Synthesis of 3-Substituted-2-Cyanoacrylates: Their Evaluation as Cross-linkers in Cyanoacrylate Adhesive Compositions

Synthesis of 3-Substituted-2-Cyanoacrylates: Their Evaluation as Cross-linkers in Cyanoacrylate Adhesive Compositions

Folder:

Journal:

Year:

Abstract:

Alkyl 2-cyano-2,4-pentadienoates and alkyl 2-cyano-2,4-hexadienoates were synthesized and characterized by spectroscopic methods. These were then evaluated as cross-linkers in 2-cyanoacrylate adhesive compositions to improve the heat stability of their adhesive bonds between various metal surfaces.

DOI:

10.1002/app.1993.070490806

Type of document:

Language:

Synthesis of 3-Substituted-2-cyanoacrylates: Their

Evaluation as Cross-linkers in Cyanoacrylate

Adhesive Compositions

V. VIJAYALAKSHMI, J. N. RUPAVANI, and N. KRISHNAMURTI'

Organic Coatings and Polymers, Indian Institute of Chemical Technology, Hyderabad 500 007, India

SYNOPSIS

Alkyl 2-cyano-2,4-pentadienoates alkyl 2-cyano-2,4-hexadienoates

and

were synthesized

and characterized by spectroscopic methods. These were then evaluated as cross-linkers

in 2-cyanoacrylate adhesive compositions to improve the heat stability of their adhesive

bonds between various metal surfaces. 0 1993 John Wiley & Sons, Inc.

INTRODUCTION

3-Substituted-2-cyanoacrylates

have been used from

time to time either as cross-linkers for alkyl 2-cyanoacrylates or on their own as adhesives apart from

other acrylic monomers. These esters are recommended to use in the alkyl2-cyanoacrylate adhesive

compositions, aiming at improvement of the joint

bond strength under higher-temperature conditions.'-6 Most of the literature available on their

synthesis and their compounding with alkyl 2-cyanoacrylates is in the form of patents that are often

misleading. In the present communication, the synthesis of 3-substituted-2-cyanoacrylates

such as alkyl2-cyano-2,4-pentadienoates, hexadienoates

and

and their effect in alkyl 2-cyanoacrylate adhesive

composition on heat aging of adhesive bond strength

has been discussed.

EXPERIMENTAL

Synthesis of Alkyl

Different alkyl 2-cyano-2,4-pentadienoates

were

prepared by reacting corresponding cyanoacetate

with acrolein in the presence of a zinc chloride catalyst:

* To whom correspondence should be addressed.

Journal of Applied Polymer Science, Vol. 49, 1387-1394 (1993)

0 1993 John Wiley & Sons, Inc.

CCC 0021-8995/93/081387-08

Zinc chloride (0.037 mol) and dioxane (40mL)

were taken in a two-neck round-bottom flask, and

this mixture was stirred for about 30 min while

heating at 70°C using an oil bath. Then, this mixture

was cooled to room temperature (25°C). Alkyl cyanoacetate (0.06 mol) and acrolein (0.075 mol) were

added slowly to this mixture. The reaction mixture

was stirred for 3 h a t 25°C. The product was isolated

by taking the product in 50 mL of hexane and further

extracting with cold dilute hydrochloric acid in ( 3

X 100 mL) portions. the organic layer was separated

and dried and the solvent removed under reduced

pressure. The crude product was recrystallized from

a petroleum ether-ethyl ether (1 : 1) mixture. Attempts to check the purity by the GLC technique

have failed due to the polymerization of these compounds over the column a t 180°C. The purity of the

compounds was therefore checked by spectroscopic

methods.

Synthesis of Alkyl 2-Cyano-2,4-hexadienoates

Alkyl 2-cyano-2,4-hexadienoates

were prepared by

reacting crotanaldehyde (0.15 mol) with the corresponding cyanoacetate (0.12 mol) in the presence

of a zinc chloride catalyst (0.074 mol) in dioxane

(80 mL ) as the solvent medium:

1387

1388

VIJAYALAKSHMI, RUPAVANI, AND KRISHNAMURTI

Table I Yields and Melting Points of

3-Substituted-2-Cyanoacrylates

Compound

Yield (%)

Melting Point ("C)

60

75

60

40

41

60

The method of synthesis was similar to that described for pentadienoates.

