Strength deformation and relaxation of joints bonded with modified cyanoacrylate adhesives

Strength deformation and relaxation of joints bonded with modified cyanoacrylate adhesives

Folder:

Year:

Article keywords:

Abstract:

The introduction of high molecular weight poly(methyl methacrylate) or poly(butadiene-co-acrylonitrile) into ethyl 2-cyanoacrylate produced viscous adhesives with a homogeneous or heterogeneous structure after cure. Steel joints bonded with these adhesives are shown to have improved tensile shear strength, deformability and stress relaxation of bonds compared with pure cyanoacrylate adhesive. Poly(methyl methacrylate)-modified adhesive is recommended for static load-bearing joints while poly(butadiene-co-acrylonitrile)-modified adhesive is more suited to cyclic or vibrating loads.

DOI:

10.1016/0143-7496(88)90081-4

Type of document:

Language:

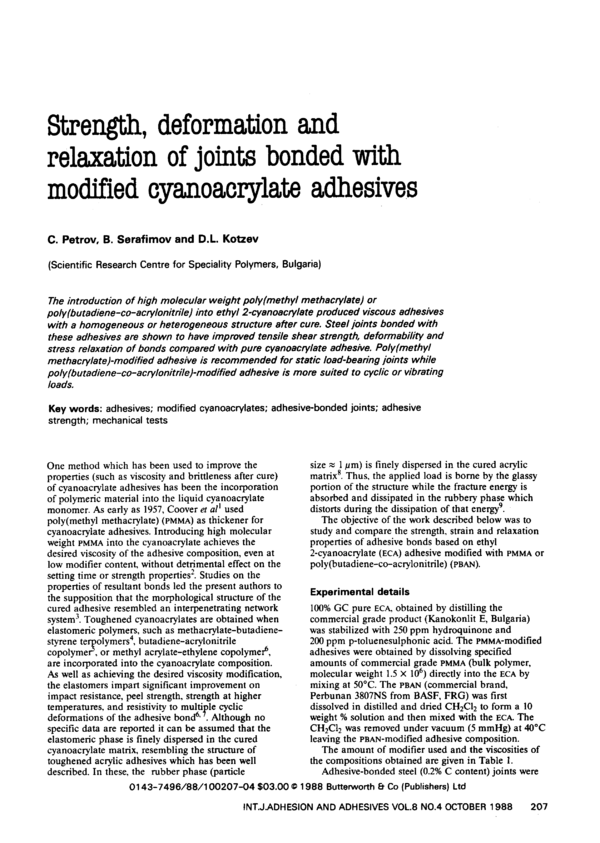

Strength, deformation and

relaxation of joints bonded with

modified cyanoacrylate adhesives

C. Petrov, B. Se raf i mo v and D.L. Kotzev

(Scientific Research Centre for Speciality Polymers, Bulgaria)

The introduction of high molecular weight poly(methyI methacrylate) or

poly(butadiene-co-acrylonitrile) into ethyl 2-cyanoacrylate produced viscous adhesives

with a homogeneous or heterogeneous structure after cure. Steel joints bonded with

these adhesives are shown to have improved tensile shear strength, deformability and

stress relaxation of bonds compared with pure cyanoacrylate adhesive. Poly(methyl

methacrylate)-modified adhesive is recommended for static load-bearing joints while

poly(butadiene-co-acrylonitrile)-modified adhesive is more suited to cyclic or vibrating

loads.

Key words: adhesives; modified cyanoacrylates; adhesive-bonded joints; adhesive

strength; mechanical tests

size ~ 1/lm) is finely dispersed in the cured acrylic

One method which has been used to improve the

matrix 8. Thus, the applied load is borne by the glassy

properties (such as viscosity and brittleness after cure)

portion of the structure while the fracture energy is

of cyanoacrylate adhesives has been the incorporation

absorbed and dissipated in the rubbery phase which

of polymeric material into the liquid cyanoacrylate

distorts during the dissipation of that energy9.

monomer. As early as 1957, Coover et a l I used

The objective of the work described below was to

poly(methyl methacrylate) (PMMA) as thickener for

study and compare the strength, strain and relaxation

cyanoacrylate adhesives. Introducing high molecular

properties of adhesive bonds based on ethyl

weight PMMA into the cyanoacrylate achieves the

2-cyanoacrylate (ECA)adhesive modified with PMMAor

desired viscosity of the adhesive composition, even at

poly(butadiene-co-acrylonitrile) (PBAN).

