�����������������������������������������������������������������������������.(21) International Application Numberi

WORLD INTELLECTUAL PROPERTY ORGANIZATION

P Intemational Bureau

INTERNATIONAL APPLICATION PUBLISHED UNDER THE PATENT COOPERATION TREATY (PCT)

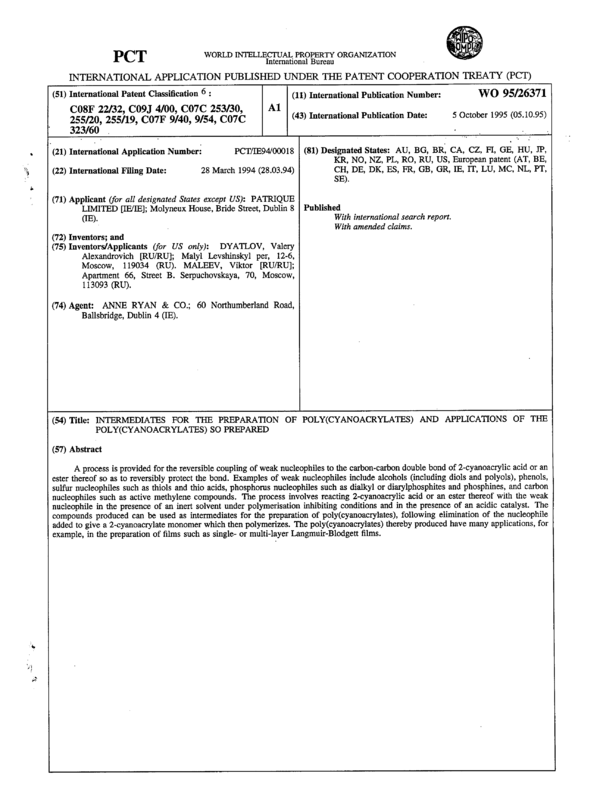

(51) International Patent Classification 6 : W0 95/26371

cosr 2 2 C09 4/00 co7c 253/30

255/20, 22,g5}19, cJo7F 9740, 9/54, C07C 5 °°‘°ber 1995

323/so .

(11) International Publication Number:

(43) International Publication Date:

PCT/IE94J00O18 (81) Designated States: AU, BG, BR, CA, CZ, FI, GE, HU, JP,

KR, NO, NZ, PL, RO, RU, US, European patent (AT, BE,

CH, DE, DK, ES, FR, GB, GR, IE, IT, LU, MC, NL, PT,

SE).

(22) International Filing Date: 28 March 1994 (28.03.94)

(71) Applicant (for all designated States except US): PATRIQUE

LIMITED [IFJIE]; Molyneux House, Bride Street, Dublin 8 Published

(IE). With international search report.

‘ With amended claims.

(72) Inventors; and

(75) Inventors/Applicants (for US only): DYATLOV, Valery

Alexandrovich [RU/RU]; Malyl Levshinskyl per, 12-6,

Moscow, 119034 (RU). MALEEV, Viktor [RU/RU];

Apartment 66, Street B. Serpuchovskaya, 70, Moscow,

113093 (RU).

(74) Agent: ANNE RYAN & CO.; 60 Northumberland Road,

Ballsbridge, Dublin 4 (IE).

(54) Title: INTERMEDIATES FOR THE PREPARATION OF POLY(CYANOACRYLATES) AND APPLICATIONS OF THE

POLY(CYANOACRYLATES) SO PREPARED

(57) Abstract

A process is provided for the reversible coupling of weak nucleophiles to the carbon-carbon double bond of 2-cyanoacrylic acid or an

ester thereof so as to reversibly protect the bond. Examples of weak nucleophiles include alcohols (including diols and polyols), phenols,

sulfur nucleophiles such as thiols and thio acids, phosphorus nucleophiles such as dialkyl or diarylphosphites and phosphines, and carbon

nucleophiles such as active methylene compounds. The process involves reacting 2-cyanoacrylic acid or an ester thereof with the weak

nucleophile in the presence of an inert solvent under polymerisation inhibiting conditions and in the presence of an acidic catalyst. The

compounds produced can be used as intermediates for the preparation of po1y(cyanoacrylates), following elimination of the nucleophile

added to give a 2-cyanoacrylate monomer which then polymerizes. The po1y(cyanoacrylates) thereby produced have many applications, for

example, in the preparation of films such as single— or multi-layer Langmuir-Blodgett films.

AT

AU

BB

BE

BF

BG

BJ

BR

BY

CA

CF

CG

CH

CI

CM

CN

CS

CZ

DE

FOR THE PURPOSES OF INFORMATION ONLY

Codes used to identify States_party to the PCT on the front pages of pamphlets publishing international

applications under the PCT.

Austria

Australia

Barbados

Belgium

Burkina Faso

Bulgaria

Benin

Brazil

Belarus

Canada

Central African Republic

Congo

Switzerland

Cote d'Ivoire

Cameroon

China

Czechoslovakia

Czech Republic

Germany

Denmark

Spain

Finland

France

Gabon

United Kingdom

Georgia

Guinea

Greece

Hung“?

Ireland

Italy

Japan

Kenya

Kyrgystan

Democratic People’s Republic

of Korea

Republic of Korea

Kazakhstan

Liechtenstein

Sri Lanka

Luxembourg

Latvia

Monaco

Republic of Moldova

Madagascar

Mali

Mongolia

Mauritania

Malawi

Niger

Netherlands

Norway

New Zealand

Poland

Portugal

Romania

Russian Federation

Sudan

Sweden

Slovenia

Slovakia

Senegal

Chad

Togo

Tajikistan

Trinidad and Tobago

Ulaaine

United States of America

Uzbekistan

Viet Nam

10

15

20

25

WO 95/26371

PCT/D394/00018

Description

Intermediates for the preparation of polygcyanoacrylatesz and

applications of the polygcyanoacrylatesz so prepared

Technical Field

This invention relates to the reversible coupling of a weak

nucleophile to the carbon—carbon double bond of 2—cyanoacry1ic acid or

an ester thereof, so as to reversibly protect said bond.

Background Art

Esters of 2-cyanoacrylic acid having the general formula:

CN

H2C= /

\

CO2R

are widely used as monomers for the preparation of polymers and

copolymers. The ability of 2—cyanoacry1ic acid esters to polymerise

rapidly under the influence of moisture or nucleophilic substances has

led to their exploitation as instantaneous adhesives. Thus,

cyanoacrylate esters are the main constituents of the rapid-bonding

adhesives commonly known as "superg1ues". Bonding results from the

conversion of a low—viscosity monomer into a solid polymer by anionic

polymerisation. Esters of 2-cyanoacrylic acid are also used for the

preparation of po1y(alky1 2—cyanoacrylate) nanoparticles and

nanocapsules which may be employed as carrier or delivery systems

for drugs or other active agents. Furthermore, esters of 2-

cyanoacrylic acid can be used to prepare Langmuir-Blodgett type thin

films which may be applied as coatings for components used in the

electronics industry.

The inherent ability of 2-cyanoacrylic acid esters to undergo

rapid anionic polymerisation causes complications as regards their

10

15

20

25

30

WO 95/26371

PCT/IE94/00018

synthesis, chemical modification, and storage. It is necessary to be able.

to control the rate of polymerisation of cyanoacrylate monomers in

order to permit their successful manipulation prior to carrying out the

bonding process. Additionally, there is a need to be able to control the

surface—active properties of cyanoacrylate monomers which are to be

utilised in Langmuir—Blodgett film applications. ‘

The principal method known for the regulation of the chemical

and physical properties of 2-cyanoacrylate monomers and polymers is

by variation of the structure of the ester moiety. However,

‘ opportunities for the chemical modification of simple cyanoacrylate

esters in order to prepare new monomers are limited due to the high

chemical reactivity of the carbon—carbon double bond.

Methods for the synthesis of 2-cyanoacrylic acid ester monomers

are few in number. An important commercial route to these

compounds is the Knoevenagel Condensation Method (H. Lee (Ed.)

(1981), "Cyanoacrylic Resins - The Instant Adhesives", Pasadena

Technology Press, Pasadena, U.S.A.). According to the Knoevenagel

method a cyanoacetic acid ester and formaldehyde are reacted together

in the presence of an amine to give alkyl cyanoacrylate oligomers. The

free cyanoacrylate ester monomer is then generated by thermally

cracking the oligomer and vacuum distilling the monomer on to an

acidic stabiliser. The Knoevenagel method is limited to the preparation

of alkyl 2—cyanoacrylates which have an alkyl moiety of no more than

ten carbon atoms. Above this limit, the monomers cease to be

distillable at temperatures which are below their respective thermal

destruction temperatures. In fact, n-octyl 2-cyanoacrylate is the

monomer with the greatest number of carbon atoms in the ester

function that has been reported to have been prepared by the

Knoevenagel method (Kublin, K.S. and Miguel, F.M., (1970), J. Amer.

Vet. Ass., Vol. 156, No. 3, 313-318; Alco, J.J. and DeRenzis, F.A.,

(1971), J. Pharmacol. Ther. Dent., Vol. 1, No. 3, 129-132).

Short chain (less than ten carbon atoms) alkyl 2—cyanoacrylates

with polar groups such as hydroxyl, carboxyl and ester groups, and

10

15

20

25

30

W0 95/2637 1

PCT/IE94/00018

aryl cyanoacrylates cannot generally be prepared by the Knoevenagel _ “

Condensation Method because of their high boiling points.

