A Review of Block Polymer Surfactants

IRVING R. SCHMOLKA, BASF Wyandotte Corp., Wyandotte, MI 48192

ABSTRACT AND SUMMARY

addition first o f p r o p y l e n e oxide and then ethylene oxide

to a low molecular weight water-soluble organic c o m p o u n d ,

propylene glycol. The h y d r o p h o b e is the inner p o l y o x y propylene glycol which changes from a water soluble- to a

water insoluble- p o l y m e r as the molecular weight goes

above 750. The a d d i t i o n o f ethylene oxide in the final step

provides water solubility to the molecule. In this-series, as

in all other syntheses to be presented, the o x y a l k y l a t i o n

steps are carried o u t in the presence of an alkaline catalyst,

generally sodium or potassium hydroxide. The alkaline

catalyst is then neutralized and usually removed from the

final product. The equations representing this synthesis are

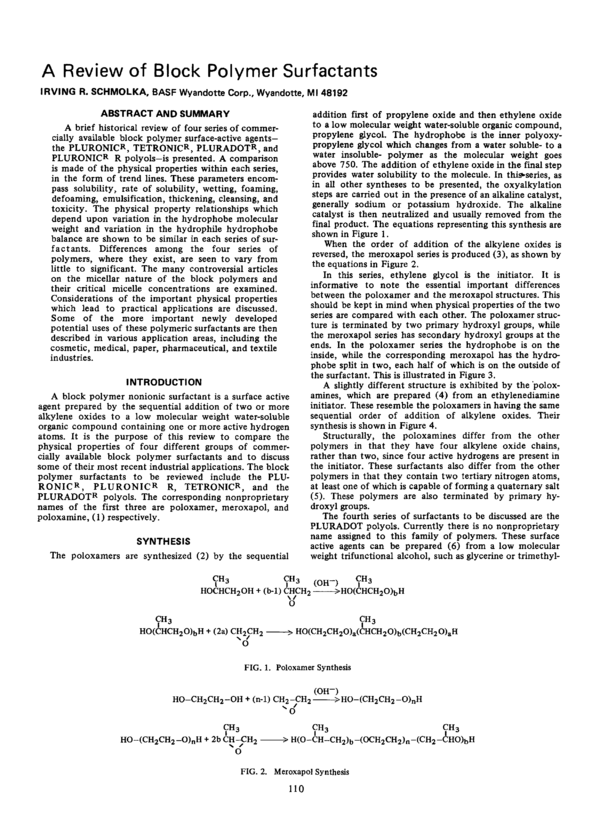

shown in Figure 1.

When the o r d e r of a d d i t i o n o f the alkylene oxides is

reversed, the m e r o x a p o l series is produced (3), as shown by

the equations in Figure 2.

In this series, e t h y l e n e glycol is the initiator. It is

informative to n o t e the essential important differences

between the p o l o x a m e r and the m e r o x a p o l structures. This

should be kept in m i n d when physical properties o f the two

series are c o m p a r e d with each other. The p o l o x a m e r structure is terminated b y two p r i m a r y h y d r o x y l groups, while

the meroxapol series has secondary h y d r o x y l groups at the

ends. In the p o l o x a m e r series the h y d r o p h o b e is on the

inside, while the corresponding m e r o x a p o l has the hydrophobe split in two, each half o f which is on the outside of

the surfactant. This is illustrated in Figure 3.

A slightly different structure is exhibited b y the 'poloxamines, which are p r e p a r e d (4) from an ethylenediamine

initiator. These resemble the poloxamers in having the same

sequential order o f a d d i t i o n o f alkylene oxides. Their

synthesis is shown in Figure 4.

Structurally, the p o l o x a m i n e s differ from the other

polymers in that t h e y have four alkylene oxide chains,

rather than two, since four active hydrogens are present in

the initiator. These surfactants also differ from the other

polymers in that t h e y contain two tertiary nitrogen atoms,

at least one of which is capable o f forming a quaternary salt

(5). These p o l y m e r s are also terminated by primary hydroxyl groups.

The fourth series o f surfactants to be discussed are the

PLURADOT polyols. Currently there is no n o n p r o p r i e t a r y

name assigned to this family of polymers. These surface

active agents can be p r e p a r e d (6) from a low molecular

weight trifunctional alcohol, such as glycerine or trimethyl-

A brief historical review of four series o f c o m m e r cially available b l o c k p o l y m e r surface-active a g e n t s the P L U R O N I C R, T E T R O N I C R, P L U R A D O T R, and

P L U R O N I C R R p o l y o l s - i s presented. A comparison

is made o f the physical properties within each series,

in the form o f trend lines. These parameters encompass solubility, rate of solubility, wetting, foaming,

defoaming, emulsification, thickening, cleansing, and

t o x i c i t y . The physical p r o p e r t y relationships which

depend u p o n variation in the h y d r o p h o b e molecular

weight and variation in the hydrophile h y d r o p h o b e

balance are shown to be similar in each series o f surf a c t a n t s . Differences among the four series of

polymers, where t h e y exist, are seen to vary from

little to significant. The m a n y controversial articles

on the micellar nature of the block p o l y m e r s and

their critical micelle concentrations are examined.

Considerations o f the i m p o r t a n t physical properties

which lead to practical applications are discussed.

