Use of t-butyldimethylsilyl cyanoacetate for preparation of α-cyano ketones

Use of t-butyldimethylsilyl cyanoacetate for preparation of α-cyano ketones

Journal:

Year:

Abstract:

The synthesis of t-butyldimethylsilyl cyanoacetate and the reactions of its anion with acyl donors are described. The reagent was found to be the method of choice for the syntheses of α-cyano ketone substrate analogues for carboxypeptidase A. These compounds have been shown to be potent mechanism-based inactivators for the enzyme.

DOI:

10.1002/bip.360290115

Type of document:

Language:

Use of t-Butyldimethylsilyl Cyanoacetate for

Preparation of a-Cyano Ketones

SOUMITRA S. GHOSH

T h e Salk Institute Biotechnology/lndustrial Associates, Inc., P.O. Box 85200,San Diego, California 92138-9216

SYNOPSIS

The synthesis of t-butyldimethylsilyl cyanoacetate and the reactions of its anion with

acyl donors are described. The reagent was found to be the method of choice for the

syntheses of a-cyano ketone substrate analogues for carboxypeptidase A. These compounds

have been shown to be potent mechanism-based inactivators for the enzyme.

INTRO D UCTlON

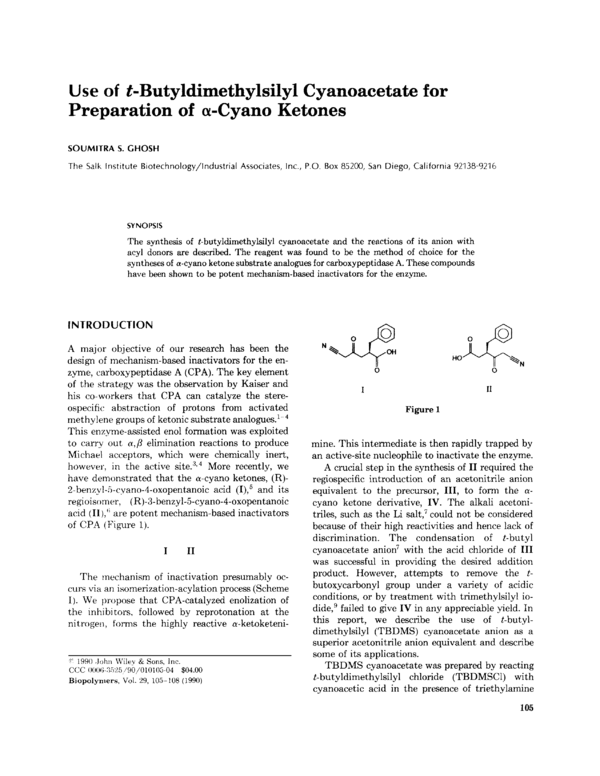

A major objective of our research has been the

design of mechanism-based inactivators for the enzyme, carboxypeptidase A (CPA). The key element

of the strategy was the observation by Kaiser and

his co-workers that CPA can catalyze the stereospecific abstraction of protons from activated

methylene groups of ketonic substrate analogues.’-4

This enzyme-assisted enol formation was exploited

to carry out a,P elimination reactions to produce

Michael acceptors, which were chemically inert,

however, in the active ~ i t e . More recently, we

~.~

have demonstrated that the a-cyano ketones, (R)2-benzyl-5-cyano-4-oxopentanoic (I),5and its

acid

regioisomer, (R)-3-benzyl-5-cyano-4-oxopentanoic

acid (I1 are potent mechanism-based inactivators

of CPA (Figure 1).

),‘I

I

I1

The mechanism of inactivation presumably occurs via an isomerization-acylation process (Scheme

I). We propose that CPA-catalyzed enolization of

the irihibi tors, followed by reprotonation at the

nitrogen, toms the highly reactive a-ketoketeni-

1990 ,John Wiley & Sons, Inc.

O(IOfi 3325 /90/OlOlO5-04

$04.00

Biopolyniers, Vol. 29, 105-108 (1990)

‘c

CCC

I

I1

Figure 1

mine. This intermediate is then rapidly trapped by

an active-site nucleophile to inactivate the enzyme.

A crucial step in the synthesis of I1 required the

regiospecific introduction of an acetonitrile anion

equivalent to the precursor, 111, to form the acyano ketone derivative, IV. The alkali acetonitriles, such as the Li salt,7could not be considered

because of their high reactivities and hence lack of

discrimination. The condensation of t-butyl

cyanoacetate anion7 with the acid chloride of 111

was successful in providing the desired addition

product. However, attempts to remove the tbutoxycarbonyl group under a variety of acidic

conditions, or by treatment with trimethylsilyl iodide,9 failed to give I V in any appreciable yield. In

this report, we describe the use of t-butyldimethylsilyl (TBDMS) cyanoacetate anion as a

superior acetonitrile anion equivalent and describe

some of its applications.

TBDMS cyanoacetate was prepared by reacting

t-butyldimethylsilyl chloride (TBDMSC1) with

cyanoacetic acid in the presence of triethylamine

105

106

GHOSH

\I/

Zn++

\I/

zn++

Scheme I

Scheme I1 (a) (COCI),, DMF (b) [NCCHCO,TBDMSI-Na' and (c) H'.

