Cyanoacrylate compositions with vinyl terminated ester groups

Cyanoacrylate compositions with vinyl terminated ester groups

US6174919

Company:

Year:

Type of document:

Language:

US006174919B1

(12) United States Patent (10) Patent No.: US 6,174,919 B1

Hickey (45) Date of Patent: Jan. 16, 2001

(54) CYANOACRYLATE COMPOSITIONS WITH 5,259,835 11/1993 Clark et al. .

VINYL TERMINATED ESTER GROUPS 5,328,687 7/ 1994 Leung Ct a1~ ~

5,480,935 * 1/1996 Greff et al. ........................ .. 524/776

(75) Inventor: Timothy P. Hickey, Raleigh, NC (US) 3 ~

(73) Assignee: Closure Medical Corporation, 53? E: 3‘ ‘

Raleigh’ NC (US) 5,624,669 4/1997 Leun: et al. .

( * ) Notice: Under 35 U.S.C. 154(b), the term of this FOREIGN PATENT DOCUMENTS

patent shall be extended for 0 days. 1527561 10/1978 (GB) .

wo 97/31598 9/1997 (wo) .

(21) Appl. No.: 09/025,473 * Cited by examiner

(22) Filed: Feb’ 18’ 1998 Primary Exami/1er—Thurman K. Page

(51) Int. Cl.7 ................................................... .. A01N 37/34 AssisramExaminer—P. Kulkosky . .

(52) U.s. Cl. ..................... .. 514/519, 156/326; 156/330.9; (74) Attorney Agenh or Flrm—0hff & Berrldge, PLC

424/400; 424/443; 424/448; 424/487 (57) A]3,s'1‘RAC'1‘

(58) Field of Search ................................... .. 424/400, 443, . . . . .

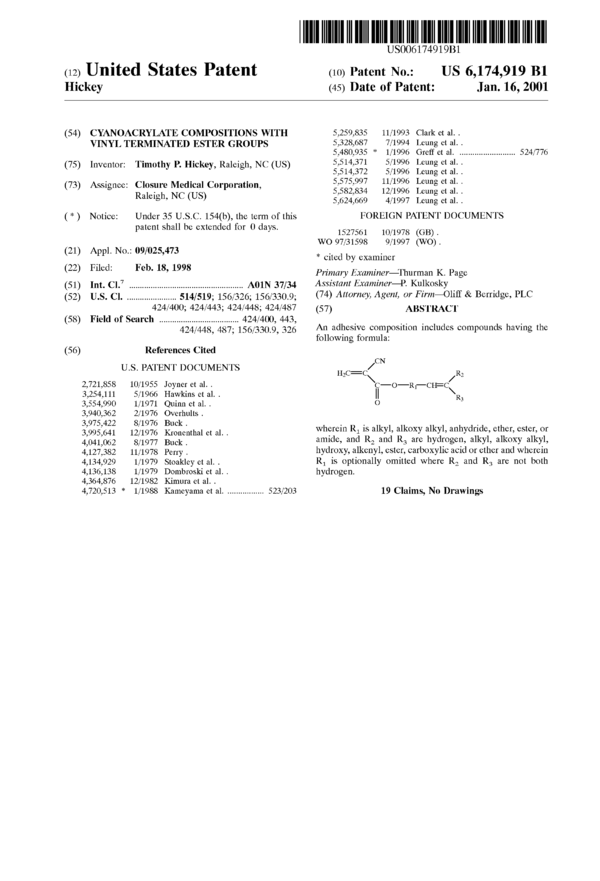

424/448, 487; 156/3309, 326 An adhesive composition includes compounds having the

following formula:

(56) References Cited

U.S. PATENT DOCUMENTS H C_C CN R

2 j 2

2,721,858 10/1955 Joyner et al. . (:—o—R1—(:H=(:

3,254,111 5/1966 Hawkins et al. . || \R3

3,554,990 1/1971 Quinn et al. . 0

3,940,362 2/1976 Overhults.

3,975,422 8/1976 Buck. . . .

3,995,641 12/1976 Kmnenthal et al. . wherein R1 1S alkyl, alkoxy alkyl, anhydride, ether, ester, or

4,041,062 8/1977 Buck. amide, and R2 and R3 are hydrogen, alkyl, alkoxy alkyl,

4,127,332 11/1973 perry . hydroxy, alkenyl, ester, carboxylic acid or ether and wherein

4,134,929 1/1979 stoakley et a1. . R1 is optionally omitted where R2 and R3 are not both

4,136,138 1/1979 Dombroski et al. . hydrogen.

4,364,876 12/1982 Kimura et al. .

