����������������������������������������WORLD INTELLECTUAL PROPETY ORGANIZATION

. Intemational Bureau

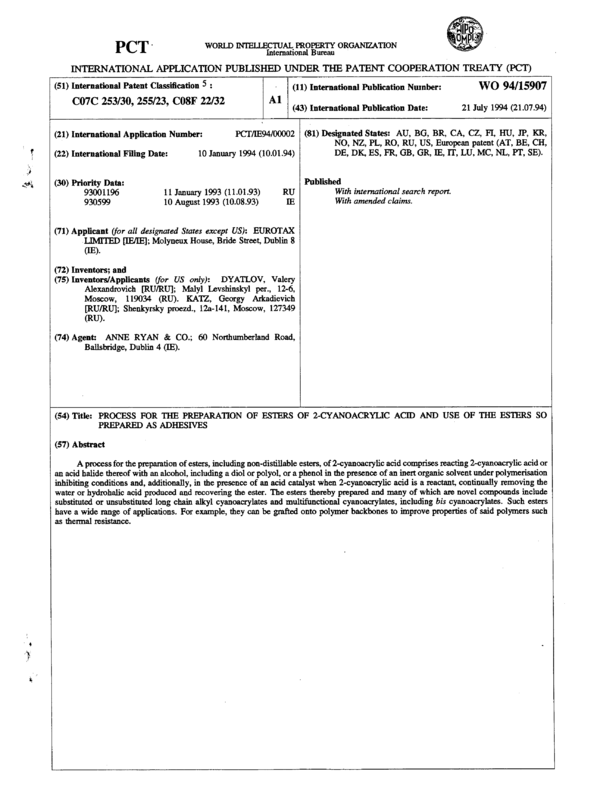

INTERNATIONAL APPLICATION PUBLISHED UNDER THE PATENT COOPERATION TREATY (PC'I')

WO 94/15907

21 July 1994 (2l.07.94)

(51) International Patent Classification 5 :

C07C 253/30, 255/23, C08F 22/32

(11) International Publication Number:

(43) International Publication Date:

PCI‘/[E94/00002 (81) Designated States: AU, BG, BR, CA, CZ, FI, I-IU, JP, KR,

NO, NZ, PL, RO, RU, US, European patent (AT, BE, CH,

DE, DK, ES, FR, GB, GR, IE, IT, LU, MC, NL, PT, SE).

(21) International Application Number:

(22) International Filing Date: 10 January 1994 (10.0l.94)

Published

With imernational search report.

With amended claims.

(30) Priority Data:

93001196

930599

11 January 1993 (1101.93) RU

10 August 1993 (10.08.93) IE

(71) Applicant (for all designated States except US): EUROTAX

LIMITED [IE/IE]; Molyneux House, Bride Street, Dublin 8

(IE)-

(72) Inventors; and

(75) Inventors/Applicants (for US only): DYATIDV, Valery

Alexandrovich [RU/RU]; Malyl Levshinskyl per., 12-6,

Moscow, 119034 (RU). KA'I'Z, Georgy Arkadievich

[RU/RU]; Shenkyrsky proezd., 12a-141, Moscow, 127349

(RU).

(74) Agent: ANNE RYAN & CO.; 60 Northumberland Road,

Ballsbridge, Dublin 4 (IE).

(54) Title: PROCESS FOR THE PREPARATION OF ESTERS OF 2-CYANOACRYLIC ACID AND USE OF THE ESTERS SO

PREPARED AS ADHESIVES

(57) Abstract

A process for the preparation of esters, including non-distillable esters, of 2-cyanoacrylic acid comprises reacting 2-cyanoacrylic acid or

an acid halide thereof with an alcohol, including a diol or polyol, or a phenol in the presence of an inert organic solvent under polymerisation

inhibiting conditions and, additionally, in the presence of an acid catalyst when 2-cyanoacrylic acid is a reactant, continually removing the

water or hydrohalic acid produced and recovering the ester. The esters thereby prepared and many of which are novel compounds include

substituted or unsubstituted long chain alkyl cyanoacrylates and multifunctional cyanoacrylates, including bis cyanoacrylates. Such esters

have a wide range of applications. For example, they can be grafted onto polymer backbones to improve properties of said polymers such

as thermal resistance.

