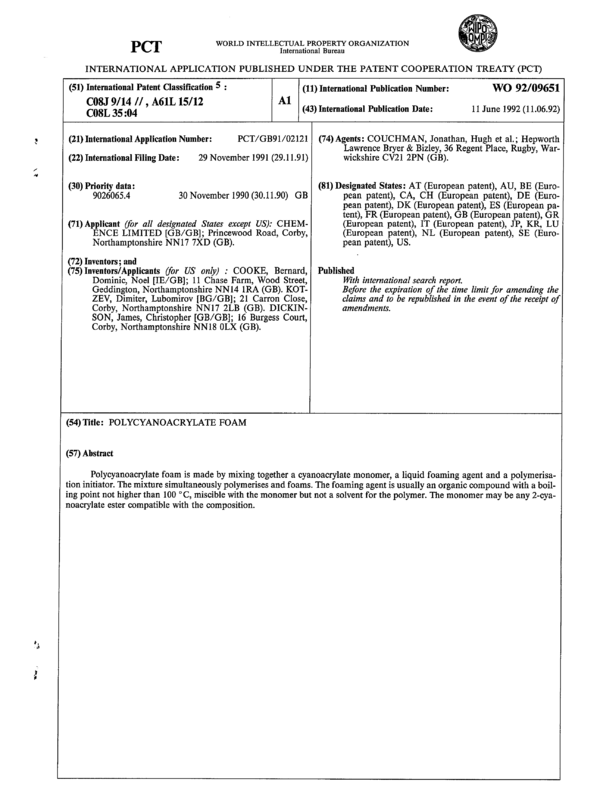

Polycyanoacrylate Foam

Folder:

Year:

Abstract:

Polycyanoacrylate foam is made by mixing together a cyanoacrylate monomer, a liquid foaming agent and a polymerisation initiator. The mixture simultaneously polymerises and foams. The foaming agent is usually an organic compound with a boiling point not higher than 100 °C, miscible with the monomer but not a solvent for the polymer. The monomer may be any 2-cyanoacrylate ester compatible with the composition.

Type of document:

Language:

V!

3\

is

I561

PCT WORLD INTELLECTUALPROPERTY ORGANIZATION

International Bureau

INTERNATIONAL APPLICATION PUBLISHED UNDER THE PATENT COOPERATION TREATY (PCT)

WO 92/09651

11 June 1992 (1l.06.92)

(51) International Patent Classification 5 :

C08J 9/14 // , A6lL 15/12

C08L 35 :04

(11) International Publication Number:

(43) Intemational Publication Date:

PCT/GB91/02121 (74) Agents: COUCHMAN, Jonathan, Hugh et a1.; Hepworth

Lawrence Bryer & Bizley, 36 Regent Place, Rugby, War-

wickshire CV21 2PN (GB).

(21) International Application Number:

(22) Intemational Filing Date: 29 November 1991 (29.1 1.91)

(81) Designated States: AT (European patent), AU, BE (Euro-

pean patent), CA, CH (European patent), DE (Euro-

pean patent), DK (European patent), ES (European pa-

tent), FR (European patent), GB (European patent), GR

(European patent), IT (European patent), JP, KR, LU

(European patent), NL (European patent), SE (Euro-

pean patent), US.

(30) Priority data:

9026065.4 30 November 1990 (30.11.90) GB

(71) Applicant (for all designated States except US): CHEM-

ENCE LIMITED [GB/GB]; Princewood Road, Corby,

Northamptonshire NNI7 7XD (GB).

(72) Inventors; and

(75) Inventors/Applicants (for US only) : COOKE, Bernard, Published

Dominic, Noel [IE/ GB]; 11 Chase Farm, Wood Street, With international search report.

Geddington, Northamptonshire NNI4 1RA (GB). KOT- Before the expiration of the time limit for amending the

ZEV, Dimiter, Lubomirov [BG/ GB]; 21 Carron Close, claims and to be republished in the event of the receipt of

Corby, Northamptonshire NNl7 2LB (GB). DICKIN- amendments.

SON, James, Christopher [GB/GB]; 16 Burgess Court,

Corby, Northamptonshire NNI8 OLX (GB).

(54) Title: POLYCYANOACRYLATE FOAM

(57) Abstract

Polycyanoacrylate foam is made by mixing together a cyanoacrylate monomer, a liquid foaming agent and a polymerisa-

tion initiator. The mixture simultaneously polymerises and foams. The foaming agent is usually an organic compound with a boil-

ing point not higher than 100 °C, miscible with the monomer but not a solvent for the polymer. The monomer may be any 2-cya-

noacrylate ester compatible with the composition.

:

FOR THE PURPOSES OF INFORMATION ONLY

applications under the PCT.’

Austria

Australia

Barbados

Belgium

Burkina Faao

Bulgaria

Benin

Brazil

Canada

AT

AU

I3

BE

IF

BC

BJ

BR

Central African Republic

Congo

Switzerland

Cote d‘lvoire

Cameroon

Ca:choslova£i.t

Germany

Denmark

+ Any desig

any such designation

ES

FI

FR

GA

GB

GN

GR

HU

IT

JP

KP

Spain

Finland

France

Gabon

,United Kingdom

Guinea

Greece

Hungary

Italy

Japan

Democratic People‘s Republic

of Korea

Republic of Korea

Liechtenstein

Sri lanka

Luxembourg

Monaco

KR

Ll

LK

LU

MC

3»?

