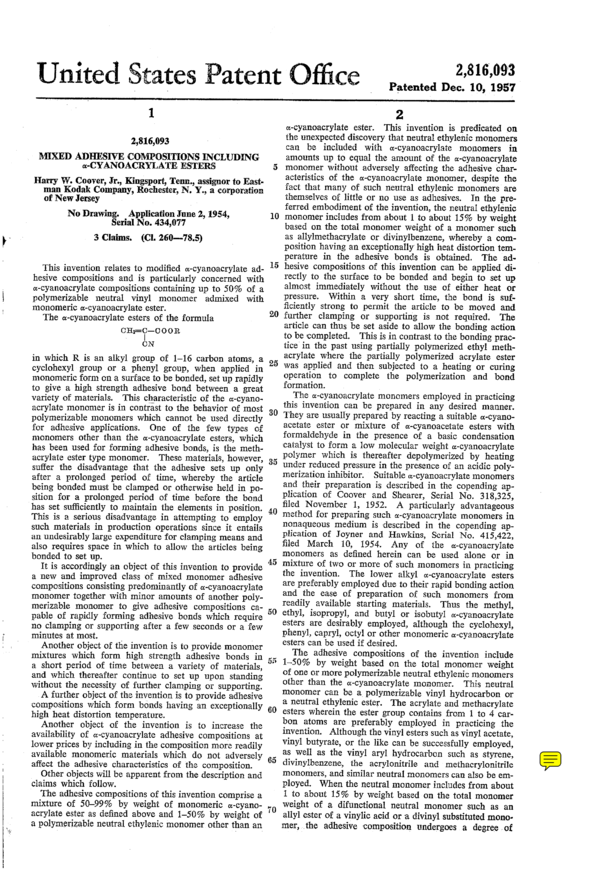

Mixed Adhesive Compositions Including Alpha-Cyanoacrylate Esters

Mixed Adhesive Compositions Including Alpha-Cyanoacrylate Esters

US2816093

Company:

Folder:

Year:

Abstract:

This invention relates to modified alpha-cyanoacrylates adhesive compositions and is particularly concerned with alpha-cyanoacrylate compositions containing up to 50% of a polymerizable neutral vinyl monomer admixed with monomeric alpha-cyanoacrylate ester.

Type of document:

Language:

United htates Patent Office

2,8l6",0i9'3

Patented Dec. 10, 1957

1

2,816,093

MIXED ADHESIVE COMPOSITIONS INCLUDING

a-CYANOACRYLATE ESTERS

Harry W. Coover, Jr., Kingsport, Tenn., assignor to East-

man Kodak Company, Rochester, N. Y., a corporation

of New Jersey

No Drawing. Application June 2, 1954,

Serial No. 434,077

3 Claims. (Cl. 260-78.5)

This invention relates to modified ac-cyanoacrylate ad-

hesive compositions and is particularly concerned with

on-cyanoacrylate compositions containing up to 50% of a

polymerizable neutral vinyl monomer admixed with

monomeric cc-cyanoacrylate ester.

The on-cyanoacrylate esters of the formula

CH2=C|3—COOR

CN

in which R is an alkyl group of 1-16 carbon atoms, a

cyclohexyl group or a phenyl group, when applied in

monomeric form on a surface to be bonded, set up rapidly

to give a high strength adhesive bond between a great

variety of materials. This ch_aracteristic of the ac-cyano-

acrylate monomer is in contrast to the behavior of most

polymerizable monomers which cannot be used directly

for adhesive applications. One of the few types of

monomers other than the ca-cyanoacrylate esters, which

has been used for forming adhesive bonds, is the meth-

acrylate ester type monomer. These materials, however,

suffer the disadvantage that the adhesive sets up only

after a prolonged period of time, whereby the article

being bonded must be clamped or otherwise held in po-

sition for a prolonged period of time before the bond

has set sufliciently to maintain the elements in position.

This is a serious disadvantage in attempting to employ

such materials in production operations since it entails

an undesirably large expenditure for clamping means and

also requires space in which to allow the articles being

bonded to set up.