4,720,513 * 1/1988 Kameyama et al. ............... .. 523/203 19 Claims, No Drawings

US 6,174,919 B1

1

CYANOACRYLATE COMPOSITIONS WITH

VINYL TERMINATED ESTER GROUPS

BACKGROUND OF THE INVENTION

1. Field of Invention

The present invention is directed to monomer composi-

tions useful to form industrial, consumer or medical adhe-

sives and sealants, and methods of applying such composi-

tions. More particularly, this invention relates to monomeric

cyanoacrylate compositions having vinyl terminated ester

groups that allow a biologically acceptable method of cross-

linking through the vinyl group.

2. Description of Related Art

U.S. Pat. No. 5,624,669 to Leung et al., discloses hemo-

static procedures for sealing punctures and incisions in

blood vessels and internal organs by applying a cyanoacry-

late monomer. Although the cyanoacrylate may polymerize

and/or cross-link in vivo, it preferably does so without the

need for external sources of physical initiation such as

irradiation.

U.S. Pat. No. 4,134,929 to Stoakley et al. discloses a

polymerizable monomeric allyl 2-cyanoacrylate containing

portion comprising an amount of an organic peroxide free

radical providing compound sufficient to cause crosslinking

of a difunctional monomer diester with the allyl

2-cyanoacrylate. Stoakley discloses that crosslinking may

occur by way of the allyl group.

U.S. Pat. No. 4,136,138 to Dombroski et al. discloses a

polymerizable monomeric 2-cyanoacrylate containing por-

tion comprising an amount of an organic peroxide free

radical providing compound sufficient to cause crosslinking

of a difunctional monomer diester with the 2-cyanoacrylate.

Dombroski discloses that the allyl 2-cyanoacrylate-based

adhesive compositions are especially useful as dental adhe-

s1ves.

U.S. Pat. No. 3,975,422 to Buck discloses difunctional

monomers where R is an organic linking group derived from

a diol or a dihalide of the formula X—R—X, where X is

either Cl, Br, I, or hydroxy. The difunctional monomers are

employed as crosslinking agents for monofunctional esters

of 2-cyanoacrylates. The monofunctional cyanoacrylate

monomers may be cyanoacrylates that are terminated by an

alkyl, cyclohexyl or phenyl group. Copolymerized compo-

sitions of the monomer blends (difunctional and

monofunctional) are useful as adhesives in dental applica-

tions. The polymerization of these compositions is initiated

by an anionic catalyst or by thermal or other means.

SUMMARY OF THE INVENTION

The present invention is directed to monomeric

cyanoacrylate compositions having vinyl terminated ester

groups that cross-link through the vinyl group, and biomedi-

cal uses of such compositions. Cross-linking occurs by way

of the vinyl terminated ester groups. In embodiments,

chemical durability, flexibility and elasticity of the resulting

polymers or copolymers may be increased and degradability

can be reduced. In addition, in embodiments high tempera-

tures or ultraviolet initiators may not be needed for cross-

linking.

DETAILED DESCRIPTION OF PREFERRED

EMBODIMENTS

Cyanoacrylate adhesive compositions of the invention

contain compounds represented by the following formula

(1)1

10

15

20

25

30

35

40

45

50

55

60

65

2

(1)

CN

I‘I2C:C R2

fi?O*R1:CH:C\

R3

0

wherein R1 is alkyl, alkoxy, anhydride, ether, ester, or amide,

and R2 and R3 are independently alkyl, alkoxy, hydrogen,

hydroxy, alkenyl, ester, carboxylic acid, ether, or electron

withdrawing groups such as halogens, amides, cyanos,

esters, acids and ethers. Preferably, R1 is an alkyl having

from about 1 to 8 carbon atoms. Preferably, R2 and R3 are

hydrogen atoms. More preferably, R2 and R3 are alkyl

groups having from about 1 to 3 carbon atoms. The R1 group

extends the distance of the R2 and R3 groups away from the

carbonyl group, thereby making them more chemically

accessible and improving chemical durability, flexibility and

elasticity of a polymer comprising the monomer. In

embodiments, R1 may be omitted if R2 and R3 are not both

hydrogen.

In embodiments, the adhesive compositions may addi-

tionally contain heat and/or light (e.g., visible or ultraviolet

light) activated initiators and accelerators that initiate cross-

linking of the cyanoacrylate compounds.

Particular initiators for particular systems may be readily

selected by one of ordinary skill in the art without undue

experimentation. Suitable polymerization initiators for the

cyanoacrylate compositions include, but are not limited to,

detergent compositions; surfactants: e.g., nonionic surfac-

tants such as polysorbate 20 (e.g., Tween 20”‘), polysorbate

80 (e.g., Tween SOTM) and poloxamers, cationic surfactants

such as tetrabutylammonium bromide, anionic surfactants

such as benzalkonium chloride or its pure components,

stannous octoate (tin (II) 2-ethylheaxanoate), and sodium

tetradecyl sulfate, and amphoteric or zwitterionic surfactants

such as dodecyldimethyl(3-sulfopropyl)ammonium

hydroxide, inner salt; amines, imines and amides, such as

imidazole, tryptamine, urea, arginine and povidine;

phosphines, phosphites and phosphonium salts, such as

triphenylphosphine and triethyl phosphite; alcohols such as

ethylene glycol, methyl gallate, ascorbic acid, tannins and

tannic acid; inorganic bases and salts, such as sodium

bisulfite, magnesium hydroxide, calcium sulfate and sodium

silicate; sulfur compounds such as thiourea and polysulfides;

polymeric cyclic ethers such as monensin, nonactin, crown

ethers, calixarenes and polymeric epoxides; cyclic and acy-

clic carbonates, such as diethyl carbonate; phase transfer

catalysts such as Aliquat 336; and organometallics such as

cobalt naphthenate and manganese acetylacetonate and radi-

cal initiators.