Another method for the preparation of alkyl 2-cyanoacrylic acid

esters is based on the transesterification reaction (Voitekunas, J .,

Polyakova, A.M., Mager, K.A., Kokhanov, Yu. V. and Voitkov, A.I.,

U.S.S.R. Patent No. 726,086). This single—stage method involves the

transesterification of methyl or ethyl 2—cyanoacrylate with a higher

alcohol under acid-catalysed conditions. Because of the relatively low

efficiency of the process it is necessary to separate residual methyl or

ethyl 2—cyanoacrylate from the product ester by vacuum distillation.

A method for the synthesis of 2-cyanoacrylic acid esters

involving prior protection of the carbon—carbon double bond of a

simple cyanoacrylate derivative is described in U.S. Patent No.

3,903,055. The method can involve three or five steps. In the five-

step process, ethyl or isobutyl 2—cyanoacrylate is reacted with

anthracene to form its stable Diels-Alder anthracene adduct. Basic

hydrolysis of the ester function in the adduct gives the corresponding

carboxylic acid salt from which the free acid is obtained upon

acidification. The carboxylic acid is next converted into its acid

chloride with thionyl chloride, and this is reacted with an alcohol to

give a new ester. A displacement reaction involving the stronger

dienophile maleic anhydride is then carried out to give the product

cyanoacrylate ester together with the anthracene-maleic anhydride

Diels-Alder adduct from which it must be separated. The

cyanoacrylate ester formed can then be used as a monomer for the

- preparation of poly(alkyl 2—cyanoacrylates). It should be noted that

this route to alkyl 2—cyanoacrylates is purely a laboratory method, and

that it has not proved practicable on a larger scale.

Patent Publication JP 91 065340 describes a route to the

cyanohydrins of pyruvic acid and its esters which can be used as

intermediates for the preparation of 2—cyanoacrylate esters.

10

15

20

25

WO 95/26371

PCT/IE94/000 18

Patent Publication JP 91 075538 describes l—acetoxy-l-

cyanopropionic acid esters which can be converted into 2—cyanoacrylate

esters by thermal elimination of a molecule of acetic acid.

As mentioned supra, some of the physical properties of alkyl 2-

cyanoacrylate monomers can be regulated by the preparation of

monomers wherein the chemical structure of the ester moiety has been

modified.

Modification of the ester moiety has been used as a means of

controlling the surface-active properties, hydrophobicities, and

solubilities of cyanoacrylate esters (Leonard, F., Collins, J .A. and

Porter, H.J., (1966), J. Appl. Polym. Sci., Vol. 10, No. 11, 1617-

1623).

Long-chain 2—cyanoacrylate esters have been used for the

formation of Langmuir-Blodgett films (Matveeva, N.K., Pasekov, V.F.

and Save1'eva, L.V., (1991), Mikroelectronika (Akad. Nauk S.S.S.R.),

Vol. 20, No. 5, 501-503).

The solubility of cyanoacrylate esters in aqueous media is a

function of the esterifying radical. A decrease in solubility is achieved

by lengthening the alkyl chain.

Some control over the properties of alkyl 2-cyanoacrylates can

thus be achieved by varying the nature of the esterifying group.

However, these changes may lead to polymers which do not have

desirable characteristics. Thus, for example, use of butyl 2-

cyanoacrylate in an adhesive composition instead of methyl 2-

cyanoacrylate may lead to a more manageable rate of polymerisation

but will cause a significant decrease in the strength of the bond which is

formed.

It will be appreciated, therefore, that control of the properties of

a 2—cyanoacrylate monomer by variation of the nature of the

10

15

20

25

30

WO 95/26371

PCT/IE94/00018

A esterifying group without at the same time influencing the properties of -

the derived polymer is not possible at present.

Accordingly, for the above reasons, a method for the

modification of the physical and chemical properties of conventional

and other alkyl 2-cyanoacrylate monomers which does not affect the

properties of the polymers obtained therefrom is highly desirable.

The synthesis of ethyl 3-methoxy-2-cyanopropionate via reaction

of the sodium salt of ethyl cyanoacetate with chloromethyl methyl ether

has been described (Foldi, Z., v. Fodor, G., Demjen, I., Szekeres, H.

and Halmos, I, Berichte, 1942, Vol.75, No. 7, 755-763). The same

ethyl 3—methoxy—2-cyanopropionate was prepared by an almost

identical method in U.S. Patent No. 2,467,926 but was not isolated or

characterised. No other 3-alkoxy-2-cyanopropionic acid derivatives

have been reported, and this is not surprising since the chloromethyl

alkyl ethers required for their synthesis as described supra are usually

hazardous and unpleasant materials.

Some products resulting from the addition of nucleophiles to the

carbon—carbon double bondof 2—cyanoacry1ates have been described.

Organosilanes have been added to 2—cyanoacrylic acid and esters

thereof with formation of the corresponding saturated products

(Kolomnikova, G.D., Prihodchenko, Yu. D. and Gololobov, Yu. G.,

Izv. R. Akad. Nauk, Ser. Khim., 1992, No. 7, 1655-1657).

Thiols and thioacetic acid can be added to ethyl 2-cyanoacrylate

to yield ethyl 2-cyano-3-thioalkylpropionates and ethyl 2-cyano-3-

acetylthiopropionatc, respectively (Kandror, I.I., Bragina, 1.0.,

Galkina, M.A. and Gololobov, Yu. G., Izv. Akad. Naul S.S.S.R., Ser.

Khim., 1990, No. 12, 2798-2801: ibid., 15th International Symposium

on the organic Chemistry of Sulfur, Caen, France, 1992).

Thiourea has been added to ethyl 2-cyanoacrylate in the presence

of trifluoroacetic acid to give the corresponding saturated

10

15

20

25

W0 95/26371

PCT/IE94/00018

. ‘S-alkylthiouronium trifluoroacetate (Kolorrmikova, Yu.-D., Krilova,

T.O., Chernoglasova, I.V., Petrovsky, P.V. and Gololobov, Yu. G.,

Izv. Russ. Akad. Nauk, Ser. Khim., (1993), No. 7, 1245).

Dialkyl and diaryl phosphites have been added to 2-cyanoacrylic

acid and its ethyl ester to give dialkyl and diaryl phosphonates

(Kolomnikova, G.D., Prihodchenko, Yu. D., Petrovsky, P.V. and

Gololobov, Yu. G., Izv. R. Akad. Nauk, Ser. Khim., 1992, No. 8,

1913).

Triethyl phosphite has been added to 2—cyanoacrylic acid to yield

the derived 3-(diethylphosphono)propionic acid (Kandror, 1.1.,

Lavrykhin, B.D., Bragina, I.O., Galkina, M.A. and Gololobov, Yu. G.,

J. Obsch. Khim., (1990), Vol. 6, No. 9, 2160-2168), and to ethyl 2-

cyanoacrylate to give ethyl 2-cyano-3-(diethylphosphono)propionate

(Kandror, I.I., er al. (1990) supra).

Diethyl chlorophosphite and chlorodiphenylphosphine react with

ethyl 2-cyanoacrylate in the presence of trifluoroacetic acid to give,

respectively, ethyl 2-cyano-3-(diethylphosphono)propionate and ethyl

2-cyano—3-(diphenylphosphinoxy)propionate (Kolomnikova, Yu. D. et

al. (1993) supra). Catechyl chlorophosphite reacts similarly with ethyl

2-cyanoacrylate to give the derived catechylphosphonate derivative

(Kolomnikova, Yu. D. et al. (1993) supra).

Triphenylphosphine reacts with ethyl 2-cyanoacrylate under

trifluoroacetic acid catalysis to give ethyl 2-cyano-3-

(triphenylphosphonium)propionate trifluoroacetate (Kolomnikova, Yu.

D. et al. (1993) supra).

Phosphorus-sulfenyl chlorides have been added to 2-

cyanoacrylates with formation of the corresponding thiophosphonates

(Kolomnikova, G.D., Krilova, T.O. and Gololobov, Yu. G., J. Obsch.

Khim., 1993, Vol. 63, No. 3, 716).

10

15

20

25

WO 95/26371

PCT/IE94/000 18

Carbon nucleophiles derived from active methylene compounds- V

such as methyl nitroacetate, diethyl malonate and ethyl cyanoacetate

have been reacted with ethyl 2-cyanoacrylate to give the expected

Michael adducts (Kandror, l.I., Bragina, 1.0., Galkina, M.A.,~Be1okon,

Yu. N., Lavrykhin, B.D. and Gololobov, Yu. N., Izv. Russ. Akad.

Nauk, Ser. Khim., (1992) No. 10, 2449-2453).

None of the compounds mentioned supra have been used for the

reversible protection of the carbon—carbon double bond of 2-

cyanoacrylates, and conditions for effecting the reverse Michael

reactions needed for their conversion into monomeric 2-cyanoacrylates

or into poly(2—cyanoacrylates) have not been described.

Disclosure of Invention

' The invention provides in a first aspect a process for the

reversible coupling of a weak nucleophile to the carbon—carbon double

bond of 2-cyanoacrylic acid or an ester thereof, so as to reversibly

protect said bond, which comprises reacting 2-cyanoacrylic acid or an

ester thereof with said weak nucleophile in the presence of an inert

solvent under polymerisation inhibiting conditions and in the presence

of an acidic catalyst.

The weak nucleophile can be an alcohol or a phenol.

The term alcohol as used herein includes diols and polyols.

The weak nucleophilecan also be selected from:

i) a thiol, thiophenol, a thioamide, a thio or dithio acid or

other thionucleophile;

ii) a dialkyl or diarylphosphite, a dialkyl or

diarylthiophosphite, a phosphine, phosphorus sulfenyl

halide or other phosphorus nucleophile; and

10

15

20

WO 95/26371

PCT/IE94/00018

iii) a carbon acid

as hereinafter described.

