��������������������

WORLD INTELLECTUAL_ PROPERTY ORGANIZATION

International Bureau

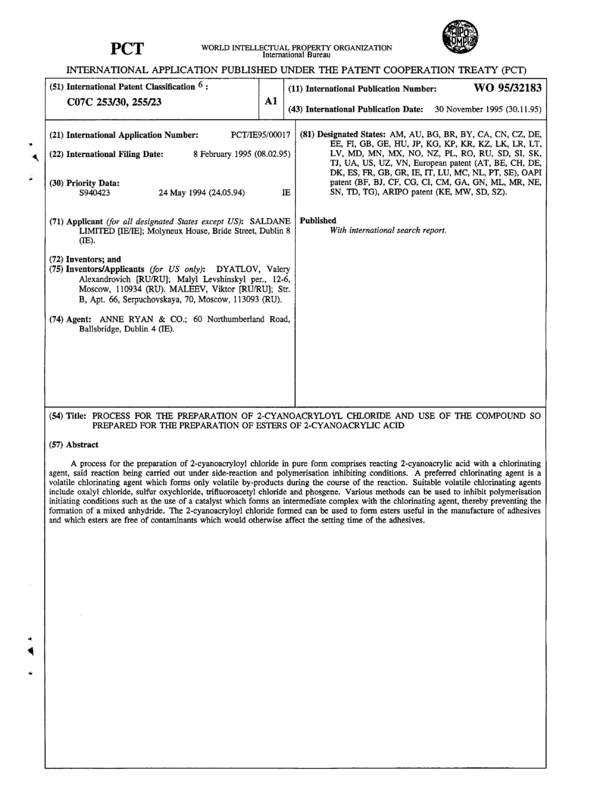

INTERNATIONAL APPLICATION PUBLISHED UNDER THE PATENT COOPERATION TREATY (PCT)

(51) IIlte1'H3ti0l131 Patent C13-9SifiC3ti0n 6 3 (11) International Publication Number: WO 95/32183

C07C 253/30, 255/23 _ , ,

(43) International Publlcatlon Date: 30 November 1995 (30.11.95)

(21) International Application Number: PCT/IE95/00017 (81) Designated States: AM, AU, BG, BR, BY, CA, CN, CZ, DE,

EE, FI, GB, GE, HU, JP, KG, KP, KR, KZ, LK, LR, LT,

(22) International Filing Date: 8 February 1995 (08.02.95) LV, MD, MN, MX, NO, NZ, PL, RO, RU, SD, SI, SK,

TJ, UA, US, UZ, VN, European patent (AT, BE, CH, DE,

DK, ES, FR, GB, GR, IE, IT, LU, MC, NL, PT, SE), OAPI

(30) Priority Data: patent (BF, BJ, CF, CG, CI, CM, GA, GN, ML, MR, NE,

S940423 24 May 1994 (24.05.94) IE SN, TD, TG), ARIPO patent (KE, MW, SD, SZ).

(71) Applicant (for all designated States except US): SALDANE Published

LIMITED [IHIE]; Molyneux House, Bride Street, Dublin 8 With international search report.

(IE).

(72) Inventors; and

(75) InventorslApplicants (for US only): DYATLOV, Valery

Alexandrovich [RU/RU]; Malyl Levshinskyl per., 12-6,

Moscow, 110934 (RU). MALEEV, Viktor [RU/RU]; Str.

B, Apt. 66, Serpuchovskaya, 70, Moscow, 113093 (RU).

(74) Agent: ANNE RYAN & CO.; 60 Northumberland Road,

Ballsbridge, Dublin 4 (IE).