Suitable initiators for both of the polymerization of the

cyanoacrylate and cross-linking of the vinyl group of the

composition include, but are not limited to, radicals, such as

di-t-butyl peroxide, azobisisobutyronitrile and benzoylper-

oxide and sodium bisulfite. The polymerizable and/or cross-

linkable material may also contain an initiator which is

inactive until activated by a catalyst or accelerator (included

within the scope of the term “initiator” as used herein).

Accelerators for radical initiators such as dimethylaminopy-

ridine and other aminopyridine type molecules may act as an

initiator for the cyanoacrylate as well as for the radical

polymerization of the vinyl moiety.

In embodiments, when R1 is omitted and R2 and/or R3 are

a moiety other than hydrogen, and the composition is to be

cationically polymerizable, materials such as strong acids,

US 6,174,919 B1

3

alkyl iodides (iodomethane), iodine, acetyl perchlorate, and

Lewis acids (boron trifluoride, tin tetrachloride, aluminum

trichloride, and organometallic derivatives, e.g., RAlCl2,

R2AlCl, wherein R is an alkyl group and R2 is two R groups)

may be used.

The monomer compositions of the present invention and

polymers formed therefrom are useful as tissue adhesives,

sealants for preventing bleeding or for covering open

wounds, and in other biomedical applications. They find

uses in, for example, apposing surgically incised or trau-

matically lacerated internal and/or external tissues; setting

fractured bone structures; retarding blood flow from

wounds; drug delivery; dressing burns; and aiding repair and

regrowth of living tissue.

Conventional surgical adhesive compositions have

included plasticizers with the adverse effect of reducing the

film strength. It has been discovered that, contrary to prior

belief, the film strength (e.g., toughness) under certain

conditions is not adversely reduced upon the addition of

greater amounts of plasticizing agent. Depending on the

particular acidic stabilizing agent and the purity of the

monomer utilized in the adhesive composition, the addition

of greater amounts of plasticizing agent may increase the

toughness of the resulting bond formed on the wound.

Acidic stabilizing agents do not significantly affect the

polymerization of the monomer in the present composition

and provide increased film strength with increasing amounts

of plasticizing agents.

Monomers that may be used in this invention are

polymerizable, e. g. anionically polymerizable or free radical

polymerizable, to form polymers. In embodiments, the

cyanoacrylate composition may comprise a homopolymer of

the monomer of formula (I) or a copolymer or terpolymer

with other monomers. Such other monomers include, but are

not limited to, acrylate monomers, methacrylate monomers,

and 1,1-disubstituted ethylene monomers of the formula:

(11)

wherein X and Y are each strong electron withdrawing

groups, and R is H, —CH=CH2, or an alkyl such as methyl,

ethyl and other lower alkyls such as butyl and the like,

provided that X and Y are both cyano groups, a C1-C4 alkyl

group.

Examples of monomers within the scope of formula (II)

include alpha-cyanoacrylates, vinylidene cyanides, C1-C4

alkyl homologues of vinylidene cyanides, dialkyl methylene

malonates, acylacrylonitriles, vinyl sulfinates and vinyl sul-

fonates of the formula H2C=CX‘Y‘ wherein X‘ is —SO2R‘

or —SO3R‘ and Y‘ is —CN, —COOR‘, —COCH3, —SO2R‘

or —SO3R‘, and R‘ is H or hydrocarbyl.

Preferred monomers of formula (II) for use in this inven-

tion are alpha-cyanoacrylates. These monomers are known

in the art and have the formula

HRC:CXY

(111)

CN

HR2C=C

COOR3,

wherein R2 is hydrogen or lower alkyl and R3 is a hydro-

carbyl or substituted hydrocarbyl group including polymeric

groups; a group having the formula —R4—O—R3—O—R6,

wherein R4 is a 1,2-alkylene group having 2-4 carbon

atoms, R3 is an alkylene group having 2-4 carbon atoms,

and R6 is an alkyl group having 1-6 carbon atoms; or a

group

10

15

20

25

30

35

40

45

50

55

60

65

having the formula R7ji|Z:O:R8, wherein R7 is

O

we

:CH2?, :CHZ, or C(CH3)2

wherein n is 1-10, preferably 1-5 carbon atoms and R8 is an

organic moiety.

