Fluorocyanoacrylates

Folder:

Year:

Abstract:

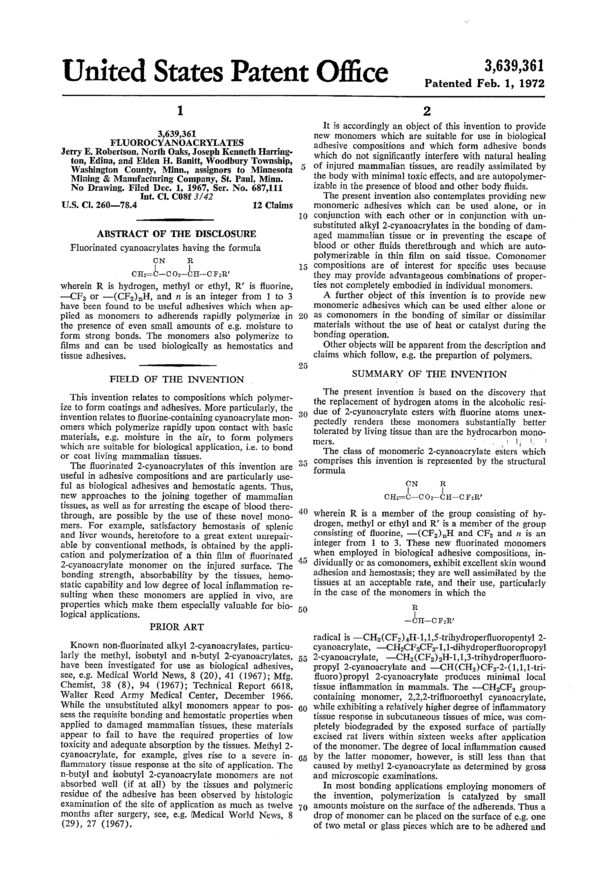

Fluorinated cyanoacrylates having the formula:

-------

wherein R is hydrogen, methyl or ethyl, R' is fluorine, -CF3 or -(CF2)nH, and n is an integer from 1 to 3 have been found to be useful adhesives which when applied as monomers to adherends rapidly polymerize in the presence of even small amounts of e.g. moisture to form strong bonds. The monomers also polymerize to films and can be used biologically as hemostatics and tissue adhesives.

Type of document:

Language:

United States Patent Ofice

3,639,361

Patented Feb. 1, 1972

1

3,639,361

FLUOROCYANOACRYLATES

Jerry E. Robertson, North Oaks, Joseph Kenneth Harring-

ton, Edina, and Elden H. Banitt, Woodbury Township,

Washington County, Minn., assignors to Minnesota

Mining & Manufacturing Company, St. Paul, Minn.

No Drawing. Filed Dec. 1, 1967, Ser. No. 687,111

Int. Cl. C08f 3/42

U.S. Cl. 260—78.4 12 Claims

ABSTRACT OF THE DISCLOSURE

-Fluorinated cyanoacrylates having the formula

CN R

l I

CH2=C—C 02-CH-—C F2R'

wherein R is hydrogen, methyl or ethyl, R’ is fluorine,

—CF3 or —(CF2),,H, and n is an integer from 1 to 3

have been found to be useful adhesives which when ap-

plied as monomers to adherends rapidly polymerize in

the presence of even small amounts of e.g. moisture to

form strong bonds. The monomers also polymerize to

films and can be used biologically as hemostatics and

tissue adhesives.

FIELD OF THE INVENTION

This invention relates to compositions which polymer-

ize to form coatings and adhesives. More particularly, the

invention relates to fluorine-containing cyanoacrylate mon-

omers which polymerize rapidly upon contact with basic

materials, e.g. moisture in the air, to form polymers

which are suitable for biological application, i.e. to bond

or coat living mammalian tissues.