This first aspect of the invention thus provides a method for the

reversible protection of the chemically reactive carbon-carbon double

bond of polymerisable alkyl or aryl 2—cyanoacry1ates whereby a weak

nucleophile added across the double bond can be eliminated under the

conditions of base—initiated anionic polymerisation to yield poly(alky1

or aryl 2—cyanoacry1ates) together with the relevant weak nucleophile.

The acidic catalyst is suitably a non-volatile acid such as an

aliphatic sulfonic acid or an aromatic sulfonic acid. Accordingly, the

non-volatile acid is suitably methane sulfonic acid or p-toluenesulfonic

acid.

Alternatively, the acid catalyst can be a carboxylic acid.

An essential feature of the acid catalyst is that it does not react

with the alcohol or phenol or other weak nucleophile being used.

Preferably, the process is carried out under conditions which

inhibit anionic polymerisation.

Further, preferably, the process is carried out in the presence of

a weak acid.

Suitably the weak acid is sulfur dioxide.

Preferably, when the weak acid is sulfur dioxide, gaseous sulfur

dioxide is bubbled into the reaction mixture as a continuous stream.

The anionic polymerisation inhibitor can be an aliphatic sulfonic

acid, an aromatic sulfonic acid or carbon dioxide.

10

15

20

25

W0 95/2637 1

PCT/IE94/000 18

Further, preferably, the process according to the invention is

carried out in the presence of a free radical polymerisation inhibitor.

Suitably the free radical polymerisation inhibitor is

benzoquinone, hydroquinone, methylhydroquinone or naphthoquinone.

Preferably the inert solvent is benzene, toluene, xylene, hexane

or a chlorinated hydrocarbon.

The process according to the invention is suitably carried out at a

temperature in the range 20—200°C, more especially in the range 80-

100°C.

When secondary alcohols or phenols are being reacted in

accordance with the invention, irrespective of whether 2—cyanoacrylic

acid or an ester thereof is used, preferably the reaction is carried out in

the presence of sulfur dioxide to optimize conditions, because of the

tendency of cyanoacrylate monomers to polymerise under the reaction

conditions.

When 2—cyanoacrylic acid is used as a starting compound in

accordance with the invention to prepare a 3—alkoxy-2-cyanopropionic

acid ester, the water produced is continually removed by azeotropic

distillation.

Preferably, the total volume of the reaction solvent is kept

constant.

Further, preferably, when an alcohol or phenol is used as the

weak nucleophile, said alcohol or phenol is added gradually to the

reaction mixture.

According to a second aspect of the invention there is provided a

process for the preparation of a compound of the general formula (I):

WO 95/26371

PCT/IE94/000 1 8

10

. CN I

/ < (1)

R10 C0218

wherein R1 is: i) C1 or higher saturated, optionally mono- or

10

and R2 is:

15

20

polysubstituted, linear or branched alkyl;

ii) C5 or higher saturated, optionally mono- or

polysubstituted cycloalkyl or poly(cycloalkyl);

iii) C3 or higher, optionally mono- or polysubstituted,

linear or branched alkenyl;

iv) C3 or higher, optionally mono- or polysubstituted,

linear or branched alkynyl; or

v) a phenyl or optionally mono- or polysubstituted

phenyl group,

i) a hydrogen atom;

ii) C1 or higher saturated, optionally mono- or

polysubstituted, linear or branched alkyl;

iii) C5 or higher saturated, optionally mono- or

polysubstituted cycloalkyl or poly(cycloalkyl);

iv) C3 or higher, optionally mono- or polysubstituted,

linear or branched alkenyl;

v) C3 or higher, optionally mono- or polysubstituted,

linear or branched alkynyl;

vi) a phenyl or optionally mono- or polysubstituted

phenyl group; or

10

15

W0 95/26371

PCT/IE94/000 18

ll

vii) a mono— or polysubstituted biphenyl, naphthyl or.

other cyclic or polycyclic aromatic or heteroaromatic

group.

which comprises reacting 2—cyanoacrylic acid or an ester thereof with

an alcohol or phenol in the presence of an inert solvent under

polymerisation inhibiting conditions and in the presence of an acidic

catalyst.

The following scheme depicts the reactions involved in the

process according to the second aspect of the invention -hereinabove

described:

(a) .= < + . 1 I < 2

COZRZ R O COZR

CN

CN \/

(b) =< + ROH —————>

COZH RO CO2H

CN CN 2 CN

(c) = < + R1QH —-—-> ("'1 L0}; f?‘

co2H R10 co2H RIO C0218

wherein R1 and R2 are as hereinabove defined.

In accordance with the second aspect of the invention, there is

produced 3—a1koxy- and 3—aryloxy—2-cyanopropionic acids and esters

thereof which may be employed as precursors to useful polymerisable

2—cyanoacrylic acid esters, said precursors having desirable chemical

and physical properties.

WO 95/26371 PCT/IE94/00018

12

Thus, the. invention ‘provides a compound of the general

formula (Ia):

CN

/ < . (Ia)

R10 CO2R2

wherein R1 is: i) a methyl group;

5 - ii) C2 or higher saturated, optionally mono- or

polysubstituted, linear or branched alkyl;

iii) C5 or higher saturated, optionally mono- or

polysubstituted cycloalkyl or po1y(cycloalkyl);

iv) C3 or higher, optionally mono- or polysubstituted,

10 linear or branched alkenyl;

v) C3 or higher, optionally mono- or polysubstituted,

linear or branched alkynyl; or

vi) a phenyl or optionally mono- or polysubstituted

phenyl group,

15 and R2 is: i) a hydrogen atom;

ii) C1, optionally mono-substituted, alkyl;

iii) C2 saturated alkyl except when R1 is methyl;

iv) C2 saturated, mono- or polysubstituted alkyl;

V) C3 or higher saturated, optionally mono- or

20 polysubstituted, linear or branched alkyl;

10

15

20

25

WO 95/26371

PCT/IE94/00018

1 3

vi) C5 or higher saturated, optionally mono—._o'r... .-

polysubstituted cycloalkyl or poly(cycloalkyl)§

vii) C3 or higher, optionally mono- or polysubstituted,

linear or branched alkenyl;

viii) C3 or higher, optionally mono- or polysubstituted,

linear or branched alkynyl;

ix) a phenyl or optionally mono- or polysubstituted

phenyl group; or

X) a mono- or polysubstituted biphenyl, naphthyl or

other cyclic or polycyclic aromatic or heteroaromatic

group.

Functional groups which are representative of those which would

normally be used to substitute an R1 or R2 group as hereinabove

defined include but are not limited to halogen, carboxyl, nitrile,

acylamino and heteroelement-containing groups.

In accordance with a third aspect of the invention the weak

nucleophile can be a sulfhydryl group as found, for example, in a thiol,

a thio acid or a dithio acid. This provides a further method for the

reversible protection of the chemically reactive carbon-carbon double

bond of polymerisable alkyl or aryl 2-cyanoacrylates whereby a thio

compound added across the double bond can be eliminated under the

conditions of base—catalysed anionic polymerisation to yield po1y(alkyl

or aryl 2-cyanoacrylates) together with the relevant thio compound.

The process according to the third aspect of the invention can be

used for the preparation of a compound of the general formula (II) and

its subsequent conversion into a 2-cyanoacrylate polymer

WO 95/26371

wherein R3 is: i)

10

and R4 is:

15

20

PCT/IE94/00018

14

CN

/ < (11)

R38 CO;,_R4

C1 or higher saturated, optionally mono- or

polysubstituted, linear or branched alkyl or cycloalkyl;

ii) C3 or higher, optionally mono- or polysubstituted

linear or branched alkenyl or alkynyl;

iii) a phenyl or optionally mono- or polysubstituted

phenyl group;

iv) a mono- or polysubstituted biphenyl, naphthyl or

other cyclic or polycyclic aromatic or heteroaromatic

group;

y) an acyl or thioacyl group;

vi) a dialkyl- or diarylphosphonyl group; or

vii) a dialkyl- or diarylthiophosphonyl group,

i) a hydrogen atom;

ii) C1 or higher saturated, optionally mono- or

polysubstituted, linear or branched alkyl;

iii) C5 or higher saturated, optionally mono- or

polysubstituted cycloalkyl or poly(cycloalkyl);

iv) C3 or higher, optionally mono- or polysubstituted

linear or branched alkenyl;

WO 95/26371 PCT/IE94/00018

15

v) C3 or higher, optionally ‘mono— or polysubstituted

linear or branched alkynyl;

vi) a phenyl or optionally mono— or polysubstituted

' phenyl group; or

5 I vii) a mono— or polysubstituted biphenyl, naphthyl or

other cyclic or polycyclic aromatic or heteroaromatic

group,

which comprises reacting 2-cyanoacrylic acid or an ester thereof with a

sulfhydryl compound in the presence of an inert solvent under

10 polymerisation inhibiting conditions and in the presence of an acidic

catalyst under the conditions hereinabove defined followed by

elimination of the sulfhydryl addend to give a 2—cyanoacrylate

monomer which then polymerises.

Alternatively, the sulfliydryl compound itself can act as the acidic

l5 catalyst.

The following scheme depicts the reactions involved in the

process according to the third aspect of the invention:

/CN CN

= \ 4 + R3SH ——> H 2»

CO2R R35 CO2R4

CN CN

m’ n

COZR4 CO2R4

20 wherein R3 and R4 are as hereinabove defined.