Codes used to identify States party to the PCT on the front pages of pamphlets publishing international

MG

ML

MN

MR

MW

NL

NO

FL

I10

SD

SE

SN

SU "

‘I'D

'I'G

US

Madagascar

Mali

Mongolia

Mauritania

Malawi

Netherlands

Norway

Poland

Romania

Sudan

Sweden

Senegal

Soviet Union

Chad

Togo

United States of America

aim”

nation of “SU” has effect in the Russian Federation. lt is not yet known whether

has effect in other States of the former Soviet Union.

nu

W0 92/ 09651

l0

15

20

PC!"/GB9l/02121

.. 1 ..

POLYCYANOACRYLATE FOAM

This invention relates to a foam forming cyanoacrylate

composition.

Since their comercialization in the sixties adhesives based

on cyanoacrylate monomers have found wide application.

Numerous compositions are known in the art. A variety of

additional components are introduced into the cyanoacrylate

monomer to impart thickening (US Patent No. 2,794,788) and

thixotropy (US Patent No. 4,533,422) of the adhesive,

toughness (W0 83/02,450), heat resistance (Japanese _Patent

No. 62,199,668), impact and peel-resistance (Japanese Patent

No. 63,00,377), electroconductivity (W0 86/06,738) and other

properties of the resultant adhesive bond.

It has now been unexpectedly found that when cyanoacrylate

monomers are mixed with organic liquids and polymerization

initiators the so formed composition can transform itself by

expansion into a

simultaneous polymerization and

polycyanoacrylate foam.

based

composition, comprising a cyanoacrylate monomer, a liquid

foaming agent and a cyanoacrylate polymerization initiator.

The present invention provides cyanoacrylate

Upon or after formation of the composition it polymerizes to

produce expanded polycyanoacrylate foam. The composition

can also optionally contain other reactive monomers, as well

as modifiers and additives such as polymeric thickeners,

plasticizers, thixotropic agents, compatibilizers, pigments

and colourants, fillers, deodorants and perfumes, for

example.

W0 92/ 09651 PCT I GB91 I 02121

_ 2 -

In another aspect the invention provides a method of

creating a polycyanoacrylate foam and the foam itself.

The cyanoacrylate monomers used in the composition of the

5 invention are 2-cyanoacrylate esters of the formula

CN 0

I ll

CH2 = C - C - O - R

10

wherein R represents an ester-forming group. In principle,

R can be any ester-forming group compatible with the monomer

and with foam formation. For example, the group R should

not initiate autopolymerization of the monomer or prevent

15 polymerization of the composition described above. R should

also desirably be selected to provide a foam with the

desired properties.

Preferably R represents alkyl, alkenyl, alkynyl, aryl or an

20. aromatic heterocyclic radical. R may also be one of the

foregoing moieties substituted with one or more other of the

moieties; this includes the case of a substituent itself

being substituted. Group R may contain other compatible

substituents, for example alkoxy, alkoxyalkoxy,

25 carbalkoxyalkyl or halogen. In general, R can be any moiety

which does not contain a sufficiently nucleophilic group to

initiate polymerization or sufficiently electrophilic group

to interfere with polymerization. The alkyl or alkenyl

moiety may be cyclic and normally R contains from 1 to 16

30 carbon atoms and often.is a 1C, 2C, 3C, 4C, SC, SC, 7C or 8C

group, more usually it is a lC—6C group. In the case of

W0 92/0965]

10

15

20

25

30

T Specific

PCT/GB91/02121

_ 3 _

moieties containing a heterocycle, heteroatom ring members

are normally counted as a carbon atom.

More preferably, R is alkyl, halogenated alkyl, alkenyl,

alkynyl, phenyl, halogenated phenyl, phenylalkyl,

halogenated phenylalkyl, alkoxyalkyl, alkoxyalkoxyalkyl,

carbalkoxymethyl or alkylideneglyceryl, wherein the terms

"alkyl" and include the corresponding cyclic

Uninterrupted carbon chains preferably contain 1,

"alkenyl"

radicals.

2 or 3 carbon atoms.

ethyl,

Pent-Y1 I

3-chloropropyl,

n'Pr°PY1:

hexyl,

examples of R are methyl,

iso-propyl, n—butyl, iso-butyl,

trifluoroethyl, 2-chloroethyl,

2-chlorobutyl, cyclohexyl, tertiary butylcyclohexyl, benzyl,

phenyl, cresyl, allyl, crotyl, methallyl, propargyl,

furfuryl, 2-methoxyethyl, 2-ethoxyethyl, 2-methoxyisopropyl,

2-(2'-ethoxy)-ethoxymethyl, 2—(2'—ethoxy)-ethoxyethyl,

2-(2'-ethoxy)-ethoxybutyl, methoxycarbonylmethyl,

ethoxycarbonylmethyl, isopropoxycarbonylmethyl,

isobutoxycarbonylmethyl, isoamyloxycarbonylmethyl and

1,2-isopropylideneglyceryl. Most

iso-butyl, 2-methoxyethyl,

preferred are ethyl,

n—butyl, 2-ethoxyethyl and

2-methoxyisopropyl cyanoacrylates.

If desired, a mixture of two or more cyanoacrylate monomers

may be used.

stabilized with

anionic and free-radical polymerization inhibitors. Anionic

polymerization inhibitors known in the art are soluble

acidic gases (for example sulfur dioxide), hyrogen fluoride,

sulfonic acids,

Usually the cyanoacrylate monomers are

phosphonic, carboxylic and organic

WO 92/09651

10

15

20

25

30

_composition and its transformation

PCT/GB9l/02121

- 4 _

and phosphazenes, for

sultones, BF3 and its complexes

example. The free-radical polymerization inhibitors are

usually hydroquinone, p-methoxyphenol or t-butyl catechol,

for example.