The fluorinated 2-cyanoacrylates of this invention are

useful in adhesive compositions and are particularly use-

ful as biological adhesives and hemostatic agents. Thus,

new approaches to the joining together of mammalian

tissues, as well as for arresting the escape of blood there-

through, are possible by the use of these novel mono-

mers. For example, satisfactory hemostasis of splenic

and liver wounds, heretofore to a great extent unrepair-

able by conventional methods, is obtained by the appli-

cation and polymerization of a thin film of fluorinated

2-cyanoacrylate monomer on the injured surface. The

bonding strength, absorbability by the tissues, hemo-

static capability and low degree of local inflammation re-

sulting when these monomers are applied in vivo, are

properties which make them especially valuable for bio-

logical applications.

PRIOR ART

Known non-fluorinated alkyl 2-cyanoacrylates, particu-

larly the methyl, isobutyl and n-butyl 2-cyanoacrylates,

have been investigated for use as biological adhesives,

see, e.g. Medical World News, 8 (20), 41 (1967); Mfg.

Chemist, 38 (8), 94 (1967); Technical Report 6618,

Walter Reed Army Medical Center, December 1966.

While the unsubstituted alkyl monomers appear to pos-

sess the requisite bonding and hemostatic properties when

applied to damaged mammalian tissues, these materials

appear to fail to have the required properties of low

toxicity and adequate absorption by the tissues. Methyl 2-

cyanoacrylate, for example, gives rise to a severe in-

flammatory tissue response at the site of application. The

n-butyl and isobutyl 2-cyanoacrylate monomers are not

absorbed well (if at all) by the tissues and polymeric

residue of the adhesive has been observed by histologic

examination of the site of application as much as twelve

months after surgery, see, e.g. {Medical World News, 8

(29), 27 (1967).

U!

10

15

20

NJ

Cl

30

C6

C4‘!

40

50

60

65

2

It is accordingly an object of this invention to provide

new monomers which are suitable for use in biological

adhesive compositions and which form adhesive bonds

which do not significantly interfere with natural healing

of injured mammalian tissues, are readily assimilated by

the body with minimal toxic effects, and are autopolymer-

izable in the presence of blood and other body fluids.

The present invention also contemplates providing new

monomeric adhesives which can be used alone, or in

conjunction with each other or in conjunction with un-

substituted alkyl 2-cyanoacrylates in the bonding of dam-

aged mammalian tissue or in preventing the escape of

blood or other fluids therethrough and which are auto-

polymerizable in thin film on said tissue. Comonomer

compositions are of interest for specific uses because

they may provide advantageous combinations of proper-

ties not completely embodied in individual monomers.

A further object of this invention is to provide new

monomeric adhesives which can be used either alone or

as comonomers in the bonding of similar or dissimilar

materials without the use of heat or catalyst during the

bonding operation.

Other objects will be apparent from the description and

claims which follow, e.g. the prepartion of polymers.

SUMMARY OF THE INVENTION

The present invention is based on the discovery that

the replacement of hydrogen atoms in the alcoholic resi-

due of 2-cyanoacrylate esters with fluorine atoms unex-

pectedly renders these monomers substantially better

tolerated by living tissue than are the hydrocarbon mono-

mers. ".,!|; K‘

The class of monomeric 2-cyanoacrylate esters which

comprises this invention is represented by the structural

formula

(EN Ii

CH2=C—-C 02—CH—C F2R’

wherein R is a member of the group consisting of hy-

drogen, methyl or ethyl and R’ is a member of the group

consisting of fluorine, —(CF2),,H and CF3 and n is an

integer from 1 to 3. These new fluorinated monomers

when employed in biological adhesive compositions, in-

dividually or as comonomers, exhibit excellent skin wound

adhesion and hemostasis; they are well assimilated by the

tissues at an acceptable rate, and their use, particularly

in the case of the monomers in which the

1?