It is accordingly an object of this invention to provide

a new and improved class of mixed monomer adhesive

compositions consisting predominantly of ac-cyanoacrylate

monomer together with minor amounts of another poly-

merizable monomer to give adhesive compositions ca-

pable of rapidly forming adhesive bonds which require

no clamping or supporting after a few seconds or a few

minutes at most. _ ,

Another object of the invention is to provide monomer

mixtures which form high strength adhesive bonds in

a short period of time between a variety of materials,

and which thereafter continue to set up upon standing

without the necessity of further clamping or supporting.

A further object of the invention is to provide adhesive

compositions which form bonds having an exceptionally

high heat distortion temperature.

Another object of the invention is to increase the

availability of as-cyanoacrylate adhesive compositions at

lower prices by including in the composition more readily

available monomeric materials which do not adversely

affect the adhesive characteristics of the composition.

Other objects will be apparent from the description and

claims which follow.

The adhesive compositions of this invention comprise a

mixture of 50-99% by weight of monomeric a-cyano-

acrylate ester as defined above and l—50% by weight of

a polymerizable neutral ethylenic monomer other than an

10

15

20

25

30

35

40

45

50

60

65

2

on-cyanoacrylate ester. This invention is predicated on

the unexpected discovery that neutral ethylenic monomers

can be included with cc-cyanoacrylate monomers in

amounts up to equal the amount of the at-cyanoacrylate

monomer without adversely affecting the adhesive char-

acteristics of the oucyanoacrylate monomer, despite the

fact that many of such neutral ethylenic monomers are

themselves of little or no use as adhesives. In the pre-

ferred embodiment of the invention, the neutral ethylenic

monomer includes from about 1 to about 15% by weight

based on the total monomer weight of a monomer such

as allylmethacrylate or divinylbenzene, whereby a com-

position having an exceptionally high heat distortion tem-

perature in the adhesive bonds is obtained. The ad-

hesive compositions of this invention can be applied di-

rectly to the surface to be bonded and begin to set up

almost immediately without the use of either heat or

pressure. Within a very short time, the bond is suf-

ficiently strong to permit the article to be moved and

further clamping or supporting is not required. The

article can thus be set aside to allow the bonding action

to be completed. This is in contrast to the bonding prac-

tice in the past using partially polymerized ethyl meth-

acrylate where the partially polymerized acrylate ester

was applied and then subjected to a heating or curing

operation to complete the polymerization and bond

formation.

The on-cyanoacrylate monomers employed in practicing

this invention can be prepared in any desired manner.

They are usually prepared by reacting a suitable oc-cyano-

acetate ester or mixture of oz-cyanoacetate esters with

formaldehyde in the presence of a basic condensation

catalyst to form a low molecular weight on-cyanoacrylate

polymer which is thereafter depolymerized by heating

under reduced pressure in the presence of an acidic poly-

merization inhibitor. Suitable cc-cyanoacrylate monomers

and their preparation is described in the copending ap-

plication of Coover and Shearer, Serial No. 318,325,

filed November 1, 1952. A particularly advantageous

method for preparing such on-cyanoacrylate monomers in

nonaqueous medium is -described in the copending ap-

plication of Joyner and Hawkins, Serial No. 415,422,

filed March 10, 1954. Any of the on-cyanoacrylate

monomers as defined herein can be used alone or in

mixture of two or more of such monomers i11 practicing

the invention. The lower alkyl oz-cyanoacrylate esters

are preferably employed due to their rapid bonding action

and the ease of preparation of such monomers from

readily available starting materials. Thus the methyl,

ethyl, isopropyl, and butyl or isobutyl on-cyanoacrylate

esters are desirably employed, although the cyclohexyl,

phenyl, capryl, octyl or other monomeric cc-cyanoacrylate

esters can be used if desired.