FOR THE PURPOSES OF INFORMATION ONLY

Codes used to identify States party to the PCI‘ on the front pages of pamphlets publishing international

applications under the PCI‘.

AT Austria

AU Australia

Barbados

Belgium

Burkina Faso

Bulgaria

Benin

Brazil

Belarus

Canada

Central African Republic

Congo

Switzerland

Cote d'Ivoire

United lfingdom

Georgia

Guinea

Portugal

Romania

Russian Fedaation

Demoaatic People's Republic Sudan

of Korea Swedm

Republic of Korea Slovenia

Kazakhstan _ Slovakia

Liechtenstein Senegal

Sri Lanka Chad

Luxembourg Togo

Latvia Tajikistan

Monaco Trinidad and Tobago

Republic of Moldova Ukraine

United States of America

Uzbekistan

Viet Nam

GB

GE

GN

GR

HU

IE

IT

JP

KE

KG

KP

KR

KZ

LI

LK

LU

LV

MC

MD

MG

ML

MN

9:'ri-'-WEEESQQQQE

W0 94/ 15907 _ PCT/IE94/00002

Description

Process for the preparation of esters of 2-cyanoacrylic acid and use of the

esters so prepared as adhesives

Technical Field

5 This invention relates to a process for the preparation of esters

of 2-cyanoacrylic acid, including long chain esters, and the use of the

esters so prepared. Many of these esters are novel compounds.

Background Art

Cyanoacrylate esters are the main constituent of instant or rapid

10 bonding adhesives, commonly known as 'superglues'. Bonding in the

case of such adhesives results from the conversion of a low viscosity

liquid to a solid polymer by anionic polymerisation. Cyanoacrylate

esters are also used for the manufacture of polyalkylcyanoacrylate

nanoparticles and nanocapsules used as drug and other active agent

15 carrier systems.

Until now, the only commercial route for the preparation of

Cyanoacrylate esters was the Knoevenagel Condensation Method (H.

Lee. (Ed.) (1981) Cyanoacrylic Resins - The Instant Adhesives,

_. Pasadena Technology Press, Pasadena, U.S.A.). According to the

20 Knoevenagel method a cyanoacetate ester and formaldehyde are reacted

together in the presence of an amine to give oligomers of

polyalkylcyanoacrylates. The free Cyanoacrylate monomer is generated

by thermally cracking the oligomer under vacuum and distilling onto

anionic acid stabiliser under vacuum. Following the distillation step, a

25 free radical stabiliser, such as methylhydroquinone, may be added to

inhibit free radical polymerisation during storage. Free radical

polymerisation can be initiated, for example, by exposure to light.

The Knoevenagel method is limited to the preparation of alkyl

cyanoacrylates which have an alkyl moiety with no more than ten

W0 94/ 15907

10

15

20

25

30

PCT/IE94/00002

carbon atoms. Above ten carbon atoms, the monomers cease to be

distillable at temperatures below their respective thermal destruction

temperatures. In fact, n—octyl cyanoacrylate is the monomer with the

greatest number of carbon atoms that has been reported in the

literature to have been prepared by the Knoevenagel method and has

been used in the preparation of a medical adhesive (Kublin, K.S. and

Miguel, F.M., (1970) J. Amer. Vet. Med. Ass. Vol. 156, No. 3, p.313-

8 and Alco, J .J . and DeRenzis, F.A., (1971) J. Pharmacol. Ther. Dent.

Vol. 1, No. 3, p.129-32).

Short chain (less than ten carbon atoms) alkyl cyanoacrylates

with polar groups such as hydroxyl, carboxyl and ester groups and aryl

cyanoacrylates cannot generally be prepared by the Knoevenagel

Condensation Method because of their high boiling points.