——CH—CF2R’

radical is —CH2(CF2)4H-1,1,5-trihydroperfluoropentyl 2-

cyanoacrylate, —CHgCF2CF3~l,1-dihydroperfluoropropyl

2-cyanoacrylate, —-CH2 (CF 2) 2H-1 , 1,3-trihydroperfluoro-

propyl 2-cyanoacrylate and —CH(CH3)CF3-2-(1,1,l-tri-

fluoro)propyl 2-cyanoacrylate produces minimal local

tissue inflammation in mammals. The —~OH2CF3 group-

containing monomer, 2,2,2-trifluoroethyl cyanoacrylate,

while exhibiting a relatively higher degree of inflammatory

tissue response in subcutaneous tissues of mice, was com-

pletely biodeg-raded by the exposed surface of partially

excised rat livers within sixteen weeks after application

of the monomer. The degree of local inflammation caused

by the latter monomer, however, is still less than that

caused by methyl 2-cyanoacrylate as determined by gross

and microscopic examinations.

In most bonding applications employing monomers of

the invention, polymerization is catalyzed by small

amounts moisture on the surface of the adherends. Thus a

drop of monomer can be placed on the surface of e.g. one

of two metal or glass pieces which are to be adhered and

3,639,361

3

the other piece brought into contact therewith. A strong

bond is soon formed by polymerization.

Similarly, desired bonding of tissues or hemostasis

proceeds well in the presence of blood and other body

fluids. The bonds formed are of adequate flexibility and

strength to withstand normal movement of tissue. In addi-

tion, bond strength is maintained as natural wound heal-

T ing proceeds concurrently with polymer assimilation.

Compositions of the invention are sterilizable by con-

ventional methods such as distillation under aseptic con-

ditions. ,

The method of repairing injured tissues with composi-

tions of this invention (for example, to control bleeding)

comprises, in general, sponging and subsequent applica-

tion to the tissue of an adhesive composition containing a

monomer of the invention which polymerizes to a thin

film of polymer while in contact with said tissue surfaces.

For bonding separate surfaces of body tissues, the mono-

mer would be applied to at least one of such surfaces, and

the surfaces brought quickly together while the monomer

polymerizes in contact with both of the surfaces.

The monomers of the invention are eflfective in adhesive

formulations with the fluoroalkyl 2-cyanoacrylates as the

major active constituent. Thus, the cyanoacrylate may be

combined in admixture with a polymerization-inhibitor

(e.g. sulfur dioxide). One or more adjuvant substances,

such as thickening agents, plasticizers, or the like, to im-

prove the surgical utility of the monomer, can also be

present.

Depending on the particular requirements of the user,

these adhesive compositions can be applied by known

means such as with a glass stirring rod, sterile brush or

medicinal dropper; however, in many situations -a pres-

surized aerosol dispensing package is preferred in which

the adhesive composition is in solution with a compatible

anhydrous propellant.

The monomers are readily polymerized to addition-type

, polymers and copolymers, which are generally optically

clear (as films) and are thermoplastic and moldable at

temperatures below their decomposition temperature.

They can be shaped at temperatures in the range of 100°

to 150° C‘.

The polymers have the general formula

wherein R and R’ are as defined above and x is a number

from 5 to 500.

Polymerization occurs by free radical initiation, ex-

posure to small amounts of base, e.g. triethylamine, or

water. The liquid monomer can be spread on e.g. a poly-

ethylene surface and exposed to triethylamine to bring

about polymerization to a coating which can‘ be peeled

from the polyethylene as a self-supporting, optically clear

film.

The monomers of the invention can be copolymerized

with other acrylates or epoxides.

The preferred method for preparing high purity (95

percent or greater) fluoroalkyl 2-cyanoacylates comprises

catalyzing the condensation of formaldehyde with esters

of cyanoacetic acid by means of a mixture of an acid and

the acidic salt of an alkyl primary or secondary amine.

