Cyanoacrylate Solutions Containing Preservatives

Folder:

Year:

Abstract:

An adhesive composition that contains a preservative is particularly useful as a medical adhesive and can include alkyl cyanoacrylate monomers. The preservative is preferably soluble in the monomer. The compostion may optionally be sterilized by placing a mixture of a polymerizalble adhesive monomer and a preservative in a container, sealing the container and sterilizing the mixture and the container.

Type of document:

Language:

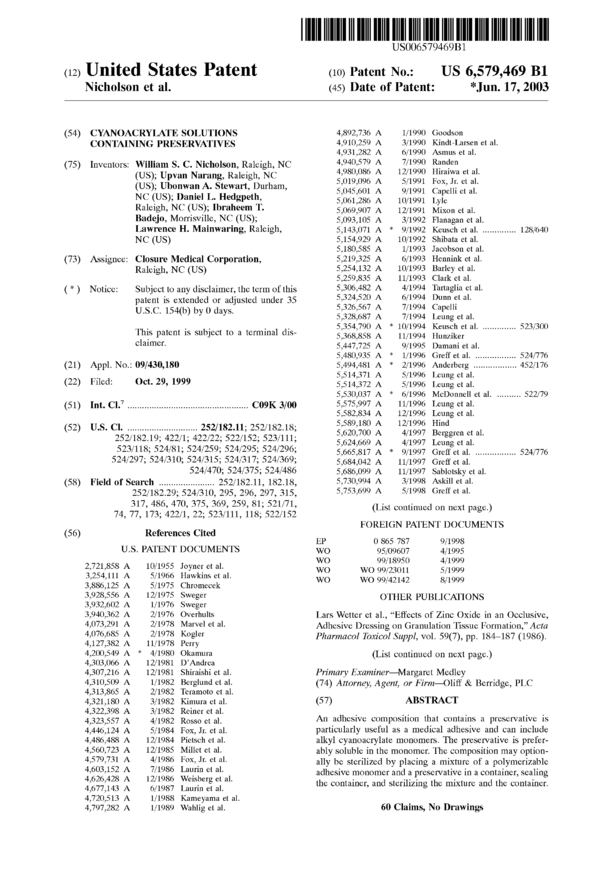

(12)

United States Patent

Nicholson et al.

US006579469B1

US 6,579,469 B1

*Jun. 17, 2003

(10) Patent N0.:

(45) Date of Patent:

(54)

(75)

(73)

(*)

(21)

(22)

(51)

(52)

(58)

(56)

CYANOACRYLATE SOLUTIONS

CONTAINING PRESERVATIVES

Inventors: William S. C. Nicholson, Raleigh, NC

(US); Upvan Narang, Raleigh, NC

(US); Ubonwan A. Stewart, Durham,

NC (US); Daniel L. Hedgpeth,

Raleigh, NC (US); Ibraheem T.

Badejo, Morrisville, NC (US);

Lawrence H. Mainwaring, Raleigh,

NC (US)

Assignee: Closure Medical Corporation,

Raleigh, NC (US)

Notice: Subject to any disclaimer, the term of this

patent is extended or adjusted under 35

U.S.C. 154(b) by 0 days.

This patent is subject to a terminal dis-

claimer.

Appl. No.: 09/430,180

Filed: Oct. 29, 1999

Int. Cl.7 ................................................ .. C09K 3/00

U.S. Cl. ........................... .. 252/182.11; 252/182.18;

252/182.19; 422/1; 422/22; 522/152; 523/111;

523/118; 524/81; 524/259; 524/295; 524/296;

524/297; 524/310; 524/315; 524/317; 524/369;

524/470; 524/375; 524/486

Field of Search ..................... .. 252/182.11, 182.18,

252/182.29; 524/310, 295, 296, 297, 315,

317, 486, 470, 375, 369, 259, 81; 521/71,

74, 77, 173; 422/1, 22; 523/111, 118; 522/152

References Cited

U.S. PATENT DOCUMENTS

2,721,858 A 10/1955 Joyner et al.

3,254,111 A 5/1966 Hawkins et al.

3,886,125 A 5/1975 Chromecek

3,928,556 A 12/1975 Sweger

3,932,602 A 1/1976 Sweger

3,940,362 A 2/1976 Overhults

4,073,291 A 2/1978 Marvel et al.

4,076,685 A 2/1978 Kogler

4,127,382 A 11/1978 Perry

4,200,549 A * 4/1980 Okamura

4,303,066 A 12/1981 D’Andrea

4,307,216 A 12/1981 Shiraishi et al.

4,310,509 A 1/1982 Berglund et al.

4,313,865 A 2/1982 Teramoto et al.

4,321,180 A 3/1982 Kimura et al.

4,322,398 A 3/1982 Reiner et al.

4,323,557 A 4/1982 Rosso et al.

4,446,124 A 5/1984 Fox, Jr. et al.

4,486,488 A 12/1984 Pietsch et al.

4,560,723 A 12/1985 Millet et al.

4,579,731 A 4/1986 Fox, Jr. et al.

4,603,152 A 7/1986 Laurin et al.

4,626,428 A 12/1986 Weisberg et al.

4,677,143 A 6/1987 Laurin et al.

4,720,513 A 1/1988 Kameyama et al.

4,797,282 A 1/1989 Wahlig et al.

4,892,736 A 1/1990 Goodson

4,910,259 A 3/1990 Kindt—Larsen et al.

4,931,282 A 6/1990 Asmus et al.

4,940,579 A 7/1990 Randen

4,980,086 A 12/1990 Hiraiwa et al.

5,019,096 A 5/1991 Fox, Jr. et al.

5,045,601 A 9/1991 Capelli et al.

5,061,286 A 10/1991 Lyle

5,069,907 A 12/1991 Mixon et al.

5,093,105 A 3/1992 Flanagan et al.