The adhesive compositions of the invention include

1—50% by weight based on the total monomer Weight

of one or more polymerizable neutral ethylenic monomers

other than the oz-cyanoacrylate monomer. This neutral

monomer can be a polymerizable vinyl hydrocarbon or

a neutral ethylenic ester. The acrylate and methacrylate

esters wherein the ester group contains from 1 to 4 car-

bon atoms are preferably employed in practicing the

invention. Although the vinyl esters such as vinyl acetate,

vinyl butyrate, or the like can be successfully employed,

as well as the vinyl aryl hydrocarbon such as styrene,

divinylbenzene, the acrylonitrile and methacrylonitrile

monomers, and similar neutral monomers can also be em-

ployed. When the neutral monomer includes from about

1 to about 15 % by weight based on the total monomer

weight of a difunctional neutral monomer such as an

allyl ester of a vinylic acid or -a divinyl substituted mono-

mer, the adhesive composition undergoes a degree of

‘W

, .6!

crosslinking during the bonding action whereby an excep-

tionally high heat distortion temperature for the adhesive

bond is obtained. Thus, for example, the inclusion of

.-1—15% by weight of allylacrylate, allylmethacrylate, or

.div-inylbenzene in the adhesive composition results in

adhesive bonds having melting points higher than 200° C.

.as contrasted to a melting point of 165° C. for a methyl

cyanoacrylate homopolymer. This is particularly useful

.when>the bonded article is to be subjected to high tem-

.peratures during normal use. In practicing the invention,

such neutral monomers as methyl acrylate, ethyl acrylate,

.isopropyl acrylate, butyl acrylate, isobutyl acrylate, methyl

.methacrylate, ethyl methacrylate, butyl methacrylate, ac-

rylonitrile, methacrylonitrile, styrene, methyl styrene, vinyl

acetate, vinyl butyrate, and the like are suitable for use.

The basic monomers such as vinyl pyridine are unsuitable

for use since they produce unstable mixtures which un-

dergo rapid polymerization upon addition of the basic

monomer to the at-cyanoacrylate ester. Acidic monomers

.such as ethylenic sulfonic acid cause excessive stabiliza-

tion of the mixture against polymerization and prevent

adhesive action.

The setting up of the adhesive compositions of this

invention, and particularly the ‘further bonding following

the initial bonding is promoted by including a small

amount of a peroxy catalyst in the adhesive composition

just prior to use. Any of the well known per-catalysts

such as the peroxides, persulfates, or perborates, and the

like, can be used for promoting the complete polymeriza-

tion of the composition. The amount of catalyst can, of

course, be varied but amounts of about 0.1% by weight

are usually suitable.

The adhesive compositions of the invention are sta-

bilized against polymerization during storage by inclusion

therein of from about 0.001% to about 2% by weight of

a suitable acidic polymerization inhibitor, and desirably

from 0.001 to about 0.01% by weight based on the mono-

mer weight. This stabilizer is desirably sulfur dioxide,

'although other gaseous inhibitors having an acidic nature

such as nitric oxide, hydrogen fluoride, boron trifluoride,

and the like can be used. When the gaseous stabilizer is

included in amounts of more than 0.01%, it is sometimes

desirable to remove a portion of the stabilizer prior to

use of the adhesive composition. This is readily done

by subjecting the composition to a reduced pressure of

about 1 -mm. for a few minutes. The adhesive composi-

tions can also include from about 0.001 to about 0.01%

by weight of a neutral free radical inhibitor such as hydro-

quinone, trinitrobenzene, or t-butylcatechol in combina-

tion with the acidic inhibitor. Such added stabilizers give

a high degree of stability in bulk to the adhesive composi-

tions during storage. In the preferred range of stabilizer

concentration, the adhesive composition undergoes auto-

polymerization in a few minutes when spread in a thin

film on the surface to be bonded without the application

of heat or pressure or the use of a polymerization catalyst.