(54) Title: PROCESS FOR THE PREPARATION OF 2—CYANOACRYLOYL CHLORIDE AND USE OF THE COMPOUND SO

PREPARED FOR THE PREPARATION OF ESTERS OF 2-CYANOACRYLIC ACID

(57) Abstract

A process for the preparation of 2-cyanoacryloyl chloride in pure form comprises reacting 2-cyanoacrylic acid with a chlorinating

agent, said reaction being carried out under side-reaction and polymerisation inhibiting conditions. A preferred chlorinating agent is a

volatile chlorinating agent which forms only volatile by-products during the course of the reaction. Suitable volatile chlorinating agents

include oxalyl chloride, sulfur oxychloride, trifluoroacetyl chloride and phosgene. Various methods can be used to inhibit polymerisation

initiating conditions such as the use of a catalyst which forms an intermediate complex with the chlorinating agent, thereby preventing the

formation of a mixed anhydride. The 2-cyanoacryloyl chloride formed can be used to form esters useful in the manufacture of adhesives

and which esters are free of contaminants which would otherwise affect the setting time of the adhesives.

AT

AU

BB

BE

BF

BG

BJ

BR

BY

CA

CF

CG

CH

CI

CM

CN

CS

CZ

DE

DK

ES

FI

FR

GA

FOR THE PURPOSES OF INFORMATION ONLY

Codes used to identify States party to the PCT on the front pages of pamphlets publishing intemational

applications under the PCT.

Austria

Australia

Barbados

Belgium

Burkina Faso

Bulgaria

Benin

Brazil

Belarus

Canada

Central African Republic

Congo

Switzerland

Cote d’Ivoire

Cameroon

China

Czechoslovakia

Czech Republic

Germany

Denmark

Spain

Finland

France

Gabon

United Kingdom

Georgia

Guinea

Greece

Hungary

Ireland

Italy

Japan

Kenya

Kyrgystan

Democratic People's Republic

of Korea

Republic of Korea

Kazakhstan

Liechtenstein

Sri Lanka

Luxembourg

Latvia

Monaco

Republic of Moldova

Madagascar

Mali

Mongolia

Mauritania

Malawi

Niger

Netherlands

Norway

New Zealand

Poland

Portugal

Romania

Russian Federation

Sudan

Sweden

Slovenia

Slovakia

Senegal

Chad

Togo

Tajikistan

Trinidad and Tobago

Uldaine

United States of America

Uzbekistan

Viet Nam

I

WO 95/32183

10

15

20

25

PCT/IE95/00017

Description

Process for the preparation of 2-cyanoacryloyl chloride and

use of the compound so prepared for the preparation of esters

of 2-cyanoacrylic acid

Technical Field

This invention relates to a process for the preparation of 2-

cyanoacryloyl chloride and to the use thereof in the preparation of

esters of 2-cyanoacrylic acid. 2-Cyanoacryloyl chloride which has

the formula:

CN

/

H2C=' C

\

0- Cl

ll

0

can potentially be used to prepare a wide range of cyanoacrylate

monomers.

Background Art

The ability of 2-cyanoacrylates to polymerise rapidly under the

influence of moisture or nucleophilic substances has led to their

exploitation as instantaneous adhesives. However, the inherent ability '

of 2-cyanoacrylates to undergo rapid anionic polymerisation gives

rise to complications as regards the synthesis of free 2-cyanoacryloyl

chloride. Accordingly, whereas esters of 2-cyanoacrylic acid are

known and well characterised since the 1940s, 2-cyanoacryloyl

chloride has not been isolated and characterised. 2-Cyanoacryloyl

chloride has been observed in solution only. The first reported

observation of 2-cyanoacryloyl chloride in solution by NMR was

described in 1990 by Kandror, I.I. et al. However, all efforts to

isolate 2-cyanoacryloyl chloride from solution were unsuccessful.

WO 95/32183

10

15

20

25

30

PCT/IE95/000 17

Kandror, I.l. et al. ((1990) Zh. Obsch. Khemii., Vol. 60, No.

9, p. 2160-8) have described two methods for the preparation of 2-

cyanoacryloyl chloride—containing solutions.