low modifier content, without detrimental effect on the

setting time or strength properties 2. Studies on the

properties of resultant bonds led the present authors to

Experimental details

the supposition that the morphological structure of the

100% GC pure ECA, obtained by distilling the

cured adhesive resembled an interpenetrating network

commercial grade product (Kanokonlit E, Bulgaria)

system 3. Toughened cyanoacrylates are obtained when

was stabilized with 250 ppm hydroquinone and

elastomeric polymers, such as methacrylate-butadiene200 ppm p-toluenesulphonic acid. The PMMA-modified

styrene terpolymers 4, butadiene-acrylonitrile

adhesives were obtained by dissolving specified

copolymer~, or methyl acrylate-ethylene copolymer6,

amounts of commercial grade PMMA(bulk polymer,

are incorporated into the cyanoacrylate composition.

molecular weight 1.5 x 106) directly into the ECA by

As well as achieving the desired viscosity modification,

mixing at 50°C. The PBAN (commercial brand,

the elastomers impart significant improvement on

Perbunan 3807NS from BASF, FRG) was first

impact resistance, peel strength, strength at higher

dissolved in distilled and dried CH2C12 to form a 10

temperatures, and resistivity to multiple cyclic

deformations of the adhesive bond 6' 7. Although no

weight % solution and then mixed with the ECA. The

CH2C12 was removed under vacuum (5 mmHg) at 40°C

specific data are reported it can be assumed that the

leaving the PBAN-modified adhesive composition.

elastomeric phase is finely dispersed in the cured

The amount of modifier used and the viscosities of

cyanoacrylate matrix, resembling the structure of

the compositions obtained are given in Table 1.

toughened acrylic adhesives which has been well

Adhesive-bonded steel (0.2% C content) joints were

described. In these, the rubber phase (particle

0143-7496/88/100207-04 $03.00 © 1988 Butterworth 8 Co (Publishers) Ltd

INT.J.ADHESION AND ADHESIVES VOL.8 NO.4 OCTOBER 1988

207

Table 1.

Viscosity of adhesive c o m p o s i t i o n s

Modifier

Type

Viscosity at 20°C (cP)

Amount (weight %)

--

PMMA

PBAN

2.5

1

2

3

4

23

52

150

495

1

3

5

8

10

I

I

i

70 mm

IJ

25

-96

180

450

620

I

i

i

0.05 mm - -

1 mm

I

1.5

mm

147.

i

PMMA poly(methyl methac~late)

PBAN poly(butadiene co-acrylonitrile)

I

i

i

used in all the mechanical tests. The surfaces to be

bonded were roughened with Igel 400 sandpaper and

degreased with trichloroethylene (chemical treatment

or activation were not employed). After application of

the adhesive the joint was clamped and left for 24 h at

j 70 mm

i

i

I

F

•

r

12mm 4

F

Fig. 2

Test specimen for tensile strain determination (Reference 12)

J

1 I0 mm" ~ ,

5 ml

I

I

.L

12mm ~

F

Fig. 1

208

Test specimen for shear strain determination (References 10, 1 1

INT.J.ADHESION AND ADHESIVES OCTOBER 1988

20-22 C and 55-65% RH. The thickness of the glue-line

(0.05 mm) was controlled with the use of calibrated

copper wire.

Tensile shear strength was determined in

accordance with ASTM D-1002 on single overlap

specimens. A Zwick 1474 Universal testing machine

was used.

The test specimen for shear strain had dimensions

as shown in.Fi~. 11°' II. The rate of loading was

0.025 mm m m - ' .

The relaxation modulus was determined with the

help of the test specimen for tensile strain

determination (shown in Fig. 2) 12. The multilayer

structure was chosen because it provided a means for

increasing the absolute value of deformation within

measurable limits, since cyanoacrylates polymerize

only in very thin films. It consists of five cylindrical

discs, 12 mm in diameter and 1.5 mm thick, assembled

between two cylindrical rods of the same diameter. The

adhesive is applied between the discs and rods, thus

providing six adhesive lines. All adhesive layers had

thicknesses of 0.05 ram. To obtain the necessary

co-axiality, a specially-cut Teflon jacket was used for

the assembly of the specimen after adhesive

application. The specimen was loaded at a rate of

20 mm min -] to a specified deformation and held

loaded for 600 s, after which, stress and deformation

values were recorded.

25

2100

p

20

1800

60

e~

15

-

50

D

o

5

-I

ro

~- 1500

40

~

m

C

10

/%

30

}

1

c

1200

~q

d

-~ 20

(/I

10

900

I

I

I

2

I

3

I

q

Content of PMMA(%)

Fig. 3 Dependence of shear stress and shear strain on content of

PMMA in adhesive

600

3

I

2s

I

I

I

I

I

20

40

60

80

100

le failure (%)

Fig. 5 Dependence of relaxation modulus on relative strain: 1, pure ECA;

2, ECA containing PBAN (3 weight %); 3, ECA containing PMMA

(4 weight %)

20

60

22

eo

Q.