5,143,071 A * 9/1992 Keusch et al. ............ .. 128/640

5,154,929 A 10/1992 Shibata et al.

5,180,585 A 1/1993 Jacobson et al.

5,219,325 A 6/1993 Hennink et al.

5,254,132 A 10/1993 Barley et al.

5,259,835 A 11/1993 Clark et al.

5,306,482 A 4/1994 Tartaglia et al.

5,324,520 A 6/1994 Dunn et al.

5,326,567 A 7/1994 Capelli

5,328,687 A 7/1994 Leung et al.

5,354,790 A * 10/1994 Keusch et al. ............ .. 523/300

5,368,858 A 11/1994 Hunziker

5,447,725 A 9/1995 Damani et al.

5,480,935 A * 1/1996 Greff et al. ............... .. 524/776

5,494,481 A * 2/1996 Anderberg ................ .. 452/176

5,514,371 A 5/1996 Leung et al.

5,514,372 A 5/1996 Leung et al.

5,530,037 A * 6/1996 McDonnell et al. ........ .. 522/79

5,575,997 A 11/1996 Leung et al.

5,582,834 A 12/1996 Leung et al.

5,589,180 A 12/1996 Hind

5,620,700 A 4/1997 Berggren et al.

5,624,669 A 4/1997 Leung et al.

5,665,817 A * 9/1997 Greff et al. ............... .. 524/776

5,684,042 A 11/1997 Greff et al.

5,686,099 A 11/1997 Sablotsky et al.

5,730,994 A 3/1998 Askill et al.

5,753,699 A 5/1998 Greff et al.

(List continued on next page.)

FOREIGN PATENT DOCUMENTS

EP 0 865 787 9/1998

WO 95/09607 4/1995

WO 99/18950 4/1999

W0 WO 99/23011 5/1999

W0 WO 99/42142 8/1999

OTHER PUBLICATIONS

Lars Wetter et al., “Effects of Zinc Oxide in an Occlusive,

Adhesive Dressing on Granulation Tissue Formation,” Acta

Pharmacol Toxicol Suppl, vol. 59(7), pp. 184-187 (1986).

(List continued on next page.)

Primary Examiner—Margaret Medley

(74) Attorney, Agent, or Firm—Oliff & Berridge, PLC

(57) ABSTRACT

An adhesive composition that contains a preservative is

particularly useful as a medical adhesive and can include

alkyl cyanoacrylate monomers. The preservative is prefer-

ably soluble in the monomer. The composition may option-

ally be sterilized by placing a mixture of a polymerizable

adhesive monomer and a preservative in a container, sealing

the container, and sterilizing the mixture and the container.

60 Claims, No Drawings

US 6,579,469 B1

Page 2

U.S. PATENT DOCUMENTS 6,248,800 B1 6/2001 Greff et 211.

6,352,704 B1 * 3/2002 Nicholson et al. ........ .. 424/407

5,760,102 A * 6/1998 Hall et al. ................ .. 523/120

5,762,919 A 6/1998 Greff et 211. OTHER PUBLICATIONS

5,783,177 A 7/1998 Greff et 211.

5,307,563 A 9/1993 Askiu et a1. Lars Wetter et al., “Effects of Zinc Oxide in an Occlusive

5,811,091 A 9/1998 Greff etal. Adhesive Dressing on Granulation Tissue Formation,”

5,866,106 A 2/1999 Papay Scand. J. Plast. Reconsr Surgery, Vol. 20, pp. 165-172

5,902,594 A 5/1999 Greff et al. (1986).

5,928,611 A 7/1999 Leung TM . .

5,998,472 A * 12/1999 Berger et al. ............. .. 514/527 DIiRMAGRAN Pr°duCtL1teramre’Derma SC1enCeS(date

6,086,906 A 7/2000 Greff etal. “ “°W“)" “ . . .

6,090,397 A 7/2000 Lee et a1. M. Fan et al., Effect of ChlorheX1d1ne Varnish System on

5,102,205 A 3/2000 Greff et a1. Streptococcus Mutant in Fissure Plaques,” Zhonghua Kau-

6,143,805 A * 11/2000 Hickey et al. ............ .. 522/152 qiang Hxue Zazhi, Col. 32(5), pp. 269-271 (1997)

RE36,994 E * 12/2000 Anderberg 452/176 (abstract).

6,183,593 B1 * 2/2001 Narang et al. . 156/327

6,191,202 B1 * 2/2001 Greff et al. ............... .. 524/310 * cited by examiner

US 6,579,469 B1

1

CYANOACRYLATE SOLUTIONS

CONTAINING PRESERVATIVES

BACKGROUND OF THE INVENTION

1. Field of the Invention

The invention relates to monomer and polymer adhesive

and sealant compositions, and to their production for indus-

trial and medical uses.

2. State of the Art Monomer and polymer adhesives are

used in both industrial (including household) and medical

applications. Included among these adhesives are the 1,1-

disubstituted ethylene monomers and polymers, such as the

ot-cyanoacrylates. Since the discovery of the adhesive prop-

erties of such monomers and polymers, they have found

wide use due to the speed with which they cure, the strength

of the resulting bond formed, and their relative ease of use.

These characteristics have made ot-cyanoacrylate adhesives

the primary choice for numerous applications such as bond-

ing plastics, rubbers, glass, metals, wood, and, more

recently, biological tissues.

It is known that monomeric forms of ot-cyanoacrylates are

extremely reactive, polymerizing rapidly in the presence of

even minute amounts of an initiator, including moisture

present in the air or on moist surfaces such as animal tissue.

Monomers of ot-cyanoacrylates are anionically polymeriz-

able or free radical polymerizable, or polymerizable by

zwitterions or ion pairs to form polymers. Once polymer-

ization has been initiated, the cure rate can be very rapid.