S o m e o f the more i m p o r t a n t newly developed

p o t e n t i a l uses o f these p o l y m e r i c surfactants are then

described in various application areas, including the

cosmetic, medical, paper, pharmaceutical, and textile

industries.

INTRODUCTION

A b l o c k p o l y m e r nonionic surfactant is a surface active

agent prepared by the sequential addition o f two or more

alkylene oxides t o a low molecular weight water-soluble

organic c o m p o u n d containing one or more active hydrogen

atoms. It is the p u r p o s e of this review to c o m p a r e the

physical p r o p e r t i e s of four different groups o f commercially available b l o c k p o l y m e r surfactants and to discuss

some of their most recent industrial applications. The block

p o l y m e r surfactants t o be reviewed include the PLUR O N I C R, P L U R O N I C R R, TETRONIC R, and the

P L U R A D O T R polyols. The corresponding n o n p r o p r i e t a r y

names o f the first three are p o l o x a m e r , m e r o x a p o l , and

p o l o x a m i n e , ( 1 ) respectively.

SYNTHESIS

The p o l o x a m e r s are synthesized (2) b y the sequential

CIH3

C-H3 (OH-)

CIH3

HOCHCH2OH + (b-l) CHCH2

>HO(CHCH20)bH

\/

O

CH3

HO(CHCH20)bH + (2a) CH2CH 2

x /

O

> HO(CH2CH20)a(CHCH20)b(CH2CH20)aH

FIG. 1. Poloxamer Synthesis

HO-CH2CH2-OH + (n-l) CH2--CH2

(OH-)

>HO-(CH2CH2-O)nH

-o'

CH 3

I

HO-(CH2CH2-O)nH + 2b CH--CH 2

%, J

O

> H(O-CH-CH2)b-(OCH2CH2)n-(CH2-CHO)bH

FIG. 2. Meroxapol Synthesis

110

�MARCH, 1977

SCHMOLKA: BLOCK POLYMER SURFACTANT

Meroxapol

I

1

Poloxamer

IF o l

o

ol

FIG. 3.

/0~

(OH-)

H2N-CH2CH2-NH 2 + 4b CH 2 - C H - C H 3

>

OH

I

(CH 3CHCH2)b~

OH

I

/ (CH 2CHCH3)b

NCH2CH2N~

(CH37HCH2)b /

(CH27HCH3)b

OH

OH

~0

(OH-)

HYDROPHOBE + 4a CH2-CH 2

>

H(C2H40)a(CaH60)b

/(C3H60)b(C2H40)aH

~NCH2CH2N

H(C2H40)a(C3H60)b /

~(C3H60)b(C2H40)aH

explained. As seen in Table I, which illustrates the

p o l o x a m e r series, the first two digits of a p o l o x a m e r , when

multiplied by 100, indicate the a p p r o x i m a t e h y d r o p h o b e

molecular weight. The last digit, when m u l t i p l i e d b y 10,

gives the percent of ethylene oxide in the molecule, the

balance being p r o p y l e n e oxide.

The m e r o x a p o l series is shown in Table II. The first two

digits, when m u l t i p l i e d by I 0 0 , give the t o t a l m o l e c u l a r

weight o f the t w o p o l y o x p r o p y l e n e glycol h y d r o p h o b e s .

The last digit, multiplied by 10, gives the percent ethylene

oxide in each polymer. In this respect the m e r o x a p o l

n o m e n c l a t u r e system resembles the p o l o x a m e r system.

The p o l o x a m i n e series is described in Table III. The

same system is used with the poloxamines as with the

previous two series. The last digit, multiplied b y 10, gives

the percent e t h y l e n e oxide in the final molecule, while the

first t w o digits are indicative of the h y d r o p h o b e m o l e c u l a r

weight. The zero was included so as to minimize confusion

with the p o l o x a m e r numbering system.

The last series, the P L U R A D O T polymers, is shown in

Table IV.

The exact relative percentages of ethylene and p r o p y l e n e

oxides in the h y d r o p h o b e and the h y d r o p h i l e in this series

a r e p r o p r i e t a r y information. However, f r o m physical

p r o p e r t y data, specifically cloud points, it can be seen that

the larger the s e c o n d digit, the greater is the t o t a l percent

of e t h y l e n e oxide in the molecule. As seen in the table, the

larger the first digit, the greater is the h y d r o p h o b e molecular weight.

PHYSICAL PROPERTI ES

FIG. 4. Poloxamine Synthesis

~C3H60. ~

R(OH)3+3n ~C2--~-~40~ (>I)

111

(OH-)

>

R[O(C3H60/C2H40)nH] 3

~ C2H40 .~

(OH-)

R[O(C3H60/C2H40)nH] 3 + 3m \C3-C--~-~} (>1)

>

R [O( C 3H 60/C 2 H40 )n-( C2 H40/C 3H60 )mH ] 3

FIG. 5. Pluradot Polyol Synthesis

olpropane, which is o x y a l k y l a t e d initially with a blend of

p r o p y l e n e and ethylene oxides, but mostly with propylene

oxide, to form the h y d r o p h o b e . This is followed b y oxyalkylating with a blend of ethylene and propylene oxides,

but mostly with ethylene oxide, to form a hydrophile. This

synthesis scheme is shown in Figure 5.