The inhibitors are normally used in small amounts of from

0.00001 to 1% by’ weight of the monomer. The preferred

quantities for the above-mentioned inhibitors are:

gases - from 0.001% to 0.06%; acids — from 0.00052; to 0.01%;

sultones - from 0.01% to 0.1%; BF3 - from 0.0001% to 0.01%;

acidic

0.0001% to 0.001%; free-radical

The foregoing percentages

phosphazenes - from

inhibitors — from 0.001% to 1%.

are percentages by weight of the cyanoacrylate monomer. It

should be noted that the quantity of inhibitor will

influence the onset of polymerization of the composition of

the present invention and could. be used as a means to

control the time interval between the formation of the

into a polymeric

cyanoacrylate foam.

The liquid foaming agent used in the composition of the

present invention can be any organic compound with a boiling

point. preferably not higher than 100°C. The liquid

foaming agent used can be a single compound or a mixture

thereof. Preferably it will be soluble or semi-soluble in

the cyanoacrylate monomer and will not act asaa solvent for

polycyanoacrylate. Preferably its

Preferably it is a

non-toxic,

the corresponding

solubility parameter should be below 9.

non—polar liquid. Preferably it should be

non—flammable and non-irritant.

W0 92/ 09651

10

15

20

25

30

‘used as liquid blowing agents.

PCT/GB9l/02121

- 5 -

Solubility parameter is a quantity used to predict the

solubility of solutes and solvents and is explained in the

"CRC Handbook of Chemistry and Physics", published by CRC

Press Inc. of Boca Raton, Florida, USA see for example page

C-676 of the 67th Edition (1986-87). The CRC Handbook also

contains lists of solubility parameter values.

Specific examples of foaming agents are pentane, hexane,

heptane, 1,1,2-trichlorotriflouroethane,

1,1,1-trichlorotrifluoroethane, petroleum ether, diethyl

ether, cyclopentane, cyclohexane, benzene, carbon

tetrachloride, chloroform, methylcyclopentane,

dimethylsulfide, 1,1-dichlororethane,

1,1,1-trichloroethane, perfluorohexane, perfluoroheptane,

1-bromopropane. Most preferred are pentane, hexane,

1,1,2-trichlorotriflouroethane, cyclohexane, petroleum ether

and diethyl ether. The above—mentioned compounds are only

representative and do not limit the compounds that can be

It was found that even very

polar liquids like ethanol and methanol or liquids which are

typical solvents for polycyanoacrylates, like acetone,

2—butanone and acetonitrile, can be used as foaming agents.

When solvents for polycyanoacrylates are used as foaming

they expand the foam but immediately thereafter the

foam shrinks in volume or sometimes Such

are therefore normally unacceptable as foaming

agents,

collapses.

solvents

agents when used alone, but in principle can be used so long

as the selected combination of solvent, polycyanoacrylate

and their relative quantities do not lead to collapse of the

foam. Polycyanoacrylate solvents are more acceptable when

used in minor amounts with other foaming agents.

W0 92/ 09651

10

15

20

25

30

'calixarenes,

PCI‘/GB91/02121

- 5 -

The volume ratio of cyanoacrylate monomer to foaming agent

is not critical but is preferably from 1:10, to 20:1, more

preferably from 1:2 to 5:1, especially from 1:1 to 4:1.

The cyanoacrylate polymerization initiator used in the

composition of the present invention may comprise any of the

accelerators of the anionic

The

known initiators and

polymerization of cyanoacrylate monomers, for example.

anionic initiator can be used singly or in admixture with

one or more other initiators.

of anionic initiators are pyridine,

methoxyethylpyridine,

N,N-dimethyl-p-toluidine,

N,N4dimethyl-m—toluidine,

tribenzylamine,

diethylenetriamine,

poly(4-vinylpyridine),

complexes,

Specific examples

aminopyridine,

piperidine, picoline,

N,N-dimethyl-o-toluidine,

triphenylphosphine, triethylphosphine,

triethylamine, benzyldimethylamine,

benzyltriethylamine , tribenzylamine ,

tertiary amine-S03

vinylpyridine,

lutidine,

polyethyleneglycol, phenolformaldehyde

triethanolaminatotitanium,

N-(oxydiethylene)

bismuth

bases and

Most

initiators are

N-(oxydiethylene)

vinylimidazole, aminosilanes,

phosphites,

benzothiazole-2-sulfenamide,

dimethyldithiocarbamate, as well as

hydroxyl or amine group

polymerization

metal acetylacetonates,

alcohols,

containing compounds.

preferred anionic

N,N-dimethyl-p-toluidine and

benzothiazole-2-sulfenamide.

The above-mentioned compounds are only representative and do

not restrict the scope of suitable initiators. For example

any of the anionic polymerization initiators known in the

resins,u

W0 92/0965]

10

15

20

25

30

PCT/GB91/02121

art for cyanoacrylate monomers or accelerators of their

anionic polymerization can successfully be used in the

compositions of the present invention. Optionally, but not

necessarily, free—radical polymerization initiators such as

methylethylketone cyclohexane peroxide, cumene

hydroperoxide or dibenzoyl peroxide,

with the anionic polymerization

peroxide,

for example, can be

used in conjunction

initiator.

In order to impart desired properties to the composition of

the present invention and to the properties of the resultant

further

They can

for economic considerations,

foam, as well as

additives can be introduced into the composition.

be, for example, any of the known polymeric thickeners and

viscosity regulators, rubbers, plasticizers and tougheners,

compatibilizers, thioxtropic agents, colourants, deodorants

or perfumes, for example, used in cyanoacrylate adhesives.

‘The composition may also contain other monomers containing a

reactive double

(di)methacry1ates,

epoxy or urethane, in minor amounts, e.g.

of the total monomer content and more preferably in an

bond, for

or reactive resins or oligomers, e.g.

up to 25 mole %

example (di)acrylates or

amount of no more than 5 or 10 mole %.