Examples of suitable hydrocarbyl and substituted hydro-

carbyl groups include straight chain or branched chain alkyl

groups having 1-16 carbon atoms; straight chain or

branched chain C1-C16 alkyl groups substituted with an

acyloxy group, a haloalkyl group, an alkoxy group, a halo-

gen atom, a cyano group, or a haloalkyl group; straight chain

or branched chain alkenyl groups having 2 to 16 carbon

atoms; straight chain or branched chain alkynyl groups

having 2 to 12 carbon atoms; cycloalkyl groups; aralkyl

groups; alkylaryl groups; and aryl groups.

The organic moiety R8 may be substituted or unsubsti-

tuted and may be straight chain, branched or cyclic,

saturated, unsaturated or aromatic. Examples of such

organic moieties include C1-C8 alkyl moieties, C2-C8 alk-

enyl moieties, C2-C8 alkynyl moieties, C3-C12

cycloaliphatic moieties, aryl moieties such as phenyl and

substituted phenyl and aralkyl moieties such as benzyl,

methylbenzyl and phenylethyl. Other organic moieties

include substituted hydrocarbon moieties, such as halo (e.g.,

chloro-, fluoro- and bromo-substituted hydrocarbons) and

oxy- (e.g., alkoxy substituted hydrocarbons) substituted

hydrocarbon moieties. Preferred organic moieties are alkyl,

alkenyl and alkynyl moieties having from 1 to about 8

carbon atoms, and halo-substituted derivatives thereof. Par-

ticularly preferred are alkyl moieties of 4 to 6 carbon atoms.

In the cyanoacrylate monomer of formula (III), R3 is

preferably an alkyl group having 1-10 carbon atoms or a

group having the formula —AOR9, wherein A is a divalent

straight or branched chain alkylene or oxyalkylene moiety

having 2-8 carbon atoms, and R9 is a straight or branched

alkyl moiety having 1-8 carbon atoms.

Examples of groups represented by the formula —AOR9

include 1-methoxy-2-propyl, 2-butoxy ethyl, isopropoxy

ethyl, 2-methoxy ethyl, and 2-ethoxy ethyl.

The preferred alpha-cyanoacrylate monomers used in this

invention are 2-octyl cyanoacrylate, dodecyl cyanoacrylate,

2-ethylhexyl cyanoacrylate, butyl cyanoacrylate, methyl

cyanoacrylate, 3-methoxybutyl cyanoacrylate,

2-butoxyethyl cyanoacrylate, 2-isopropoxyethyl

cyanoacrylate, or 1-methoxy-2-propyl cyanoacrylate.

The alpha-cyanoacrylates of formula (III) can be prepared

according to methods known in the art. Reference is made,

for example, to U.S. Pat. Nos. 2,721,858 and 3,254,111, each

of which is hereby incorporated by reference herein. For

example, the alpha cyanoacrylates can be prepared by react-

ing an alkyl cyanoacetate with formaldehyde in a non-

aqueous organic solvent and in the presence of a basic

catalyst, followed by pyrolysis of the anhydrous intermedi-

ate polymer in the presence of a polymerization inhibitor.

The alpha-cyanoacrylate monomers prepared with low

moisture content and essentially free of impurities are pre-

ferred for biomedical use.

The alpha-cyanoacrylates of formula (III) wherein R3 is a

group having the formula —R4—O—R3—O—R6 can be

prepared according to the method disclosed in U.S. Pat. No.

4,364,876 to Kimura et al., which is hereby incorporated by

reference herein. In the Kimura et al. method, the alpha-

US 6,174,919 B1

5

cyanoacrylates are prepared by producing a cyanoacetate by

esterifying cyanoacetic acid with an alcohol or by transes-

terifying an alkyl cyanoacetate and an alcohol; condensing

the cyanoacetate and formaldehyde or para-formaldehyde in

the presence of a catalyst at a molar ratio of 0.5-1.521,

preferably 0.8-1.221, to obtain a condensate; depolymeriz-

ing the condensation reaction mixture either directly or after

removal of the condensation catalyst to yield crude

cyanoacrylate; and distilling the crude cyanoacrylate to form

a high purity cyanoacrylate.

The alpha-cyanoacrylates of formula (III) wherein R3 is a

group having the formula

—R7—C—o—R8

O

can be prepared according to the procedure described in U.S.