Methyl

Ethyl

t-Butyl

Synthesis of Alkane Diol

Bis ( 2-cyano-2,4-hexadienoates)

Alkane diolbis ( 2-cyano-2,4-hexadienoates)were

prepared from alkane dioldicyanoacetates, which

were previously prepared from different diols and

cyanoacetic acid in the following manner:

Alkyl2-cyano-2,4-hexadienoates

Methyl

Ethyl

t-Butyl

Propargyl

Ally1

3-Chloropropyl

95

70

58

45

58

70

58

60

74

65

60

62

Characterization of Alkyl

2-Cyano-2,4-pentadienoates and

Hexadienoates by Spectroscopy

Infrared (IR) Spectroscopy

Alkane dioldicyanoacetates ( 1 were synthesized by

)

reacting cyanoacetic acid ( 1.2 mol) with alkane diol

(0.5 mol) in the presence of PTSA ( 1%on reactants ) and benzene in an amount equal to the total

weight of reactants. The water of the reaction was

removed azeotropically using a Dean-Stark trap.

After the completion of the reaction, the solvent was

removed and the product was dissolved in dichloromethane (DCM) and washed with water several

times to remove excess cyanoacetic acid. The crude

product was purified by vacuum distillation.

In the second step, zinc chloride (0.029 mol) and

dioxane (40 mL) were stirred for 30 min at 80°C.

T o this alkane, dioldicyanoacetate ( 1) (0.02 mol)

and crotonaldehyde (0.05 mol) were added slowly

after cooling. Then, the reaction mixture was stirred

for about 4 h. The temperature was maintained below 30°C until the completion of the reaction. The

reaction mixture was extracted with petroleum ether

and an ether mixture (1: 1w/w) and washed with

dil aq HC1; concentration of the solvent followed by

recrystallization from ether and hexane in (1 : 1)

ratio yielded pure compounds. The purity was

checked by spectroscopic methods. Yields ( % ) and

melting points of the 3-substituted-2-cyanoacrylates

are reported in Table I.

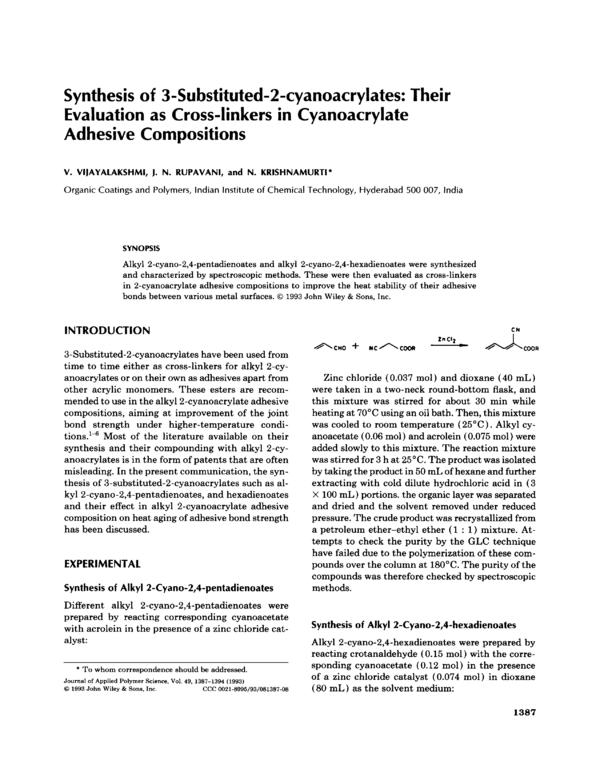

The IR spectra were recorded using Perkin-Elmer

(Model 221 ) spectrophotometer. Monomeric esters

showed absorption at 2210 cm-' (for the conjugated

CN group) and at 1720-1730 cm-' (for the conjugated CO group). The two bands in the region 15801620 cm-' are due to the presence of the conjugated

butadienoic 11-electron system. The absorption

bands a t 990 to 910 cm-' are typical of the allyl

double bond. The IR spectrum of allyl 2-cyano-2,4hexadienoate is shown in Figure 1.

'H-Nuclear Magnetic Resonance Spectroscopy

('H-NMR)

'H-NMR spectra were recorded using a Gemini 200

MHz spectrophotometer. Methyl and ethyl 2-cyano2,4-pentadienoates showed signals of the conjugated

butadienoic system doublet at 6 7.65-7.81 for the

methyne proton of the group (= CH-CH=

CH2).A multiplet a t 6 6.56-7.02 is due to the neighboring methyne proton ( =CH =CH =CH2).The

triplet a t 6 4.81-6.03 with the integral intensity corresponding to two protons is attributed to methylene

protons ( = CH -CH =CH2).