W0 95/26371 PCT/IE94/00018

16

V In this third aspect of the invention there is provided . ~. .

3-thioalkyl—, 3-thioa1yl—, 3-thioacyl—, 3-dithioacyl—, 3-thiophosphoryl-

and 3-dithiophosphoryl—2-cyanopropionic acids and esters thereof

which may be employed as precursors to useful polymerisable 2-

5 cyanoacrylic acid esters.

Thus the invention provides a compound of the general formula

(Ila):

CN

/ < (Ila)

R38 CO2R4

wherein R3 is: i) C1 optionally monosubstituted alkyl wherein the

10 substituent is not a free carboxyl group whenever R4 is

an ethyl group;

ii) C2 optionally mono- or polysubstituted saturated

alkyl wherein the or each substituent is not a primary

amino group or a hydroxyl group whenever R4 is an

15 ethyl group, or wherein the substituents do not include

a primary amino group and a free carboxy group

attached to the same carbon atom whenever R4 is an

ethyl group, or wherein the [3—substituent is not another

sulfur atom bearing a 2'-carboxy-2'-cyanoethyl

20 function as the free carboxylic acid or as its ethyl or

allyl ester whenever the substituent R4 is, respectively,

a hydrogen atom, an ethyl group or an allyl group;

iii) C3 linear or branched, optionally mono- or

polysubstituted saturated alkyl;

25 iv) C4 linear or branched, optionally mono- or

polysubstituted saturated alkyl wherein the mono-

W0 95/26371

10

15

20

and including

PCT/IE94/00018

17

substituent is not a hydrogen atom whenever R4 is an

' ethyl group;

v) C5 or higher linear or branched, optionally mono-

or polysubstituted saturated alkyl or cycloalkyl;

vi) C3 or higher, optionally mono- or polysubstituted

linear or branched alkenyl;

vii) C3 or higher, optionally mono- or polysubstituted

linear or branched alkynyl,

viii) an unsubstituted phenyl group whenever R4 is not

an ethyl group;

ix) a mono- or polysubstituted phenyl group;

x) a mono- or polysubstituted biphenyl, naphthyl or

other polycyclic aromatic or heteroaromatic group,

xi) an acyl group other than acetyl except when R4 is

other than an ethyl group when R3 may then be any

acyl group;

xii) a thioacyl group;

xiii) a dialkyl or diaryl phosphonyl group excluding

diethyl phosphonyl whenever R4 is an ethyl group;

xiv) a dialkyl or diaryl thiophosphonyl group

excluding diethyl thiophosphonyl when R4 is an ethyl

group,

sulfoxides and sulfones derived from any of i) - x)

above,

WO 95/26371

and R4 is:

10

PCT/IE94/00018

18

, i) _ a hydrogen. atom;

ii) C1 or higher, linear or branched optionally mono-

or polysubstituted saturated alkyl;

iii) C5 or higher saturated, optionally mono- or

polysubstituted cycloalkyl or poly(cyc1oalkyl);

iv) C3 or higher, optionally mono- or polysubstituted

linear or branched alkenyl;

V) C3 or higher, optionally mono- or polysubstituted

linear or branched alkynyl;

vi) a phenyl or optionally mono- or polysubstituted

phenyl group; or

vii) a mono- or polysubstituted biphenyl, naphthyl or

other cyclic or polycyclic aromatic or heteroaromatic

group.

15 In accordance with a fourth aspect of the invention the weak

nucleophile can be a dialkyl or diaryl phosphite, a dialkyl or diaryl

thiophosphite, a phosphine or other phosphorus nucleophile. This

aspect of the invention provides another method for the reversible

protection of the chemically reactive carbon-carbon double bond of

20 polymerisable alkyl or aryl 2-cyanoacrylates as outlined supra.

The process according to the fourth aspect invention can be used

for the preparation of a compound of the general formula (III) and its

subsequent conversion into a 2—cyanoacrylate polymer:

W0 95/26371 PCT/IE94/00018

19

_ 5

Ix’ RO\ / < (111)

6

L P\ C0212

\\_R5O/

wherein R5 is: i) C1 or higher linear or branched saturated alkyl;

ii) C5 or higher cycloalkyl; or

iii) a phenyl or optionally mono- or polysubstituted

5 phenyl group,

and R6 is: i) a hydrogen atom;

ii) C1 or higher saturated, optionally mono- or

polysubstituted, linear or branched alkyl;

iii) C5 or higher saturated, optionally mono- or

10 polysubstituted cycloalkyl or poly(cycloalkyl);

iv) C3 or higher, optionally mono- or polysubstituted

linear or branched alkenyl;

V) C3 or higher, optionally mono- or polysubstituted

linear or branched alkynyl;

15 vi) a phenyl or optionally mono- or polysubstituted

phenyl group; or

vii) a mono-or polysubstituted biphenyl, naphthyl or

other cyclic or polycyclic aromatic or heteroaromatic

g1'O11p,

20 and X is: i) an oxygen atom; or

W0 95/2637]

10

PCT/IE94/000 18

20

ii) V a sulfur atom;

which comprises reacting 2-cyanoacrylic acid or an ester thereof with a

phosphite or thiophosphite in the presence of an inert solvent under

polymerisation inhibiting conditions and in the presence of an acidic

catalyst under the conditions outlined .hereinabove defined followed by

elimination of the addend to give a 2-cyanoacrylate monomer which

then polymerises.

Alternatively, the phosphite or thiophosphite itself can act as the

acidic catalyst.

The following scheme depicts the reactions involved in the

process according to this aspect of the invention:

CN

0 O

H /CN 5 ll

(R50) pHA+ -= ——-> (RO)2P 6—->

2

CN CN

:> n

CN

S S

n ,CN 5 II

(R50) PH+ = 6 -—>(R0)2P CORs-*

COZR 2

CN CN

—-> n

W0 95/26371

10

15

20

PCT/IE94/00018

21

-wherein R.5 and R5 are as hereinabove defined. A

In this fourth aspect of the invention there is provided 2-cyano-

3-(dialkylphosphono)-, 2-cyano-3-(diarylphosphono)-, 2-cyano-3-

(dia1ky1thiophosphono)- and 2-cyano-3-(diarylthiophosphono)-

propionic acids and esters thereof which may be employed as

precursors to useful polymerisable 2-cyanoacrylic acid esters.

Thus the invention provides a compound of the general formula

(IIIa):

CN

/‘R50 / < (IIIa)

, \ 6

I‘ P\ COZR

\\\ _ / \ X

wherein R5 is: ' i) a methyl group;

ii) an ethyl group except when R6 is an ethyl group or

a hydrogen atom;

iii), a propyl group or substituted propyl group;

iv) an isopropyl group except when R6 is an ethyl

group or a hydrogen atom and when X is an oxygen

atom;

V) C4 or higher saturated, optionally mono- or

polysubstituted linear or branched alkyl;

vi) a cyclohexyl group;

vii) an unsubstituted phenyl group except when R6 is

an ethyl group or a hydrogen atom and when X is an

oxygen atom;

wo 95/25371

5 i and R6 is:'

10

15

and X is:

20

PCT/IE94/000 18

22

viii) a mono- or polysubstituted phenyl group; or

ix) a phenyl group attached simultaneously and ortho

to both oxygen atoms except when R6 is an ethyl group

and when X is an oxygen atom,

i) a hydrogen atom;

ii) C1 or higher saturated, optionally mono- or

polysubstituted, linear or branched alkyl;

iii) C5 or higher saturated, optionally mono- or

polysubstituted cycloalkyl or poly(cycloalkyl);

iv) C3 or higher, optionally mono- or polysubstituted,

linear or branched alkenyl;

v) C3 or higher, optionally mono- or polysubstituted,

linear or branched alkynyl;

vi) a phenyl or optionally mono- or polysubstituted

phenyl group; or

vii) a mono- or polysubstituted biphenyl, naphthyl or

other cyclic or polycyclic aromatic or heteroaromatic

gl'O11p,

i) an oxygen atom; or

ii) a sulfur atom.

According to a fifth aspect of the invention there is provided a

process for the preparation of a compound of the general formula (IV)

and its subsequent conversion into a 2-cyanoacrylate polymer:

WO 95/26371 PCT/IE94/00018

23

CN

C ,——< (IV)

Y'} R73P+

co2R8

wherein R7 is: i) C4 or higher saturated alkyl or cycloalkyl;

ii) phenyl except when R8 is an ethyl group; or

iii) a mono- or polysubstituted phenyl group,

5 and R3 is: i) a hydrogen atom;

ii) C1 or higher saturated, optionally mono- or

polysubstituted, linear or branched alkyl;

iii) C5 or higher saturated, optionally mono- or

polysubstituted cycloalkyl or poly(cyc1oalky1);

10 iv) C3 or higher, optionally mono- or polysubstituted,

linear or branched alkenyl;

v) C3 or higher, optionally mono- or polysubstituted,

linear or branched alkynyl;

vi) a phenyl or optionally mono- or polysubstituted

15 phenyl group; or

vii) a mono- or polysubstituted biphenyl, naphthyl or

other cyclic or polycyclic aromatic or heteroaromatic

group,

and Y is: a negatively charged ion,

20 which comprises reacting 2—cyanoacrylic acid or an ester thereof with a

phosphine in the presence of an inert solvent under polymerisation

10

15

WO 95/26371

PCT/IE94/000 18

24

inhibiting conditions and in the presence of anacidic catalyst undertheg "

conditions hereinabove defined followed by elimination of the

phosphine to give a 2-cyanoacrylate monomer which then polymerises.