NCCH,CO,H

TBDlllS (21

NCCH,CO,TBDMS

Figure 2

(Figure Z).'O The silyl ester was isolated in 90%

yield by filtration and then concentration of the

filtrate under vacuo. Reaction of the sodium salt of

the reagent with freshly prepared acid chloride of

111, followed by acid quench, directly provides the

a-cyano ketone derivative (Scheme 11; 48% overall

yield from 111). Similarly, the a-cyan0 ketone

derivative of the half ester of benzylmalonic acid

was obtained in 38% overall yield.

The reactivity of the TBDMS cyanoacetate anion toward anhydrides is modulated by the nature

of its countercation. Thus, while its Na salt did not

react a t all with (R)-benzylsuccinic anhydride, the

Li derivative added facilely to give a 1:1 mixture

of I and I1 in 87%isolated yield after silica gel flash

chromatography (Figure 3). The two regioisomers

are well resolved by C-8 semi-preparative reversephase high performance liquid chromatography

(HPLC). The efficacy of the reagent was borne out

in the subsequent syntheses of 14C-labeledI and 11.

14

C-labeled TBDMS cyanoacetate was prepared in

two steps by reacting chloracetic acid with 14CNaCN," followed by esterification with TBDMSCI. Reaction of its Li salt with (R)-benzylsuccinic

anhydride and then purification by reverse-phase

chromatography afforded the desired radiolabeled

compounds. This sequence of reactions is far more

economical than the use of the very expensive

14

C-labeled acetonitrile.

THDMS cyanoacetate was designed to allow a

facile one-step introduction of a CH,CN group by

taking advantage of the known acid lability of

TBDMS esters. In its reactions with acid chlorides

and anhydrides, the silyl esters of the initially

formed products rapidly hydrolyze under the acidic

work-up conditions and then decarboxylate to give

rise to a-cyano ketones. The ease of its synthesis

and application recommends its use as an attractive alternative to other synthetic methods for the

preparation of cyanomethylated compounds.

EXPERIMENTAL

Infrared spectra were obtained on a Perkin Elmer

1420 spectrometer or a Mattson Cygnus 25 Fourier

transform (FT) ir instrument. Optical rotations

were taken on a Perkin Elmer 241 polarimeter.

Nuclear magnetic resonance spectra were recorded

on a Nicolet 360 MHz FT-nmr using tetramethylsilane as an internal standard. All mass spectra were

USE OF TBDMS CYANOACETATE

obtained a t the Rockefeller University Biotechnology Mass Spectrometric Research Resource.

(TB DMS) Cyanoacetat e

To a solution of cyanoacetic acid (1.7 g, 20 mmoles)

and TBDMS chloride (3.14 g, 20 mmoles) in 22 mL

of anhydrous ethyl acetate at 0°C and under N,

was added 2.71 mL of triethylamine, resulting in

the immediate precipitation of triethylamine hydrochloride. The reaction mixture was stirred a t

0°C for 30 min and then allowed to warm to an

ambient temperature. The suspension was filtered,

and the salt precipitate was washed with ethyl

acetate (2 x 20 mL). The filtrates were combined

and concentrated to afford 3.55 g (90%) of the

TBDMS ester as a clear oil. 'H-nmr (CDC1,): 6

3.47 (s, 2H), 0.96 (s, 9H), 0.32 (s, 6H); ir (thin film)

3455, 2934, 2862, 2266, 1731, 1471 cm-'.

(R)-2-Benzyl-3-Carbomethoxy-Propionyl Chloride

To 0.33 g (1.5 mmoles) of (R)-2-benzyl-3-carbomethoxy-propionic acid in 19 mL of anhydrous

benzene were added 0.019 mL of dimethylformamide (DMF) and 0.163 mL (1.88 mmoles) of

oxalyl chloride, resulting in rapid gas evolution.

After stirring for 30 min a t 23"C, the solution was

concentrated, taken up in 20 mL tetrahydrofurane

(THF), and evaporated once again to ensure removal of unreacted oxalyl chloride. Traces of solvent were removed under high vacuum, and the

acid chloride was used immediately for the next

step without further purification.

(R)-Methyl 3-Benzyl-4-0~0-5-Cyano-Pentanoate

(IV)

To 0.072 g (3 mmoles) of sodium hydride in 30 mL

of anhydrous THF under N, was added a solution

of 0.591 g (3 m o l e s ) of TBDMS cyanoacetate in 5

mL THF over 5 min, and the reaction was allowed

to proceed for 15 min. The reaction mixture was

then cooled to - 78"C, and a solution of the (R)-2benzyl-3-carbomethoxy-propionyl

chloride (max 1.5

mmoles) in 7 mL of THF was added dropwise over

a period of 15 min. After stirring a t -78°C for 30

minutes, the mixture was warmed to 23°C over 30

minutes and then quenched with 27 ml of 0.06 N

HCl. The solution was extracted with ethyl acetate

(3 x 40 mL), and the organic phase was washed

with brine, dried, and concentrated. Two drops of

triethylamine were added to the residue, and the

mixture was purified by flash chromatography.