This group o f surfactants has three chains, one more

than the p o l o x a m e r and m e r o x a p o l series, b u t one less than

the p o l o x a m i n e polymers. Because o f the slower rate of

reaction o f p r o p y l e n e oxide, c o m p a r e d to ethylene oxide, it

is suggested that the terminal h y d r o x y l group is composed

primarily o f secondary h y d r o x y l groups rather than of

primary h y d r o x y l groups.

Obviously there are no chemical differences within any

one series of p o l y m e r i c surfactants. A m o n g the four series,

there are two differences. (1) The presence of the two

tertiary nitrogen a t o m s in the poloxamines and their

absence in the o t h e r polymers, and (2) the terminal

secondary or primary h y d r o x y l groups, as mentioned

previously.

NOMENCLATURE

Since there are more than seventy-five different polymeric surfactants, the nomenclature of each system will be

Cloud Point

Major differences in physical properties are seen to exist

within any one series. In addition, when one c o m p a r e s one

series with another, some differences and some similarities

are readily apparent. All four nonionic series are alike in

that t h e y derive their solubility in water from h y d r o g e n

b o n d f o r m a t i o n between the m a n y ether o x y g e n atoms

present and p r o t o n s in the water. When the t e m p e r a t u r e of

a solution of a nonionic surfactant is raised, the h y d r o g e n

b o n d is b r o k e n and the nonionic clouds out o f solution.

This is k n o w n as the cloud point. F o r p o l o x a m e r s , the 1%

cloud p o i n t ranges from a low of 14 C t o a high of 100 C.

This latter figure is for the most h y d r o p h i l i c p o l y m e r s containing 80% e t h y l e n e oxide. In contrast, the m e r o x a p o l s

have a n a r r o w e r cloud p o i n t range. The i m p o r t a n t difference w o u l d be the lowered cloud p o i n t with the most

h y d r o p h i l i c members, those that contain 80% ethylene

oxide. The p o l o x a m i n e s resemble the p o l o x a m e r s in this

property,

s i n c e t h e y are structurally similar. The

P L U R A D O T p o l y m e r s have the lowest m a x i m u m cloud

p o i n t p r i m a r i l y because the m o s t h y d r o p h i l i c m e m b e r s have

a l o w e r e t h y l e n e oxide c o n t e n t t h a n the 80% e x h i b i t e d b y

the o t h e r series, and perhaps, p a r t l y due to the presence of

some p r o p y l e n e oxide in the terminal h y d r o p h i l e . These

data are shown in Table V.

Water Solubility

Within any one series, as the percent o f e t h y l e n e oxide

increases, or the molecular weight of the h y d r o p h o b e

decreases, the solubility in water increases. This is true for

all f o u r series.

Within any one series, the rate o f solubility o f a p o l y m e r

in water decreases as the h y d r o p h o b e m o l e c u l a r weight

increases. In a comparison of the rate o f solubility in water

of t w o similar polymers, one with the h y d r o p h i l e on the

outside, p o l o x a m e r 188, and the o t h e r with the h y d r o p h i l e

on the inside, mero~/apol 17R8, the latter h a d a faster rate

of solubility t h a n the former.

In a n o t h e r comparison b e t w e e n t w o p o l y m e r s with a

�112

J O U R N A L O F T H E A M E R I C A N O IL C H EMIS TS ' S O C I E T Y

VOL. 54

TABLE I

P o l o x a m e r Series

Hydrophobe

molecular

weight

4000

3250

2750

2250

2050

1750

1200

950

401

331

402

403

333

407

334

284

234

282

231

181

212

182

122

183

123

184

124

20

30

40

101

10

335

235

215

185

338

288

238

237

217

188

105

108

50

60

70

80

% Ethylene oxide

TA B LE II

Meroxapol Series

Hydrophobe

molecular

weight

31RI

25R1

17R1

31R2

25R2

17R2

10

3100

2500

1700

1000

20

31R 4

25R4

17R4

25R5

25R8

17R8

10R8

10R5

30

40

50

60

70

80

% Ethylene oxide

TABLE 111

P o l o x a m i n e Series

Hydrophobe

molecular

weight

1501

1301

1101

901

701

1502

1302

1102

10

6750

5750

4750

3750

2750

1750

750

20

1504

1304

1104

904

704

504

304

702

30

40

1508

1307

1107

908

707

50

60

70

80

% Ethylene oxide

similar molecular weight and the same ethylene oxide/

p r o p y l e n e oxide ratio, the t e t r a f u n c t i o n a l p o l y m e r , poloxamine 707, was f o u n d to dissolve more rapidly than the

difunctional p o l y m e r , p o l o x a m e r 407. This suggests that

the length of the p o l y m e r chain has an effect on the rate of

solubility.

This is substantiated when one compares the rate of

solubility, within any one series, of a group of polymers

with the same ethylene o x i d e / p r o p y l e n e oxide ratio, but of

varying molecular weight. It has been f o u n d that the larger

the molecular weight of the h y d r o p h o b e , the slower is the

rate of solubility.

No solubility rate comparisons have been carried out

with the P L U R A D O T polymers.