Suitable negatively charged ions as values for Y include but are

not limited to a chloride or other halide ion, a trifluoroacetate ion or a

perchlorate ion.

Preferably the acidic catalyst has as its counterion the desired

negatively charged ion Y of formula (IV).

The following scheme depicts the reaction involved in the

process according to the fifth aspect of the invention:

CN

7 /CN HY Y" R71-3l-/ I - —>

C0212

CN CN

TD» n

_ 8

wherein R7, R3 and Y are as hereinabove defined.

In this fifth aspect of the invention there are provided salts of 2-

cyano—3-(trialkylphosphonium)- and 2-cyano—3—(triarylphosphonium)

propionic acid and esters thereof which may be employed as precursors

to useful polymerisable 2—cyanoacrylic acid esters.

Thus, the invention provides a compound of the general formula

(IVa):

W0 95/26371

wherein R7 is: i)

5 and R3 is:

10

15

and Yis:

PCT/IE94/0001 8

25

CN

Y '} R73P+/ : ( Va)

COZR8

C4 or higher saturated alkyl or cycloalkyl;

ii) phenyl except when R8 is an ethyl group; or

iii) a mono- or polysubstituted phenyl group,

i) a hydrogen atom;

ii) C1 or higher saturated, optionally mono- or

polysubstituted, linear or branched alkyl;

iii) C5 or higher saturated, optionally mono- or

polysubstituted cycloalkyl or poly(cycloalky1);

iv) C3 or higher, optionally mono- or polysubstituted,

linear or branched alkenyl;

V) C3 or higher, optionally mono- or polysubstituted,

linear or branched alkynyl;

vi) a phenyl or optionally mono- or polysubstituted

phenyl group; or

vii) a mono- or polysubstituted biphenyl, naphthyl or

other cyclic or polycyclic aromatic or heteroaromatic

group,

a negatively charged ion.

10

15

20

WO 95/26371

PCT/IE94/00018

26

Suitable negatively charged ions as values for Y include but -are

"not limited to a chloride or other halide ion, a trifluoroacetate ion or a

perchlorate ion.

In a sixth aspect of the invention the weak nucleophile can be a

carbon acid. This provides a further ‘method for the reversible

protection of the carbon-carbon double bond of polymerisable 2-

cyanoacrylic acid esters.

The process according to the sixth aspect of the invention can be

used for the preparation of a compound of the general formula (V) and

its subsequent conversion into a 2-cyanoacrylate polymer:

CN

(V)

9 11

R R10

wherein R9 is: i) ahydrogen-atom;

ii) an electron-withdrawing organic functional group

including but not limited to groups such as nitro,

carboalkoxy, cyano, acyl, sulfonyl and phosphonyl

groups;

and R10 is: an electron-withdrawing organic functional group

including but not limited to groups such as nitro,

carboalkoxy cyano, acyl, sulfonyl and phosphonyl

groups,

and R11 is: i) a hydrogen atom;

ii) C1 or higher saturated, optionally mono- or

polysubstituted, linear or branched alkyl;

W0 95/26371 PCT/IE94/00018

27

iii) C5» or higher saturated, optionally mono- or .

polysubstituted cycloalkyl or poly(cycloalkyl);

iv) C3 or higher, optionally mono- or polysubstituted,

linear or branched alkenyl;

5 i v) C3 or higher, optionally mono- or polysubstituted,

linear or branched alkynyl;

vi) a phenyl or optionally mono- or polysubstituted

phenyl group; or

vii) a mono- or polysubstituted biphenyl, naphthyl or

10 " other cyclic or polycyclic aromatic or heteroaromatic

gI‘O11p,

_ which comprises reacting 2-cyanoacrylic acid or an ester thereof with a

singly or doubly activated carbon acid in an inert solvent under

polymerisation-inhibiting conditions and in the presence of an acidic

15 catalyst under the conditions hereinabove defined followed by

elimination of the addend to give a 2—cyanoacrylate monomer which

then polymerises.

The following scheme depicts the reaction involved in the

process according to the sixth aspect of the invention:

R9 CN

\ ,cN

CH2 + =\ 11

R10 / co2R“ R9 C02R

20 R10

wherein R9, R10 and R11 are as hereinabove defined.

Thus the invention provides compounds of the general formula

(Va):

WO 95/26371

PCT/IE94/00018

28

(Va)

R9 co2R“

R10

wherein R9 is: i) a hydrogen atom except when R10 is a nitro group

5

10

15 R10is:

and R11is:

20

and R11 is an ethyl group;

ii) a carboxymethyl group except when R10 is a nitro

group and R11 is an ethyl group;

iii) a carboxyethyl group except when R10 is a

carboxyethyl group or an acetyl group or a cyano

group when R11 is an ethyl group;

iv) a carboxyalkyl group wherein the alkyl radical is

C3 or higher saturated, linear or branched; '

v) an acyl or aroyl group;

vi) any other compatible electron-withdrawing

organic functional group including but not limited to

nitro, cyano, sulfonyl and phosphonyl groups,

any compatible electron-withdrawing organic

functional group including but not limited to groups

such as nitro, carboalkoxy, cyano, acyl, aroyl, sulfonyl

and phosphonyl groups,

i) a hydrogen atom;

ii) C1 or higher saturated, optionally mono- or

polysubstituted, linear or branched alkyl;

10

15

20

25

W0 95/26371

PCT/IE94/00018

29

iii) C5 or higher saturated, optionally mono— or

polysubstituted cycloalkyl or poly(cycloalkyl);

iv) C3 or higher, optionally mono— or polysubstituted,

linear or branched alkenyl;

V) C3 or higher, optionally mono— or polysubstituted,

linear or branched alkynyl;

vi) a phenyl or optionally mono— or polysubstituted

phenyl group; or

vii) a mono— or polysubstituted biphenyl, naphthyl or

other cyclic or polycyclic aromatic or heteroaromatic

group.

The processes according to the invention can be carried out in a

simple, rapid, facile one—step manner with attendant advantages. Thus,

the process according to the invention is a "one-step" process in

contrast with the prior art methods described supra with their inherent

limitations.

The reversible protection afforded by the invention can be used

to protect the carbon—carbon double bond of a wide range of 2-

cyanoacrylate monomers including substituted or unsubstituted long-

chain alkyl cyanoacrylates and multi-functional cyanoacrylates

including bis—cyanoacrylates.

The invention also provides a composition comprising a

compound of any of the formulae (1), (II), (III), (IV) or (V) as

hereinbefore defined. Such compositions can include excipients such as

a thinner.

The compounds of the formulae (1), (II), (III), (IV) and (V)

hereinbefore defined can be used in adhesive compositions.

5

10

15

20

25

WO 95/26371

PC T/IE94/000 18

30

The invention also provides poly(cyanoacrylate) materials

formed from a compound of any one of the formulae (1), (11), (III),

(IV) and (V) hereinbefore defined.

A further use of the compounds of any one of the formulae (1),

(H), (III), (IV) and (V) hereinbefore defined is in the formation of

poly(cyanoacrylate) films. Such films include single or multi-layer

Langmuir-Blodgett films.

The compounds of the formulae (1), (II), (III), (IV) and (V)

hereinbefore defined can also be used in the preparation of

poly(cyanoacrylate) nanocapsules. The compounds of the formula (I)

are especially suitable for the preparation of such poly(cyanoacrylate)

nanocapsules.

Poly(cyanoacrylate) nanocapsules prepared in accordance with

the invention suitably contain an active agent such as a drug.

Compounds of any one of the general formulae (1), (II), (III),

(IV) and (V) wherein the esterifying group R2, R4, R5, R8 or R11, as

appropriate is a terminal alkyne could be precursors to useful 2-

cyanoacrylate monomers and polymers which could be further

modified by cross—linking via the well-known Glaser oxidative coupling

reaction.

Compounds of any one of the general formulae (1), (11), (HI),

(IV) and (V) wherein the esterifying group R2, R4, R6, R3 or R11, as

appropriate incorporates di- or poly-yne functionality may be valuable

for the formation of thin films having useful non—1inear optical

properties.

The compounds according to the invention are expected to be

capable of broad application, particularly where thin-film technology is

involved and especially where Langmuir-Blodgett type films are

desirable.

10

15

20

25

30

W0 95/26371

PCT/IE94/00018

31

Poly(alkyl 2—cyanoacrylate) films are used as semiconductor , .

coating materials wherein they are applied to act as rnicrolithographic

photoresists due to their sensitivity to electron beams and to X-rays as

described, for example, in U.S. Patent No. 4,279,984, and in Matveeva,

N.K., (1990), Biol. Membr., Vol. 7, No. 11, 1200-1204. Such films

are usually deposited by application of a solution of an alkyl 2-

cyanoacrylate polymer, or its monomer followed by its subsequent

polymerisation. Even solutions of cyanoacrylate polymers tend to be

unstable over time as indicated in Patent Publications JP 9262588 and

JP 0462558, and vapour-deposition techniques have been devised in an

attempt to overcome this disadvantage (Woods, J ., Guthrie, J ., Rooney,

J ., Kelly, L., Doyle, A. and Noonan, E., (1989), Polymer, Vol. 30, No.

6, 1091-1098). This requires special apparatus, however.

The compounds according to the invention offer an alternative

method of depositing such films since they are stable as solutions in

inert solvents and can be converted into poly(alkyl 2—cyanoacrylates)

under anionic conditions. Furthermore, when films laid down in this

way are Langmuir-Blodgett or other very thin films then the necessary

period of exposure to electron beams or to X-rays should be

beneficially reduced. Also such thin films can be expected to greatly

modify the capacitance effect and the relative permittivity effect

thereby improving dynamic memory capability of the microchip.