D

121 2

D

-- 40

o

C

L

to

.C

-

30

oJ

ru3

18

o

-20

16

I

I

I

I

I

I

I

5

I

I

I

i

lO

C o n t e n t o f PBAN (%)

Fig. 4

Dependence of shear stress and shear strain on content of PBAN

in adhesive

I

50

I

100

Rate of stress increase (mmmin - 1 )

Fig. 6 Dependence of stress at failure on rate of applied load: 1, ECA

containing PBAN (3 weight %); 2, ECA containing PMMA (3 weight %);

3, pure ECA

INT.J.ADHESION

AND ADHESIVES

OCTOBER

1988

209

Strain was measured using an Instron G-51-11-M

extensiometer and the strain/time dependence was

recorded with the help of an additional Tacussel EPL-2

recorder.

Results end discussion

The dependence of tensile shear strength and relative

elongation at break of bonded joints on the content of

PMMA in the ECA adhesive and PBAN in the ECA

adhesive is shown in Figs 3 and 4 respectively.

Increasing the content of PMMA causes slight and

almost uniform increase of the tensile shear strength

and deformability of the bond. PBAN-modified

adhesive show increased strength when the elastomer

content is in the range 0.5-4.0 weight %, with a well

pronounced maximum at 1.0 weight %. Further

increase in modifier content affects the strength value

detrimentally. The deformability of the adhesive bond

increases with the increase of PBAN content. On

comparing Fig. 3 with Fig. 4 over the 0-4 weight %

modifier content range, it can be seen that the adhesive

containing PBAN has better strength and a more

pronounced susceptibility of the joint to deformation.

The change of relaxation modulus with the increase

of the deformation relative to deformation at failure of

adhesive bond (e/efailure) is shown in Fig. 5. The curves

for pure ECA bonds and PMMA-modified ECA bonds

have similar shape. The relaxation modulus steadily

decreases in value up to 70-80% of failure strain; above

this deformation its value drops sharply. In the case of

PBAN-modified adhesive the decrease of modulus value

up to e/efailure = 50% is less pronounced, but falls

steeply at higher values ratios. This is associated with

the change of mechanism of the deformation process

caused by the beginning deformation of the

elastomeric phase.

Fig. 6 shows the dependence of the tensile shear

strength of bonded joints on the rate of applied stress.

Decreasing the stress rate decreases the value of the

tensile shear strength for all adhesive systems. The

PBAN-modified adhesive bonds, however, are the least

affected.

210

INT.J.ADHESION AND ADHESIVES OCTOBER 1988

Conclusions

The data obtained in this study confirm practical

results reported previously2. 5 for cyanoacrylate

adhesives containing PMMA or PBAN. The modified

adhesives display improved strength properties,

deformation susceptibility, and stress relaxation.

Adhesives modified with PMMA would be appropriate

for static load-bearing joints whereas joints bonded

with PBAN-modified cyanoacrylate adhesives could

better withstand cyclic or vibrating loads,

References

1

Coover, Jr, H.W. et e l U S Patent 2 794 788 (1957)

2

Kotzev, D.L. and Dichava, L.B, 'Cyanoacrylate adhesives with

increased viscosity' in First National Conference on Chemistry

(Ministry of National Education, Sofia, Bulgaria, 1985) p 4 1 5

3

Petrov, C., Sarafirnov, S. and Kotzav, D. 'Adhesive bond properties

of ethyl 2-cyanoacrylate modified with poly(methyl methacwlate)'

J Adhesion (submitted)

4

Gleave, V. US Patent 4 102 945 (1978)

5

Kabaivenov, V. at al Bulgarian Patent 29487 (1979)

6

O'Connor, J.T. US Patent 4 440 910 (1984)

7

Kotzev, D.L. and Kabaivanov, V.S, 'Improvement and diversification

of cyanoacrylate adhesives' in Adhesion-12 edited by K,W. Alien

(Elsevier Applied Science Publishers, London, UK, 1988)

pp 82-105

8

Chernoek, R.S. and Martin, F.R. Adhesion and Adhesives, Durham

University, September 1980 (The Plastics and Rubber Institute,

London, UK, 1980) Reprints paper 16

9

Lees, W.A. The British Polymer J 11 (June 1979) p 69

10

Jenadrau, J.P. 'Intrinsic mechanical characterization of structural

adhesives' Int J Adhesion and Adhesives 6 No 4 (October 1986)

PD 229-231

11

Althof, W. and Brockmann, W. Adhesives Age 20 No 11 (1977)

p27

12

Freidin, A.E. in Strength and Durability of Adhesive Joints (Hirnia,

Moscow, USSR, 1981 ) pp 113-114

Authors

The authors are with the Scientific Research Centre for

Speciality Polymers, Kliment Ohridski Street 4A, 1156

Sofia, Bulgaria. Enquiries should be addressed to Dr

D.L. Kotzev.

Coments go here:

- Log in to post comments