Medical applications of 1,1-disubstituted ethylene adhe-

sive compositions include use as an alternate or an adjunct

to surgical sutures and staples in wound closure as well as

for covering and protecting surface wounds such as

lacerations, abrasions, burns, stomatitis, sores, and other

surface wounds. When an adhesive is applied, it is usually

applied in its monomeric form, and the resultant polymer-

ization gives rise to the desired adhesive bond.

For example, polymerizable 1,1-disubstituted ethylene

monomers, and adhesive compositions comprising such

monomers, are disclosed in U.S. Pat. No. 5,328,687 to

Leung et al. Suitable methods for applying such composi-

tions to substrates, and particularly in medical applications,

are described in, for example, U.S. Pat. Nos. 5,582,834,

5,575,997, and 5,624,669, all to Leung et al.

It is known to use cyanoacrylate adhesives to deliver

bioactive agents to a wound site. For example, the above

patents to Leung et al. disclose such technology in some

detail. Examples of such bioactive agents include antimi-

crobial agents to be released into the wound. U.S. Pat. Nos.

5,684,042; 5,753,699; 5,762,919; 5,783,177; 5,811,091; and

5,902,594, all to Greff et al., disclose that an antimicrobially

effective amount of an antimicrobial agent may be incorpo-

rated into the polymerizable cyanoacrylate ester composi-

tion to promote wound healing and retard infection of the

wound. See col. 2, lines 50-53 and Abstract of the ’699

patent. In order to achieve an antimicrobial effect, an anti-

microbial complex of iodine molecules with a biocompatible

polymer is used. The iodine/polymer complexes are dispers-

ible in the cyanoacrylate ester. See col. 7, lines 45-48 of the

’699 patent. However, the iodine/polymer complexes were

not soluble in the cyanoacrylate ester. See Table I, col. 12,

line 55—col. 13, line 14 of the ’699 patent. See also, U.S. Pat.

Nos. 5,730,994 and 5,807,563 to Askill et al. and WO

99/18950 to Berger et al.

It is also important to prevent the introduction of micro-

organisms to the wound site during treatment of the wound.

10

15

20

25

30

35

40

45

50

55

60

65

2

Cyanoacrylate compositions, at least those for use in medi-

cal applications, are generally initially sterile. That is, the

compositions as manufactured do not contain live microor-

ganisms. However, through improper handling of the com-

positions or repeated exposure of the compositions to a

non-sterile environment, such as with multiple use

applicators, microorganisms that are present in the air may

be introduced into a cyanoacrylate composition and survive,

resulting in the contamination of the composition. Although

the source for this characteristic is not understood, it has

been observed that cyanoacrylate compositions inherently

possess some antimicrobial activity. In particular,

cyanoacrylate compositions themselves prevent the growth

of some types of microorganisms within the composition.

However, cyanoacrylate compositions by themselves do not

possess such a broad spectrum of antimicrobial activity that

all amounts of every type of microorganisms would not

grow in the compositions.

A way to inactivate microorganisms in the cyanoacrylate

compositions is to sterilize the composition. However, ster-

ilization of ot-cyanoacrylate adhesive compositions is often

difficult to achieve. For example, widely practiced methods

of sterilization, such as dry and moist heat sterilization,

ionizing radiation, exposure to gas, and aseptic filtration, are

not always convenient for use with monomeric cyanoacry-

late compositions. Problems sometimes arise due to poly-

merization of the monomer during the sterilization process.

In many cases, sterilization-induced polymerization is so

severe that the resulting product is unusable.

Additionally, even if complete sterilization of cyanoacry-

late compositions is achieved, such that all microorganisms

present in the composition are destroyed, improper handling

or exposure to air after sterilization could result in introduc-

tion and growth of microorganisms in the cyanoacrylate

compositions.

Thus, a need exists for improved monomer cyanoacrylate

adhesive compositions, especially for medical uses, wherein

the growth of microorganisms in a cyanoacrylate composi-

tion is prevented and the performance of the adhesive

composition is not compromised.

SUMMARY OF THE INVENTION

The present invention provides a monomeric adhesive

composition comprising an antimicrobial preservative agent

and a polymerizable alkyl cyanoacrylate monomer. In

embodiments, the antimicrobial agent is soluble in the

monomer at room temperature and the resultant composition

is stable for at least a given amount of time. However, in

some specific embodiments, complete solubility may not be

required. Production of the composition includes mixing a

polymerizable alkyl cyanoacrylate monomer and an antimi-

crobial agent in a container. The monomeric adhesive com-

position may be sterilized. Production of the sterilized

composition includes placing a polymerizable alkyl

cyanoacrylate monomer and an antimicrobial agent in a

container, sealing the container and sterilizing the container

and the mixture. Optionally, the container used to hold the

composition in embodiments of the present invention can be

a multi-use container or packaging system. The composi-

tions produced, packaged and sterilized according to the

present invention are stable, and have extended utility, as

compared to adhesive compositions of the prior art.

DETAILED DESCRIPTION OF PREFERRED

EMBODIMENTS

According to the present invention, a monomeric adhe-

sive composition comprises a preservative agent and a

polymerizable alkyl cyanoacrylate monomer.

US 6,579,469 B1

3

An antimicrobial preservative agent is a compound that

either destroys or usefully suppresses the growth or metabo-

lism of a variety of microscopic or submicroscopic life

forms. Such life forms include, but are not limited to

microorganisms, bacteria, fungi, algae, protozoa, and

viruses. The agent preferably has a positive antimicrobial

effect against at least microorganisms. In particular, the

agent should be effective so that most, and preferably all, of

the microscopic or submicroscopic life forms are killed,

without compromising the monomeric adhesive composi-

tion. Preferably, the agent is effective at reducing or main-

taining the level of microbes in the composition at a com-

mercially acceptable level, or at a level as regulated by an

appropriate governing body, such as the USP (United States

Pharmacopia) or the European Pharmacopia, or recom-

mended by associations such as the Cosmetic, Toiletry and

Fragrance Association.