Accordingly, it is expected that these thin films will find application in

the manufacture of low power microchips.

Another benefit resulting from the application of thinner films is

-increased transconductance with accompanying improved efficiency in

terms of speed and memory capacity of thus formed devices. Reduced

voltages employing such devices result in reduced power dissipation.

Additionally, tighter control over threshold voltage means that such

devices may find use in lower power applications with sub-threshold

operation in VLSI (very large-scale integration) required, for example,

in hearing aids and implants.

10

15

20

25

30

W0 95/26371

PCT/IE94/000 18

32

Thinner film thickness also means improved resolution and

reduced feature sizes on microchips, such as, for example, the

important interconnection feature between two adjacent "gates"

resulting in improved overall performance.

When the alkyl ester part of the alkoxycyanopropionic ester

molecule contains a metal such as iron (for example, in a ferrocenyl

function) and the alkyl of the alkoxy part of the molecule is a long-

chain alkyl group, the resulting ordered Langmuir-Blodgett poly(alkyl

cyanoacrylate) film laid down on a substrate such as a silicon chip may

then be etched with a laser. Such treated areas of film would give rise

to low-coke iron or iron oxide indented regions depending on whether

the ablation is carried out under an inert atmosphere such as nitrogen

or in the oxidising atmosphere of the air, respectively. Also, when

sulfur is additionally contained in the alkyl ester radical of such a long-

chain alkoxycyanopropionic acid ester, a well-ordered Langmuir-

Blodgett poly(alkyl cyanoacrylate) layer would be expected. to give

semiconductor FeS regions when etched with a laser.

More easily programmable EPROMS may also result from

application of this technology.

The prospect of achieving ultra-thin films as described herein

opens up a wide range of possible applications in the manufacture of

future generations of integrated circuits. Many of the key factors

which must be present for the specifications of future semiconductor

devices as predicted in the literature (see for example Chenming, Hu

(1993) Proceedings of the IEEC, Vol. 81, No. 5, p. 682-689), such as,

for example, decreased feature size to less than O.lum, improved

feature definition, higher speeds, greater density, increased reliability

and thinner oxides, are facilitated by the present invention.

Thin, tightly controlled, low impurity films offer many advances

in semiconductor device fabrication. Depolymerisation by means of

laser (or other high-energy beam) etching has potential applications for

accurately controlled volumetric geometries. Areas of surface can be

10

15

20

25

30

WO 95/26371

PCT/IE94/00018

33

selectively insulated. The engineering of regions, interconnects,

' channels and layers could be accomplished largely through a chemical

route using available production equipment. By laying multiple layers

of poly(cyanoacrylate) film where the alkyl ester contains a metal, a

semiconductor or an oxide (or where the oxide is produced by carrying

out ablation in an oxidising atmosphere), laser etching can produce the

features hereinabove mentioned. Furthermore, device trimming,

essential in analogue integrated circuits, is also more readily achievable

to improved accuracies.

The application of the present invention to semiconductor

technology may provide digital devices with very low gate delays

operating at lower voltages (l.5V), thereby offering greater circuit

speeds while maintaining low chip power levels. The reduced feature

size, junction depth, and effective channel length could offer SRAM

densities up to 4G. While operating voltage can be reduced, as

mentioned, the technology could offer tighter control over threshold

voltages by ensuring very low impurity levels.

Linear devices could benefit from the improved control in

manufacturing and region/feature definition, low power and higher

levels of integration. MOS and bipolar technologies are equally

amenable to the processes.

Treatment of thin poly(cyanoacrylate) films with laser or high

energy plasma gives coke-free clean holes.

Solvent removable (linear poly(cyanoacrylate) films may be laid

down on silicon wafers from the monofunctional 2—cyanopropionate

derivatives described herein and then masked. Subsequent treatment

with laser followed by treatment with hydrofluoric acid (HF) and

subsequent removal of remaining polymer using common organic

solvents such as benzene, chloroform or acetone would be expected to

give clean, well defined holes on the silicon surface.

10

15

20

25

30

WO 95/26371

PCT/IE94/00018

34

Cross-linked and insoluble poly(cyanoacrylate) films may also be _ .~ . ‘

laid down on a silicon surface from multifunctional 2—cyanopropionate

derivatives described herein and again be masked and treated in the

manner hereinabove described with laser followed by HF. A further

poly(cyanoacrylate) layer could then be deposited on the stable solvent-

resistant cross-linked poly(cyanoacrylate) film from an appropriate 2-

cyanopropionate derivative. When the ester portion of this derivative

contains a metal such as iron, for example, in a ferrocenyl radical,

ablation of exposed regions of resulting poly(cyanoacrylate) film in an

inert atmosphere would give a layer of metal - in this case iron - on the

surface. Such a layer would, of course, be conducting in nature.

A further layer of silicon dioxide could be laid down, where

required, by initial deposition of a poly(cyanoacrylate) film from a

silicon-containing (ester portion of molecule) 2—cyanopropionate

derivative followed by treatment with laser or high energy plasma in

an oxygen—rich atmosphere. Such a layer could also be directly laid

down on the silicon surface.

In this way, silicon chips containing insulating, conducting and

semiconductor multilayers may be fabricated.

Also phosphorus—containing poly(cyanoacrylate) films could be

laid down from equivalent cyanopropionate derivatives directly onto

silicon. Ablation of unmasked regions of film with laser in an inert

atmosphere should give phosphorus—doped silicon semi-conductor

region used in pnp transmission.

Sulfur-containing cyanopropionate derivatives would in the same

way as above give sulfur doped semiconductor regions on the silicon

surface following treatment of polymer with laser. Such sulfur-doped

areas would be expected to improve adhesion of subsequently formed

metal films from ablation of metal-containing poly(cyanoacrylate)

prepared from a metal-containing (in the ester portion of the molecule)

2—cyanopropionate derivative.

10

15

20

25

30

WO 95/26371

PCT/IE94/0001 8

35

Diacety_lene functional 2.-cyanopropionate derivatives (ester . _

portion of molecule) would give poly(cyanoacrylate) films which could

be further modified. For example, some regions could be exposed to

high energy ultra-violet light to give, by a free-radical polymerisation

process, serni-conducting poly(acety1ene) regions - masked or

remaining polymer 1-ayer would be an insulating region. Doping of the

semi—conducting poly(acetylene) region by, for example, iodine would

give conductive zones. Hence three types of region (insulating,

semiconducting, conducting) could be designed into the same

poly(cyanoacrylate) monolayer. Such techniques would be useful for

the fabrication of molecular electronic devices for super-thin pnp

transmission with dramatic component size reduction (down to 10-50

A).

A wide variety of poly(cyanoacrylate) films could be prepared

from the cyanopropionate derivatives according to the invention for

use in photosensitive, non—linear optical and liquid crystal applications.

Non-linear optical 2—cyanopropionates would possess asymmetric

radicals in the alkyl portion of the molecule. In the same way liquid

crystal 2—cyanopropionates would possess cholesterol or

methoxy/cyanobiphenyl functionality in the alkyl portion of the

molecule.

Patent Publication EP 146,505 describes the use of thin (10 um)

poly(alkyl 2-cyanoacrylate) films in a process for image formation.

The ability to lay down Langmuir—Blodgett, multi-layer or other very

thin films utilising compounds of the invention which are precursors to

alkyl 2-cyanoacrylate esters and thus to poly(alkyl 2-cyanoacrylates)

should permit further useful developments in this area.

Conversion of the monomers produced in accordance with the

invention into polymer may be carried out by prior application of a V

base such as an amine or tetraalkylammonium hydroxide to the surface

to be coated or application of base from above as vapour, for example

once a film of the compound has been laid down on the untreated

surface. In addition the compounds prepared in accordance with the

10

15

20

25

30

35

W0 95/26371

PCT/IE94/00018

36

_ invention could be vapour depositedfollowing the method of Woods J ., »

' et al. supra. Priming of surfaces to be bonded by a suitable base means

that the compounds in accordance with the invention may be used as

adhesives as indicated above. The cyanoacrylate monomer produced in

situ between the two surfaces would be expected to polymerise rapidly

in the presence of base forming a solid polymer and hence an adhesive

bond. The presence’ of an alcohol or phenol co-product may not be

disadvantageous since in fact alcohols have been used as physical

additives with cyanoacrylate adhesives to impart porous bonding ability

to same as described in Patent Publications JP 55012166 and JP

88039627.

Long chain or fluorine containing alkoxycyanopropionic esters

would be expected to wet previously difficult to bond surfaces such as

polyolefins or poly(tetrafluoroethy1ene) (PTFE) and provide adhesive

bonds between previously appropriately base-primed substrates.

However, even peeled poly(cyanoacrylate) films have found use in a

transfer printing process in Patent Publication JP 8251487. Similarly

long chain alkoxcyanopropionic esters instead of aligning themselves

onto surfaces as Langmuir—Blodgett films may form micelles in

aqueous solution and be used as a means to encapsulate active agents

such as drugs upon subsequent polymerisation by addition of a base to

the medium to form nanocapsules. This technique of rnicelle

polymerisation has previously been employed starting with alkyl

cyanoacrylate monomer to give pilocarpine-containing poly(alkyl

cyanoacrylate) nanoparticles (Harmia-Pulkkenes, T, Tuomi, A., and

Kristoffersson, E. in J . Microencapsulation 1989, Vol. 6, No. l p. 87).