Pat. No. 3,995,641 to Kronenthal et al., which is hereby

incorporated by reference herein. In the Kronenthal et al.

method, such alpha-cyanoacrylate monomers are prepared

by reacting an alkyl ester of an alpha-cyanoacrylic acid with

a cyclic 1,3-diene to form a Diels-Alder adduct which is then

subjected to alkaline hydrolysis followed by acidification to

form the corresponding alpha-cyanoacrylic acid adduct. The

alpha-cyanoacrylic acid adduct is preferably esterified by an

alkyl bromoacetate to yield the corresponding carbalkoxym-

ethyl alpha-cyanoacrylate adduct. Alternatively, the alpha-

cyanoacrylic acid adduct may be converted to the alpha-

cyanoacrylyl halide adduct by reaction with thionyl

chloride. The alpha-cyanoacrylyl halide adduct is then

reacted with an alkyl hydroxyacetate or a methyl substituted

alkyl hydroxyacetate to yield the corresponding car-

balkoxymethyl alpha-cyanoacrylate adduct or carbalkoxy

alkyl alpha-cyanoacrylate adduct, respectively. The cyclic

1,3-diene blocking group is finally removed and the car-

balkoxy methyl alpha-cyanoacrylate adduct or the car-

balkoxy alkyl alpha-cyanoacrylate adduct is converted into

the corresponding carbalkoxy alkyl alpha-cyanoacrylate by

heating the adduct in the presence of a slight deficit of

maleic anhydride.

Examples of monomers of formula (III) include cyano-

pentadienoates and alpha-cyanoacrylates of the formula:

(IV)

CN

Hzc=c

COOR3

wherein Z is —CH=CH2 and R3 is as defined above. The

monomers of formula (IV) wherein R3 is an alkyl group of

1-10 carbon atoms, i.e., the 2-cyanopenta-2,4-dienoic acid

esters, can be prepared by reacting an appropriate

2-cyanoacetate with acrolein in the presence of a catalyst

such as zinc chloride. This method of preparing

2-cyanopenta-2,4-dienoic acid esters is disclosed, for

example, in U.S. Pat. No. 3,554,990, which is hereby

incorporated by reference herein.

Preferred monomers are alkyl alpha-cyanoacrylates and

more preferably octyl alpha-cyanoacrylates, especially

2-octyl alpha-cyanoacrylate. Monomers utilized in the

present application should be very pure and contain few

impurities (e.g., surgical grade).

Compositions of the present invention may include at

least one plasticizing agent that imparts flexibility to the

polymerized monomer formed on the wound or incision.

10

15

20

25

30

35

40

45

50

55

60

65

6

The plasticizing agent preferably contains little or no mois-

ture and should not significantly affect the polymerization of

the monomer.

Other compositions are exemplified by U.S. Pat. Nos.

5,259,835 and 5,328,687 and U.S. patent applications Ser.

Nos. 08/609,921, 08/714,288, 08/909,845, 08/755,007,

08/920,876, and 08/488,411, all incorporated by reference

herein in their entirety.

Examples of suitable plasticizers include acetyl tributyl

citrate, dimethyl sebacate, triethyl phosphate, tri(2-

ethylhexyl)phosphate, tri(p-cresyl)phosphate, glyceryl

triacetate, glyceryl tributyrate, diethyl sebacate, dioctyl

adipate, isopropyl myristate, butyl stearate, lauric acid,

trioctyl trimellitate, dioctyl glutarate and mixtures thereof.

Preferred plasticizers are tributyl citrate and acetyl tributyl

citrate. In embodiments, suitable plasticizers include poly-

meric plasticizers, such as polyethylene glycol (PEG) esters

and capped PEG esters or ethers, polyester glutarates and

polyester adipates.

Compositions of the present invention may also include at

least one acidic stabilizing agent that inhibits polymeriza-

tion. Such stabilizing agents may also include mixtures of

anionic stabilizing agents and radical stabilizing agents.

Examples of suitable anionic stabilizing agents include,

but are not limited to, sultones (e.g., ot-chloro-ot-hydroxy-

o-toluenesulfonic acid-y-sultone), sulfur dioxide, sulfuric

acid, sulfonic acid, sulfurous acid, lactone, boron trifluoride,

organic acids, alkyl sulfate, alkyl sulfite, 3-sulfolene,

alkylsulfone, alkyl sulfoxide, mercaptan, and alkyl sulfide

and mixtures thereof. Preferable anionic stabilizing agents

are acidic stabilizing agents of organic acids such as acetic

acid or phosphoric acid. In embodiments, the amount of

sulfur dioxide stabilizer is less than 100 ppm, preferably

5-75 ppm, and more preferably from about 20-50 ppm. The

amount of sultone and/or trifluoracetic acid is about

500-3000 ppm.

Examples of suitable radical stabilizing agents include

hydroquinone, hydroquinone monomethyl ether, catechol,

pyrogallol, benzoquinone, 2-hydroxybenzoquinone,

p-methoxy phenol, t-butyl catechol, butylated hydroxy

anisole, butylated hydroxy toluene, and t-butyl hydro-

quinonc.