Preferably, in embodiments of the present invention, the

preservative is effective at killing, or at least preventing the

growth of, any microbes that may be initially present in the

adhesive formulation, or that may be subsequently intro-

duced into the adhesive formulation during normal use. In

embodiments where the adhesive formulation containing the

preservative is sterilized, the preservative is particularly

useful in killing or preventing the growth of any microbes

that may be subsequently introduced into the adhesive

formulation during normal use thereof, such as during

normal use of a multiple-use applicator system, where air

and contaminants may be introduced into the applicator. The

present invention, in embodiments, is applicable to single-

use containers or applicators, where it is desired to maintain

a high degree of prolonged sterility and stability of the

composition, by supplementing an optional sterilization

treatment by addition of the antimicrobial agent. Likewise,

in embodiments, the present invention is also particularly

applicable to multiple-use containers or applicators, where it

is desired to maintain a high degree of prolonged sterility

and stability of the composition against microbial action

despite loss of initial sterility upon first use of the compo-

sition.

The preservative of the present invention operates to

destroy microorganisms that may be present or grow in the

polymerizable alkyl cyanoacrylate monomer composition.

Although some preservatives may also advantageously

function as polymerization inhibitors, in embodiments of the

present invention the preservative does not operate as such,

and does not affect polymerization of the monomer material.

The preservative may be selected from among known

anti-microbial agents. In embodiments, the preservative may

be selected from among known preservatives, including, but

not limited to, parabens and cresols. For example, suitable

parabens include, but are not limited to, alkyl parabens and

salts thereof, such as methylparaben, methylparaben

sodium, ethylparaben, propylparaben, propylparaben

sodium, butylparaben, and the like. Suitable cresols include,

but are not limited to, cresol, chlorocresol, and the like. The

preservative can also be selected from other known agents

including, but not limited to, hydroquinone, pyrocatechol,

resorcinol, 4-n-hexyl resorcinol, 3a,4,7,7a-tetrahydro-2-

((trichloromethyl)thio)-1H-isoindole-1,3(2H)-dione, benza-

lkonium chloride, benzalkonium chloride solution, benze-

thonium chloride, benzoic acid, benzyl alcohol,

cetylpyridinium chloride, chlorobutanol, dehydro acetic

acid, o-phenylphenol, phenol, phenyl ethyl alcohol, potas-

sium benzoate, potassium sorbate, sodium benzoate, sodium

dehydroacetate, sodium propionate, sorbic acid, thimerosal,

thymol, phenylmercuric compounds such as phenylmercuric

10

15

20

25

30

35

40

45

50

55

60

65

4

borate, phenylmercuric nitrate and phenylmercuric acetate,

formaldehyde, and formaldehyde generators such as the

preservatives Germall II® and Germall 115®

(imidazolidinyl urea, available from Sutton Laboratories,

Charthan, N.J In embodiments, mixtures of two or more

preservatives can also be used.

Furthermore, various other compounds can be screened

for their antimicrobial and preservative effects, and then

selected based on the results of this screening. For example,

compounds can be tested for their antimicrobial and preser-

vative effectiveness by one or more of a USP preservative

test regimen, a USP microbial limits test, a USP bacteriosta-

sis and fungistasis test, and a USP antibiotics-microbial

assay. See, for example, USP 23, Supplement 8, “Anti-

microbial Effectiveness Testing,” the entire disclosure of

which is incorporated herein by reference.

According to the present invention, a selection process

may be used to select appropriate agents for use in specific

polymerizable alkyl cyanoacrylate monomer compositions

in accordance with the invention. Such a screening process

can be used to select from among the various known

preservative, or from those agents determined by the above

USP testing regimens. The preservative should be soluble in

the monomer composition and without significantly

adversely affecting the stability of the monomer composi-

tion. In addition, in embodiments, the preservative in com-

bination with the monomer composition should also be

compatible with one or more sterilization procedures. Thus,

a suitable procedure for selecting an agent generally

involves selecting a group of potential agents, assessing

their solubility and stability in the monomer composition,

and testing for their compatibility with one or more steril-

ization procedures.

Potential agents for testing can readily be selected by one

of ordinary skill in the art from known sources. For example,

such sources can include the USP list of approved agents, or

other such lists maintained by various governmental or

non-governmental agencies, such as the U.S. Food and Drug

Administration (US FDA).

Once a potential agent is selected, it can be tested for

solubility and stability in the monomer composition, such as

by mixing an appropriate amount of the agent with a desired

amount of the monomer composition and any other desired

additives. It is preferred that the agent is soluble, i.e.,

dissolves, in the monomer composition.

Solubility is preferred because a higher antimicrobial

effect can be provided by the agent when it is dispersed

throughout the monomer composition in the form of a

solution. If the agent is not in the form of a solution, then it

is possible that the agent may settle or otherwise

agglomerate, and thereby not provide an antimicrobial effect

to all of the monomer composition.

Thus, it is preferred in embodiments that the agent exhib-

its a uniform concentration, or substantially so, throughout

the monomer composition. Of course, where excess agent is

added to the composition, i.e., in an amount above the

solubility point of the agent, it is acceptable that a portion of

the agent remains undissolved in the composition so long as

it does not significantly interfere with the stability and/or use

of the composition. Furthermore, the antimicrobial agent can

be provided by a component that is not itself necessarily

soluble in the monomer composition. For example, various

non-polymer stabilized agents, such as some elemental

metals and metal compounds, which themselves are not

soluble in the monomer composition, can provide an anti-

microbial agent, such as metal ions, which is soluble in the

monomer composition.