As indicated above, the use of poly(alkyl cyanoacrylates) is not limited

to the encapsulation of drugs. Thus poly(alkyl cyanoacrylates) can be

used to encapsulate other active agents. They have been used for

example in an electrostatic suspension developer (Patent Publication

DE—A 35 14 867). Cyanoacrylate monomer itself has been

rnicroencapsulated together with colour-former in a heat—developable,

photo- and pressure—sensitive composition in Patent Publication JP

92278953. In the same way, alkoxycyanopropionic acid esters should

be able to be rnicroencapsulated by poly(alkyl cyanoacrylate) to give an

10

15

20

25

WO 95/26371

PCT/IE94/00018

37

adhesive composition when used inconjunction with appropriate basic .

primer.

Other potential applications for the compounds prepared in

accordance with the invention include use as transparent fixation agents

of plant tissues (the portions to be fixed should be treated with

appropriate base) which may offer advantages over the more reactive

and less ‘discriminate’ cyanoacrylate monomer described in Patent

Publication JP 63255201.

Two recently reported applications of poly(alkyl -cyanoacrylates)

is their use as passivating layers on the lithium anode of lithium-thionyl

chloride cells (Hsing Yaw H., Hsien Wen K., J. Power Sources 1989

Vol. 26 No. 3-4 p. 419) and Langmuir-Blodgett poly(cyanoacrylate)

films as coatings for indium antimonide capacitors (Matveeva, N.K.,

Pasekov, V.F., and Sa Vel'eva, L.V. (Mikroelektronika Akad. Nauk.

SSSR 1991, Vol 20, No. 5 pp. 501-503)). The compounds prepared in

accordance with the invention could be used to lay down such layers in

photo-resist fabrication.

Brief Description of Figures

Fig. l is a Langmuir isotherm for the Langmuir-Blodgett

film formed in Example 7;

Fig. 2 is a Langmuir isotherm for the Langmuir-iBlodgett

film formed in Example 8;

Fig. 3 is a Langmuir isotherm for the Langmuir—B1odgett

film formed in Example 9; and

Fig. 4 is a graph of area at constant pressure versus time

before and after transferring a Langmuir-Blodgett

film formed as described in Example 9 to a silicon

[100] surface.

10

15

20

25

30

WO 95/26371

PCT/[E94/00018

38

Modes for Carrying Out the Invention

The invention will be further illustrated by the following

Examples.

Example 1

Synthesis of 2-cyano-3-hexadecyloxypropionic acid

2-Cyanoacrylic acid (0.98 g), p—toluenesulfonic acid (0.17 g) and

hydroquinone (0.05 g) were dissolved in dry benzene (250 ml)

contained in a 500 ml flask which had previously been washed with

10% sulfuric acid and dried using acetone, and which was fitted with a

stirrer, a thermometer, sulfur dioxide and argon inlet adaptors, a

dosing funnel and a Liebig condenser arranged for distillation. The

solution was sparged with sulfur dioxide and 50 ml of water—benzene

azeotrope was distilled off in order to ensure anhydrous conditions.

The condenser was then arranged for reflux and a solution of n-

hexadecyl alcohol (2.42 g) in dry benzene (50 ml) was added dropwise

to the boiling contents of the flask with stirring and continuous

sparging with dry sulfur dioxide. Following addition of the alcohol,

the solution was heated under reflux during two hours. After this time,

sparging with sulfur dioxide was substituted by sparging with argon

and the volume of the mixture was reduced to 50 ml by distillation of

solvent. The residue was extracted using boiling heptane (100 ml), and

heptane and remaining benzene were removed in vacuum to give an oil

which crystallised. The solid was recrystallised from hexane to give 2-

cyano-3-hexadecyloxypropionic acid (1.37 g; 40%), m.p. 63—65°C,

calculated for C2()H37NO3: C 70.8, H 10.1, N 4.1%; found C 69.15, H

10.07, N 4.65%, 1H NMR (C5D6) 0.81 (3H, t, J = 5.7 Hz, —CH3), 1.18

(28H, m, -CH2—), 2.87 (1H, ABX dd, JXA = 5.28 Hz, JXB = 4.43 Hz,

-CH(CN)CO2H), 3.07 (2H, t, J = 6.44 Hz, -OCHZCHZ-), 3.18 (1H, ABX

m, J AB = 9.30 Hz, -OCL-I_2CH(CN)CO2H), 3.31 (1H, ABX m,

-OCfl2CH(CN)CO2H) and 7.13 (1H, s, -CO2H) p.p.m.

10

15

20

25

30

WO 95/26371

PCT/IE94/000 18

39

Example 2

Synthesis of ethyl 2-cyano-3-hexadecyloxypropionate

Ethyl 2-cyanoacrylate (1.25 g), 2—cyanoacry1ic acid (0.05 g) and

hydroquinone (0.05 g) were dissolved in a mixture of dry benzene (200

ml) and dry toluene (50 ml) contained in a 500 ml flask which had

previously been washed with 10% sulfuric acid and then dried using

acetone, and which was fitted with a stirrer, a thermometer, sulfur

dioxide and argon inlet adaptors, a dosing funnel and a Liebig

condenser arranged for distillation. The solution was sparged with

sulfur dioxide while water-benzene azeotrope (50 ml) was distilled off

in order to ensure anhydrous conditions. The condenser was then

arranged for reflux and a solution of n-hexadecyl alcohol (2.7 g) in dry

benzene (50 ml) was added to the boiling contents of the flask with

stirring and continuous sparging with dry sulfur dioxide. Following

addition of the alcohol the mixture was continuously sparged with

sulfur dioxide and heated in such a manner that slow distillation of

solvent continued during two and one-half hours. After this time,

sparging with sulfur dioxide was substituted by sparging with argon

and the volume of the reaction mixture was reduced to 50 ml by _

distillation. The remaining solution was cooled, a solid residue which

formed was removed by filtration, and remaining solvent was removed

by distillation in vacuum to give a solid product (3.4 g). This was

recrystallised from hexane to give ethyl 2-cyano—3-hexadecyloxy

propionate (2.37 g; 61%), m.p. 44-46°C, g for C22H41NO3: C

71.93, H 11.17, N 3.81%; £Q1.1L1 C 72.17, H 11.68, N 3.56%,1H NMR

(C6D6) 0.847 (3H, m,‘-(CH2)nCfl3), 0.913 (3H, t, J = 7.16 Hz,

-OCH2C_I:1.3), 1.42 (28H, m, —CH2-), 3.01 (1H, ABX dd, JXA = 5.21 Hz,

JXB = 5.23 Hz, —CH(CN)CO2Et), 3.23 (2H, t, J = 6.32 Hz,

-CH2OCH2CH-), 3.42 (1H, ABX m, J AB = 9.35 Hz, -OCL-I_2CH(CN)

CO2Et), 3.53 (1H, ABX m, —OCfl2CH(CN)CO2Et) and 3.88 (2H, q, J =

7.16 Hz, -CO2CH2CH3) p.p.m.

10

15

20

25

30

WO 95/26371

PCT/IE94/00018

40

_ Example 3 ‘

Synthesis of hexadecyl 2-cyano-3-hexadecyloxypropionate

2-Cyanoacrylic acid (0.96 g, 0.01 mol), p—toluenesulfonic acid

(0.17 g) and hydroquinone (0.05 g) were dissolved in dry benzene (250

ml) contained in a 500 flask which had previously been washed with

10% sulfuric acid and then dried using acetone, and which was fitted

with a stirrer, a thermometer, sulfur dioxide and argon inlet adaptors,

a dosing funnel and a Liebig condenser arranged for distillation. The

solution was sparged using dry argon while water-benzene azeotrope

(50 ml) was distilled off in order to ensure anhydrous conditions. The

condenser was then arranged for reflux and a solution of n—hexadecyl

alcohol (2.42 g 0.01 mol) in dry benzene (100 ml) was added to the

boiling contents of the flask with stirring and continuous sparging with

dry sulfur dioxide. Following addition of the alcohol, the mixture was

refluxed during two hours. After this time, the sulfur dioxide sparging

was substituted by argon sparging and the condenser was arranged for

distillation. A solution of n—hexadecyl alcohol (2.6 g, 0.0108 mol) in

dry benzene (100 ml) was added dropwise with constant removal of

solvent by distillation. Following this addition, dry benzene (200 ml)

was added and the mixture was distilled with stirring and constant

sparging using argon until the volume had been reduced to 50 ml. The

residue was extracted using boiling hexane (100 ml), and hexane and

remaining benzene were removed in vacuum after prior cooling and

filtration to give a solid residue (3.95 g). This was recrystallised from

hexane to give the hexadecyl ester of 2-cyano—3-hexadecyloxypropionic

acid (3.4 g; 60%) m.p. 42-43°C, _caQ1_l_z1t_ecl for C35H69NO3: C 76.73, H

10.48, N 2.48%; mm C 75.57, H 11.09, N 2.59%, 1H NMR (C5D5)

0.85 (6H, 1, J — 6.2 Hz, 2 @ —CH2CH3), 1.12 (4H, m, 2 @ -CH2C_H_3),

1.33 (52H, m, -CH2-), 2.94 (1H, ABX dd, JXA = 5.42 Hz, JXB = 5.10

Hz, -CH2Cfl(CN)CO2-), 3.10 (2H, 1, J = 6.3 Hz, —cH2oCH2cH(CN)—),

3.29 (1H, ABX m, JBA = 9.33 Hz, —OCH_2CH(CN)-), 3.42 (1H, ABX m,

-OC_H2CH(CN)-) and 3.86 (2H, 1, J = 6.43 Hz, -CO2C_H2CH2-) p.p.m.

