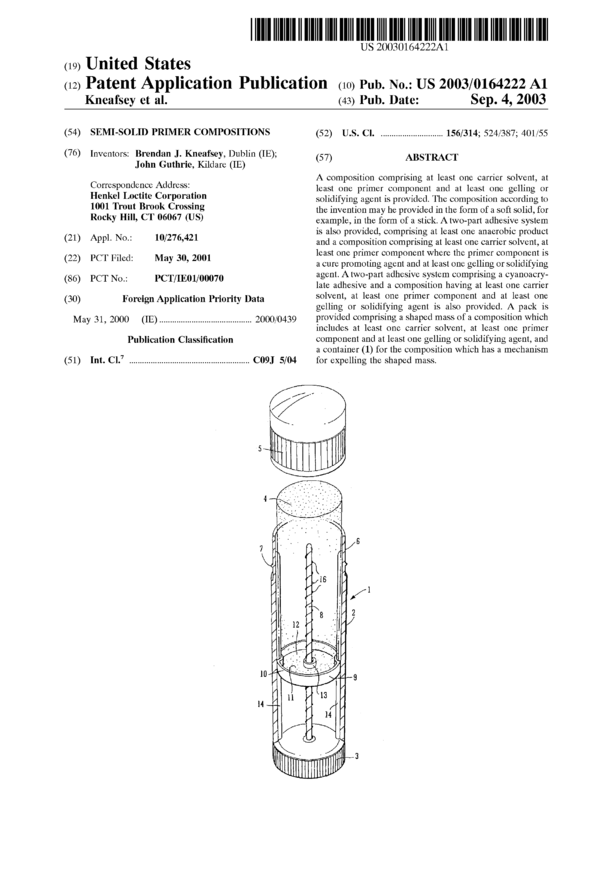

[0094] FIG. 1 is a side (part-sectional) elevational view of

a container suitable for holding the composition of the

present invention; and

[0095] FIG. 2 is a top View of a carrier which forms part

of the container of FIG. 1.

DETAILED DESCRIPTION OF THE

INVENTION

[0096] Many primer components and primary composi-

tions have been developed for use in bonding of substrates,

in particular difficult-to-bond substrates as described above.

Some primers components and primer compositions are now

discussed. In accordance with the present invention the

primer components disclosed below in the documents dis-

cussed may be taken and formulated in a composition of the

present invention for casting in stick form.

[0097] For example, Japanese patent application Nos.

52-98062, 56-141328 and 57-119929 suggest the use of

primers prepared by dissolving a chlorinated polyethylene or

chlorinated polypropylene or a fatty acid modified acrylated

alkyd resin in an organic acid.

[0098] Primer based or organometallic compound are also

known. For instance, European patent application no. 0 129

069 A2 discloses the use of a primer comprising at least one

organometallic compound, for use with alpha cyanoacrylate

adhesives, which is useful in bonding non-polar substrates.

Japanese patent application No. 61023630 proposes orga-

nometallic primers for joining plastic models. U.S. Pat. Nos.

5,292,364, 5,110,392 and 4,818,325 also disclose the use of

primer compositions containing organometallic compounds

for use with cyanoacrylate adhesives.

[0099] Primers for polyolefins comprising modified or

grafted polyolefins such as chlorinated polyolefins, ethylene/

vinyl acetate copolymer or ethylene/propylene terpolymer,

(ii) a crosslinking binder and (iii) crosslinking agents, are

disclosed in European application No. 0 187 171A. German

application No. DE 3601518-A suggests the use of primers

for polyolefins comprising an organometallic compound and

an organic polymer; the organometallic compound being a

metal alcoholate and the term “metal” including metalloids,

phosphorous, boron or silicon atoms Japanese application

No. 61136567 describes a titanate primer for bonding

polypropylene.