Upon mixing the three major components of the present

invention foaming agent and initiator) a mixture

(monomer,

is formed in which, under the action of the anionic

polymerization of the cyanoacrylate monomer

which leads to the

As a

initiator,

occurs. It is fast and exothermic,

simultaneous evaporation of the liquid foaming agent.

produced. The expanded

40 times the

result polycyanoacrylate foam is

material can occupy a volume of as much as

WO 92/09651

10

15

20

25

30

PCT/GB91/02121

_ 3 _

volume of the original liquid composition. The expansion

coefficient and the properties of the foam are dependent on

the components used and their ratios. They are also

dependent on the availabile volume for expansion. The

formed polymeric foam is of a closedscell type.

A distinctive feature is that the foam is covered by a thin

film of polycyanoacrylate, which resembles a

polycyanoacrylate glue-line and ensures excellent adhesion

of the foam to the surface(s) which it has contacted. The

time necessary for the onset of polymerization and foaming

can be regulated from seconds to minutes by varying the type

and amount of anionic initiator and/or stabilizer present in

the cyanoacrylate monomer or composition.

Another distinctive feature of the composition of the

present invention is that it is easy to prepare, the foaming

reaction takes place at room temperature and compressed

‘gases are not required or utilized.

Another distinctive feature of the foamed polycyanoacrylate

is that it can easily bet collapsed when contacted with

solvents for polycyanoacrylates like acetone, acetonitrile,

methylenechloride, N,N-dimethylformamide,

butyrolactone or alkyl cyanoacetates, for example.

nitromethane,

Applications of the foaming composition of the present

invention and the method of obtaining polycyanoacrylate

plugging of ducts,

adhesive bonding and

foams include two major areas, i.e.

pipes and vessels and, secondly,

sealing of porous substrates.

W0 92/0965 1

10

15

20

25

30

PCT/GB91/02121

- 9 -

Using the foaming composition of the present invention

temporary, permanent or semi-permanent blocking of flow of

fluids in pipelines can be achieved. Gas and oil pipelines

are of particular interest. Following repairs or other work

on the pipeline the foam blockage can easily be collapsed by

application of a suitable solvent. The main advantage of

the material and method of the invention is the simplicity

and speed of forming the foam, its high adhesion to the

and the simplicity and speed of

walls of the pipe,

collapsing the foam.

Using the foaming composition of the present invention blood

fallopian tube sealing or other medical

The above—mentioned

applications are currently executed with conventional

for the purpose of stopping haemorrhage and

Using the foaming composition in

vessel occlusion,

or surgical procedures can be achieved.

cyanoacrylates

for female sterilization.

those cases would greatly increase the success rate of the

’ present methods, ensuring excellent plugging capacity as a

result of polymer expansion in the vessel. Furthermore the

quantity of the cyanoacrylate introduced into the body will

be reduced more than tenfold, which would greatly increase

the physiological safety of the procedures.

Using the foaming composition of the present invention

orthopaedic casts for broken limbs can be prepared. The

distinct be the

preparation of the casts, their extremely low weight and

advantages will speed and ease of

advantages specially valuable in

sufficient rigidity,

emergency cases and military action.

PCI‘/GB91/02121

WO 92/09651

10

15

20

25

30

-10-

The cyanoacrylate monomer and the initiator must obviously

be kept separate until it is desired to form the foaming

composition, but the foaming agent may if desired be mixed

with one or other (or both) of the monomer and the initiator

to form a preblend.

It is therefore convenient to provide a binary delivery

nomer and.the initiator in separate

system holding the mo

If

containers from which they may be dispensed and mixed.

desired, the binary system could include a third container

containing all or part of the foaming agent, and.if desired

containers holding other components may be

separate

Such a binary or multipart delivery system forms

provided.

one aspect of the invention.

The delivery system or kit may take the form of a syringe

having an in-line static (stationary phase) mixer or of

In any event, it preferably includes means

spray apparatus.

their

to mix the components prior to, or in the process of,

dispensing from the apparatus. In the case of a syringe, a

thickener is preferably provided to increase the viscosity

of the final composition.

Preferably, the delivery system is a two-part system, in

which all the components are included in the containers

holding the monomer preparation and the initiator.

The invention includes a preblend for forming the foaming

composition, comprising the monomer and a foaming agent.

The above-mentioned applications are only indicative and do

not limit the scope or application of the foaming

T composition of the present invention.

W0 92/0965]

10

15

20

PCF/GB9]/0212]

-11..

The invention is illustrated by the following examples.

Example 1

In an open polyethylene cylindrical container with a

diameter of 50 mm, 4 ml of pure, freshly distilled ethyl

2—cyanoacrylate are placed. To the cyanoacrylate is added a

given amount of liquid

N,N-dimethyl-p-toluidine.

foaming agent, containing

The contents are manually mixed

for 3 seconds so that a clear solution is produced. The so

formed composition is left static and the time lapse before

the onset of expansion and the time interval of actual

expansion is recorded. The volume of the expanded foam is

measured and the coefficient of expansion is calculated as

the ratio of the volume of the polycyanoacrylate foam to the

volume of the cyanoacrylate monomer in the composition. The

results are shown in Table 1.

-In Table 1, the concentration of initiator is expressed as

percentage by weight based on the total composition.

PCT/GB9]/02121

W0 92/ 09651

..]_2_.

zoflmzmmunw uwuum mmmmmaaoo Em.O.m.«

n mm m m m .

m 3 3 S :3: m.2 Sod TN 32»

ofl oa . .

S S m . _ ..