Oil Solubility

None of the poloxamers is soluble is mineral oil. However, b y placing the p o l y p r o p y l e n e glycol h y d r o p h o b e on

the outside o f the molecule, it is o f interest t o note that

m a n y of the m e r o x a p o l p o l y m e r s do exhibit m o d e r a t e

solubility in this lipophilic solvent. The p o l o x a m i n e and

P L U R A D O T p o l y m e r s are also insoluble in mineral oil. This

is t o be e x p e c t e d , since they m o r e closely resemble the

p o l o x a m e r than the m e r o x a p o l structure.

The solubility characteristics of the four series of

p o l y m e r s in an organic solvent, such as p r o p y l e n e glycol,

are quite similar. The higher the h y d r o p h o b e molecular

T A B L E IV

P l u r a d o t H A Series

Increasing

hydrophobe

molecular

w e i ght

l

510

520

530

540

550

410

420

430

440

450

Low

High

% Ethylene oxide

TABLE V

1% Cloud Point, ~

Surfactant

Minimum

Maximum

A

Poloxamer

Meroxapol

Poloxamine

Pluradot

14

25

15

25

100

99

100

77

86

74

85

52

weight, the less soluble is the polymer. Also, those polymers with a high percentage of ethylene oxide or a high

percentage of p r o p y l e n e oxide, everything else being equal,

are less soluble in p r o p y l e n e glycol than those p o l y m e r s

which have an ethylene oxide c o n t e n t o f between 40 and

60%.

�MARCH, 1977

113

SCHMOLKA: BLOCK POLYMER SURFACTANT

T A B L E VI

P o l o x a m i n e W e t t i n g Times, a Sec.

Hydrophobe

molecular

weight

6750

5750

4750

3750

2750

1750

51

30

15

84

48

37

88

185

>360

38

10

20

30

40

>360

>360

50

60

70

80

% Ethylene oxide

a D r a v e s t e s t , 3 g H o o k , 0 . 1 % s o l u t i o n , 2 5 C.

T A B L E VII

M e r o x a p o l D y n a m i c F o a m H e i g h t s , 25 C a

Hydrophobe

molecular

weight

3100

2500

1700

1000

15

40

115

40

45

195

10

20

215

260

300

125

110

145

125

260

30

40

S0

60

70

80

% Ethylene oxide

a F o r 0 . 1 % s o l u t i o n at 4 0 0 m l / m i n f l o w r a t e .

Wetting

In each of the p o l y m e r series, the same wetting trend is

observed in that wetting time, as measured by the Draves

test for a 0.1% solution at 25 C, decreases as the percent

hydrophile decreases. Also as the molecular weight of the

hydrophobe increases, the wetting time decreases. However,

above a certain limit, which varies with each series, there is

no decrease in the wetting time as the hydrophobe molecular weight increases. This is exemplified in Table VI, by

the poloxamine series, which shows that wetting time

reaches a m i n i m u m as the hydrophobe molecular weight

increases from 750 to 4750 but then rises slightly as the

molecular weight increases further to 6750.

Foaming

Within each series, the foam property reaches a maximum at a different ethylene oxide/propylene oxide ratio.

With the meroxapols, m a x i m u m foam height, at 25 C, is at

a 40:60 ethylene oxide/propylene oxide ratio, but at 49 C,

the m a x i m u m shifts to a 50:50 ratio. The poloxamers

exhibit m a x i m u m foam at a slightly higher ethylene oxide/

propylene oxide ratio, namely 60:40, at 49 C. From data

on the limited n u m b e r of polymers prepared in the poloxamine series, it appears that foam is maximized between the

40:60 and 7 0 : 3 0 ethylene oxide/propylene oxide ratios.

Foam values in the P L U R A D O T series increase as the cloud

point of the p o l y m e r increases. However, the limited

n u m b e r of polymers makes it impossible to draw any valid

conclusions. F o a m properties of each surfactant series

increase and t h e n decrease slightly, as the hydrophobe

molecular weight increases. This is exemplified in Table VII

where the n u m b e r s represent millimeters of foam generated

at a 400 m l / m i n flow rate in the dynamic foam machine for

the meroxapols.

However, the biggest difference in foam properties is

found in a comparison of the foam properties of the two

series which have terminal hydrophile groups, the poloxamers and the poloxamines, with the meroxapols, where

the h y d r o p h o b e groups are on the outside. The latter series

exhibits little or n o foam, even by its most hydrophilic

members. As an example, a 0.1% solution of p o l o x a m e r

188 has a foam value of 600 m m at 40 C at a 400 m l / m i n

dynamic flow rate, while its meroxapol counterpart, 17R8,

has a foam height of only 44 mm, u n d e r the same conditions. Poloxamer and poloxamine foam heights appear

comparable for comparable polymers. Thus, for example,

poloxamer 407 has a foam value of 160 m m at a 200 ml

flow rate, while poloxamine 707 has a foam value of

180 mm, u n d e r identical test conditions.

For defoaming properties, all four series resemble each

other in that the highest propylene oxide/ethylene oxide

ratio surfactants are very effective defoamers and n o t r e n d

lines can be drawn or large differences noted. If any generalization can be drawn, it might be that the meroxapols

appear to be better defoamers than their corresponding

poloxamers.