[0100] The English language abstract [from JAPIO data-

base, accession no.1987-018486] for Japanese application

No. 60157940 discloses a primer composition based on a

solution of 4-vinyl pyridine as an essential ingredient, and

3,4-lutidine as an optional ingredient, for bonding polyole-

fins, polyacetal, polyamide, polyester, boron-polymer, sili-

cone or PVC.

[0101] The Derwent Abstract [Accession no.

19942559135] for Japanese patent application JP 610 0839

discloses dialkylamino diazabicycloundecene primer com-

positions for use with cyanoacrylate adhesives for plastics

bonding. For example polyolefins and EPDM. The com-

pounds, are those of formula I below

Sep. 4, 2003

[0102] (R, R1=C1_14 alkyl, benzyl).

[0103] U.S. Pat. No. 5,314,562 describes a method for

bonding substrates, one of which is a plastic, comprising (a)

applying to the plastic substrate a primer solution of an

adhesion-promoting ethylenediamine compound dissolved

in a solvent, (b) allowing the primer solution to dry, (c)

applying an alpha cyanoacrylate adhesive to one of the

substrates and (d) joining the substrates. The active adhe-

sion-promoting agent is dissolved in a solvent and applied as

a primer solution.

[0104] German patent publication no. DE 40 35 680

describes imidazole derivatives which are useful as adhe-

sion-promoting agents.

[0105] German patent publication DE 40 17 802 A1 also

relates to imidazole derivatives which are useful primers for

inclusion in the compositions of the present invention. In

particular the document discloses primer compounds of the

Formula:

N

E A

2

N R

R1

[0106] wherein R1 is a C1-C4 alkyl group optionally sub-

stituted with a phenyl group, and R2 is hydrogen or a C1-C4

alkyl group.

[0107] The Derwent Abstract [Accession no. 1994-

107035] for Japanese patent application JP-A-6057218 dis-

closes a primer composition containing a tert-amine, where

the three groups are each a hydrocarbon group, but at least

one among them is a long chain hydrocarbon group con-

taining 8 to 24 carbon atoms. The active adhesion-promoting

agent is applied by dissolution in isopropanol. WO 91/ 18956

discloses imidazole derivatives such as 1-benzyl-2-meth-

ylimidazole, 1-benzylimidazole, 1-(2-thyl)-2-phenyl-4,5-di-

hydroimidazole, 2-phenyl-4,5-dihydroimidazole, and N,N‘-

carbonyldiimidazole, for use as primers in the bonding of

plastics, including polyolefins, with cyanoacrylate adhe-

s1ves.

[0108] U.S. Pat. No. 4,869,772 discloses di- and tri-

azabicyclo primer compositions for use in bonding non-

polar substrates. The active adhesion-promoting agents are

dissolved in a solvent, applied as a solution, and allowed to

dry leaving the adhesion-promoting agent on the substrate

before subsequent bonding with cyanoacrylate.

[0109] EP 0 333 448 (equivalent to U.S. Pat. No. 5,079,

098) discloses primer solutions (in low surface tension

US 2003/0164222 A1

organic solvents) of quaternary ammonium compounds of

the formula: R4N+ A‘ where R is alkyl, hydroxyalkyl, aryl,

alkaryl, aralkyl, and alkenyl, optionally substituted by het-

eroatoms; A‘ is an anion with pKa>0 in deprotonation

equilibrium reactions.

[0110] Anaerobic products with which certain primer

compositions (in particular cure-promoting primer compo-

nents) of the present invention are useful include polymer-

izable compositions which are often in the liquid state. The

(polymerizable) anaerobic product remains unpolymerized

in the presence of air but polymerizes upon exclusion of air.

This property of anaerobic products finds application as for

example a sealant between closely fitting metal surfaces.

Anaerobic product placed between closely fitting metal

surfaces such as flanges cures due to a lack of air.

