2-Cyanoacrylate Adhesive Composition

Folder:

Year:

Abstract:

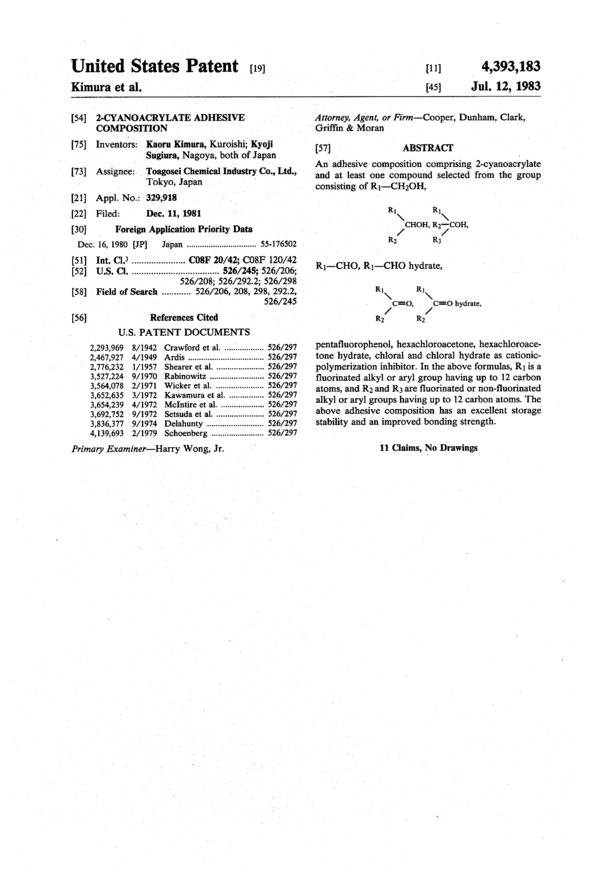

An adhesive composition comprising 2-cyanoacrylate and at least one compound selected from the group consisting of R1-CH2OH,

pentafluorophenol, hexachloroacetone, hexachloroacetone hydrate, chloral and chloral hydrate as cationic-polymerization inhibitor. In the above formulas, R1 is a fluorinated alkyl or aryl group having up to 12 carbon atoms, and R2 and R3 are fluorinated or non-fluorinated alkyl or aryl groups having up to 12 carbon atoms. The above adhesive composition has an excellent storage stability and an improved bonding strength.

Type of document:

Language:

_[22] Filed:

United States Patent [19]

Kimura et al.

[54] 2-CYANOACRYLATE ADHESIVE

COMPOSITION ’

[75] Inventors: Kaoru Kimura, Kuroishi; Kyoji

Sugiura, Nagoya, both of Japan

Toagosei Chemical Industry Co., Ltd.,

Tokyo, Japan

[21] Appl. No.: 329,918

Dec. 11, 1981

[30] Foreign Application Priority Data

Dec. 16, 1980 [JP] Japan .............................. .. 55-176502

[51] Int. Cl.3 .................... .. C08F 20/42; COSF 120/42

[52] U.S. Cl. .................................. .. 526/245; 526/ 206;

526/208; 526/292.2; 526/298

[58] Field of Search .......... .. 526/206, 208, 298, 292.2,

526/245

[73] Assignee:

[56] References Cited

U.S. PATENT DOCUMENTS

2,293,969 8/1942 Crawford et al. ................ .. 526/297

2,467,927 4/1949 Ardis .............. .. 526/297

2,776,232 1/1957 Shearer et al. 526/297

3,527,224 9/1970 Rabinowitz .. 526/297

3,564,078 2/1971 Wicker et al. 526/297

3,652,635 3/1972 Kawamura et a1. . 526/297

3,654,239 4/1972 Mclntire et al. 526/297

3,692,752 9/1972 Setsuda et al. 526/297

3,836,377 9/1974 Delahunty‘ ..... .. 526/297

4,139,693 2/1979 Schoenberg ...................... .. 526/297

Primary Examiner—Harry Wong, Jr.