US 6,579,469 B1

5

Asecond screening procedure is to test the potential agent

for stability with the monomer composition. This screening

procedure can also be performed by mixing an appropriate

amount of the agent with a desired amount of the monomer

composition and any other desired additives. Stability is

preferred because it is important to maintain the stability of

the monomer composition within acceptable levels, such as

commercially acceptable levels whereby the composition is

not prematurely polymerized prior to application of the

monomer composition to a desired substrate. One possible

measure of the stability of the composition, other than a

visual examination of the properties of the composition, is a

measure of any changes in viscosity of the composition from

a time prior to adding the agent to a time after adding the

agent. For example, dramatic increases or decreases in the

viscosity can indicate instability of the composition, such as

premature polymerization or other chemical degradation of

the monomer composition or components thereof.

In embodiments of the present invention, it is preferred

that the agent exhibit stability in the monomer composition

for at least five minutes after mixing or dissolving the agent

in the polymerizable monomer compound. More preferably,

stability of the monomer composition is maintained for at

least one hour, preferably ten hours, and more preferably

twenty-four hours after mixing the agent with the polymer-

izable monomer compound. Even more preferably, stability

of the monomer composition is maintained for a time period

sufficient to provide a commercially significant shelf-life to

the monomer composition, or even an extended shelf-life as

compared to similar monomer compositions not including

such an agent. As used herein, “stability” refers to the

resultant composition maintaining a commercially accept-

able form for the prescribed amount of time. That is, the

composition does not prematurely polymerize or otherwise

change form or degrade to the point that the composition is

not useful for its intended purpose. Thus, while some

polymerization or thickening of the composition may occur,

such as can be measured by changes in viscosity of the

composition, such change is not so extensive as to destroy

or significantly impair the usefulness of the composition.

Optionally, in embodiments of the present invention, the

potential agent can be tested for its compatibility with one or

more sterilization procedures. This optional screening pro-

cedure can also be performed by mixing an appropriate

amount of the agent with a desired amount of the monomer

composition and any other desired additives, and then sub-

jecting the resultant composition to one or more sterilization

procedures. Compatibility of the agent with one or more

sterilization procedures is preferred in embodiments of the

present invention because many uses of the polymerizable

monomer compositions, such as many medical applications,

require or prefer sterilized products. Following sterilization,

the agent can exert antimicrobial action in killing or pre-

venting growth of microbes that may be introduced into the

pre-sterilized monomer compositions.

Of course, as will be apparent to those skilled in the art,

the above selection procedures need not be conducted in any

particular order, and need not be conducted sequentially.

That is, the procedures can be conducted in any order, and

can be conducted simultaneously, if desired. Likewise, not

all of the procedures may be necessary, and other screening

procedures may be used as necessary depending on particu-

lar applications.

The amount of preservative that is added to the monomer

composition depends upon several factors, including, but not

limited to, the specific preservative being used, the amount

of the preservative suitable for use in the compositions, and

10

15

20

25

30

35

40

45

50

55

60

65

6

whether and to what extent the preservative is regulated by

the U.S. FDA (or other appropriate regulatory agencies or

bodies of the United States or foreign countries). Benzoic

acid may be present in a concentration of from about

0.05—0.1% of the adhesive composition. Benzyl alcohol may

be present in a concentration of from about 0.5—5.0% of the

adhesive composition. Butylparaben, ethylparaben,

methylparaben, methylparaben sodium, propylparaben, and

propylparaben sodium may each be present in a concentra-

tion of from about 0.001—0.2% of the adhesive composition.

Suitable amounts of other preservatives can be determined

by one of ordinary skill in the art, for example with reference

to readily available resources such as S. Seymour Block,

Disinfection, Sterilization and Preservation, 3”’ Ea'., Phila-

delphia:Lea & Febiger, 1983, the entirety of which is

incorporated herein by reference.

Additionally, many compounds that are not polymer-

stabilized, i.e., that are not complexed with or otherwise part

of a polymer species, have antimicrobial properties. Such

compounds can be either soluble or insoluble in the mono-

meric composition. Where the compounds are insoluble in

the monomeric composition, they must be capable of releas-

ing species, such as ions, which are soluble in the monomer

composition and provide the antimicrobial effect. Thus such

compounds either themselves are, or provide, the antimi-

crobial agent.

For example, many metals and metal compounds have

antimicrobial properties. The antimicrobial agent may be

selected from among known metal compounds or elemental

metals, including, but not limited to, mercurial compounds,

such as phenolmercuric chloride, phenolmercuric acetate,

acetomeroctol, nitromersol, thimerosal, mercurochrome,

mercuric chloride, and mercuric iodide; elemental metals,

such as silver and copper; and metal compounds, such as

copper chloride, copper sulfate, copper peptides, zinc

chloride, zinc sulfate, silver nitrate, silver iodide, silver

acetate, silver benzoate, silver carbonate, silver chloride,

silver citrate, silver oxide, silver sulfate, and tincture of

iodine. Copper peptides are discussed, for example, in

“Copper: An Essential Element for Life,” ProCyte

Corporation, available at http://www.humatech.com/

technology.html (Oct. 28, 1999), the entire disclosure of

which is incorporated herein by reference. Further informa-

tion on antimicrobial activities of metals can be found, for

example, in S. Seymour Block, Disinfection Sterilization

and Preservation, 3”’ Ea'., Philadelphia:Lea & Febiger,

1983, the entire disclosure of which is incorporated herein

by reference. The ions from the metal, which constitute the

antimicrobial agent, diffuse into and through the adhesive

composition.

Various non-polymer stabilized compounds, such as the

elemental metals and metal compounds, may be placed into

the adhesive composition in any shape or configuration, as

necessary or desired to provide the desired antimicrobial

effect and the desired solubility of the antimicrobial agent in

the monomer composition. In embodiments, for example,

elemental copper and/or silver may be placed in the adhesive

composition as spheres or balls, either hollow or solid, cubes

or fiat sheets or other shapes as desired. In such cases, the

material should preferably dissolve to provide the desired

concentration of antimicrobial agent in the monomer

composition, or should release the antimicrobial agent at a

desired level or rate to provide the antimicrobial effect.