Additionally, multifunctional cyanoacrylates, such as bis

cyanoacrylates, cannot be synthesised because they are non—disti1lable

below their thermal destruction temperatures.

A method for the preparation of bis cyanoacrylates, which are

indicated to be useful as thermally and moisture resistant acrylate

additives are the subject of U.S. Patent No. 3,903,055. The method can

involve essentially three or five steps. In the five-step method, ethyl or

isobutyl cyanoacrylate is reacted with anthracene to form its stable

Diels-Alder anthracene adduct. Basic hydrolysis of the adduct gives the

corresponding acid salt from which the corresponding acid is obtained

upon acidification. The carboxylic acid is then converted to its acid

chloride with thionyl chloride and then reacted with diol to give the bis

anthracene diester. Displacement of the adduct by the stronger

dienophile maleic anhydride gives bis cyanoacrylates in good yield.

However, this mu1ti—step method is purely a laboratory method and

scaling up to a commercially viable level has not proved practicable.

To date, the method of U.S. Patent No. 3,903,055 supra has

remained the only feasible. method of producing bis, multifunctional or

long chain non-distillable cyanoacrylates.

WO 94/15907

10

15

20

25

30

PCT/IE94/00002

L Patent Publication DE 34 15 181 Al describes the preparation

for the first time of on-cyanoacrylic acid which can be considered as the

obvious precursor for alkylcyanoacrylates. The cyanoacrylic acid is

prepared from a cyanoacrylic acid alkyl ester, in which the alkyl group

contains from 2-18 carbon atoms, or the Diels-Alder adduct thereof by

pyrolysis. The pyrolysis is preferably carried out on silicate-type

surfaces such as quartz surfaces. The cyanoacrylic acid so prepared is

indicated to be useful for stabilising or regulating the curing time of

adhesives based on monomeric cyanoacrylic acid esters. It is also

indicated that the cyanoacrylic acid so prepared can be used to prepare

the diol esters of the acid. However, there is no indication in the

specification as to how this can be accomplished.

Patent Publication JP 91 065340 describes a versatile route to

pyruvic acid cyanohydrin and its esters as intermediates for the

preparation of ot-cyanoacrylate esters.

Patent Publication JP 91 075538 describes ot-acetoxy-ot-

cyanopropionic acid esters which can be thermally converted to

cyanoacrylate esters by elimination of a molecule of acetic acid.

Kandror I.I. et al. ((1990) Zh. Obsch. Khemii., Vol. 60, No. 9,

p.2l60-8) successfully converted ot-cyanoacrylic acid (prepared

according to Patent Publication DE 34 15 181 A1) to its acid chloride

by the use of phosphorus pentachloride. Other chlorinating agents,

such as thionyl chloride, were found not to be suitable. The product

was obtained as a solution in o-xylene/toluene. Any attempts to isolate

the pure product resulted in its decomposition. However, Kandror er

al. successfully converted the acid chloride in solution to its thioester

which spontaneously polymerised upon isolation. Kandror et al. have

also successfully converted ot-cyanoacrylic acid to its very unstable

trialkylsilyl esters.

To date there have been no reports in the literature concerning

the conversion of cyanoacrylic acid or its chloride to its alkyl ester

monomers, whether short chain, long chain, bis or multifunctional

W0 94/ 15907

10

15

20

25

30

PCT/IE94/00002

cyanoacrylates, more particularly by a method which can be canied

out on a commercial scale.

The preparation of a long chain cyanoacrylate (a thioester) by

the strictly laboratory method of U.S. Patent No. 3,903,055 supra was

synthesised by S.J. Harris ((1981) J. Polym. Sci. Polym. Chem. Ed.

Vol. 19, No. 10, p.2655-6). The n-dodecylthio cyanoacrylate so

prepared conferred improved moisture resistance when used as an

additive in an ethyl cyanoacrylate adhesive.

Cyanoacrylate adhesive monomers, such as the most commonly

used ethyl ester, can have their physical properties improved by the

addition of linear organic polymers. Thus, non-reactive rubbers can be

dissolved in such monomers to give adhesive compositions with much

improved toughness/impact resistance when cured in the final adhesive

bond. However, to date improvement in thermal/moisture resistance of

rapid bonding cyanoacrylates has only been modest.