[11] 4,393,183

[45] Jul. 12, 1983

Attorney, Agent, or Firm—Cooper, Dunham, Clark,

Griffin & Moran

[57] ABSTRACT

An adhesive composition comprising 2-cyanoacrylate

and at least one compound selected from the group

consisting of R1—CH2OH,

R1 R1

\ \

CHOH, R2-—C0H,

/

R2 R3

R1-4-CH0, R1———CHO hydrate,

R1 R1

\ \

C=O,

C=O hydrate,

/

R2 R2

pentafluorophenol, hexachloroacetone, hexachloroace-

tone hydrate, chloral and chloral hydrate as cationic-

polymerization inhibitor. In the above formulas, R1 is a

fluorinated alkyl or aryl group having up to 12 carbon

atoms, and R2 and R3 are fluorinated or non-fluorinated

alkyl or aryl groups having up to 12 carbon atoms. The

above adhesive composition has an excellent storage

stability and an improved bonding strength.

11 Claims, 1_‘Io Drawings

4,393,183

1

2-CYANOACRYLATE ADHESIVE COMPOSITION

The present invention relates to a 2-cyano acrylate

adhesive composition. More particularly, it relates to a

2-cyanoacrylate adhesive composition having an excel-

lent storage stability and an improved bonding strength.

2-Cyanoacrylate adhesives are reactive adhesives

which comprise 2-cyanoacrylate monomer as the main

component, and therefore, they are often cured during

storage in their containers owing to the radical or ani-

onic polymerization of 2-cyanoacrylate monomer. In

order to obtain a good storage stability, a polymeriza-

tion inhibitor is added to them as a stabilizer. As inhibi-

tors for the radical polymerization of 2-cyanoacrylate

monomer, there are used hydroquinone, hydroquinone

monomethyl ether, catechol, pyrogallol, Bisphenol A

and the like. The inhibitor is added in the range of 1 to

10,000 ppm in order to prevent the radical polymeriza-

tion during storage at room temperature.

On the other hand, the anionic polymerization is

initiated by a very small amount of a basic substance

such as water, an amine, ammonia or the like incorpo-

rated during storage. For preventing the viscosity in-

crease and gelation resulting from this anionic polymer-

ization, it is known that S02, S03, SOCI2, SO2Cl2, HF,

N02, p-toluenesulfonic acid, methanesulfonic acid, pro-

panesultone, phosphoric acid, sulfuric acid and the like

are effective. However, the addition of these anionic-

polymerization inhibitors causes the coloring of adhe-

sive composition with time and the prolongation of the

setting time thereof with time. Accordingly, anionic-

polymerization inhibitors of better quality which do not

cause the above problems have been desired in this field.

In view of the above need, the present inventors have

made research on stabilizers which can prevent the

anionic polymerization of 2-cyanoacrylate monomer.

As a result, it has been found that a compound having

an active hydroxyl group or a group which can be

converted into an active hydroxyl group is an effective

anionic-polymerization inhibitor unlike the conven-

tional one. ‘

According to this invention, there is provided an

adhesive composition which comprises a 2-cyanoacry-

late and a compound having an active hydroxyl group

or a group which can be converted into an active hy-

droxyl group. The present invention has enabled the

prevention of the reduction in the adhesive properties

of 2-cyanoacrylate monomer with time during storage

experienced with conventional anionic-polymerization

inhibitors, namely the prevention of the coloring with

time and the prolongation of setting time with time.

Further, the adhesive composition according to the

present invention has not only excellent storage stabil-

ity, but also an improved bonding strength.

The present anionic-polymerization inhibitor for 2-

cyanoacrylate monomer which has an active hydroxyl

group or a group which can be converted into an active

hydroxyl group is a compound possessing in the mole-

cule fluorine or chlorine atoms and a hydroxyl, alde-

hyde or carbonyl group. Specifically, the following

compounds are included:

10

15

20

25

30

35

40

45

50

55

65

2

R1 R1 (1)

\ \

R1‘-CH7_OH, CHOH, R2“COH;

/ /

R2 R3

(2) R1—CHO, R1—CHO hydrate;

(3)

C=O hydrate;

R2

(4) pentafluorophenol;

(5) hexachloroacetone, hexachloroacetone hydrate; and

(6) chloral, chloral hydrate.

In the above formulas, R1 is a fluorinated alkyl or aryl

group having up to 12 carbon atoms; and R2 and R3 are

fluorinated or non-fluorinated alkyl or aryl groups hav-

ing up to 12 carbon atoms.

Among the above compounds, the compounds (1),

(2), (3), (4) and (5) are preferred, and more preferable

are the compounds represented by the formulas,

R] R1 R1

\ \ \

R2—COI-I, C=O, C=O hydrate,

/ / /

R3 R2 R2

and pentafluorophenol.