Alkyl 2-cyano-2,4-hexadienoates

and bis ( 2-cyano-2,4-hexadienoates) showed signals of a conjugated butadienoic system multiplet at 6 7.75-7.83

for the methyne proton of the group

( - CH- CH =CH -CH3). The remaining two

SYNTHESIS OF 3-SUBSTITUTED-2-CYANOACRYLATES

1389

100

1

80

-

I

60

Y

CN

A

I

C-H

Str

Y

z

1

I

In

In

CT N

z 40

a

Str

a

t

20

Str

0

I

3000

I

2800

:O

tr

I

2000

1700

i-o

Str

d

olrtinic

C-H oo(,

I

1

1400

I

1100

800

L

50

WAV E NU M 8 E R ( CM")

Figure 1 IR spectrum of allyl 2-cyano-2,4-hexadienoate.

methyne protons appeared a t 6 6.56-6.68 as a multiplet (= CH-C€J=CE-CH,).

Protons attached to terminal carbon appeared as doublet at

6 2.02-2.08 ( = CH -CH =CH -C&). Disappearance of the singlet at 6 3.5 corresponding to two

protons of cyanoacetate (NC -C -COOR) and

€

&

appearance of the above peaks confirm the formation

of dienoates. Detailed spectral data are given in Table 11. The 'H-NMR spectrum of propargyl 2-cyano2,4-hexadienoate is shown in Figure 2.

13C-NuclearMagnetic Resonance Spectroscopy

("C-NMR)

These spectra were recorded using Bruker A.M. 300

MHz spectrophotometer. 13C-NMRspectra of alkyl

2-cyano-2,4-pentadienoates,alkyl2-cyano-2,4hexaare

dienoates, and bis ( 2-cyano-2,4-hexadienoates)

reported now for the first time. 13C-NMR data of

the compounds are given in Table 111. The 13C-NMR

spectrum of 1,4-butanediol bis ( 2-cyano-2,4-hexadienoate) is shown in Figure 3.

Mass Spectroscopy

Mass spectra of the monomers were recorded using

a Micromass VG 7070 U.K. mass spectrophotometer

with an electron beam at 70 eV. The important

characteristic peaks of the dienoates are shown in

Table IV. The mass spectrum of ethyl 2-cyano-2,4hexadienoate is shown in Figure 4. The base peak

is observed a t m / z 106 for all alkyl2-cyano-2,4-pentadienoates. In the case of methyl and ethyl 2-cyano2,4-hexadienoates, the base peak appeared a t m / z

120. For allyl, propargyl, and t-butyl 2-cyano-2,4hexadienoates, R + appears as the base peak. Other

important fragments are listed below:

Alkyl Z-Cyano-2,4-pentadienoates:

HZC=CH-CH-C,

/

CN

COOR

M', ( M - l ) +(M-R)',

,

(M-HCN)'

Alkyl Z-Cyano-2,4-hexadienoates:

1390

VIJAYALAKSHMI, RUPAVANI, AND KRISHNAMURTI

Table I1 'H-NMR (a ppm) Values of

3-Substituted-2-Cyanoacrylates

Alkyl (R)

ii ppm Values of Alkyl Protons

Methyl

Ethyl

3.81 (s, 3H)

1.20-1.37 (t, 3H, 6), 4.08-4.37

(q,2H, 6)

1.61 (s, 9H)

t-Butyl

2-Cyano-2.4-hexadienoate

Methyl

Ethyl

3.87 (s, 3H)

1.25-1.43 (t, 3H, 7), 4.15-4.42

(9, 2H, 7.1)

1.55 (s, 9H)

2.65-2.71 (t, IH, 2), 4.81-4.85

(d,2H, 2)

4.71-4.78 (d, 2H, 7), 5.26-5.49

(m, 2H, 4) 5.87-6.08 (m,

1H, 6)

2.14-2.25 (m, 2H, 5), 3.563.75 (t, 2H, 7.5), 4.43-4.46

(t, 2H, 7.2)

t-Butyl

Propargyl

Ally1

3-Chloropropyl

Bis(2-cvano-2.4-hexadienoate)

1,4-Butanediol

Diethylene glycol

1.8-Octane diol

1.75-1.87 (t, 4H, 2), 4.18-4.35

(t, 4H, 3.5)

4.35-4.46 (t, 4H, 4), 3.73-3.89

(t, 4H, 5.2)

1.31-1.39 (m, 12H, 2), 4.24.24 (t, 4H, 7.5)

The figures in parentheses are type of signal, no. protons, and

J values in Hz.