An improvement in adhesion, as well as toughness, would be

expected if the non-reactive rubbers additionally contained chemically

bound multi-cyanoacrylate functionality. Furthermore, it would be

expected that any resulting increased cross-linked density could well

provide significantly improved thermal moisture resistance to the final

cyanoacrylate bond, relative to that of compositions containing only

non-reactive rubbers.

J .P. Kennedy et al. ((1990) Am. Chem. Soc. Div. Polym. Chem.

31(2) p.255-6) prepared a cyanoacrylate-capped polyisobutylene by

esterification of a hydroxy—terrninated polyisobutylene. The method of

U.S. Patent No. 3,903,055 supra was used to generate a multifunctional

cyanoacrylate ester monomer which can be used as a glue which

resulted in a copolymer being formed. Such copolymers have desirable

properties for the reasons stated in the preceding paragraph. However,

such multifunctional cyanoacrylate monomers cannot be used as

improving additives because of their insolubility in cyanoacrylates.

W0 94/15907

10

15

20

25

PCT/[E94/00002

Linear polymers such as poly(methyl methacrylate) are used as

thickeners for cyanoacrylate monomers, so that the viscosity of the

adhesive can be increased to a desirable level for a particular

application. The use of cyanoacrylate-capped poly(alky1 methacrylates)

as reactive thickeners would be expected to provide improved

thermal/moisture resistance to the final joint and also improve the gap-

filling ability of the adhesive.

Accordingly, for the above reasons, a method for generating

cyanoacrylate esters on a practical and commercial scale is sought.

Disclosure of Invention

The invention provides a process for the preparation of esters of

2—cyanoacrylic acid, which process comprises reacting 2—cyanoacrylic

acid or an acid halide thereof with an alcohol or a phenol in the

presence of an inert organic solvent under polymerisation inhibiting

conditions and, additionally, in the presence of an acid catalyst when 2-

cyanoacrylic acid is a reactant, continually removing the water or

hydrohalic acid produced and recovering the ester.

The process according to the invention can be used to prepare a

wide range of cyanoacrylate esters, including substituted or

unsubstituted long chain alkyl cyanoacrylates and multifunctional

cyanoacrylates, including bis cyanoacrylates.

The process according to the invention can be carried out in a

simple, rapid and facile, effectively one step process with the attendant

advantages. Thus, the process according to the invention is a ‘one pot‘

process in contrast with the prior art methods described above with

their inherent limitations.

The term alcohol as used herein includes diols and polyols.

The preferred acid halide is the acid chloride.

W0 94/ 15907 . PCT/IE94/00002

The following reaction scheme depicts the reactions involving a)

the acid and b) the acid chloride.

CNO CNO

II

a) CH =C—C——OH + ROH ———> CH =C—C—OR +H2O

CNO CNO

II

b) CH=C—C—Cl + ROH ———» cH=c—c—oR +HCl

5 When 2—cyanoacry1ic acid is used as a reactant, the acid catalyst

is a non-volatile acid stabiliser.

Preferably, the acid catalyst is an anionic non-volatile acid

stabiliser such as, for example, an aliphatic sulphonic acid, an aromatic

sulphonic acid or a sultone. An essential characteristic of the acid

10 catalyst is that it does not react with the alcohol or phenol. Especially

suitable acid catalysts are methane sulphonic acid and p-toluene

sulphonic acid.

Preferably, the process is carried out under anionic

polymerisation inhibiting conditions. Such anionic polymerisation

15 inhibiting conditions can involve the use of an excess of 2—cyanoacry1ic

acid, where cyanoacrylic acid is a reactant.

Alternatively, the anionic polymerisation inhibiting conditions

can involve the use of a weak acid.

An especially suitable weak acid is sulphur dioxide, more

20 especially gaseous sulphur dioxide which is bubbled into the reaction

mixture, as further demonstrated below.