Specific examples of these compounds include triflu-

oroethanol, 1H,1H-pentafluoropropanol, 1H,lH-hepta-

fluorobutanol, lH,1H-nonafluoropentanol, 1, l, 1-tri-

fluoroisopropanol, hexafluoroisopropanol, octafluoro-

sec-butanol, perfluoro-tert-butanol, hexafluoro-tert-

butanol, 2-trifluoromethylpropanol-2, 1-ch1oro-

1,1,3,3,3-pentafluoro-2-propanol, 3,3,4,4,4-penta-

fluorobutanol-2, 3,3,4,5,5,5-hexafluoro-2-methylpen-

tanol-2, 1H,1H,5H-octafluoro-1-pentanol, 1H, lH-pen-

tadecafluorooctanol-1, trifluoroacetaldehyde, tri-

fluoroacetaldehyde hydrate, heptafluorobenzaldehyde,

2,2,3,3,4,4-hexafluoro-1,5-pentanediol, pentafluoroben-

zyl alcohol, hexafluoroacetone, hexafluoroacetone hy-

drate, trifluoromethyl trichloromethyl ketone, penta-

fluoroethyl ethyl ketone, pentafluorophenyl methyl

ketone, methyl heptafluoropropyl ketone, hexafluoro-2-

phenylisopropanol, hexafluoro-2-(p-tolyl)isopropanol,

pentafluorophenol, hexachloroacetone, hexachloroace-

tone hydrate, sym-dichlorotetrafluoroacetone and sym-

dichlorotetrafluoroacetone hydrate.

Among the above specific compounds, preferable are

trifluoroethanol, 1H,1H—pentafluoropropanol, 1, 1, l-tri-

fluoroisopropanol, hexafluoroisopropanol, octafluoro-

sec-butanol, perfluoro-tert-butanol, hexafluoro-tert-

butanol, 2-trifluoromethylpropanol-2, 3,3,4,4,4-penta-

fluorobutanol-2, trifluoroacetaldehyde, tri-

fluoroacetaldehyde hydrate, heptafluorobenzaldehyde,

pentafluorobenzyl alcohol, hexafluoroacetone, hexa-

fluoroacetone hydrate, trifluoromethyl trichloromethyl

ketone, pentafluorophenyl methyl ketone, methyl hep-

tafluoropropyl ketone, pentafluorophenol, hexachlor-

oacetone, and sym-dichlorotetrafluoroacetone. More

preferable are hexafluoroisopropanol, perfluoro-tert-

butanol, trifluoroacetaldehyde, trifluoroacetaldehyde

hydrate, hexafluoroacetone, hexafluoroacetone hydrate

and pentafluorophenol.

4,393,183

3

These compounds possess a hydroxyl group activated

by electron-attractive fluorine or chlorine atoms, or, in

the case of aldehyde and ketone compounds, they can

be converted into compounds having active hydroxyl

group as shown in the following formulas, by combin-

ing or reacting with a very small amount of water or an

alcohol present in the adhesive composition:

OH

H 0 /

CF3CHO 2% CF3CH

OI-I

c H OH

CF3CHO -—2—5—-9 CF3(|2H--OH

OCZH5

/on

H 0

CF3CCH3 2% (CF3)2C

ll

0 OH

The above fluorinated or chlorinated compounds

have the nature that they become acidic because of the

dissociation of hydroxyl groups into H+ due to the

electron attractive property of the fluorinated or chlori-

nated alkyl or aryl groups. Therefore, these compounds

prevent the anionic polymerization of 2-cyanoacrylate

monomer during storage, and accordingly, no reduc-

tion of its bonding performance with time takes place.

The 2-cyanoacrylate adhesive composition according

to the present invention can be obtained by adding at

least one compound selected from the above com-

pounds (1) to (6) to a 2-cyanoacrylate monomer, prefer-

ably in a quantity of 0.1 to 10,000 ppm, more preferably

1 to 6,000 ppm. In this case, the above compound may

also be used in combination with a conventional anion-

ic-polymerization inhibitor such as S02, S03, p-toluene-

sulfonic acid, propanesultone or the like.