3-Substituted-2-cyanoacrylatesas Cross-linkers in

Cyanoacrylate Adhesive Compositions

Adhesive Formulations

Four different formulations were prepared by adding

( 10% by weight) methyl Z-cyano-2,4-pentadienoate,

ethyl 2-cyano-2,4-pentadienoate,

methyl 2-cyano2,4-hexadienoate, and ethyl 2-cyano-2,4-hexadienoate separately to propyl 2-cyanoacrylate ( PCA )

adhesive containing ( 0.03% by weight) hydroquinone and (0.01% by weight) sulfur dioxide. Resultant mixtures were agitated to form a homogeneous

mobile adhesive composition. These adhesive formulations were then used for bonding various metal

surfaces and their tensile shear strength and impact

strength were determined after heat soaking a t 25,

100, 125, 150, and 175°C for 1 h. The results are

tabulated in Tables V and VI.

Tensile Bond Strength at Different Temperatures

The pi specimens (adherends) were cleaned with

fine emery paper and then wiped with dry acetone

solvent. Approximately 0.03 mL of adhesive composition was placed on one of the pi specimens and

the other one was placed on top of it to spread the

adhesive. Glued specimens were left for 24 h at 25°C

and then placed in an air oven at different temperatures, as mentioned earlier, for 1h. Later, the samples were cooled and tested for resistance to a uniform direct pull at 25°C using a tensiometer. Results

are given in Table V.

lmpact Strength at Different Temperatures

H3C-CH =CH-

M + ,( M

+ l)',

CH = C

/

\

CN

COOR

( M - l ) + ,(M-R)+, (M-HCN)+

Mild steel blocks were bonded with the adhesive as

per ASTM D-950 (78) specification. After 24 h of

bonding, the composite unit was placed in an air

oven heated to 100, 125, 150, and 175°C for 1 h,

cooled, and tested with an impact caused by a pendulum swinging at a known velocity of 335 cm/s

along an axis parallel to the glue line.

Alkane Diol Bis ( 2-cyano-2,4-hexadienoates)

:

RESULTS AND DISCUSSION

1,4-Butanediol: m / z : 328 ( M + ) ,192,191 ( M + CTH$NOz), 138 ( H , C - C H = C H F H = C ( C N )

COOfH2), 55 (H&-CH=CH-CCHz).

1,8-Octanediol : m / z : 384 ( M + ) , 248 (M+C7HsN02), 234 (M+- CgHgN02), 206 (M+CloH12N02), 111 (110).

Synthesis of Alkyl 3-Substituted-2-cyanoacrylates

The synthesis and properties of methyl and ethyl 2cyano-2,4-pentadienoateshave already been described in the l i t e r a t ~ r eAll other monomers syn.~

thesized in the present work are new and reported

for the first time. These monomers are soluble in

aromatic hydrocarbons, chloroform, acetone, and

CN

a

b

H3C-CH

e

d

= CH=

CH

1

= C - CII

0

0

c .81

t

- CH2 - C

CH

- 4.65

202

r

6.56-6.68

I

b,c

- 2.08

a

2.65-2.71

I

I

6 .O

I

8.0

7 .O

I

5 .o

I

I

3 .O

I

4 .O

2.0

I

1 .o

6P P ~

Figure 2 'H-NMR spectrum of propargyl2-cyano-2,4-hexadienoate.

Table III lsC-NMR (6ppm) Values of

3-Substituted-2-cyanoacrylates

CN

1 .

&COOR

4

6

6OOR

* 7

2

CN

1. 106.16

2 161.4

.

3 113.32

.

4 155.03

.

5. 131.68

6. 134.01

52.54

13.44,62.0

1. 103.5

2 162.44

.

3. 114.23

4 155.88

.

5. 150.09

6. 127.96

7 19.19

.