Further, preferably, when sulphur dioxide is used as an anionic

polymerisation inhibitor, gaseous sulphur dioxide is bubbled into the

reaction mixture as a continuous stream of sulphur dioxide.

W0 94/ 15907

10

15

20

25

PCT/IE94/00002

Other anionic polymerisation inhibitors include aliphatic

sulphonic acids, aromatic sulphonic acids, sultones, carbon dioxide and

boron trifluoride.

Further, preferably, the process is carried out in the presence of

a free radical polymerisation inhibitor.

A suitable free radical polymerisation inhibitor is benzoquinone,

hydroquinone, methylhydroquinone or naphthoquinone.

The inert organic solvent can be any inert solvent which does not

cause anionic polymerisation of cyanoacrylic acid or its esters. Suitable

inert solvents include benzene, hexane, toluene, xylene and chlorinated

hydrocarbons.

In the case of acid - catalysed esterification nitroalkanes can be

used.

The process according to the invention can be carried out at a

temperature in the range 20-200°C, more especially 80-100°C.

When 2-cyanoacrylic acid is a starting compound, the

esterification reaction is carried out under the conditions hereinabove

specified with continual removal of water by azeotropic distillation.

Preferably, the total volume of the reaction solvent is kept

constant.

Also preferably there is a gradual addition of alcohol or phenol

into the reaction mixture.

When secondary alcohols or phenols are being esterified in

accordance with the invention, irrespective of whether 2-cyanoacrylic

acid or an acid halide thereof is used, the reaction should preferably be

carried out in the presence of sulphur dioxide to optimize conditions,

because of the tendency of the cyanoacrylate monomers produced to

polymerise under the reaction conditions.

W0 94/ 15907

10

15

20

25

PCT/IE94/00002

When a cyanoacryolyl halide is a starting compound, an acid

catalyst is not required as indicated above. In one embodiment the

method of Kandror, I.I. (1990) supra can be used so that the

cyanoacryolyl halide is reacted with the alcohol or phenol in sulphur

dioxide saturated solvent under a dry inert gas such as argon. Other

suitable inert gases include xenon, helium and nitrogen. The alcohol or

phenol is added to the acid halide solution in sulphur dioxide - saturated

solvent and the hydrohalic acid is removed as solvent is distilled off

preferably under a stream of sulphur dioxide and argon.

As an alternative to sulphur dioxide in the above embodiment,

there can be used boron trifluoride.

In each case, the removal of water or hydrohalic acid, as

appropriate, forces the reaction to go to completion, more particularly

under boiling solvent conditions and stirring.

The invention also provides a novel method for the preparation

of 2-cyanoacryloyl chloride, which comprises reacting 2—cyanoacrylic

acid with phosphorus trichloride.

Many of the esters which can be prepared by the process

according to the invention are novel compounds. Thus, in a further

aspect of the invention there is provided esters of 2—cyanoacrylic acid

of the general formula I:

CN

/ O

v \.

ll

HZC = (I)

wherein R is i) C11 or C13 or higher saturated, optionally mono-

or polysubstituted, linear-, branched- or cyc1o—a1kyl;

ii) C7—C1g saturated, optionally mono- or

polysubstituted, branched alkyl;

W0 94/ 15907

10

15

20

25

PCT/IE94/00002

iii) C7—C10, optionally mono- or polysubstituted,

cycloalkyl;

iv) C12 saturated, optionally mono- or polysubstituted,

branched- or cyclo-alkyl;

v) C5 or higher unsaturated, substituted or

unsubstituted, linear-, branched- or cyc1o—alkenyl or -

alkynyl;

vi) C2-C1; substituted alkyl where the or each

substituent is a functional group which is not a free

hydroxyl group, a hydroxyl group esterified by 2-

cyanoacrylic acid, or an ether group;

vii) C2—C1_9_ substituted alkyl where the alkyl group is

substituted by more than one ether group;

viii) C13 or higher substituted alkyl where the or each

substituent is a functional group;

ix) C3 or higher substituted alkyl where the or each

substituent is a hydroxyl group;

x) C5 or higher substituted alkyl where the or each

substituent is a simple or compound ether group;

xi) a mono- or polysubstituted phenyl group;

xii) a mono- or polysubstituted biphenyl, naphthyl,

anthracyl, phenanthryl or other cyclic or polycyclic

aromatic or heteroaromatic group; or

xiii) a hydroxy-terminated or a hydroxy-substituted

oligomer or polymer.