EMULSIFICATION

Attempts to correlate emulsification properties with

ethylene oxide/propylene oxide ratios and h y d r o p h o b e

molecular weights have n o t been very successful. Within

any one series, the higher molecular weight h y d r o p h o b e s

are generally better emulsifiers than their lower molecular

weight homologs. Some of the poloxamers appear to be

better emulsifying agents for mineral oil or f l u o r o c a r b o n s

in aqueous systems than the meroxapol or p o l o x a m i n e

polymers, while several of the latter appear superior for

preparing stable emulsions of glyceryl trioleate in water.

However, no trend lines can be presented.

Thickening

The thickening power of each series of surfactants in

w a t e r increases as the h y d r o p h o b e molecule weight

increases and as the ethylene oxide/propylene oxide ratio

increases.

The available data, b u t n o t shown here, indicate that the

meroxapol and P L U R A D O T series do n o t form gels at a n y

concentrations in water, whereas only 20% o f either

poloxamer 407 or p o l o x a m i n e 1508 is needed to form a

�114

JOURNAL OF THE AMERICAN OIL CHEMISTS' SOCIETY

VOL. 54

strong gel. In comparison, a 20% solution of p o l o x a m e r

403, p o l o x a m e r 188, p o l o x a m i n e 1504, or p o l o x a m i n e 908

is a fluid liquid at r o o m temperature.

Cleansing

Because of the varying nature o f substrates, soils, cleaning conditions, and t y p e s of e q u i p m e n t used, n o one trend

line can be drawn which would best describe the cleaning

properties of the four series o f b l o c k p o l y m e r surfactants.

Toxicity

Within any one series the t o x i c i t y o f a b l o c k p o l y m e r

surfactant decreases as the ethylene o x i d e / p r o p y l e n e oxide

ratio increases and as the molecular weight of the hydrop h o b e increases. This has been shown by the acute oral

L D s 0 values for the p o l o x a m i n e and m e r a x o p o l series.

Most values are very high, generally =>5 g/kg, which is at the

lower limit of the slightly toxic class in the classification

s c h e m e given in Clinical T o x i c o l o g y of Commercial

Products (I 2). It is n o t valid to c o m p a r e the t o x i c i t y of any

one series with another.

FIG. 6. Suggested poloxamer micelle configuration.

Critical Micelle Concentrations (CMC)

The early published reports (13-15) on the s t u d y of

micelle f o r m a t i o n o f b l o c k c o p o l y m e r s of ethylene and

p r o p y l e n e oxides claimed that these surfactants did not

form micelles, in contrast to the o x y e t h y l a t e d f a t t y alcohols or alkylphenols. However, Becher (16) r e p o r t e d that

the CMC for p o l o x a m e r 182 was 2.4 wt % while Ross and

Olivier (17) r e p o r t e d the CMC for p o l o x a m e r 184 to be

0.026 wt %. Subsequently, Williams and Graham (private

c o m m u n i c a t i o n ) d e t e r m i n e d critical micelie concentrations

for several o f the p o l o x a m e r s , using surface tension depression methods. This c o n t r o v e r s y as to whether or n o t the

p o l o x a m e r s form micelies was e x a m i n e d once again when

Schmolka and R a y m o n d used a differential dye absorption

technique (18) and verified the existence of micelles. The

values t h e y obtained, n a m e l y t h a t the poloxamers had

critical micelle c o n c e n t r a t i o n s in the range o f 3.0 to

11.0 #tool per liter, agreed closely with the data previously

f o u n d by Williams and Graham.

At a b o u t this time, Saski and Shah (19), using three

different techniques, r e p o r t e d considerably higher critical

micelle concentration values for the poloxamers. These

were 2.4, 2.2, and 0.1 wt % respectively, for p o l o x a m e r s

182, 184, and 188. On the o t h e r hand, Sheth (20) r e p o r t e d

a critical micelle c o n c e n t r a t i o n value for p o l o x a m e r 188 of

0.2 wt %, by means o f surface tension depression.

This confusion on CMC values has been c o m p o u n d e d

even further. Thus, A n d e r s o n (21) has reported, using the

same surface tension depression m e t h o d , that the critical

micelle concentration values for p o l o x a m e r s 181, 182, and

1 8 8 w e r e significantly lower t h a n those previously

r e p o r t e d . Anderson also used the differential dye absorption technique with b e n z o p u r p u r i n 4B and iodine m e t h o d s

t o s t u d y this problem, b u t claimed that, due to interaction

o f the iodine and dye with the polymers, resulting in

increases in absorbance, these m e t h o d s would not p e r m i t a

satisfactory d e t e r m i n a t i o n o f the critical micelle concent r a t i o n values of the b l o c k c o p o l y m e r surfactants.

Nuclear magnetic resonance has been used (22) to s t u d y

the interaction o f p o l o x a m e r 188 and phenol. Starting with

l o w phenol concentrations, up t o 2%, in a I0% aqueous

p o l o x a m e r 188 solution, the authors r e p o r t e d that the

p h e n o l was associated mainly with the p o l o x y p r o p y l e n e

chain. However, as the ratio o f p h e n o l to p o l o x a m e r

increased, it a p p e a r e d that the p o l y o x y p r o p y l e n e chain

b e c a m e saturated with p h e n o l and relatively more phenol

e n t e r e d the p o l y o x y e t h y l e n e chain. The authors c o n c l u d e d

t h a t this indicated the presence o f micelles in the p o l o x a m e r phenol water system. However, t h e y suggested t h a t

FIG. 7. Suggested poloxamer micelle configuration.

the micelle would not necessarily be aggregates of cop o l y m e r molecules as is f o u n d with other types of surfactants, but consisted o f one molecule with the poloxyethylene chains rolled a r o u n d the p o l o x y p r o p y l e n e region.