10

15

20

25

30

WO 95/26371

PCT/IE94/00018

41

Example 4

Preparation of polygethyl 2-cyanoacrylate from ethyl 2-cyano-3-

hexadecyloxypropionate

Ethyl 2-cyano-3-hexadecyloxypropionate (0.36 g) was dissolved

in ethanol (5 ml) and water (1 ml) and the mixture was stirred during

24 hours to give an amorphous colourless solid. This solid was

separated by centrifugation and dried in vacuum to give 0.35 g of an

equimolar mixture of hexadecyl alcohol and poly(ethyl 2-

cyanoacrylate, calculated C 71.93, H 11.17, H 3.81, found C 70.03, H

10.94, N 3.35%. The mixture was washed with alcohol and with

acetone, and the solid residue was dissolved in chloroform. It was then

precipitated with hexane, filtered and dried in vacuum to give 0.1 g of

poly(ethyl 2-cyanoacrylate), Ql_c:_11Lc1t£c1 for C6H7NO2: C 57.6, H 5.6, N

11.2; fmljnd C 58.31, H 6.11, N 10.43%, 1H NMR (CDCI3) 0.77 (m, -

OCHQCH3), 2.20-2.55 (m, -CH2-) and 4.23 (m, -OCHQCH3) p.p.m.

Example 5

Preparation of poly: ethyl 2-cyanoacrylate from triphenyl((2-cyano—2-

ethoxycarbonyl )ethyl )phosphonium trifluoroacetate

To a solution of 1.6 g (2 ml, 12.5 mmol) of ethyl 2-

cyanoacrylate and 2.6 ml (18 .mmol) of trifluoroacetic acid in 2 ml of

dry chloroform was added dropwise with stirring and sparging with

sulfur dioxide a solution of 3.28 g (12.5 mmol) of triphenylphosphine

in 4 ml of dry chloroform. The mixture was stirred at room

temperature during 20 minutes and solvents were then evaporated in

vacuum. The residual oil contained triphenyl((2-cyano-2-

ethoxycarbonyl)et.hyl)phosphonium trifluoroacetate, 31P NMR 21.82

p.p.m., 1H NMR (CDCI3) 1.06 (3H, t, —OCH2C_I:I_3), 3.72 (1H, m, -

Cfl(CN)CO2Et), 4.00 (2H, m, -OCHZCH3), and 4.18 and 4.45 (each

1H, m, Ph3P-C_I;I_2—) p.p.m. A solution of 3 g of the above compound in

5 ml of acetone was added dropwise to 30 ml of water and the mixture

was stirred during 24 hours to give an amorphous colourless solid.

10

15

20

25

WO 95/26371

PCT/IE94/00018

42

This solid was separated by centrifugation, washed sequentially with. _

water, alcohol and acetone, and dried in vacuum. It was then dissolved

in chloroform, precipitated using hexane, filtered and dried in vacuum

to give 0.72g (96%) of poly(ethyl 2-cyanoacrylate), calculated for

C5H7NO2: C 57.6, H 5.6, N 11.2; mm C 58.01, H 5.86, N 10.83%,

1H NMR (CDCI3) 0.77 (3H, -OCH2Cfi3), 2.20-2.55 (2H, m, -CH2-) and

4.23 (2H, -OCLI_2CH3) p.p.m.

Example 6

Preparation of poly(ethyl 2-cyanoacrylate) from ethyl 2-cyano-4-

thiaoctanoate

To a solution of 1.68 g (2 In], 18.7 mmol) of n-butylmercaptan

in 2 ml of dry chloroform was added dropwise with stirring to a

solution of 1.6 g (2 ml, 12.5 mmol) of ethyl 2-cyanoacrylate in 2 ml of

dry chloroform. The mixture was stirred at 20°C during 24 hours

when solvent was evaporated in vacuum to give a colourless transparent

oil. This oil was distilled in vacuum to give 1.88 g (70%) of ethyl 2-

cyano-4-thiaoctanoate, b.p. 110°C at 0.5 mm Hg, 1H NMR (CDCl3)

0.90 (3H, t, J 6 Hz, Cfl3CH2CH2-), 1.32 (3H, t, J 6.5 Hz, -OCH2Cfl3),

1.4 (2H, m, CH3CLI_2CH2-), 2.64 (2H, t, -CH2C_I-128-), 2.99 and 3.09

(each 1H, ABX, -SCHZCH-), 3.70 (1H, m, -CH2Cfl(CN)CO2Et) and

4.28 (2H, q, J 6.5 Hz, ~OCH2CH3) p.p.m. The above compound (1 g)

was added dropwise to 30 ml of water and the mixture was stirred

during 48 hours to give an amorphous colourless solid. This solid was

separated by centrifugation, washed with water, dried in vacuum,

- dissolved in chloroform, precipitated using hexane, filtered and dried

in vacuum to give 0.53 g (92%) of poly(ethyl 2-cyanoacrylate),

calculated for C6H7NO2: C 57.6, H 5.6, N 11.2; found C 57.23, H.

5.45, N. 11.62%, 1H NMR (CDCI3) 0.77 (m, -OCH2C_I;I_3), 2.20-2.55

(m, -CH2-) and 4.23 (m, -OC_I-12CH3) p.p.m.

10

15

20

25

W0 95/26371

PCT/H994/00018

43

Example 7

Formation of a Langmuir—Blodgett film using 2—cyano-3-

hexadecyloxypropionic acid

The title compound was dissolved in pure, dry chloroform to

give a solution containing 1 g/L. A measured volume (8 x 1O'5 L) of

this solution was applied to the surface of pure water of pH 7.13

contained in a Langmuir trough fitted with a movable barrier

connected to a torsion balance and a data handling system. After

allowing time for the chloroform to evaporate, the surface of the

trough was swept by the barrier at a speed of 1.2 cm2/s'1 and the

isotherm of surface tension in mN/m versus surface area of the film in

cm2 was recorded. A classical Langmuir isotherm showing gas, liquid

and solid phases was obtained and is reproduced in Fig. 1.

Example 8

Formation of a Langmuir—Blodgett film using ethyl 2-cyano-3-

hexadecyloxypropionate

This experiment was carried out exactly as described for

Example 7 supra except that the amount of chloroform solution of the

title compound which was applied to the surface of the water in the

trough was 6 x 105 L. The Langmuir isotherm obtained is reproduced

in Fig. 2.

Example 9

Formation of a Langmuir—Blodgett film using hexadecyl 2-cyano-3-

hexadecyloxypropionate

This experiment was carried out exactly as described for

Example 7 supra. The Langmuir isotherm obtained is reproduced in

Fig. 3.

W0 95/26371 PCT/IE94/00018

44

Example 10

Formation of a Langmuir—Blodgett film using hexadecyl 2—cyano-3-

hexadecyloxypropionate, and its transfer to a silicon |100| surface

This experiment was initially carried out in the same way as

5 Example 9 supra. A stable, constant area Langmuir—Blodgett film was

obtained and maintained at a surface pressure of 35mN/m. At t = 54s

(Fig. 4) a portion of the film was transferred by dipping to a silicon

[100] surface of known area, giving a fi1m—transfer ratio of 0.8:1.0.

After dipping at t = 843 a stable Langmuir—Blodgett film of reduced

10 constant area was obtained.

l0

15

20

25

W0 95/26371

PCT/IE94/00018

45

Claims: -

1. A process for the reversible coupling of a weak

nucleophile to the carbon-carbon double bond of 2-cyanoacrylic acid or

an ester thereof, so as to reversibly protect said bond, which comprises

reacting 2-cyanoacrylic acid or an ester thereof with said weak

nucleophile in the presence of an inert solvent under polymerisation

inhibiting conditions and in the presence of an acidic catalyst.

2. A process according to Claim 1, wherein the weak

nucleophile is an alcohol.

3. A process according to Claim 1, wherein the weak

nucleophile is a phenol.

4. A process according to Claim 1, wherein the weak

' nucleophile is a thiol, a thiophenol, a thioamide or a thio or_dithio acid.

5. A process according to Claim 1, wherein the weak

nucleophile is a dialkyl or diaiylphosphite, a dialkyl or

diarylthiophosphite, a phosphine, or a phosphorus sulfenyl halide.

6. A process according to Claim 1, wherein the weak

nucleophile is a carbon acid.

7. A process according to any preceding claim, wherein the

acidic catalyst is a non—volatile acid.

8. A process according to Claim 7, wherein the non—volatile

acid is an aliphatic sulfonic acid or an aromatic sulfonic acid.

9. A process according to Claim 8, wherein the acid catalyst

is methanesulfonic acid or p-toluenesulfonic acid.

10. A process according to any one of Claims 1-6, wherein the

acid catalyst is a carboxylic acid.

10

15

20

25

WO 95/26371

PCT/IE94/000 18

46

11. .A_ process according to any one of Claims 1-10, which is V _

carried out under conditions which inhibit anionic polymerisation.

12. A process according to Claim 11, which is carried out in

the presence of a weak acid.

13. A process according to Claim 12, wherein the weak acid is

sulfur dioxide.

14. A process according to Claim 13, wherein gaseous sulfur

dioxide is bubbled into the reaction mixture as a continuous stream.

15. A process according to any one of Claims 1-11, wherein

the anionic polymerisation inhibitor is an aliphatic sulfonic acid, an

aromatic sulfonic acid or carbon dioxide.

16. A process according to any one of Claims 1-15, which is

carried out in the presence of a free radical polymerisation inhibitor.

17. A process according to Claim 16, wherein the free radical

polymerisation inhibitor is benzoquinone, hydroquinone,

methylhydroquinone or naphthoquinone.