Although an excess of the agent may be present, such as to

allow for adsorption and absorption by containers and

changes in solubility levels due to, for example, changes in

temperature, consumption of the agent, use of the monomer

US 6,579,469 B1

7

composition and the like, the excess should not significantly

interfere with the use of the monomer composition.

Still further, various zinc compounds can be used in

embodiments of the present invention. Such zinc com-

pounds are preferred in embodiments because they possess

multiple benefits, including the benefits of providing an

antimicrobial effect while also helping to promote wound

healing. The zinc compound can be present in the

cyanoacrylate composition in various forms, such as zinc

salts. For example, suitable zinc compounds include, but are

not limited to, zinc salts of cyanoacrylic acid, zinc salts of

cyanoacetic acid, zinc salts of dicyanoglutaric acid, zinc

salts of rosin, zinc oxide, zinc salts of polycyanoacrylic acid,

zinc salts of polyacrylic acid, zinc bacitracin, zinc salicylate,

zinc stearate, zinc citrate, zinc lactate, mixtures thereof, and

the like. Preferably, the zinc complexes and salts are of Zn“.

The zinc complexes and/or salts can be incorporated into the

cyanoacrylate composition, either prior to or concurrent

with application and/or initiation; however, incorporation

into the composition is preferred so that the antimicrobial

effects can be utilized. Furthermore, once applied, the zinc

compounds are particularly effective in promoting wound

healing of leg ulcers, thermal burns, and the like. The

amount of metal that is added to the monomer composition

depends upon such factors as the form and combination of

the metal used. The amount of metal can be determined by

one of ordinary skill in the art using known techniques

without undue experimentation.

Preferably, the agent is soluble in a monomer composition

at room temperature (i.e., 20-25° C.) so that it may be added

to the monomer composition without excessive heating of

the monomer composition, and so that it remains soluble in

the monomer composition during storage of the composition

prior to use. The agent is selected such that it is compatible

with the monomer (i.e., does not adversely affect

polymerization, bond strength, cure properties, or shelf-life).

In embodiments, the adhesive composition has a viscosity

of about 1-5000 centipoise, such as 3-600 centipoise, or

5-40 centipoise. The viscosity can be selected according to

the proposed use—e.g., 4-50 centipoises for certain uses

and 100-250 centipoises for other uses. Additionally, the

composition may be a gel, e.g., 50,000-500,000 centipoise.

A gel is a combination of a disperse phase with a continuous

phase to produce a semisolid material. The viscosity of the

adhesive composition may be measured with a Brookfield

Viscometer at 25° C. Additionally, in embodiments where a

sterilization treatment is applied, the viscosity of the com-

position should preferably be maintained or increased by a

controlled and acceptable amount after sterilization.

Typically, for medical purposes, an adhesive should have

a shelf-life of at least one year; however, an increased

shelf-life beyond this provides increased economic advan-

tages to both the manufacturer and the consumer. As used

herein, shelf-life refers to the amount of time the container

and composition therein can be held at approximately room

temperature (21-25° C.) without degradation of the compo-

sition and/or container occurring to the extent that the

composition and container cannot be used in the manner and

for the purpose for which they were intended. Thus, while

some degradation to either or both of the composition and

container can occur, it must not be to such an extent that the

composition and/or container is no longer useable. Appro-

priate amounts of preservative agents should be present so as

to allow its effectiveness to be maintained throughout the

shelf-life of the product. As used herein, an “extended

shelf-life” refers to a shelf-life of at least 12 months,

preferably at least 18 months, more preferably at least 24

months, and even more preferably, at least 30 months.

10

15

20

25

30

35

40

45

50

55

60

65

8

The present invention provides alkyl cyanoacrylate

monomer compositions, that provide an extended shelf-life

for industrial and/or medical uses, by killing or preventing

growth of microbial entities such as microorganisms in the

composition, in single-use and/or in multiple-use containers

or applicators.

According to embodiments of the present invention, the

stability, and thus the shelf-life, of some monomeric adhe-

sive compositions can be further enhanced and extended

through careful regulation of the packaging (i.e., dispensing

into a container) and sterilizing procedures. In preferred

embodiments, there is substantially no initiation of poly-

merization of the monomeric liquid adhesive compositions

that affects the utility of the monomer or monomers caused

by the sterilization process. In particular, a polymerizable

alkyl cyanoacrylate monomer and a preservative are dis-

pensed into a container without any, or without any

substantial, initiation of polymerization. The container may

then be sealed and, in embodiments, subjected to known

sterilization techniques.

The monomeric composition may be packaged in any

type of suitable container fabricated from materials

including, but not limited to, glass, plastic, metal packages,

and film-formed packages. Suitable containers include those

into which the compositions can be dispensed and sterilized

without unacceptable damage to, or degradation of, the

container or the components of the monomer composition.

Glass is especially preferred when sterilization is achieved

with dry heat because of the lack of stability of many plastics

at the temperatures used for dry heat sterilization (typically

at least 160° C.). Examples of types of containers include,

but are not limited to, ampoules, vials, syringes, pipettes,

and the like.

In embodiments of the present invention, any suitable

applicator can be used to apply the adhesive composition to

a substrate. For example, the applicator can include an

applicator body, which is formed generally in the shape of

a tube having a closed end, an open end, and a hollow

interior lumen, which holds a crushable or frangible

ampoule. In this embodiment, the ampoule may contain the

polymerizable monomer composition that is to be dispensed

from the applicator. The ampoule may, in embodiments, be

made of glass, plastic, ceramic, or the like, or any other

brittle materials, and may be in any shape including, but not

limited to, the shape of a tube, an oval, round, and the like.