{ S 3 S . .

om uofi m m >Ho.o Hum wcocmusmtm

0% T . .3 u ,

o :0: N m nHo.o Hum wcmxwnoaomo

3 . T

m 3 mm cos V.» oS.o iv 3:3

V 3 3 m .

.. m :2. w » o~.o.o iv magnum

mm o m wv :0: . wSBEmoHH£u

m P So o iv Lfiouoasu

mg m mm mo . T

mm m om mm .

IIIIIIIIIIIIIIIIl|ll|lllIll||lllll!llli%c o 5 mNo.o Hug mcmucwm

as: an 9.; 0.. .x.:.:. . .

nfimmwou Lcmmwm

gown no msfiu ¢m am no uoumfiu ¢m 0» mama

xnamxm NEH L .9. > Hum no aumnwemumm . uflcfl mo uwuomocmao mo ucwmm

_ u cmuco oa my was 0 mcaamom

A¢m. mucmmm mcflsmou ucmumumfio co vwmmn mcoauamo sou casmom

H magma

W0 92/0965]

10

15

20

25

30

PCI‘/GB91/0212]

_ 13 -

The ratio of ethyl 2-cyanoacrylate monomer to foaming agent

in Table 1 was established to be the best for each pair in

previous experiments. The results indicate that the most

important factor in choosing the foaming agent is its

boiling point and as can be seen the lower the boiling point

the higher is the expansion which can be achieved. The

following major consideration is the polarity and the

solubility parameter of the foaming agent.

produced with non-polar solvents with solubility parameters

pentane,

with

Best results are

at the lower end of the scale, e.g.

1,1,2-trichlorotrifluoroethane.

solubility parameters at the other end of the scale and high

polarity are normally unsuitable due to the formation of

Foaming agents

exceptionally brittle foams. Foaming agents with a

solubility parameter similar to poly(ethyl 2-cyanoacrylate)

and thus being good solvents for the foam, e.g. acetone,

are also unsatisfactory due to immediate shrinkage and

collapse of the foamed material. Solvents in the mid—range

‘of the solubility parameter scale and with boiling point

around 80°C, like cyclohexanone, produce resilient

foams.

Example 2

Experiments according to the procedure described in Example

1 were carried out. Ethyl 2-cyanoacrylate was used as the

cyanoacrylate monomer and 1,1,2—trichlorotrifluoroethane as

Different

initiators were evaluated. The ratio of cyanoacrylate to

1,1,2-trichlorotrifluoroethane and the concentration levels

of the initiators were optimized in previous experiments.

the foaming agent. anionic polymerization

The results are presented in Table 2.

PCT/GB91/02121

W0 92/ 09651

-14-

mcflamcwmasm

mm m mm Hum nHo.o

Awcmawcuwflcwxovuz

, wcflnmmosm

q no mom muv mvoo.o amcmfimaue

mmosm

H H" moo.o mafia

FH ow mm N Hazuwflue

,

ma ofl om Hum T oHo.o mcflcflummflm

m om omv muv mooo o mcfinfluam

N . oHo.o .m:ficfisHo»um

m o o H.¢ -H»numaflo-z.z

0mm 0mm $.u3

ucwmm ma“

cofim nemom oa mama cofiuflmomsou

nzwfloflumwoo uzmmxm mafia nauumocmao mo cw Hm< mo

cofimcmmxm we mafia ummco ofiumu.wEsao> coflpmuucwucoo Hm<

muoumflpflcfl coflpmufluwa do

Uficowcm ucmummuflv CO vwmmp mcoflpfimo ECU cflsmom

N magma

lNIwHONmߣuONcwQ,

W0 92/09651 PCT/GB9] /02121

-15-

The results summarized in Table 2 show that best expansion

coefficients and time of expansion are achieved with N,N—

dimethyl—p—toluidine and N-(oxydiethylene)benzothiazo1e—2—

sulfenamide, the latter having the advantage of no odour.

Piperidine gives slightly longer onset times and is very

smelly. Very slow onset and expansion times can be achieved

with triethylphosphine and triphenylphosphine

Example 3.

Experiments according to the procedure described in Example 1

were carried out. Ethyl 2-cyanoacrylate was used as the cyano-

acrylate monomer. 1,1,2-Trichlorotrifluoroethane was used as

foaming agent. Their ratio was 4:1 by volume. N,N—dimethyl—p—

toluidine was used as initiator in 0.01% by weight of the

composition. The cyanoacrylate monomer was stabilized with

p—toluenesulfonic acid or trifluoromethanesulfonic acid. The

results of the onset time of foaming are presented in Table 3.

WO 92/09651 PCT / GB91 / 02121

-15-

Table 3

Stabilized foaming comgositions

Acid Concentration of acid Onset time

in cyanoacrylate

wt.% sec

p—Toluenesulfonic O 10

_____________________________________________________——_——

p—To1uenesfilfonic 0.0003 j 14

_________________________________________________________

p—Toluenes0lfonic 0.0006 16

_________________________________________________________________

p—To1uenesulfonic 0.0012 200 0

__________________________________________________________

p—To1uenesulfonic 0.002 37

_________________________________________________________

p—To1uenesulfonic 0.005 66

_____________________________________________________________

p-Tolfienesulfonic 7O.0i 195

.___________________________________________________________

Trif1uoro— 0 10

methanesulfonic

____________________________________________________________

Trifluoro—

. 1

methanesulfonic O O01 1

_______________________________________________________

Trifluoro-

methanesulfonic 0'0O2 240

Trifluoro— T O 005 43

methanesulfonic

________________________________________________________

Trifluoro— I O_Ol 117

methanesulfonic

_____________________________________________________________

W0 92/09551 PCT/GB91/02121

-17-

The results presented in Table 3 clearly demonstrate that

the introduction of sulfonic acids, which are often used

commercially to stabilize the cyanoacrylate monomers, can

increase the onset time of foam expansion and by regulating

their level the period between mixing the composition of

the present invention and its expansion into polymer foam

can be controled.