This is illustrated in Figure 6.

The solution properties o f several of the poloxamers

were studied in water as well as in a nonaqueous solvent,

such as benzene, dioxane, and b u t y l chloride. Considerable

difference was found (23) b e t w e e n the weight and numberaverage molecular weight o f the p o l o x a m e r micelles, as

determined by light scattering and t w o methods of measuring vapor pressure lowering. The n u m b e r of molecules per

miceile found by light scattering varied, for example, for

p o l o x a m e r 188, from 1.5 to 8 in the various solvents and

less widely for p o l o x a m e r s 108 and 338. The authors coneluded that the poloxamers with a molecular weight below

2000, such as 101 and 105, failed to associate in benzene

whereas higher molecular weight homologs, such as poloxamers 108 and 188, did.

In order to meet the r e q u i r e m e n t s of 2-8 molecules per

micelle, it is suggested t h a t each surfactant molecule is

shaped like a horseshoe, and t h a t 2-8 interlocking horseshoe-shaped molecules form a micelle, as illustrated in

Figure 7.

The solid lines represent the molecules which lie in the

plane o f the paper, while those represented b y a d o t t e d line

are below and above the plane o f the paper. On the other

hand, the micellar molecular weight o f p o l o x a m e r 188, as

determined by light scattering, has been reported (24) to be

l0 s .

Two of the poloxamines have been reported to exhibit

micelles. Poloxamine 707 was f o u n d (18) to exhibit a

critical micelle concentration o f 0.005 wt % at 25 C, using

the differential dye a b s o r p t i o n technique. On the other

�MARCH, 1977

SCHMOLKA: BLOCK POLYMER SURFACTANT

hand, the CMC value for p o l o x a m i n e 908 was found to be

0.06 w t % , using b o t h surface tension depression and

solubility methods.

Previous measurements were carried out at 25 C. Most

recently, the effects of t e m p e r a t u r e on the micellar properties of p o l o x a m e r 184 have been studied (25) over a range

of temperatures by surface tension and light scattering techniques. The authors r e p o r t e d t h a t at 25 C the micellar

molecular weight is 2656, which is close to the molecular

weight of 2900. However, at 30 C and 35 C, the authors

r e p o r t e d aggregation numbers of 5.9 and 29.9, respectively.

These results suggested to the authors that poloxamers

behave differently from o t h e r nonionic surfactants. First,

whereas other nonionic surfactant micellar sizes increase

with temperature, with the poloxamers there may be

temperature ranges within which no micelles form at all.

Secondly, the authors believed that the growth of aggregates to a stable size takes place over much wider concentration ranges than for o t h e r nonionic surfactants, and

lastly, the authors thought that the normal methods for

determining CMC values of the poloxamers were inaccurate.

Thus, one is led to conclude t h a t the micellar nature of the

block p o l y m e r surfactants and their critical micelle concentrations is a very c o m p l e x and confused subject.

APPLICATION AREAS

Many new and interesting industrial applications for the

block p o l y m e r nonionic surfactants have been developed,

just in the past five or six years alone.

Most o f these uses have been r e p o r t e d in publications

such as magazine articles or patents and are not proprietary

information. In reviewing these new applications, consideration will be given to the i m p o r t a n t physical p r o p e r t y

or properties which led to the selection of the block

polymer. No a t t e m p t will be made to present a complete

application picture, b u t rather only selected cases in just a

few industries will be described.

The first application area to be reviewed will be cosmetics. Obviously, the p r i m a r y reason for using block

p o l y m e r surfactants here is their absence of toxicity, but in

addition, o t h e r very specific physical properties are required.

A new dentifrice, designed for sensitive teeth, called

PROTECT, uses p o l o x a m e r 407 because it is a gelling agent.

The p o l o x a m e r / s o d i u m citrate combination was reported

(26) t o have a highly significant desensitizing effect, in

comparison with a control formulation of unknown composition. A n o t h e r desirable p r o p e r t y of the poloxamer in this

application is its absence o f any bitter taste. This is a new

p r o d u c t currently being m a r k e t e d in several locations in the

United States.

An alcohol-based m o u t h w a s h was reported stabilized

(27) by the addition of a p o l o x a m e r with an ethylene oxide

content of :>40%. The a d d i t i o n of the p o l o x a m e r prevents

the f o r m a t i o n of a cloudy appearance which would otherwise develop on standing. In this application, the lack of

taste of the p o l o x a m e r , plus its ability to solubilize water

insoluble aromatic flavors, are i m p o r t a n t considerations for

its use.

In the field of aerosol antiperspirants, it has been

r e p o r t e d (28) that the use of certain polyalkylene oxides,

including certain poloxamers, would prevent the staining of

clothing after repeated use o f the antiperspirant formulation. The nonirritating properties, plus the solubilizing

action, would be responsible for selecting the block

p o l y m e r surfactants in this application. In the same type of

aerosol p r o d u c t , the a d d i t i o n o f a p o l o x a m e r to the formulation was r e p o r t e d (29) to prevent formation of lumps in

storage. The dispersing p r o p e r t i e s of the poloxamer are

believed to be the reasons for its selection in this application.