In embodiments of the invention, the applicator can

comprise elements other than an applicator body and an

ampoule. For example, an applicator tip cam be provided on

the open end of the applicator. The applicator tip can have

a variety of suitable shapes, including, but not limited to,

conical, cylindrical, chisel or polygonal shapes. The length

and size of the tip can be varied depending on various

application parameters. The tip may be detachable from the

applicator body, or may be an integral part of the applicator.

The tip further may be in the form of a nozzle for atomizing

liquid solutions. The tip can be composed of any of a variety

of materials including polymerized materials such as

plastics, foams, rubber, thermosets, films, or membranes.

Additionally, the applicator tip may be composed of mate-

rials such as metal, glass, paper, ceramics, cardboard, and

the like. The applicator tip material may be porous,

absorbent, or adsorbent in nature to enhance and facilitate

application of the composition within the ampoule. In

general, the only limitation on the materials used to fabricate

the tip is that the tip must be sufficiently compatible with the

composition to be dispensed that undesirable effects on the

composition do not prevail during contact of the composi-

US 6,579,469 B1

9

tion with the tip. Suitable designs for applicator tips that may

be used according to the present invention are disclosed in,

for example, U.S. Pat. No. 5,928,611 and U.S. patent appli-

cations Ser. No. 09/069,979, filed Apr. 30, 1998, and Ser.

No. 09/069,875, filed Apr. 30, 1998, the entire disclosures of

which are incorporated herein by reference.

The applicator and its related packaging can be designed

as a single-use applicator or as a multi-use applicator. The

present invention is particularly useful in multi-use

applicators, because the preservative can inhibit the growth

of microorganisms that may be introduced into the compo-

sition during use of the applicator. Suitable multi-use appli-

cators are disclosed, for example, in U.S. patent application

Ser. No. 09/385,030, filed Aug. 30, 1999, the entire disclo-

sure of which is incorporated herein by reference.

Further, the applicator can comprise a screen or filter

located within the applicator between the crushable ampoule

and the open end of the applicator body. Such a screen or

filter can be provided to stop any shards that are released

upon breaking of the ampoule from exiting the applicator

along with the composition being applied.

In embodiments, monomer compositions according to the

invention are sterilized. The sterilization can be accom-

plished by techniques known to the skilled artisan, and is

preferably accomplished by methods including, but not

limited to, chemical, physical, and irradiation methods.

Examples of physical methods include, but are not limited

to, sterile fill, filtration, sterilization by heat (dry or moist)

and retort canning. Examples of irradiation methods include,

but are not limited to, gamma irradiation, electron beam

irradiation, and microwave irradiation. Preferred methods

are dry and moist heat sterilization and electron beam

irradiation. In embodiments where a composition is to be

used for medical applications, the sterilized composition

should show low levels of toxicity to living tissue during its

useable life.

In embodiments when the adhesive monomeric compo-

sition is sterilized, the sterilization should not destroy or

counter the antimicrobial effect of the preservative. That is,

in embodiments where a composition is to be sterilized, the

type of sterilization used should preferably be selected based

on the preservative used. For example, the parabens and

cresols, which are soluble and stable in the monomer, are

compatible with electron beam and dry heat sterilization

methods. However, not all preservatives are compatible with

such sterilization methods, and one method may be pre-

ferred over other methods. Thus, for example, where one or

more sterilization procedures is to be used to sterilize the

monomer composition, it is preferred that the above-

described sterilization compatibility screening procedure be

used.

However, a particular advantage of the present invention

is that, in embodiments, sterilization processing of the

composition and packaging can be eliminated. That is,

where the preservative provides suitable and desired anti-

microbial activity, subsequent sterilization of the adhesive

composition can be dispensed with. The preservative thus

provides benefits in terms of cost savings, by eliminating a

subsequent sterilization step, and increased shelf-life, since

some sterilization procedures tend to reduce shelf-life.

Furthermore, in terms of multi-use packaging or containers,

sterility is not lost after the first use because the preservative

continues to provide antimicrobial action.

The monomer (including prepolymeric) composition may

include one or more polymerizable monomers. In

embodiments, at least one of the one or more monomers is

5

10

15

20

25

30

35

40

45

50

55

60

65

10

an alkyl cyanoacrylate monomer, e.g., alkyl

2-cyanoacrylate. Preferred monomer compositions of the

present invention, and polymers formed therefrom, are use-

ful as tissue adhesives, sealants for preventing bleeding or

for covering open wounds, and in other biomedical appli-

cations. They find uses in, for example, apposing surgically

incised or traumatically lacerated tissues; retarding blood

flow from wounds; drug delivery; dressing burns; dressing

skin or other superficial or surface wounds (such as

abrasions, chaffed or raw skin, and/or stomatitis); and aiding

repair and regrowth of living tissue. Other preferred mono-

mer compositions of the present invention, and polymers

formed therefrom, are useful in industrial and home

applications, for example in bonding rubbers, plastics,

wood, composites, fabrics, and other natural and synthetic

materials.

Monomers that may be used in this invention are readily

polymerizable, e. g. anionically polymerizable or free radical

polymerizable, or polymerizable by zwitterions or ion pairs

to form polymers. Such monomers include those that form

polymers, that may, but do not need to, biodegrade. Such

monomers are disclosed in, for example, U.S. Pat. No.

5,328,687 to Leung, et al., which is hereby incorporated in

its entirety by reference herein.

Preferred monomers for use in this invention are alkyl

ot-cyanoacrylates. These monomers are known in the art and

have the formula

(1)

CN

rhc==c

COOR1

wherein R1 is an alkyl or substituted alkyl group.

Examples of suitable alkyl and substituted alkyl groups

include straight chain or branched chain alkyl groups having

1-16 carbon atoms; and straight chain or branched chain

C1—C16 alkyl groups substituted with a haloalkyl group, a

halogen atom, a cyano group, or a haloalkyl group.

In the cyanoacrylate monomer of formula (I), R1 is

preferably an alkyl group having 1-10 carbon atoms.

The ot-cyanoacrylates of formula (I) can be prepared

according to methods known in the art. U.S. Pat. Nos.