107

Elution with 30% ethyl acetate in hexane containing 0.5% triethylamine separated a minor contaminant, which was followed by elution with ethyl

acetate to afford 172 mg (48% from the acid) of the

product as an oil. 'H-nmr (CDCI,): 6 7.37-7.14 (m,

5H), 3.64 (s, 3H), 3.54 (d, J = 19.7 Hz, lH), 3.31

(m, lH), 3.05 (d, J = 19.7 Hz, lH), 2.89 (m, lH),

2.71 (dd, J = 13.3, 7.1 Hz, lH), 2.52 (dd, J = 17.6,

3.5 Hz, 1H); ir (thin film) 3028, 2953, 2261, 1730,

1438 cm-'. HRMS (CI) calculated for C,,H160,N

(M + 1) 246.1130, found 246.1126. [ a ] : + 75.2 (c

0.7, ethyl acetate).

Syntheses of I and I1

To 0.414 mL of a 2.41M solution of butyl lithium

(1 mmole) under argon were added 1 mL of anhydrous THF and then 0.14 mL (1 mmole) of diisopropylamine, and the mixture was stirred for 15

min a t 0°C. The solution was cooled to -78"C,

and a solution of 0.203 g of TBDMS cyanoacetate

in 2 mL of THF was added over 5 min. After

stirring for 30 min, a solution of 0.094 g (0.5 mmoles)

of (R)-benzylsuccinic anhydride in 3 mL of THF

was added over a period of 5 min. The mixture was

stirred a t -78°C for 1h and then a t 4°C for 3.5 h.

The reaction was quenched by the addition of 0.5

mL of 10% HC1, taken up in 40 mL of ether, and

washed with 15 mL of water. The aqueous layer

was extracted with 2 x 15 mL of ether, and then

the ethereal solutions were combined, washed with

20 mL of brine, dried over MgSO,, and concentrated under vacuo. The crude products were purified by flash chromatography using 50% ethyl acetate in hexane containing 0.5% acetic acid to afford 0.1 g of a 1:l mixture of I and I1 as an oil (87%

yield).

Spectral Data for I. 'H-nmr (CDCI,): S 7.34-7.16

(5H, m), 6 3.37 (2H, bs), 6 3.32-3.17 (2H, m), 6

2.83-2.76 (2H, dd, J = 9.3, 13.5 Hz), S 2.54--2.48

(lH, dd, J = 4.4, 17.4 Hz); ir (thin film) 3200 (br),

2916, 2264, 1731, 1713 cm-'. MS (CI) 232 (M + 1).

Spectral Data for 11. 'H-nmr (CDCl,): 6 7.37-7.14

(m, SH), 3.41 (br.d, J = 18.6 Hz, lH), 3.28 (m, lH),

3.01 (d, J = 19.7 Hz, lH), 2.89 (m, 2H), 2.73 (dd,

J = 13.4, 7.2 Hz, lH), 2.55 (dd, J = 17.9, 3.7 Hz,

1H); ir (thin film) 3500-3000 (br), 2263, 1730, 1393

cm-'. HRMS (CI) calculated for C,,H,,O,,N (M +

1) 232.0974, found 232.0970. [a]$ + 77.8 (c 0.7,

ethyl acetate).

10s

GHOSH

This work was supported by funds from SIBIA. I thank

Dr. Shahriar Mobashery for helpful discussions, and I

owe a debt of gratitude to Dr. Tom Kaiser, without

whom this work would not have been possible.

REFERENCES

1. Sugimoto, T. & Kaiser, E. T. (1978) J . Am. Chem.

SOC.

100,7750-7751.

2. Sugimoto, T. & Kaiser, E. T. (1979) J . Am. Chem.

SOC.101, 3946-3951.

3. Nashed, N. T. & Kaiser, E. T. (1981) J . Am. Chem.

SOC.103, 3611-3612.

4. Nashed, N. T. & Kaiser, E. T. (1986) J . Am. Chem.

SOC.108, 2710-2715.

5. Mobashery, S., Ghosh, S. S., Tamura, S. Y. & Kaiser,

E. T., Proc. Natl. Acad. Sci. U.S.A. (in press).

6. Ghosh, S. S., Spratt, T. E., Miller, W. T. & Kaiser,

E. T., submitted.

7. Kaiser, E. M. & Hauser, C. R. (1968) J . Org. Chem.

33, 3402-3404.

8. Lawsson, S.-O., Larsen, E. H. & Jacobsen, H. J.

(1965) Arkiu. Kemi. 23, 453-462.

9. Jung, M. E. & Lyster, M. A. (1977) J . Org. Chem. 99,

968-969.

10. Mobashery, S. &Johnston, M. (1985) J. Org. Chem.

50, 2200--2202.

11. Inglis, J. K. H. (1932) in Organic Syntheses collective

Vol. I, Gilman, H. & Blatt, A. H., Eds., Wiley, New

York, pp. 254-256

Received May 4,1989

Accepted June 9, 1989

Coments go here:

- Log in to post comments