[0111] Anaerobic products such as adhesives and sealant

compositions are known in the art. Examples of documents

which describe these products include U.S. Pat. Nos. 2,895,

950, 3,043,820, 3,218,305 (all to Krieble) and 4,287,330

(Rich) the entire contents of each of which is expressly

incorporated herein by reference.

[0112] In particular U.S. Pat. Nos. 2,895,950 and 3,043,

820 disclose anaerobic sealant compositions comprising

polymerisable compounds of the formula:

‘Ii i i ‘Ii

H2C:(|Z—C—O (CH2)m (I: (|:—o C—(|I:CH2

R’ R” H R’

P II

[0113] where R is selected from hydrogen, —CH3,

—C2H5, —CH2OH, and

0

||

—cH2—o—c—c=cH2

Ry

[0114] radicals, R‘ is selected from hydrogen, chlorine,

methyl and ethyl radicals; R“ is selected from hydrogen,

—OH radical, and

O

—o—c—c=cH2

Ry

[0115] radicals; m is an integer equal to at least one, e.g.

from 1 to 8 or higher, for instance from 1 to 4, inclusive, n

is an integer equal to at least 2, for example from 2 to 20 or

more, inclusive, and p is 0 or 1. Anaerobic compositions

including these polymerizable compounds are useful in

conjunction with the primer compositions of the present

invention in particular those primer compositions of the

present invention identified as being cure-promoting.

Sep. 4, 2003

[0116] U.S. Pat. No. 3,218,305 discloses anaerobic prod-

ucts containing polmerizable compounds of the formula:

‘Ii i i ‘Ii

H2c=c|:—c—o (CH2)m (I: (|:—o c—(|:=CH2

R’ R” P H R’

n

[0117] where R is a radical selected from hydrogen, C1-C 4

alkyl, or C1-C4 hydroxyalkyl or

O

—cH2—o—c—c=cH2

Ry

[0118] radicals, R‘ is selected from hydrogen, halogen, and

C1-C4 alkyl; and [text missing or illegible when filed],

m, n and p, are as defined above. Anaerobic compositions

including these polymerizable compounds are useful in

conjunction with the primer compositions of the present

invention in particular those primer compositions of the

present invention identified as being cure-promoting.

[0119] In particular polymerizable compounds useful in

the present invention may be:

‘Ii i i ‘Ii

H2c=c|:—c—o (CH2)m (I: (|:—o c—(|:=CH2

R’ R” H R’

P II

[0120] where R is a radical selected from hydrogen, C1-C4

alkyl, or C1-C4 hydroxyalkyl or

O

—cH2—o—c—c=cH2

Ry

[0121] radicals, R‘ is selected from hydrogen, halogen, and

C1-C4 alkyl, OH; and R“ is selected from hydrogen, —OH

radical, and

O

—o—c—(:=cH2

Ry

[0122] radicals; m is an integer equal to at least one, e.g.

from 1 to 8 or higher, for instance from 1 to 4, inclusive, n

is an integer equal to at least 2, for example from 2 to 20 or

more, inclusive, and p is 0 or 1.

US 2003/0164222 A1

[0123] These polymerisable compounds are typically for-

mulated in a composition which contains at least sufficient

components to make the composition curable. The person

skilled in the art will, depending on the polymerizable

monomer selected, consider any further appropriate compo-

nents. Typical further components for inclusion include an

initiator which may independently initiate or assist initiation

of polymerization in the absence of air. These initiators are

often oxidising agents. These initiators include peroxides for

example hydroperoxides such as cumene hydroperoxide.

[0124] A further component which may be added is a

reducing agent. Typical reducing agents include tertiary

amines and for instance U.S. Pat. No. 4,287,330 (Rich)

discloses rhodanine and organic hydrazines which are effec-

tive accelerators for the cure of anaerobic compositions.

Other suitable reducing agents are well known to those

skilled in the art. Another potential component is a co-

catalyst (for example saccharine) which may catalyse poly-

merization of the polymerizable compounds.