2,721,858 and 3,254,111, each of which is hereby incorpo-

rated in its entirety by reference, disclose methods for

preparing ot-cyanoacrylates. For example, the

ot-cyanoacrylates can be prepared by reacting an alkyl

cyanoacetate with formaldehyde in a non-aqueous organic

solvent and in the presence of a basic catalyst, followed by

pyrolysis of the anhydrous intermediate polymer in the

presence of a polymerization inhibitor. The ot-cyanoacrylate

monomers prepared with low moisture content and essen-

tially free of impurities are preferred for biomedical use.

Preferred ot-cyanoacrylate monomers used in this inven-

tion are alkyl ot-cyanoacrylates including octyl

cyanoacrylate, such as 2-octyl cyanoacrylate; dodecyl

cyanoacrylate; 2-ethylhexyl cyanoacrylate; butyl

cyanoacrylate such as n-butyl cyanoacrylate; ethyl

cyanoacrylate; and methyl cyanoacrylate. More preferred

monomers are n-butyl and 2-octyl ot-cyanoacrylate. Mono-

mers utilized for medical purposes in the present application

should be very pure and contain few impurities (e.g., sur-

gical grade). Monomers utilized for industrial purposes need

not be as pure.

The composition may optionally also include at least one

plasticizing agent that imparts flexibility to the polymer

US 6,579,469 B1

11

formed from the monomer. The plasticizing agent preferably

contains little or no moisture and should not significantly

affect the stability or polymerization of the monomer. Such

plasticizers are useful in polymerized compositions to be

used for closure or covering of wounds, incisions, abrasions,

sores or other applications where flexibility of the adhesive

is desirable. Some thickeners, such as poly-2-

ethylhexylcyanoacrylate, can also impart flexibility to the

polymer.

Examples of suitable plasticizers include acetyl tributyl

citrate, dimethyl sebacate, triethyl phosphate, tri(2-

ethylhexyl)phosphate, tri(p-cresyl)phosphate, glyceryl

triacetate, glyceryl tributyrate, diethyl sebacate, dioctyl

adipate, isopropyl myristate, butyl stearate, lauric acid,

trioctyl trimellitate, dioctyl glutarate, and mixtures thereof.

Preferred plasticizers are tributyl citrate and acetyl tributyl

citrate. In embodiments, suitable plasticizers include poly-

meric plasticizers, such as polyethylene glycol (PEG) esters

and capped PEG esters or ethers, polyester glutarates and

polyester adipates.

The addition of plasticizing agents in amounts ranging

from about 0.5 wt. % to about 25 wt. %, or from about 1 wt.

% to about 20 wt. %, or from about 3 wt. % to about 15 wt.

% or from about 5 wt. % to about 7 wt. % provides increased

elongation and toughness of the polymerized monomer over

polymerized monomers not having plasticizing agents.

The composition may also optionally include at least one

thixotropic agent. Suitable thixotropic agents are known to

the skilled artisan and include, but are not limited to, silica

gels such as those treated with a silyl isocyanate. Examples

of suitable thixotropic agents are disclosed in, for example,

U.S. Pat. No. 4,720,513, the disclosure of which is hereby

incorporated in its entirety.

The composition may also optionally include at least one

natural or synthetic rubber to impart impact resistance,

which is preferable especially for industrial compositions of

the present invention. Suitable rubbers are known to the

skilled artisan. Such rubbers include, but are not limited to,

dienes, styrenes, acrylonitriles, and mixtures thereof.

Examples of suitable rubbers are disclosed in, for example,

U.S. Pat. Nos. 4,313,865 and 4,560,723, the disclosures of

which are hereby incorporated in their entireties.

The composition may also optionally include both at least

one anionic vapor phase stabilizer and at least one anionic

liquid phase stabilizer. These stabilizing agents inhibit pre-

mature polymerization. Such stabilizing agents may also

include mixtures of anionic stabilizing agents and radical

stabilizing agents. Any mixture of stabilizers is included as

long as the mixture does not inhibit the desired polymer-

ization of the monomer.

The anionic vapor phase stabilizers may be selected from

among known stabilizers, including, but not limited to,

sulfur dioxide, boron trifluoride, and hydrogen fluoride. The

amount of anionic vapor phase stabilizer that is added to the

monomer composition depends on the identity of the liquid

phase stabilizer(s) chosen in combination with it, the mono-

mer to be stabilized, as well as the packaging material to be

used for the composition. Preferably, each anionic vapor

phase stabilizer is added to give a concentration of less than

200 parts per million (ppm). In preferred embodiments, each

anionic vapor phase stabilizer is present from about 1 to 200

ppm, more preferably from about 10 to 75 ppm, even more

preferably from about 10 to 50 ppm, and most preferably

from 10 to 20 ppm. The amount to be used can be deter-

mined by one of ordinary skill in the art using known

techniques without undue experimentation.

In embodiments, the vapor phase comprises, among other

things, an anionic stabilizer that is sulfur dioxide. In

embodiments, the vapor phase comprises, among other

things, a stabilizer that is boron trifluoride or hydrogen

10

15

20

25

30

35

40

45

50

55

60

65

12

fluoride. A combination of sulfur dioxide and boron trifluo-

ride or hydrogen fluoride is preferable in some embodi-

ments.

In embodiments, the liquid phase anionic stabilizer is a

very strong acid. As used herein, a very strong acid is an acid

that has an aqueous pKa of less than 1.0. Suitable very strong

acidic stabilizing agents include, but are not limited to, very

strong mineral and/or oxygenated acids. Examples of such

very strong acids include, but are not limited to, sulfuric acid

(pKa-3.0), perchloric acid (pKa-5), hydrochloric acid (pKa-

7.0), hydrobromic acid (pKa-9), fluorosulfonic acid (pKa

Coments go here:

- Log in to post comments