Suitable acidic stabilizing agents include those having

aqueous pKa ionization constants ranging from -12 to 7,

preferably from about -3.5 to about 6, and more preferably

from about 2 to about 5.5. For example, suitable acidic

stabilizing agents include: hydrogen sulfide (pKa 7.0), car-

bonic acid (pKa 6.4), triacetylmethane (pKa 5.9), acetic acid

(pKa 4.8), benzoic acid (pKa 4.2), 2,4-dinitrophenol (pKa

4.0), formic acid (pKa 3.7), nitrous acid (pKa 3.3), hydrof-

luoric acid (pKa 3.2), chloroacetic acid (pKa 2.9), phospho-

ric acid (pKa 2.2), dichloroacetic acid (pKa 1.3), trichloro-

acetic acid (pKa 0.7), 2,4,6-trinitrophenol (picric acid) (pKa

0.3), trifluoroacetic acid (pKa 0.2), sulfuric acid (pKa _3.0),

and mixtures thereof.

When adding the above-mentioned acidic stabilizing

agents to the adhesive composition, the addition of plasti-

cizing agents in amounts ranging from about 0.5 wt. % to

about 16 wt. %, preferably from about 3 wt. % to about 9 wt.

%, and more preferably from about 5 wt. % to about 7 wt.

% provides increased film strength (e.g., toughness) of the

polymerized monomer over polymerized monomers having

amounts of plasticizing agents and acidic stabilizing agents

outside of the above ranges.

The concentration of the acidic stabilizing agents utilized

may vary depending on the strength of the acid. For

example, when using acetic acid, a concentration of 80-200

US 6,174,919 B1

7

ppm (wt/wt), preferably 90-180 ppm (wt/wt), and more

preferably 100-150 ppm (wt/wt) may be utilized. When

using a stronger acid such as phosphoric acid, a concentra-

tion range of 20-80 ppm (wt/wt), preferably, 30-70 ppm

(wt/wt) and more preferably 40-60 ppm (wt/wt) may be

utilized. In embodiments, the amount of trifluoroacetic acid

is about 100 to 3000 ppm, preferably 500-1500 ppm. In

other embodiments, the amount of phosphoric acid is about

10-200 ppm, preferably about 50-150 ppm, and more

preferably about 75-125 ppm.

Other compositions are exemplified by U.S. Pat. Nos.

5,624,669, 5,582,834, 5,575,997, 5,514,371, 5,514,372,

5,259,835 and 5,328,687, incorporated by reference herein

in their entirety. The compositions of the present invention

may also include at least one biocompatible agent effective

to reduce active formaldehyde concentration levels pro-

duced during in vivo biodegradation of the polymer (also

referred to herein as “formaldehyde concentration reducing

agents”). Preferably, this component is a formaldehyde

scavenger compound. Examples of formaldehyde scavenger

compounds useful in this invention include sulfites;

bisulfites; mixtures of sulfites and bisulfites; ammonium

sulfite salts; amines; amides; imides; nitriles; carbamates;

alcohols; mercaptans; proteins; mixtures of amines, amides,

and proteins; active methylene compounds such as cyclic

ketones and compounds having a b-dicarbonyl group; and

heterocyclic ring compounds free of a carbonyl group and

containing an NH group, with the ring made up of nitrogen

or carbon atoms, the ring being unsaturated or, when fused

to a phenyl group, being unsaturated or saturated, and the

NH group being bonded to a carbon or a nitrogen atom,

which atom is directly bonded by a double bond to another

carbon or nitrogen atom.

Bisulfites and sulfites useful as the formaldehyde scav-

enger compound in this invention include alkali metal salts

such as lithium, sodium and potassium salts, and ammonium

salts, for example, sodium bisulfite, potassium bisulfite,

lithium bisulfite, ammonium bisulfite, sodium sulfite, potas-

sium sulfite, lithium sulfite, ammonium sulfite, and the like.

Examples of amines useful in this invention include the

aliphatic and aromatic amines such as, for example, aniline,

bcnzidinc, aminopyrimidinc, tolucnc-diaminc,

triethylenediamine, diphenylamine, diaminodiphenylamine,

hydrazines and hydrazide.

Suitable proteins include collagen, gelatin, casein, soy-

bean protein, vegetable protein, keratin and glue. The pre-

ferred protein for use in this invention is casein.

Suitable amides for use in this invention include urea,

cyanamide, acrylamide, benzamide, and acetamide. Urea is

a preferred amide.

Suitable alcohols include phenols, 1,4-butanediol,

d-sorbitol, and polyvinyl alcohol.

Examples of suitable compounds having a b-dicarbonyl

group include malonic acid, acetylacetone, ethylacetone,

acetate, malonamide, diethylmalonate or another malonic

ester.

Preferred cyclic ketones for use in this invention include

cyclohexanone or cyclopentanone.

Examples of suitable heterocyclic compounds for use as

the formaldehyde scavenger in this invention are disclosed,

for example, in U.S. Pat. No. 4,127,382 (Perry) which is

hereby incorporated by reference herein. Such heterocyclic

compounds include, for example, benzimidazole, 5-methyl

benzimidazole, 2-methylbenzimidazole, indole, pyrrole, 1,2,

4-triazole, indoline, benzotriazole, indoline, and the like.