10

20

25

30

40

45

50

55

60

65

70

75

4

With particular reference to the preparation of the

fluoroalkyl 2-cyanoacrylate esters of the present inven-

tion, the preferred method of preparation employs the

cyanoacetates corresponding to the desired cyanoacrylates

(e.g. 2,2,2-trifluoroethyl cyanoacetate for 2,2,2—trifluoro-

ethyl 2-cyanoacrylate). The cyanoacetate is reacted with

formaldehyde or polymers thereof such as paraformalde-

hyde, excepting aqueous solutions of formaldehyde as typi-

fied by formalin. The reaction medium may be any suit-

able inert organic solvent capable of forming an azeotrope

with water.

The essential feature of the synthesis is the particular

combination of catalytic materials employed. Any acid

salt of an alkyl primary or secondary amine and any free

acid may be utilized as components of the catalytic mix-

ture, provided they establish the necessary pH value as

described in detail below.

All phases of the synthetic sequence are carried out

under acidic conditions. A criterion for utility of the cata-

lytic mixture selected is that it have a corrected pH value

if not over pH 5. This pH value can be determined as fol-

ows:

The exact amounts of amine acid salt and free “acid to

be used in the condensation step are dissolved in 25 ml.

of water, and the pH of the solution is measured. If the re-‘

sulting pH value is 5 or less, the mixture will adequately

catalyze the condensation reaction. When the mixture is

soluble in water, this is the “corrected pH value.”

Catalytic mixtures comprising organic acids which are

not readily soluble in water may be dissolved in 25 ml. of

an ethanol-water mixture; however, the measured pH must

then be corrected as described by B. Gutbezehl and E.

Grunwald in J. Am. Chem. Soc., 75, 565 (1953).

Both primary or secondary amine salt and free acid are

always present. Glacial acetic or strong mineral acids such

as hydrochloric acid or sulfuric acid are preferred. The

amount of catalyst employed is not critical -and may be

varied. Ordinarily a small amount, e.g. 0.5 to 0.1 percent

by weight, based on the weight of cyanoacetic ester, is

adequate.

Other than employing the imine acid salt and free acid,

the condensation of cyanocacetic esters with formaldehyde

and the subsequent depolymerization process are carried

out by methods similar to prior art methods.

The following examples will illustrate preferred em-

bodiments of the invention. It will -be understood, how-

ever, that the examples are included merely for the pur-

poses of illustration and are not intended to limit the scope

of the invention, unless otherwise specifically indicated.

All parts are by weight unless otherwise specified, and the

pressures are shown in millimeters of mercury.

Example 1.—Fluoroalkyl cyanoacetates

Fluoroalkyl cyanoacetates required as starting materials

in the synthesis of fluoroalkyl 2-cyanoacrylates described

in this invention are not available by simple esterification

of cyanacetic acid. A general procedure for the special

preparation of these materials from cyanoacetyl chloride

on a large scale is given below. ’

A 5-1. three-necked, round-bottomed flask equipped

with an eflicient mechanical stirrer, large addition funnel

and reflux condenser topped with a gas exit tube was

charged with 1000 ml. of diethyl ether and 1042.5 g. of

phosphorus pentachloride. This suspension was stirred and

cooled in an ice bath. In a separate container, a solution

of 425.5 g. (5.0 moles) of cyanoacetic acid in 1750 ml.

of diethyl ether was dried over magnesium sulfate and

filtered to remove drying agent. It was then added over a

period of 3 to 7 minutes with good stirring to the cold

suspension. (The exothermic reaction which occurs can

be controlled by adjusting the rate of addition, but a rapid

rate is essential for optimum yield.) The condenser was

immediately replaced with a short head and condenser.

Ether and phosphorus oxychloride were then distilled off

3,639,361

5

under reduced pressure (aspirator) to afford crude cyano-

acetyl chloride as an orange-red, mobile liquid. During

this operation, the internal pot temperature was not al-

lowed to exceed 55° C. This step is critical since higher

temperatures will cause degradation of cyanoacetyl chlo-

ride and may induce exothermic and uncontrollable polym-

..erization. Samples of cyanoacetyl chloride should be used

directly after preparation and should not be stored.