The first method involved the reaction of 2-cyanoacrylic acid

with phosphorus pentachloride at a temperature of 110°C using a

toluene—xylene mixture as a solvent, followed by distillation off of

phosphorus oxychloride and a portion of the solvent. The resulting

solution contained a mixture of 2—cyanoacryloyl chloride,

polyphosphoric acid and polymers formed from 2-cyanoacrylic acid

in the form of a solution in xylene. Conversion of 2-cyanoacrylic

acid to 2—cyanoacryloyl chloride together with polymer was reported

by NMR to be 95-99%, the yield of 2-cyanoacryloyl chloride was not

estimated. 13C and 31P NMR analysis of 2—cyanoacryloyl chloride

prepared by this method shows that deleterious by—products which

are formed include those resulting from chlorination of, and addition

of hydrogen chloride to, the olefinic bond of cyanoacryloyl chloride,

and from the addition of phosphorus oxychloride to its nitrile group

to yield substances containing the -C(Cl)=N-P(O)Cl;;_ function. 2-

Cyanoacryloyl chloride obtained by this method cannot be isolated

from the mixture and polymerises spontaneously once the solvent is

distilled off in vacuo. Vacuum distillation or precipitation of the

product with an inert solvent also leads to instantaneous

polymerisation.

The second method involved the reaction of 2-cyanoacrylic

acid with thionyl chloride in toluene or toluene—xylene solution at a

temperature of 110°C followed by distillation off of hydrochloric

acid, sulfur dioxide and a portion of the solvent to give a mixture of

2—cyanoacryloyl chloride, 2-cyanoacrylic acid and polymers formed

from 2-cyanoacrylic acid in the form of a solution in xylene. No

yield or conversion has been estimated. NMR analysis shows that the

product of the reaction is a solution of a mixture of 2—cyanoacryloyl

chloride and 2-cyanoacrylic acid in a ratio of 65:35, together with

mixed anhydride by-products resulting from the side and

polymerisation reactions. Attempts to complete the reaction and

WO 95/32183

10

15

20

25

30

PCT/IE95/00017

convert residual 2-cyanoacrylic acid and mixed anhydrides into 2-

cyanoacryloyl chloride resulted in polymerisation of the mixed

anhydrides, 2-cyanoacryloyl chloride and 2-cyanoacrylic acid. The

2—cyanoacryloyl chloride could not be isolated in pure form from the

reaction mixture using this method and the yield could not be 5

estimated. However, according to NMR data, the yield is less than

65% and it appears that a significant amount of polymeric and side

reaction products were not taken into account.

Thus, pure 2-cyanoacryloyl chloride was not obtained and

chemically characterised in accordance with either of the two

methods described above. In the case of each method, 2-

cyanoacryloyl chloride can only be obtained in the form of a solution

contaminated with non-volatile by—products.

2-Cyanoacryloyl chloride is used as a starting material for

obtaining esters of 2-cyanoacrylic acid. Because of the contamination

of the 2-cyanoacryloyl chloride referred to above this necessitates

that any resulting ester be purified to remove the contaminants

formed during 2-cyanoacryloyl chloride production. If such

contaminants, which are generally of an acidic nature, are not

removed, these can affect the setting times of adhesives formed from

the esters. The highest level of strongly acidic contamination

tolerable in cyanoacrylate adhesive compositions is generally less

than 1 p.p.m. As regards the contaminants, the most undesirable

contaminants are traces of residual phosphorus oxychloride, non-

volatile strong acids such as phosphoric and polyphosphoric acids,

and the deleterious chlorinated by-products mentioned supra. These

by-products can slowly release hydrochloric acid via hydrolysis by

atmospheric moisture during, for example, storage of a

cyanoacrylate adhesive composition, leading to loss of adhesive

properties by acid inhibition of the anionic polymerisation pathway.

Complicated procedures are required to purify the esters from the

non-volatile mixtures of contaminants, in particular in the case of

non—distillable liquid esters which cannot be purified by either

distillation or by recrystallisation.

W0 95/32183

10

15

20

25

PCT/H