In some cases, it may be desirable to heat the article dur-

ing the bonding operation in order to speed up the bond-

ing action. In some cases, it may be desirable to further

accelerate the bonding action by the application of very

small amounts of bases such as ammonia, piperidine,

pyridine, or the like to the article prior to bonding. The

use of such basic catalysts tends to give weak bonds,

however, and it is preferred to merely moisten the sur-

face with an aliphatic alcohol such as methanol, ethanol,

isobutanol, capryl alcohol, or the like prior to application

of the adhesive composition thereto. This use of alcohol

is of particular advantage in the bonding of materials

exhibiting an acidic surface character, such as green wood

or phenolic resins, or when using adhesive compositions

containing -relatively large amounts of stabilizer which

slow the adhesive action.

The adhesive compositions can be used in the form of

amixture of ‘the monomer alone, or it can include as

much as 25% by weight of a —viscosity regulator such as

2,816,093

Q7!

10

03

U I

40

50

55

60

65

70

75

4

polymeric ac-cyanoacrylate, polyacrylate, po1ymethacry-

late or a cellulose ester, or up to about 20% by weight of

a plasticizer such as a monofunctional aliphatic ester, a

difunctional aliphatic or aromatic ester, a phosphate ester,

a phosphonate ester, or the like. i

Although the compositions of this invention can con-

tain up to 50% by weight based on the total weight of

monomer of a neutral monomer or monomers other than

the oz-cyanoacrylate monomer or monomers, the compo-

sition begins to bond rapidly asis characteristic of o:-cy-

anoacrylate adhesive compositions containing no other

added monomer. Once the bonding action has started,

a high strength bond forms in a very short time, and the

further bonding then proceedsat room temperature until

the bond has become completely polymerized. The addi-

tional vinyl monomer does not adversely affect the

strength of the adhesive bond thereby obtained. In this

way, the available supply of ac-cyanoacrylate monomers

is greatly extended, and compositions of increased utility

are readily prepared.

The invention is illustrated by the following examples,

but it will be understood that the examples are included

for purposes of illustration and are not intended to limit

the scope of the invention unless otherwise specifically

indicated.

Example I

A mixture of 10 parts by weight of methyl acrylate

with 90 parts by weight of methyl at-cyanoacrylate, both

in monomeric form, and containing 0.1% by weight of

acetyl peroxide, was employed for bonding together a

variety of objects made of glass, metal, plastics and wood.

The methyl wcyanoacrylate polymerized rapidly to set

the pieces being bonded to the extent that the article could

be moved within aifew minutes without disturbing the

bond. During this period, the methyl acrylate remained

in monomeric form. Over a period of hours, however,

the methyl acrylate also polymerized to complete the

formation of a very strong bond. No heat was required

at any stage of the bonding operation.

Example 2

As has been described, the adhesive composition can

contain equal parts by weight of at-cyanoacrylate mono-

mer and other neutral vinylmonomers with excellent

results. Thus a mixture of 50 parts by weight of methyl

methacrylate monomer with 50 parts by weight of ethyl

cc-cyanoacrylate monomer containing 0.1% by weight of

acetyl peroxide was employed for bonding a variety of

glass, metal, plastic, and wood articles. The bond formed

rapidly, and the bonding action was completed at 35° C.

Example 3

Similar results were obtained using an adhesive com-

position comprising a mixture of 20‘ parts by weight of

ethyl acrylate and 80 parts by weight of methyl cx-cyano-

acrylate, the mixture containing 0.05% by weight of

acetyl peroxide.

Example 4

Although the use of a perovide catalyst is preferred to

promote the polymerization of the non-cyanoacrylate

monomer, such catalyst not necessary for successful

bonding. Thus the procedure set out in Example 1 was

followed using an adhesive composition comprising 10

parts by weight of methyl acrylate and 90 parts by weight

of methyl on-cyanoacrylate. No peroxide catalyst was used

in this composition. The methyl ax-cyanoacrylate poly-

merized rapidly to set the bond as before. Then, over a

period of several days, the methyl acrylate polymerized

to complete the formation of a high strength bond.

Example 5

A variety of objects were bonded using an adhesive

composition containing 5 parts by weight of allyl acrylate,

10 parts by weight of methyl acrylate, 85 parts by weight

rt‘

2,816,093

5

of methyl av.-cyanoacrylate and 0.05% of acetyl peroxide.