Apreferred formaldehyde scavenger for use in this inven-

tion is sodium bisulfite.

10

15

20

25

30

35

40

45

50

55

60

65

8

In practicing the present invention, the formaldehyde

concentration reducing agent, e.g., formaldehyde scavenger

compound, is added in an effective amount to the cyanoacry-

late. The “effective amount” is that amount sufficient to

reduce the amount of formaldehyde generated during sub-

sequent in vivo biodegradation of the polymerized

cyanoacrylate. This amount will depend on the type of active

formaldehyde concentration reducing agent, and can be

readily determined without undue experimentation by those

skilled in the art.

The formaldehyde concentration reducing agent may be

used in this invention in either free form or in microencap-

sulated form. Other compositions are exemplified by U.S.

patent application Ser. No. 08/714,288, incorporated by

reference herein in their entirety.

When microencapsulated, the formaldehyde concentra-

tion reducing agent is released from the microcapsule con-

tinuously over a period of time during the in vivo biodeg-

radation of the cyanoacrylate polymer.

For purposes of this invention, the microencapsulated

form of the formaldehyde concentration reducing agent is

preferred because this embodiment prevents or substantially

reduces polymerization of the cyanoacrylate monomer by

the formaldehyde concentration reducing agent, which

increases shelf-life and facilitates handling of the monomer

composition during use.

Microencapsulation of the formaldehyde scavenger can

be achieved by many known microencapsulation techniques.

For example, microencapsulation can be carried out by

dissolving a coating polymer in a volatile solvent, e.g.,

methylene chloride, to a polymer concentration of about 6%

by weight; adding a formaldehyde scavenger compound in

particulate form to the coating polymer/solvent solution

under agitation to yield a scavenger concentration of 18% by

weight; slowly adding a surfactant-containing mineral oil

solution to the polymer solution under rapid agitation;

allowing the volatile solvent to evaporate under agitation;

removing the agitator; separating the solids from the mineral

oil; and washing and drying the microparticles. The size of

the microparticles will range from about 0.001 to about 1000

microns.

The coating polymer for microcncapsulating the formal-

dehyde concentration reducing agent should be polymers

which undergo in vivo bioerosion, preferably at rates similar

to or greater than the cyanoacrylate polymer formed by the

monomer, and should have low inherent moisture content.

Such “bioerosion” can occur as a result of the physical or

chemical breakdown of the encapsulating material, for

example, by the encapsulating material passing from solid to

solute in the presence of body fluids, or by biodegradation

of the encapsulating material by agents present in the body.

Examples of coating materials which can be used to

microencapsulate the formaldehyde concentration reducing

agent include polyesters, such as polyglycolic acid, poly-

lactic acid, poly-1,4-dioxa-2-one, polyoxaltes,

polycarbonates, copolymers of polyglycolic acid and poly-

lactic acid, polycaprolactone, poly-b-hydroxybutyrate,

copolymers of epsilon-caprolactone and delta-valerolactone,

copolymers of epsilon-caprolactone and DL-dilactide, and

polyester hydrogels; polyvinylpyrrolidone; polyamides;

gelatin; albumin; proteins; collagen; poly(orthoesters); poly

(anhydrides); poly(alkyl-2-cyanoacrylates); poly

(dihydropyrans); poly(acetals); poly(phosphazenes); poly

(urethanes); poly(dioxinones); cellulose; and starches.

Examples of the surfactant which can be added to the

mineral oil include those commercially available under the

designations Triton x-100, Tween 20 and Tween 80.

US 6,174,919 B1

9

The composition of this invention may further contain one

or more adjuvant substances, such as thickening agents,

medicaments, or the like, to improve the medical utility of

the monomer for particular medical applications.

Suitable thickeners include, for example,

polycyanoacrylates, polylactic acid, polyglycolic acid,

lactic-glycolic acid copolymers, polycaprolactone, lactic

acid-caprolactone copolymers, poly-3-hydroxybutyric acid,

polyorthoesters, polyalkyl acrylates, copolymers of alky-

lacrylate and vinyl acetate, polyalkyl methacrylates, and

copolymers of alkyl methacrylates and butadiene. Examples

of alkyl methylacrylates and acrylates are poly(2-ethylhexyl

methacrylate) and poly(2-ethylhexyl acrylate), also poly

(butylmethacrylate) and poly(butylacrylate), also copoly-

mers of various acrylate and methacrylate monomers, such

as poly(butyl methacrylate-co-methylacrylate).

To improve the cohesive strength of adhesives formed

from the compositions of this invention, difunctional mono-

meric cross-linking agents may be added to the monomer

compositions of this invention. Such crosslinking agents are

known. Reference is made, for example, to U.S. Pat. No.