Example 4

Experiments according to the procedure described in Example 1

were carried out. Different types of cyanoacrylate mono-

mers were used. 1,1,2—Trichlorotrifluoroethane was used as

foaming agent. N,N-dimethyl—p—toluidine was used as initia-

tor in amount of 0.01% by weight of the composition. The

expansion coefficient data are shown in Table 4.

wo 92/09651 PC!‘/GB91/02121

-13-

Table 4

Foaming comgositions based on different czanoacrxlate monomers

Volume ratio of Expansion

Cyanoacrylate

cyanoacrylate to coefficient

monomer

foaming agent

__________________________________________________________

Methyl 2—cyanoacry1ate 4:1 13

________________________________________,________________________

4:1 25

Ethyl 2—cyanoaorylate

_____________________________________________________________

Butyl 2—cyanoacry1ate 1:1 29

_____________________________________________________________

iso-Butyl 1:1 _ 35

2—cyanoacrylate

______________________________________________________________

Allyl 2—cyanoacrylate 1:1 20

_____________________________________________________________

2—Methoxyethyl

2—cyanoacrylate

_____________________________________________________________

4:3 20

2—Ethoxyethyl

a 4:3 15

2—cyanoacry1ate

________________________________________________________________

2—Methoxyisopropy1 4_3 23

2-cyanoacrylate '

________________________________________________________________

W0 92/0965]

10

PCT/GB91/02121

-19..

Example 5

Compositions based on various cyanoacrylate monomers and

1,1,2-trichlorotrifluoroethane in a volume ratio of 4:1 and

containing 0.01% by weight N,N-dimethyl-p-toluidine as

initiator were injected into polyethylene tubes with an

internal diameter of 12.5 mm. Seconds after the injection,

the composition expanded into polycyanoacrylate foam which

plugged the tubes. The walls of the tubes were carefully

cut and the foamed material removed. Test pieces of the

foam were cut from it and tested.

physical characteristics of the foams are presented in Table

5.

The results of some

WO 92/09651 PCT / GB9] I 02121

-20-

Table 5

Physical characteristics of Qolycyanoacrylate foams

2—Cyano— Specific Tensile Elonga— Tensile Compression

acrylate gravity strength tion at shear strength at

monomer at break break strength 10% deforma-

at break tion

g/cm3 Kg/Cmz % kg/Cmz kg/cmz

__________________________________________________________

Methyl 0.28 0.8 2.5 ' 0.5 5.7

_________________________________________________________

Ethyl 0.13 10.6 3.7 5.2 . 4.9

________________________________________________________

Butyl 0.25 5.7 6.7 1.8 4.9

iso-Butyl . 0.24 3.2 3.7 3.0 5.7

_______________________________________________________

Allyl 0.18 5.0 3.0 3.0 7.3

________________________________________________________

2‘Meth°"Y‘ 0.41 1.6 2.0 1.9 6.5

ethyl

________________________________________________________________

2-Ethoxy- O 7

ethyl .22 1.6 1. 1.5 5.5

______________________________________________________________

2—Methoxy—

0.28 1.8 2.0 1.7 4.0

isopropyl

W0 92/0965] PCI‘/GB9]/02121

_ 21 -

Example 6

Tubes and pipes made of cast iron, stainless steel, copper,

polycarbonate, polystyrene, polyvinylchloride, polypropylene

5 and polyethylene having inside diameters from 1 mm to 100 mm

were plugged with foam by injecting through a specially

drilled opening a foaming composition consisting of ethyl 2

cyanoacrylate and 1,1,2-trichlorotrifluoroethane in a volume

ratio of 4:1 and containing 0.01% by weight

10 N,N—dimethyl-p-toluidine. The expanded foam created an

efficient plug, whose adhesion to the pipe wall was higher

than the strength of the foam material itself. The pipes

were hermetically sealed by the foam plug and easily

withstood pressure of 10 Atmospheres.

15

In a following operation acetone was injected with a syringe

through the same opening used for injecting the composition,

which subsequently was also plugged with foam. In 5 seconds

-to 2 minutes, depending on the size of the pipe, the foam

20 collapsed and flow through the pipe was restored.

W0 92/09651 PCT / G139] / 02121

-22-

CLAIMS

1,A foam-forming cyanoacrylate composition comprising a

2-cyanoacrylate ester monomer, a liquid foaming agent and a

5 polymerization initiator, for anionic polymerization of the

monomer, which composition upon or after mixing polymerizes

and foams:to produce a polycyanoacrylate foam.

2. A composition as claimed in claim 1, wherein the

10 cyanoacrylate monomer and the liquid foaming agent are in a

volume ratio from 1:10 to 20:1.

3. A composition as claimed in claim 1 or claim 2, wherein

the polymerization initiator is in an amount of from

15 0.00001% to 1% by weight of the composition.

4. A composition as claimed in any one of the preceding

claims, wherein the foaming agent is an organic compound

with a boiling point not higher than 100°C.

20

5. A composition as claimed in claim 4, wherein the foaming

agent is miscible with the cyanoacrylate monomer..

6. A composition as claimed in claim 5, wherein the foaming

25 agent has a solubility parameter below 9 and is nonspolar.