Substituents can include heteroelements.

It will be appreciated that the main chain of any ester herein

described can contain a heteroelement or ether function.

Functional groups which are representative of those which would

30 normally be used to substitute an R group as hereinabove defined

include, for example, halogen, carboxyl, nitrile, acyl-amino,

unsaturated and heteroelement-containing groups.

W0 94/ 15907

10

15

20

25

30

PCT/IE94/040002

1 O

In a still further aspect of the invention there is provided the

mono— or bis(2-cyanoacrylate) esters of di—, tri-, tetra-, penta-, hexa-

and poly-ethylene glycols or derivatives thereof.

As indicated above, the process according to the invention can be

used to prepare previously unobtainable, non-distillable cyanoacrylate

monomers for a wide variety of uses. Cyanoacrylates prepared in

accordance with the invention can be grafted onto polymer backbones

to improve properties of said polymers such as thermal resistance. For

example, aryl cyanoacrylates prepared in accordance with the invention

would inherently be expected to give more thermally resistant bonds on

account of their aromaticity and would also be expected to be low

viscosity monomers similar to the methyl - and ethyl esters. As

indicated above, to date improvement in thermal resistance of rapid

bonding cyanoacrylates has been only modest. For example, the

monomers can be prepared with a high number of ether linkages or

multifunctional hydroxyl groups for the preparation of biodegradable

drug or other active agent—containing nanocapsules or nanoparticles,

more especially nanocapsules. Furthermore, drugs and other active

agents can be chemically bound to such cyanoacrylates so as to achieve

controlled release/absorption of the active agents with time.

Other uses for the cyanoacrylate monomers prepared in

accordance with the invention include use in the preparation of a wide

range of adhesives, including rapidly biodegradable medical adhesives

or adhesives for temporary bonding.

Further specific examples of the uses of the cyanoacrylate esters

prepared in accordance with the invention are indicated below.

U.S. Patent No. 3,903,055, supra describes bis cyanoacrylates as

thermally resistant cyanoacrylate additives which are prepared from '

their respective anthracene adducts by displacement with maleic

anhydride. However, as indicated above the bis cyanoacrylates so

prepared are difficult to purify by this method.

W0 94/ 15907 _ PCT/IE94/00002

11

The process according to the invention is versatile and can be

used to produce a wide variety of bis cyanoacrylates according to the

following general reaction scheme, wherein "R" can have a multiplicity

of values as hereinabove described: -

CH H CN CN H

/ \ / \ /

HZC : C :—--> C 3 C C 3 C

\ / \ / \

CO2H H EOROEIS H

5 o o

In the same way tri and tetrafunctional cyanoacrylates can be

prepared in accordance with the invention, for example from

pentaerythritol

O

C\

C = CH

/ 2

CN

4

10 The quantities of tetrafunctional additive needed to provide

significant improvements in cross—1ink density for thermal resistance

improvement would be less than for bis cyanoacrylates. Polyfunctional

cyanoacrylates can be readily synthesised in accordance with the

invention from polyvinylalcohol as follows:

(C|IH— CH2)n

(CH— CH2)n OH

O +

I H CN

C\= O ‘T \C 2 C /

/C -7- CH2 H/ \ CO2H

15 CN'

W0 94/ 15907

10

15

PCT/IE94/00002

12

It is also postulated that further improvement can be rendered by

attachment of cyanoacrylate units to a thermally resistant backbone

containing OH functionality in the following manner:

0 o

n /u\

H/ _ \ R_1\I/\R'—R—R' N-R

COZH \/ I \/

J) O=