115

Many new applications in the medical field have been

r e p o r t e d , and only a small n u m b e r can be described here.

The use of poloxamers with at least 50% e t h y l e n e oxide

c o n t e n t has been reported (30) in a new process for the

p r e p a r a t i o n of a stable and c o n c e n t r a t e d antiserum from

h u m a n or animal plasma and serum, b y fractional precipitation.

At b e l o w r o o m t e m p e r a t u r e conditions, the

p o l o x a m e r selectively precipitates the p r o t e i n fractions in

various molecular weights. This p r e c i p i t a t i o n is due to the

ability o f the two macromolecules, the p o l y m e r i c poloxamer and the b l o o d proteins, to form insoluble complexes

at low temperatures. The c o m p l e x e s are then readily separated and purified.

Several p o l o x a m i n e s and their tetraesters have been

f o u n d (31) to be useful as h y p o c h o l e s t e r o l a e m i c agents in

animals and man. The starting p o l o x a m i n e s have a maxim u m e t h y l e n e oxide c o n t e n t of 30% and the h y d r o p h o b e

molecular weight lies between 2250 and 3250. A dramatic

r e d u c t i o n in b l o o d serum cholesterol levels was r e p o r t e d

when the p o l y m e r s were regularly i n c o r p o r a t e d in the diet.

It is suggested that the ability of the p o l o x a m i n e or its

esters to solubilize the sterol is the reason for this useful

application.

The clinical use o f p o l o x a m e r 188 as an emulsifying

agent for a p e r f l u o r o o c t y l b r o m i d e emulsion, useful as a

r a d i o p a q u e m e d i u m for contrast studies in medicine, is a

relatively new development (32). The radiographs are

equally as effective as, or more effective than, those

o b t a i n e d with organic i o d i d e c o m p o u n d s and b a r i u m

sulfate. The p o l o x a m e r was selected because o f its a b i h t y to

function as an emulsifying agent, and due to its lack of

t o x i c i t y , including its n o n t h r o m b o g e n i c properties.

In a similar application, p o l o x a m e r 188 has been the

emulsifying agent o f choice in the artificial b l o o d program,

for preparing stable emulsions o f f l u o r o c a r b o n in physiological saline (33).

An antiseptic skin cleaning f o r m u l a t i o n based u p o n

chlorhexidine gluconate has been developed (34) containing

25% p o l o x a m e r 187. A p r o b l e m is o f t e n e n c o u n t e r e d in

h a n d wash formulations, n a m e l y t h a t the cationic or antiseptic is inactivated in the micelles o f the surfactant being

used. This was eliminated b y using a p o l o x a m e r as the

wetting agent because, of all the nonionics tested, it

e x h i b i t e d the least inactivation of the chiorhexidine. The

187 grade was selected because it e x h i b i t e d the highest

foam. The 25% concentration was used in o r d e r to provide

suitable f o a m viscosity and washing p r o p e r t i e s in the final

product.

A m e t h o d for enhancing drug or antibiotic levels in the

b l o o d has been r e p o r t e d (35) b y oral administration of a

capsule containing the drug and a p o l o x a m e r . Gastrointestinal h y p o m o t i l i t y is i n d u c e d and as a result o f the

delayed gastrointestinal transport, dwell time in the u p p e r

p o r t i o n of the gastrointestinal tract is increased. This is

desirable since drugs are preferentially a b s o r b e d in the

u p p e r G.I. tract. The properties associated with the selection o f a p o l o x a m e r , which contains from 5-80% ethylene

oxide, no d o u b t include absence of b i t t e r taste, lack of

t o x i c i t y , and its rate of solubility.

The effective c o n t r o l o f bloat in b e e f cattle during feeding lot fattening, was r e p o r t e d (36) to be c o n t r o l l e d when

the cattle were fed a high c o n c e n t r a t i o n of a feed lot bloat

inducing ration for an e x t e n d e d p e r i o d of t i m e and concurrently fed a bloat controlling c o m p o u n d , such as p o l o x amine 1501 or P L U R A D O T H A 520, t o g e t h e r with a water

soluble salt of a d i m e t h y l d i a l k y l q u a t e r n a r y a m m o n i u m

compound.

P o l o x a m e r 188 has been used (37) to s t u d y the developm e n t o f t u m o r metastasis in rats. T r e a t m e n t o f rats, which

had been intravenously administered t u m o r cells, with the

p o l o x a m e r decreased the incidence o f p u l m o n a r y metastasis

�1 16

JOURNAL OF THE AMERICAN OIL CHEMISTS' SOCIETY

f r o m 85.3% in the control to only 16.1%. The p01oxamer

p r o p e r t y believed responsible for this application is its

ability to prevent microvascular sludging of red cells, as well

as its lack o f toxicity. This is but one of a few hundred

articles in various medical and pharmaceutical journals

which describe the use of a p o l o x a m e r being studied in a

research project.