Methyl

Ethyl

Ropargyl

Ally1

1,4-ButanedioI

1,8-Octanediol

53.56

13.85,62.09

53.84,

77.26,78.26

66.49,

76.58,77.35

24.86,65.39

25.58.28.32.28.89.66.19

I

0.0

1392

VIJAYALAKSHMI, RUPAVANI, AND KRISHNAMURTI

24.86

65.39

8

150.61

156.31

4

127.96

2

7

162.60

L

I

180

16 0

140

120

100

80

60

LO

I

20

0

6P P ~

Figure 3 13C-NMR spectrum of butanediol bis ( 2-cyano-2,4-hexadienoate).

diethyl ether and sparingly soluble in aliphatic hydrocarbon solvents. In the presence of alcohols,

small quantities of water, and organic or inorganic

bases, these monomers polymerize, with considerTable IV Characteristic Peaks of Fragments in

3-Substituted-2-Cyanoacrylates

Fragment

m/z

Pentadienoates

CN

/

H&=CH-CH=C

able exothermal effect, to form colorless or yellowish

rubberlike polymer. This property is probably due

to the specific structure of 1,l-disubstituted dienes.

The distribution of the a-electron density in their

molecule is strongly affected by the combined mesomeric and inductive effect of CN and COOR

groups. Therefore, the presence of even a weak base

(e.g., OH ion from the dissociation of water molecule ) is enough to initiate anionic polymerization.

The resulting dienoate anion is stabilized by the two

substituents ( CN and COOR) . Chain propagation

is a result of nucleophilic attack of the anionic active

end on a monomer molecule.

106

\+

co

Tensile Strength at Different Temperatures

+

78

H&=CH-CH=C-CN

+

51

HzC=CH -CEC

Hexadienoates

CN

/

H3C-CH =CH-CHIC

\+

+

co

92

HjC--CH=CH-CH=C-CN

H,C-CH=CH-C=C

120

+

65

Tensile bond strength of unmodified PCA reduced

rapidly with increase in the temperature from 25 to

175°C. Addition of 3-substituted-2-cyanoacrylates

in PCA increased the bond strength at all temperatures over the unmodified PCA. Addition of these

cross-linking agents increased the bond strength up

to 150°C and thereafter it reduced (Table V ) . PCA

with alkyl 2-cyano-2,4-pentadienoatesshowed

higher tensile bond strength than did PCA with alkyl

2-cyano-2,4-hexadienoates,i.e., increasing the

number of carbons in the diene group decreased the

bond strength. The adhesive formulation of PCA

showed more

with ethyl Z-cyan0-2,4-pentadienoate

heat resistance than that of those made from dif-

SYNTHESIS OF 3-SUBSTITUTED-2-CYANOACRYLATES 1393

-

-100

2*

65

R-1 29 39

R

D-2

Y

I

n

C-HCN

€3

D--

93

z

ct1

w 60- 27

I

-

z

-

H$-CH=CH+CH=

137

92

C

A+ 1

-

4

20-

W

41

D

1

p:

1 - - ~

'

C

C

I

II

I

0 f CH2- C H 3

I

*--#

I

A

.

I

I

U

2

V

64

CNB-7

co-l

165

w LO>

I

-

I

1

Mti

166

&I5

la6138

1

1

ferent 3-substituted-2-cyanoacrylates. could be

This

explained on the basis of degradation studies of the

polymer.' Addition of ethyl 2-cyano-2,4-pentadienoate increased the bond strength between stainless-steel surfaces considerably to 22.8 and 25.0 MPa

a t 100 and 125"C, respectively, as against 8.00 and

6.42 MPa from unmodified PCA. Increase in the

amount of the cross-linking agent from 10 to 20%

in PCA showed a very slight increase in the bond

strength at higher temperatures.

2-Cyanoacrylate adhesives modified with 3-substituted-2-cyanoacrylatescan be used to join surfaces together that are exposed to temperatures in

the range from 100 to 150°C. The stability of these

Table V Tensile Bond Strength (MPa) of PCA Containing Different Substituted 2-Cyanoacrylatesat

Different Temperatures

Tensile Strength (MPa)

Adhesives

PCA

+ methyl 2-cyano-2,4-pentadienoate

Adhered

Materials

M-M

s-s

A-A

c-c

B-B

PCA

+ methyl 2-cyano-2,4-hexadienoate

M-M

s-s

A-A

c-c

B-B

PCA

+ ethyl Z-cyano-2,4-pentadienoate

M-M

s-s

A-A

c-c

B-B

PCA

M-M

s-s

A-A

c-c

B-B

M, mild steel; S, stainless steel; A, aluminium; C, copper; B, brass.