[0125] Suitable compositions for use with primer compo-

sitions of the present invention are described in detail in our

co-pending Irish application entitle “SEMI-SOLID ONE-

AND TWO-PART COMPOSITIONS” filed on even date

herewith in the name of Loctite (R&D) Limited.

[0126] The use of primer solutions to facilitate more rapid

cure, greater through depth cure, or improve adhesion to

substrates has been considered also for anaerobic products.

These primer solutions have been proposed in particular for

use on substrates which do not have readily leachable metal

ions or polar groups to facilitate effective adhesion. U.S. Pat.

Nos. 4,990,281 (Clark), 3,970,505 (Hauser), 3,591,438

(Toback), 3,625,930 (Toback), among others disclose the

use of various types of primers. The teaching of each of

these documents is expressly incorporated herein by refer-

ence. A common feature of all these primer composition is

that the active ingredient is contained in a solvent and the

primer solution has to be applied from the liquid state with

a variety of techniques.

[0127] The ’505 patent teaches the use of in particular a

substituted thiourea (in conjunction with an acid) as a cure

accelerator for anaerobic products. The substituted thiourea

(optionally together with the acid) can be used as a primer

to activate the surface to which it is desired to apply

anaerobic product. The substituted thiourea can be formu-

lated (optionally together with the acid) in a primer com-

position of the present invention.

[0128] The ’438 patent teaches the use of a reducing

activator which is either a sulphur-containing free radical

accelerator, or a compound containing an oxidizable transi-

tion metal. The compounds containing an oxidizable tran-

sition metal are especially useful in compositions of the

present invention and includes those compounds containing

the following transition metals: Cu, Cr, Co, Fe, and Mn.

Desirable compounds include salts and complexes of these

metals including mono- or poly-nuclear and homo- or het-

ero-nuclear compounds.

[0129] Other transition metal-based compounds are dis-

closed in the ’281 patent are desirable for inclusion. These

include Cu(II), Co(II), Mn(II), Mn(III) and Cr(II) based

compounds in particular salts of these metals. The ’281

patent is particularly concerned with the salts of these metals

Sep. 4, 2003

with acid phosphate acrylic monomer. Particular acid phos-

phate acrylic monomer disclosed include those of the for-

mula:

R10 0

cH2=c—c—R2—o—P—A

OH

[0130] where R1 is H or methyl, R2 is a divalent organic

group having from 2 to 20 carbon atoms and the group A is

OH or

R10

cH2=c—c—o—R2o—

[0131] where R1 and R2 are as defined for the formula

immediately above.

[0132] Suitable metal compounds include copper (I) and

(II) salts in particular those of carboxylic acids or those of

beta diketones or beta keto esters. Specific examples include

for example Cu(II) 2-ethylhexanoate and Cu(II) acetylac-

etonate.

[0133] A representative of a Cu(II) based primer is Loctite

product “Primer NTM”.

[0134] Other anaerobic products commercially available

from Loctite Corporation Rocky Hill Connecticut, US

include the following products sold under the following

trade names Loctite 636, Loctite 326, Loctite 648, Loctite

270, and Loctite 290.

[0135] The ’930 patent discloses a primer composition for

anaerobic adhesives which contains as accelerator a com-

pound having one of the following groups:

[0136] These compounds are also suitable for use with the

primer compositions of the present invention.

[0137] A container for holding a cast (solidified) compo-

sition of the invention is now described.

[0138] FIG. 1 shows a side view of a container 1 suitable

for holding a composition of the present invention. The

container is cylindrical in cross-section having cylindrical

side walls 2. On the base of the container is a knurled wheel

3 which forms part of a propulsion mechanism for a (soft-

solid or semi-solid) mass or stick 4 of the primer composi-

tion of the present invention. The mass 4 has been cast in a

generally cylindrical shape as described in the Examples

below. The container further comprises a cap 5 which is

snap-fit engageable over the top end 6 of the container 1 to

protect the mass 4 of product. The top end 6 is of lesser

diameter than the side walls 2 and has a rim 7 which engages

in a corresponding recess on the underside of the cap 5 to

secure the cap 5 in place.