7. A composition as claimed in claim 4, wherein the foaming

agent is pentane, hexane, heptane,

1,l,2-trichlorotriflouroethane,

30 1,1,l—trichlorotrifluoroethane, petroleum. ether, diethyl

ether, cyclopentane, cyclohexane, benzene, . carbon

tetrachloride, chloroform, methylcyclopentane,

dimethylsulfide, 1,l—dichlororethane, 1,1,1-trichloroethane,

fl

WO 92/09651

10

15

20

25

30

PCT/GB91/02121

_ 23 _

perfluorohexane,

mixture thereof.

perfluoroheptane, 1-bromopropane or a a

8. A composition as claimed in claim 7, wherein the foaming

hexane, 1,1,2-trichlorotrifluoroethane,

cyclohexane or diethyl ether or is a

agent is pentane,

petroleum ether,

mixture thereof.

9. A composition as claimed in any 'one of the preceding

claims, wherein the cyanoacrylate monomer comprises one or

more compounds of the formula

wherein R is alkyl, cycloalkyl, alkenyl, cycloalkenyl,

alkynyl, aryl or an aromatic heterocyclic radical or is one

of these moieties substituted with one or more other of the

moieties, and wherein these moieties may optionally be

substituted with alkoxy, carbalkoxyalkyl, halogen or another

inert substituent.

10. A composition as claimed in claim 9, wherein R

contains from 1 to 16 carbon atoms, the heteroatom ring

members of any aromatic heterocycle being counted as a

carbon atom.

11. A composition as claimed in claim 9 or claim 10,

alkyl, halogenated alkyl, cycloalkyl,

cycloalkylalkyl, alkylcycloalkyl, alkenyl, alkynyl, phenyl,

halogenated phenyl, phenylalkyl, halogenated phenylalkyl,

wherein R is

PCI‘ /GB91/02121

WO 92/09651

- 24 -

alkylphenyl, halogenated alkylphenyl, alkylphenylalkyl,

halogenated alkylphenylalkyl, alkoxyalkyl,

alkoxyalkoxyalkyl, carbalkoxymethyl or

isopropylideneglyceryl.

5

10

15

20

25

30

12. A composition as claimed in claim 11, wherein R is

ethyl, n-butyl, iso-butyl, 2-methoxyethyl, 2-ethoxyethyl or

2-methoxyisopropyl.

13. A composition as claimed in any one of the preceding

claims, wherein the initiator is pyridine, aminopyridine,

vinylpyridine, methoxyethylpyridine, piperidine, picoline,

N,Nedimethyl-p—toluidine,

lutidine,

N,Nsdimethyl-o-toluidine, N,N4dimethyl-m-toluidine,

triphenylphosphine, triethylphosphine, tribenzylamine,

triethylamine, benzyldimethylamine, diethylenetriamine,

benzyltriethylamine, tribenzylamine, poly(4-vinylpyridine),

a _ calixarene, p a tertiary amine-S03 complex,

polyethyleneglycol, a phenolformaldehyde resin,

vinylimidazole, triethanolaminatotitanium, an aminosilane,

a phosphite, a metal acetylacetonate, N—(oxydiethylene)

benzothiazole-2-sulfenamide, bismuth

dimethyldithiocarbamate, an alcohol, a base or a hydroxyl or

amine group containing compound.

14. A composition as claimed in claim 13, wherein the

initiator is N,N-dimethyl-p-toluidine or N6(oxydiethylene)

benzothiazole-2-sulfenamide.

15. A composition as claimed in any one of the preceding

claims and which further comprises a free-radical

polymerization inhibitor

or an anionic polymerization-

/A

W0 92/09651 PCI‘/GB91/02121

- 25 -

inhibitor in an amount insufficient to inhibit the

initiator, or both.

16. A composition as claimed in any one of the preceding

5 claims and further comprising another reactive monomer or a

reactive resin or oligomer, a thickener, a viscosity

regulator, a rubber, a plasticizer, a toughener, a

compatibilizer, a thixotropic agent, a colourant, a

deodorant or a mixture thereof. '

10

17; A poly(2-cyanoacrylate ester) foam, the polymer

15 optionally including a minor amount of one or more other

monomer units than 2-cyanoacrylate ester unitsor.a reactive

resin or oligomer.

18. A foam as claimed in claim 17, wherein the

2-cyanoacrylate ester is as defined in any one of claims 9

20 to 12. ’

19. A method of forming a poly(2-cyanoacrylate ester) foam,

comprising formingt a composition as defined in any one of

claims 1 to 16 and allowing the monomer to polymerize and

25 form a foam.

20. A method as claimed in claim 19. wherein the components

of the composition are mixed together in a static mixer or

in a spray.

30

21. A kit or device for forming a poly(2-cyanoacrylate

ester) foam, comprising a first container containing

2-cyanoacrylate ester monomer and a second container

W0 92/0965]

10

15

20

25

30

PCT/GB91/02121

_ 25 -

containing a polymerization initiator for anionic

polymerization, the kit additionally containing a liquid

foaming agent in the first container, in the

d container or in any combination

second

container or in a thir

thereof.

A kit or device as claimed in claim 21 , wherein the

is as defined in any one of claims 9 to 12, the

foaming agent is as defined in any one of claims 4 to 8,

initiator is as defined in claim 13 or claim 14, the monomer

and the foaming agent are in a volume ratio of from 1:10 to

20:1, and/or the polymerization initiator is in an amount of

from 0.00001% to 1% by weight of the total contents of the

ion inhibitor or a free radical polymerization

polymerizat

containers

inhibitor or both, and/or one or more of the

additionally contains one or more of the further components

defined in claim 16.

24. A.kit or device as claflm§iin.any one of claims 21 to

23 Which comprises a two part o£_three‘part syringe. -

25. A kit or device as claimed in any one of claims 21 to

p23 wherein the first and second containers and any third

are connected by ducts to a spray head for mixing

provided to

container

the contents of the containers

of the containers through the ducts to

and means is

expel the contents

the spray head.