25°C

100°C

125°C

150°C

15C

7'

18.20

20.52

10.64

12.20

12.78

20.52

21.30

10.60

12.94

13.84

24.30

25.44

12.92

13.76

15.92

24.82

25.63

13.42

14.00

16.20

6.08

8.35

3.79

3.90

3.42

18.20

19.33

9.11

9.11

12.52

19.52

20.20

11.22

10.63

13.62

22.72

22.90

12.13

12.95

14.43

23.00

23.60

13.52

13.47

15.83

6.02

7.39

5.31

2.27

2.27

20.51

21.00

11.92

12.51

12.83

21.20

22.81

12.22

13.03

15.25

24.82

25.00

13.76

13.84

16.72

25.20

26.00

13.84

14.03

17.23

11.40

15.40

4.56

5.32

60

.8

12.15

13.65

87

.4

10.63

13.22

8.29

8.00

6.21

5.10

5.60

6.50

6.42

4.23

4.20

4.35

2.80

3.12

2.10

2.10

2.50

2.66

2.50

1.00

1.00

1.00

1394

VIJAYALAKSHMI, RUPAVANI, AND KRISHNAMURTI

Table VI Impact Strength (kJ/m2)of Propyl Cyanoacrylate Containing Different

3-Substituted-2-Cyanoacrylates Different Temperaturesbetween Mild Steel Surfaces

at

Impact Strength (kJ/m2)

25°C

1. PCA

2 PCA

.

3. PCA

4. PCA

5 PCA

.

+ methyl 2-cyano-2,4-pentadienoate

+ methyl 2-cyano-2,4-hexadienoate

+ ethyl 2-cyano-2,4-pentadienoate

+ ethyl 2-cyano-2,4-hexadienoate

100°C

125°C

150°C

175°C

1.

02

9.3

12.4

93

.

40

.

Adhesives

12.4

12.4

15.5

1.

04

15

.

15.5

12.8

1.

60

1.

16

1.0

16.0

1.

32

1.

65

11.8

0.8

62

.

60

.

6.8

4.6

0.4

adhesives is also good. The setting times are generally in the range of 10-20 s, depending on the type

of surfaces to be joined. The effect of these crosslinking agents depends upon the end group

Adhesive formulation of PCA with ethyl 2-cyano2,4-pentadienoate showed higher impact strength

than those made from other 3-substituted-Z-c~anoacrylates.

CN

(CH,=CH

I

-CH =C

-)

CONCLUSIONS

and unsaturation in the alkyl group. 2-Cyanoacrylate adhesives formulated with 3-substituted-2-cyanoacrylates are found to be resistant to organic

solvents and water.

Impact Strength at Different Temperatures

Addition of 3-substituted-2-cyanoacrylates PCA

to

increased the impact strength substantially at all

temperatures over the unmodified PCA. This is due

to the stronger bonds, developed due to the crosslinking of 3-substituted-2-cyanoacrylates

with PCA.

The impact strength increased up to 15OOC; thereafter, it reduced (Table VI) . The improved heat resistance is attributed to the cross-linking of the residual olefin after the anionic polymerization at 3substituted-2-cyanoacrylates

according to the following equation:

n H,C=CH-CH=C

/CN

___t

‘COOR

1

COOR],

I

n CH2=C

cross linked polymer

Addition of alkyl 2-cyano-2,4-pentadienoates alto

kyl2-cyanoacrylates gave improved and heat-resistant ( 15OOC)bonds between various metal surfaces

due to the formation of cross-linking polymers. Addition of alkyl 2-cyano-2,4-hexadienoates alkyl

to

2-cyanoacrylates also improved the bond strength

at higher temperatures, but not as much as those

obtained from pentadienoates.

RFRNE

EE E CS

1 G. H.Millet, U.S. Pat. 4,415,471(1984).

.

2 T. Teramoto, N. Ijuin, and E. Kotani, Jpn. Pat.

.

4,125,070( 1981 ) .

3. N. N. Trofimov, W. S. Etlis, and D. A. Aronowitsch,

Ger. Pat. 2,357,321(1975).

4 M. N. Quinn, U.S. Pat. 3,554,900(1971).

.

5. T. Teramoto, N. Ijuin, and E. Kotani, U.S. Pat.

4,313,865(1982).

6. N. N. Trofimov, W. S. Etlis, and D. A. Aronowitsch,

U.S. Pat. 1,415,102(1975).

7 A. H. Gerber, U.S. Pat. 4,415,471(1984).

.

8. F. Leonard, R. K. Kulkarni, G. Brandes, J. Nelson,

and J. J. Cameron, J. Appl. Polym. Sci., 10, 259

( 1966).

/CN

‘COOR

Received June 2, 1992

Accepted December 21, 1992

Coments go here:

- Log in to post comments