Representative examples of the 2-cyanoacrylate mon-

omer, which is the main component of the adhesive

composition according to the present invention, include

methyl 2-cyanoacrylate, ethyl 2-cyanoacrylate, propyl

2-cyanoacrylate, allyl 2-cyanoacrylate, butyl 2-cyanoa-

crylate, heptyl 2-cyanoacrylate, hexyl 2-cyanoacrylate,

octyl 2-cyanoacrylate, decyl 2-cyanoacrylate, dodecyl

2-cyanoacrylate, 2-chloroethyl 2-cyanoacrylate, methyl

Cellosolve 2-cyanoacrylate, ethyl Cellosolve 2-cyanoa-

crylate, butyl Cellosolve 2-cyanoacrylate, benzyl 2-

cyanoacrylate, phenyl 2-cyanoacrylate, trifluoroisopro-

pyl 2-cyanoacrylate, and the like.

The adhesive composition according to the present

invention may also contain a radical polymerization

inhibitor in a quantity of l to 10,000 ppm, preferably 10

to 5,000 ppm. For example, hydroquinone, hydroqui-

none monomethyl ether, catechol and pyrogallol are

effective.

When it is desired to thicken the present adhesive

composition, a thickener such as methyl methacrylate

polymer, vinyl acetate polymer, cellulose acetate isobu-

tyrate, acrylic rubber or the like may also be dissolved

in a proportion of several percent.

Other additives such as plasticizers for imparting

flexibility to cured adhesive layers, modifiers for im-

parting impact resistance and heat resistance and dyes

and pigments for identification of coating may also be

added.

Because of containing a small amount of at least one

of the compounds (1) to (6), the adhesive composition

l0

15

20

25

30

35

45

50

55

60

65

4

according to this invention exhibits aniexcellent storage

stability and simultaneously has a higher bonding

strength than the conventional adhesive compositions.

The adhesive composition according to this invention

has a high setting rate (namely a short setting time) and

is suitable for instantaneous adhesion of most materials

such as rubbers, plastics, metals, wood and the like. The

composition is used, for instance, for assembling small

parts.

This invention is explained in more detail below re-

ferring to Examples. However, this invention should

not be understood to be limited to the Examples. In the

Examples and Comparative Examples, parts are by

weight unless otherwise specified.

Examples 1 to 17 and Comparative Example 1

To 100 parts of ethyl 2-cyanoacrylate were added

0.05 part of hydroquinone and 0.002 part of each of the

inhibitors shown in Table 1. Each of the adhesive com-

positions thus obtained was charged into a polyethylene

container and then subjected to heating tests at 60° C.

Results are shown in Table 1.

TABLE 1

Tensile

shear

strength

of bond

(iron)

(Kgf/cmz)

Setting

time

(iron)

(sec)

Heat

gelation

test at

Inhibitor 60° C.

Ex-

ample

1 CF3Cl-I201-I 10 200 Stable for

more than

35 days

Stable for

more than

35 days

Stable for

more than

46 days

2 (CF3)2CHOH 10 205

3 (CF3)3COH 10 205

4 CH3 10 200 Stable for

I more than

CF3"CHOH 35 days

5 CF3CF2Cl-I201-I 10 200 Stable for

more than

35 days

Stable for

more than

35 days

Stable for

more than

43 days

Stable for

more than

35 days

Stable for

more than

50 days

Stable for

more than

35 days

Stable for

more than

40 days

Stable for

more than

35 days

Stable for

more than

43 days

Stable for

more than

45 days

6 HCFZCFZCI-I201-I 10 210'

7 C5F5Ol-I 10 210

3 C5F5CH20H 10 220

9 (CF3)2C=O hydrate 10 220

10 (cc13-)2—c=o 10 200

ll CF3CHO hydrate 10 210

12 10

CCl3CI-IO 190

13 C5F5CHO 10 195

14 (cc11=2-)z—c=o

hydrate

10 200

4,393,183

5 6

TABLE 1-continued TABLE 3

Tensile Tensile

shear shear

Setting strength Heat Strength Heat‘

time ‘ of bond gelation 5 al Seniflg 0f bond 8913*)“

(iron) (1,-oh) test gt fsddition time (iron) test at

Inhibitor (sec) (Kg,-/cmz) 60- C_ Inhibitor (sec) (Kgf/cmz) 60' C.

is C3F7CCH3 10 200 Stable for _1:3_X2I2L1

Coments go here:

- Log in to post comments