The distillation apparatus was then removed from the

flask and replaced with a reflux condenser topped with a

gas exit tube. The selected fluoroalcohol was placed in the

funnel and about one-third added to the crude cyanoacetyl

chloride. If the reaction did not begin spontaneously as

evidenced by evolution of hydrogen chloride, the mixture

was heated to 55 °—65 ° C.; the remaining fluoroalcohol was

then added slowly to maintain a smooth reaction. After

completion of addition, the mixture was stirred at 55°-

65° C. until no more hydrogen chloride was evolved. The

acidic product was transferred to a smaller flask and crude-

ly distilled to afford fluoroalkyl cyanoacetate. Fractional

redistillation provided pure fluoroalkyl cyanoacetate with

yields in the range of 75-85 percent.

TABLE I

[Fluoroalkyl Cyanoaeetates, N C CH2C 02R]

R B .1’. (°C./mm.) ma 25°

-—-—CH2CFa ------- -— 93/9 1.3692

—CH2CF2C Fa.--. 83-85/6 1.3546

-—CH2(CF2)2H_._- 71/0.25 1.3785

—-CH2 (C F2) 4H- - . _ 105-106/0. 9 1. 3585

/CH3 96 /I3 1. 3724

—C1{

\

C F:

Example 2.—2-,2,2-trifluoroethyl 2-cyanoacrylate

Six hundredmilliliters of benzene, 167.1 g. (1.0 mole)

of 2,2,2-trifluoroethyl cyanoacetate, 36.0 g. (1.2 moles)

of powdered paraformaldehyde, 1.0 g. of piperidine hy-

drochloride and 0.2 ml. of glacial acetic acid were com-

bined in a 1-1. two-necketd, round-bottomed flask equipped

with mechanical stirrer, Dean-Stark water trap and re-

flux condenser. The heterogeneous mixture was stirred

and heated under gentle reflux until all water formed dur-

ing the reaction had been azeotropically removed and col-

lected in the Dean-Stark trap. -Only a portion of the poly

(trifluoroet-hyl 2-cyanoacrylate) formed in the reaction

separated; the remainder was precipitated by cooling the

flask in an ice bath.

After the cold benzene had been decanted, 300 ml. of

anhydrous acetone were added and warmed to dissolve

polymer. The clear polymer solution was filtered (to re-

move piperidine hydrochloride and any unreacted para-

formaldehyde) into a clean 1-1. two-necked, round-bot-

tomed flask equipped with mechanical stirrer, and 100 g.

of tricresyl phosphate were added to aid in fluidizing the

mixture. Acetone was then removed by distillation. Pres-

sure in the system was gradually reduced to 15-20 mm.

Hg, and the bath temperature slowly raised to 110°—120°

C. Last traces of acetone were eliminated by stirring the

yellow, viscous mixture vigorously for 30 minutes under

these conditions.

At this point, 6-10 g. of polyphosphoric acid and 0.5

g. of pyrogallol were added to serve as inhibitors, and the

flask was equipped with a short take-ofi head fitted with a

gas inlet tube mounted in the thermometer well. Thermal

depolymerization was effected by heating this mixture un-

der reduced pressure with good stirring while sulfur di-

oxide was bled into the system. Collection of monomeric

2,2,2-trifluoroethyl 2-cyanoacrylate in a Dry Ice-cooled re-

ceiver was begun when the bath temperature/system pres-

sure reached 155° C./ 20 mm. and continued up to .a maxi-

mum of 200° C./ 10 mm. Clear, colorless monomer ob-

tained in this fashion is sufficiently pure for most adhesive

applications; yield, 95 g. (53 percent based on 2,2,2-tri-

fluoroethyl cyanoacetate) .