W0 92/09651 PCT/GB91/02121

-27-

26.A delivery system for forming a composition as defined

in any one of claims 1 to 16 the system comprising the

monomer and the initiator in separate containers from which

they may be dispensed, the foaming agent being included in

5 said containers and/or in a separate container, and the

system optionally including means to mix the container

contents before or as they are dispensed from the system.

27. A preblend for forming a cyanoacrylate foam, comprising

10 a 2-cyanoacrylate ester monomer and a liquid foaming agent.

28. A preblend as claimed in claim 27, wherein the

cyanoacrylate monomer and the foaming agent are in a volume

ratio of from l:lD to 20:1, the foaming agent is as defined

15 in any one of claims 4 to 8 and/or the cyanoacrylate monomer

is as defined in any one of claims 9 to 12.

29... A preblend as claimed in claim 27 or claim 28 and which

further comprises a free-radical polymerization inhibitor,

20 an anionic polymerization inhibitor or both, and/or one or

more further components as defined in claim 16.

30. A method of blocking a pipe, comprising placing in the

pipe a composition as defined in any one of claims 1 to 16

25 and allowing the composition to polymerize to form a foam

which blocks the pipe.

31. A method as claimed in claim 30, wherein the pipe is

blocked temporarily and is subsequently unblocked by

30 applying to the foam a solvent therefor.

WO 92/09651

10

15

20

25

PCT /GB91/02121

-28..

32. A.method of forming a cast, for example for a broken or

injured limb, comprising applying a composition as defined

in, any one of claims 1 to 16 to the limb or other body

around which the cast is to be formed and allowing the

composition to polymerize and foam to fcrm.a cast.

33. A method of occluding or stopping a blood vessel,

fallopian.tube or other tubular part or a; human or animal

body, comprising applying to the tubular part a composition

as defined in any one of claims 1 to 16 and allowing the

composition to polymerize to form a foam occluding to

stopping the tubular part.

34. The use of 2-cyanoacrylate ester monomer as a starting

material to form a polyoyanoacrylate foam.

35. The. use of claim 34, wherein the monomer is as defined

in any one of claims 9 to 12.

36. The use of an organic liquid with a boiling point of no

than. 100°C as a foaming agent. to form a

polycyanoacrylate foam.

greater

37. The use of claim 36, wherein the organic liquid is as

further defined in any one of claims 6 to 8.

38. A composition as defined in any one of claims 1

to 16 for use in the treatment of the human or’

animal body by surgery or therapy.

39. A method of forming a polymer foam on or aroundjapart

of the human or animal body, comprising applying a

composition as defined in any one of claims l to 16

on'or around the part.

INTERNATIONAL SEARCH REPORT

Intemational Appliution No PCT/GB 91 /0 2 1 21

I. CLASSIFICATION OF SUBJECT MATTER (if several classification symbols apply, indicate all)“

According to International Patent Classification (IPC) or to both National Classification and IPC

Int.Cl.5 C 08 J 9/14 // A 61 L 15/12 C 08 L 35:04

II. FIELDS SEARCHED

Minimum Documentation Searcbed7

Classification System Classification Symbols

Int.Cl.5 C 08 J A 61 L

Documentation Searched other than Minimum Documentation

to the Extent that such Documents are Included in the Fields Searched‘

Ill. DOCUMENTS CONSIDERED TO BE RELEVANT9

Citation of Document, " with indication, where appropriate, of the relevant passages 12 Relevant to Claim No.”

X,P

Chemical Abstracts, vol. 115, no. 6, 12 August

1991, (Columbus, Ohio, US), see abstract no.

51548k, & JP,A,3091542 (TORAY INDUSTRIES) 17

April 1991, see abstract

DE,A,3421360 (REICH SPEZIALMASCHINEN

GmbH) 12 December 1985, see claims 1-3

FR,A,2359170 (POLYMERICS INC.) 17

February 1978, see claims 1-2

FR,A,2610828 (MOSKOVSKY

GOSUDARSTVENNY MEDITSINSKY INSTITUT) 19 August

1988, see claims 1-3

_.._ ../_

later document published after the intemational filing date

° Special categories of cited documents : ‘O

or priority date and not in conflict with the application but

, ,, d . . . . _ _ V _

A £:::1‘:;‘e'ddg'L';“§f';':rfi:'l:::lr::::;:’£e‘he 3" "h'°h '5 “°‘ ttiiinpnderstand the principle or theory underlying the

‘Qt: gfigligrdgttfument but published on or after the intemational rxu document of pafiicular relevanoe; the chimedjnvemon

'L" document which may throw doubts on priority claim(s) or 3:33:32 2: ‘i§3§i§1?5§ds§'e'LV°' or “mm be considered ‘O

which is cited to establish the publication date of another IYR documem of - . - - -

. . . . . particular relevance, the claimed invention

°'m'°" °' °"'°"_5p°°'a' "Q50" (35 specmed) cannot be considered to involve an inventive step when the

‘'0'’ document referring to an oral disclosure, use, exhibition or document is combined with one or more other such docu-

other means ments, such combination being obvious to a person skilled

"P" document published prior to the international filing date -but "' ‘he 3"‘

later than the priority date claimed "'&” document member of the same patent family

IV. CERTIFICATION

Date of the Actual Completion of the International Search

06-03-1992

International Searching Authority

EUROPEAN PATENT OFFICE

Date of Mailing of this International Search Report

0 9. 0.4. 92

Signature of Authorize! Officer ,

/’

1 u.:=zz.-1. 1'0?-

Coments go here:

- Log in to post comments