The bond formation was very rapid, and the articles could

e moved within a few minutes. After the bonded articles

1

_ad been allowed to stand at room temperature for 24

hours, the heat resistance of glass to rubber and wood to

wood bonds was tested. The bonds retained their strength

at temperatures at high as 205° C.

Example 6

Other difunctional neutral monomers act in similar

ashion to crosslink the adhesive composition during

bonding to give equally heat-resistant bonds. Thus the

procedure of Example 5 was repeated using 10 parts by

weight of divinylbenzene instead of the allyl acrylate. As

before, the adhesive bonds thereby obtained remained

strong at temperatures above 200° C.

Example 7

Although the acrylate and methacrylate esters are pre-

ferred for use as the neutral vinyl monomer because of

their ready availability, other neutral vinyl monomers can

be employed with equally good results. For example, the

procedure of Example 1 was folowed using an adhesive

composition comprising 5 parts by weight of methyl acry-

late, 5 parts by weight of styrene, 90 parts by weight

of ethyl cyanoacrylate, and 0.01% by weight of acetyl

peroxide. The bonds thereby obtained had a high de-

gree of tensile‘ strength.

Example 8

Similarly advantageous results were obtained using an

adhesive composition comprising 5 parts by weight of

crylonitrile and 95 parts by weight of isobutyl u-cyano-

acrylate. The bonding was promoted by incorporating

0.02% of acetyl peroxide into the composiiton just prior

to the bonding.

The neutral monomers which are included within the

scope of this invention are those which do not polymerize

concomitantly with the u-cyanoacrylate monomers but

which polymerize following the initial bonding. Thus the

neutral vinyl monomers are those which are normally

non-autopolymerizable, that is, which do not begin to

polymerize within a few seconds or a few minutes when

spread in a thin film. This is in contrast to mixtures of

u-cyanoacrylate monomers in which the monomers often

polymerize at diflerent rates but which begin to auto-

10

15

20

25

30

35

40

45

6

polymerize almost at once. The adhesive action of the

compositions of this invention is thus a two stage process

and the compositions can be designated as two-stage ad-

hesives as contrasted to a single-stage adhesive wherein

all of the monomeric components enter into the initial

bonding action.

Thus by means of this invention adhesive compositions

are provided which have a rapid bonding action initially,

and which continue to set up after the initial bonding to

give adhesive bonds of exceptional strength between a

variety of materials. Unlike the usual polymerizable ad-

hesive compositions, no heating or curing operation is

necessary, and the articles being bonded need not be

clamped or supported during the setting up of the ad-

hesive bond.

Although the invention has been described in consider-

able detail with particular reference to certain preferred

embodiments thereof, variations and modifications can

be effected within the spirit and scope of the invention as

described hereinabove and as defined in the appended

claims.

I claim:

1. An adhesive composition comprising a mixture of

at least 50% by weight of monomeric alkyl a-cyano-

acrylate wherein the alkyl group contains 1-4 carbon

atoms, 1-15 % by weight of a member of the group con-

sisting of allyl acrylate and divinyl benzene, and 1—49%

by weight of alkyl acrylate wherein the alkyl group

contains 1-4 carbon atoms.

2. An adhesive composition comprising a monomeric

mixture of at least 50% by weight of methyl u-cyano-

acrylate, 1-15 % by weight of allyl acrylate and 1—49%

by weight of methyl acrylate.

3. An adhesive composition comprising a monomeric

mixture of at least 50% by weight of methyl a-cyano-

acrylate, 1—15% by weight of divinyl benzene and 1-49%

by weight of methyl acrylate.

References Cited in the file of this patent

UNITED STATES PATENTS

2,437,231 Mowry ______________ _.. Mar. 2, 1948

2,439,081 Dickey et al ____________ _.. Apr. 6, 1948

2,467,927 Ardis _______________ ._ Apr. 19, 1949

2,615,879 Folt et al. ____________ __ Oct. 28, 1952

@

Coments go here:

- Log in to post comments