10

15

20

30

40

45

50

60

65

70

75

6

Greater purity may be achieved by redistillation from

a small amount of phosphorus pentoxide using a short

Vigreux column. A sulfur dioxide bleed to serve as inhib-

itor and prevent anionic polymerization is essential dur-

ing any such redistillation. On redistillation, the distilla-

tion cut boiling at 83 °-84° C./13 mm. weighed 71 g. and

was shown to be 95.8 percent pure 2,2,2-trifluoroethyl

2-cyanoacrylate.

Monomer purity was established by gas chromatography

using a chromatograph equipped with a 6’ x 1/1" nitrile-

containing silicone column packed on diatomaceous earth

(of the type commercially available under the trade name

“60/ 70 Anakrom ABS”) and operated at column tempera-

tures of 150°—l90° C. Monomer samples were injected as

10 percent solutions in spectrograde nitromethane.

Polymeric 2,2,2-trifluoroethyl cyanoacrylate was formed

by pouring the monomer into a large excess of rapidly

stirred '1 :1 methanol-water solution. The polymer precipi-

tated in finely divided form and was removed by filtration,

washed with methanol and dried. This was molded into

disks at about l00°—125° C. which have useful dielectric

properties. These disks can be machined and used as in-

sulating washers. The polymer is soluble in acetone and

films or coatings can be made from -these solutions in

the usual manner. These also have useful electrical in-

sulating properties.

Example 3.——2-( 1, 1,1-trifluoro) propyl—2-cyanoacrylate

A 2-1. three-necked flask equipped with a mechanical

stirrer and Dean-Stark water trap was charged with 438

g. (2.42 moles) 2-( 1,1,1-trifluoro)propyl cyanoacetate,

96.0 g. (3.2 moles) powdered paraformaldehyde, 3.0 g.

piperidine hydrochloride, 0.5 ml. glacial acetic acid and

900 ml. benzene. The mixture was stirred and slowly

brought to reflux over a period of 3 hours. Heating under

reflux was continued until no more water separated in

the trap. The cooled solution of low molecular weight

polymer was then filtered into a round-bot-tomed flask con-

taining 240 g. tricresylphosphate. Benzene was then re-

moved by distillation. Last traces of solvent were elimi-

nated by stirring the mixture at 110° C./ 0.3 mm.

The distillation head was removed and replaced with a

clean, dry one-piece head and condenser fitted with a gas

inlet tube in the thermometer well. About 10 g. poly-

phosphoric acid were added to the orange syrupy mixture.

Thermal depolymerization was effected by heating this

mixture under reduced pressure while sulfur dioxide was

bled into the system. Collection of crude monomeric 2-

(1,l,1-trifluoro)propyl 2-cyanoacrylate in a Dry Ice-

cooled receiver was begun when the bath temperature/

system pressure reached 150° C./20 mm. and continued

up to a maximum of 190° C./0.45 mm.; yield, 251 g. On

redistillation of crude monomer from a small amount of

phosphorus pentoxide as described in Example 1, the

fraction boiling at 83°—85° C./ 17 mm. was shown to be

at least 98 percent pure 2-.(1,l,l-trifluoro)propyl cyano-

acrylate. The monomer is converted to polymer by the

procedure described in Example 1.

Examples of other 2-cyanoacrylates.—Other cyano-

acrylates which have been prepared in a manner similar

to that described in Examples 1 and 2 are collected in

Table II.

TABLE II

Fluoroalkyl 2-cyvanoacrylates

CN

/

CH2=C

\

CO2R

R: B.P.

—CH2(CF2)2H _________ __ 89—90°/0.3 mm.

——CH2(CF2)4H _________ -_ 91-95“/0.2-0.4 mm.

-—CH2CF2CF3 __________ __ 98—100°/ 15 mm.

These monomers can be polymerized in the same

manner as described in Examples 1 and 2.