3,940,362 to Overhults, which is hereby incorporated by

reference herein. Examples of suitable crosslinking agents

include alkyl bis(2-cyanoacrylates), triallyl isocyanurates,

alkylene diacrylates, alkylene dimethacrylates, trimethylol

propane triacrylate, and alkyl bis(2-cyanoacrylates). A cata-

lytic amount of an amine activated free radical initiator may

be added to initiate polymerization of the cyanoacrylate

monomer/crosslinking agent blend.

The compositions of this invention may further contain

fibrous reinforcement and colorants, i.e., dyes and pigments.

Examples of suitable fibrous reinforcement include PGA

microfibrils, collagen microfibrils, cellulosic microfibrils,

and olefinic microfibrils. Examples of suitable colorants

include 1-hydroxy-4-[4-methylphenyl-amino]-9,10

anthracenedione (D+C violet No. 2); disodium salt of

6-hydroxy-5-[(4-sulfophenyl)axo]-2-naphthalene-sulfonic

acid (FD+C Yellow No. 6); 9 -(o-carboxyphenyl)-6-

hydroxy-2,4,5,7-tetraiodo-3H-xanthen-3-one, disodium salt,

monohydrate (FD+C Red No. 3); 2-(1,3-dihydro-3-oxo-5-

sulfo-2H-indol-2-ylidene)-2,3-dihydro-3-oxo-1H-indole-5-

sulfonic acid disodium salt (FD+C Blue No. 2); and

[phthalocyaninato (2-)] copper.

Depending on the particular requirements of the user, the

adhesive compositions of this invention can be applied by

known means such as with a swab, glass stirring rod, sterile

brush or medicine dropper. However, in many situations a

spray dispensing package is preferred in which the adhesive

composition is in solution with a compatible anhydrous

propellant. Other modes of application are exemplified in

U.S. patent application Ser. No. 08/488,411, incorporated by

reference herein in its entirety.

What is claimed is:

1. An adhesive composition with improved properties of

chemical durability, flexibility and elasticity of resulting

polymers and copolymers, comprising a compound of the

following formula (I):

(1)

CN

H2C:C R2

C*O*R ‘ CH1 C

II 1 \

R3

wherein R1 is selected from the group consisting of alkyl

having at least 2 carbon atoms, alkoxy, anhydride,

10

15

20

25

30

35

40

45

50

55

60

65

10

ether, ester, and amide, wherein R2 and R3 are inde-

pendently selected from the group consisting of

hydrogen, alkyl, alkoxy, hydroxy, alkenyl, ester, car-

boxylic acid, ether and electron withdrawing groups,

and

wherein R1 may also optionally be omitted or be an alkyl

having 1 carbon atom when R2 and R3 are not both

hydrogen.

2. The adhesive composition according to claim 1,

wherein said electron withdrawing groups are selected from

the group consisting of halogens, amides, cyanos, esters,

acids and ethers.

3. The adhesive composition according to claim 1,

wherein R1 is an alkyl having from about 2 to 8 carbon

atoms.

4. The adhesive composition according to claim 1,

wherein R2 and R3 are hydrogen.

5. The adhesive composition according to claim 1,

wherein R2 and R3 are alkyls having from 1 to 3 carbon

atoms.

6. The adhesive composition according to claim 1, further

comprising an initiator.

7. The adhesive composition according to claim 6,

wherein said initiator is selected from the group consisting

of benzalkonium chloride, stannous octoate and sodium

tetradecyl sulfate.

8. The adhesive composition according to claim 1, further

comprising a radical initiator.

9. The adhesive composition according to claim 8,

wherein said radical initiator is selected from the group

consisting of di-t-butyl peroxide, azobisisobutyronitrile and

benzoylperoxide.

10. A method of joining together surfaces, comprising:

(a) holding together at least two surfaces to form abutted

surfaces, and

(b) applying across said abutted surfaces an adhesive

composition according to claim 1.

11. An adhesive composition comprising a homopolymer

of the compound of claim 1.

12. An adhcsivc composition comprising a copolymcr of

the compound of claim 1 and a 1,1-disubstituted ethylene

monomer.

13. The adhesive composition according to claim 12,

wherein said ethylene monomer is n-butyl cyanoacrylate or

2-octyl cyanoacrylate.

14. The adhesive composition according to claim 1,

wherein crosslinking occurs through the vinyl terminated

ester group.

15. The adhesive composition according to claim 1,

further comprising an ultraviolet initiator.

16. A method of treatment comprising using the adhesive

composition of claim 1 in a biomedical application selected

from the group consisting of drug delivery, burn treatment,

setting fractured bone structures, retarding blood flow from

wounds, aiding repair and regrowth of living tissue and

apposing surgically incised or traumatically lacerated inter-

nal or external tissues.

17. The adhesive composition according to claim 1,

further comprising at least one acidic stabilizing agent.

18. The adhesive composition according to claim 17,

further comprising at least one radical stabilizing agent.

19. The adhesive composition according to claim 18,

further comprising at least one plasticizing agent.

* * * * *

Coments go here:

- Log in to post comments