US 2003/0164222 A1

[0139] The knurled wheel 3 is attached to an elongate

drive or winding shaft 8 which is centrally located within the

housing formed by the side walls of the container. On the

winding shaft 8 is located a moveable carrier 9. The carrier

9 is generally cylindrical (from an end View thereof—see for

example FIG. 2) and has a short peripheral upstanding wall

10 formed on its base 11. During the casting process the

carrier 9 is positioned to secure itself to the lower end 12 of

the mass 4 on solidification of the mass 4. Indeed the mass

4 may be cast also with the shaft 8 (and optionally the wheel

3) in place. As best seen from FIG. 2 the carrier 9 has a

central threaded aperture 13 in which the threads 16 of the

shaft 8 engage. The knurled wheel 3 and the shaft 8 are both

[text missing or illegible when filed] for relative rota-

tion to the container body. When the wheel 3 is turned in the

direction of the arrow it moves the carrier up or down the

shaft 8 thus controlling the relative position of the mass and

the container. In the position shown the carrier has travelled

part way up the shaft, moving the mass to a position where

it protrudes from the container. The mass can then be applied

by rubbing against a substrate by manual force. Sufficient

shearing of the mass takes place to allow it to rub off onto

the substrate. No separate applicator/brush etc. is necessary.

The composition can be applied with manual pressure. To

prevent rotation of the carrier 9 with the shaft, elongate ribs

14 are provided on opposing sides of the internal wall of the

container. The ribs 14 run from the base of the container to

a position proximate to the mouth if the container. The ribs

14 each engage one of corresponding grooves 15 in the

carrier 9 thus preventing relative rotation of the container

and the carrier and ensuring that the carrier moves upwardly

or downwardly when the shaft 8 turns. The carrier 9 and the

mass 4 can be retracted by rotation of the wheel 3 in an

opposing direction.

[0140] The words “comprises/comprising” and the words

“having/including” when used herein with reference to the

present invention are used to specify the presence of stated

features, integers, steps or components but does not preclude

the presence or addition of one or more other features,

integers, steps, components or groups thereof.

[0141] The following examples will serve to illustrate the

invention.

EXAMPLES

[0142] General

[0143] In the following examples the dibenzylidene sor-

bitol used was the product DisorbeneTM described above.

[0144] Bonding tests were carried out using various sub-

strates, including natural polyethylene and natural polypro-

pylene as the non-polar substrates, various solutions of the

active adhesion promotion compounds as the primer and

various grades of cyanoacrylate adhesive commercially

available from Loctite (Ireland) Limited, Dublin, Ireland.

The bond strength of the resulting joints was determined

using conventional [text missing or illegible when

filed] following standard test method ASTM D 1002.

[0145] The 3 kg Test as described below is the minimum

time following assembly for bonds to support a 3 kg weight.

The minimum time is determined in accordance with ASTM

D1002.

Example 1

[0146] 2.0 g of dibenzylidene sorbitol was dissolved in

refluxing ethanol (148 g) with vigorous stirring and the

Sep. 4, 2003

solution allowed to cool for a short period. Then 1,8-

diazabicyclo[5.4.0]undec-7-ene (0.15 g) was added with

stirring and the solution was allowed to cool further. The

solution was then cast into empty stick cartridges of the type

typically used for adhesives such as PrittStickTM (and as

described above) and was allowed to cool to room tempera-

ture. During this time the solution solidified. The solidified

stick was clear (homogeneous) resembling a frozen mass.

The solid stick primer solution could then be extruded using

the cartridges inbuilt propulsion mechanism.

[0147] Test pieces of natural polyethylene of dimensions

100 mm>