3,639,361

7

Example 4.—-Hemostasis in vascular organs

(excised cat spleen)

A male cat was anesthetized intravenously with pento-

barbital-sodium and prepared for aseptic surgery. Prior

to surgery 25 milligrams of heparin sodium USP were

intravenously administered. The spleen was exteriorized

through a ventral midline incision, and a disk-shaped por-

tion of splenic tissue 1 to 2 centimeters in diameter and 3

-to 5 millimeters deep was excised. Resulting profuse

hemorrhage from the Wound was controlled by occluding

the blood supply to the spleen with soft clamps and gauze

sponging. A thin layer of 2,2,2-trifluoroethyl 2-cyano-

acrylate adhesive monomer was applied to the wound sur-

face immediately thereafter by spraying with an aerosol

at a distance of from 4 -to 8 centimeters from the wound

surface. After allowing suflicient time for polymerization

of the monomer, the organ was replaced in the peritoneal

cavity. The ventral midline incision was closed using con-

ventional sutures. Post-operative antibiotics and vitamins

were routinely administered. Adhesive and hemostatic

properties were recorded at the time of application.

The cat, except for depression during the first few post-

operative days, made an uneventful recovery and re-

mained healthy until sacrificed -six weeks after surgery.

Adhesions between the spleen and surrounding tissue, an

expected sequela following surgery of this nature, and‘

mild inflammation of the splenic capsule were the only

gross tissue’ changes observed at necropsy. None of the

adhesive was grossly visible and normal healing appeared

to be in progress. '

What is claimed is:

1. 2-(1,1,1-trifluoro)propy1 2-cyanoacrylate.

2. -1,1,3-trihydroperfluoropropyl 2-cyanoacrylate.

3. 1,l,5—trihydroperfluoropentyl 2-cyanoacrylate.

4. 1,1-dihydroperfluoropropyl 2-cyanoacrylate.

5. Composition according to claim 1 comprising addi-

tionally sulfur dioxide as polymerization inhilbitor.

6. Composition according to claim 2 comprising addi-

tionally sulfur dioxide as polymerization inhibitor.

7. Composition according to claim 3 comprising addi-

tionally sulfur dioxide as polymerization inhibitor.

8. Composition according to claim 4 comprising addi-

tionally sulfur dioxide as polymerization inhibitor.

9. A thermoplastic addition homopolymer of the mono-

mer of claim 1 having the general formula:

ioHz—o(cN)_'

L 02. J.

F3C—-J3—CHz

1%:

wherein x is 5 to 500.

UK

10

20

30

40

45

50

8

10. A thermoplastic addition homopolymer of the

monomer of claim 2 having the general formula:

3°” ‘

CH2C FzCF2H

wherein x is 5 to 500.

11. A thermoplastic addition homopolymer of the

monomer of claim 3 having the general formula:

-—|:CH2—C(CN)—-l—-

L I J.

(E0

CHz(CF)4H

wherein x is 5 to 500.

‘12. A thermoplastic addition homopolymer of the

monomer of claim 4 having the general formula:

__ (C-N)__

FCH C .-I

L ‘" 0 J.

(i‘,'HaCF2CF;

wherein x is 5 to 500.

References Cited

UNITED STATES PATENTS

2,765,332 10/ 1956‘ Coover et al. ____ __ 260—465.4

2,784,127 3/1957 Joyner et al _______ __ 260-88.7

2,794,788 6/1957 Coover et al. _____ .. 260—88.7

3,275,462 9/1966 Strobel et al. ____ __ 260—465.4

3,255,059 6/1966 Hamermesh et al .... __ 149-22

3,223,083 12/1965 Cobey _________ __ 260__78_4 N

3,282,773 11/1966 Wicker et al. ..____ 260--78.4 ‘N

3,360,124 12/1967 Stonehill _______ __ 260—78.4 N

3,483,870 12/ 1969 Coover et al. .._.___ 260—78.4 N

HARRY WONG, JR., Primary Examiner

U.S. Cl. X.R.

117—124, 132, 138.8; 128-156; 260-32.8, 78.5; 465.4

Coments go here:

- Log in to post comments