In the paper industry, the preparation o f a single transfer

coating for paper utilized a p o l o x a m e r on a production

scale (38). P o l o x a m e r 182 was used as the wetting and

dispersing agent to apply a coating on a backing surface of

the paper sheet. Afte r drying, the coating is tested for

transfer properties by typing the front surface o f the sheet

with a second u n t re a te d sheet in facial c o n t a c t with the

coating. The second sheet was f o u n d to apply a transferred

copy which had a sharp blue image and offered good

smudge resistance.

It has been reported (39) that the moisture level in.a

sheet of cellulose, such as paper, can be stabilized by using

a polyalkylene oxide as a stabilizing agent and a p o l o x a m e r

to enhance the rate o f absorption of the polyglycol by the

sheet material. Using p o l y o x y e t h y l e n e glycols of molecular

weights varying from 400 to 4000, a dramatic decrease

occurred in the time needed to saturate the sheet, from

more than 2 min t o less than 5 ser u p o n addition o f the

block polymer. The wetting properties o f the poloxamers

proved useful in this application.

The textile industry has recognized the antistatic properties of the p o l o x am i n e s and their derivatives. This is due

to the following: (a) the presence o f the t w o pairs of

unshared electrons on the tertiary nitrogen atoms provides

a slight cationic effect; (b) the p o l o x a m i n e branched structure more readily lends itself to crossllnking and increased

viscosity, and (c) the superior p o l o x a m i n e th e r m a l stability

is believed to be due to the ability to form amine oxides

u p o n oxidation. H y d r o p h o b i c fibers having antistatic

properties were made (40) by incorporating an ester of a

dibasic acid with a p o l o x a m i n e having up to 30% propylene

oxide at a mol wt of 2 0 0 - I 0 0 0 0 into the spin bath prior to

spinning the n y l o n fiber.

A p o l o x a m i n e having a mol wt b e t w e e n 4000-135,000

has been r e p o r t e d (41) to give excellent antistatic action in

n y l o n 6 when used at 1-12%, based on the weight o f the

nylon. The fibers showed excellent antistatic activity

through 25 washes.

An effective antistatic agent giving improved performance to nylon was obtained (42) by chain e x t e n d i n g a

p o l o x a m i n e with a diepoxide or a diisocyanate. Even better

antistatic effectiveness was reported achieved by further

reaction with a sulfuric acid derivatives, such as sodium

paratoluene sulfonate. This increased the viscosity of the

polymer, thus making it more compatible with the high

viscosity n y l o n melt prior to spinning.

A novel m e t h o d for softening laundry was reported (43)

by t u m b l i n g it in a damp state with coated polystyrene

foam spheres. By dip-coating the spheres in a blend o f a

p o l o x a m e r 407, sodium tallow alcohol sulphate slurry, and

ethyl alcohol, the softener was readily transferred to the

laundry while tumbling in a dryer.

I m p r o v e d lubricating oil compositions containing lubricating viscosity and conventional gear oil and hydraulic oil

additives m a y be obtained (44) by i n c o r p o r a ti n g relatively

small amounts, as little as 0.01%, of a p o l o x a m i n e with a

VOL. 54

molecular weight range o f 1650-15000 and an ethylene

oxide co n t en t of about 10-50%. The poloxamine addition

serves to improve the oil compositions by giving improved

rust protection, by a standardized test, by improving rate of

demulsibility in a standard demulsification test, and by

giving less emulsion sludge in a standard engine test. The

surfactant properties reponsible for this i m p r o v e m e n t

i n c l u d e its wetting, interracial tension lowering, a n d

dispersing abilities.

REFERENCES

1. CTFA Cosmetic Ingredient Dictionary, 1st Ed., Bull. No. 9,

CTFA Inc., Washington, DC (March 1975).

2. Vaughn, T.H., H.P. Suter, L.G. Lundsted, and M.G. Kramer,

JAOCS 28:294 (1951).

3. Jackson, D.R., and L.G. Lundsted, U.S. Pat. 3,036,118 (1962).

4. Lundsted, L.G., U.S. Pat. 2,979, 528 (1961).

5. Rudner, B., and A.G. Prapas, U.S. Pat. 3,189,653 (1965).

6. Patton, J.T. Jr., U.S. Pat. 3,101,374 (1963).

7. "The Wonderful World of Pluronic Polyols," BASF Wyandotte

Corp., Wyandotte, MI (1971).

8. "Pluronic R Nonionic Surface Active Agents," 0-110, BASF

Wyandotte Corp., Wyandotte, MI (1971).

9. "Tetronic Series Nonionic Surfactants," 0-85R, BASF Wyandotte Corp., Wyandotte, MI (1970).

10. "Pluradot Polyols," 0-86R, BASF Wyandotte Corp., Wyandotte, MI (1971).

1 I. Huronic Polyols Toxicity and Irritation Data, 3rd Ed., Revised,

BASF Wyandotte Corp., Wyandotte, MI (1971).

12. Gleason, M.N., P.E. Gosselin, and H.C. Hedge, "Clinical Toxicology of Commercial Products," 2nd Ed., Williams & Wilkins

Co., Baltimore, MD (1963).

13. Mankowich, A.M., J. Phys. Chem. 58:1028 (1954).

14. Bell, W.E., Ibid. 63:299 (1959).

15. Dwiggins, C.W. Jr., R.J. Bolen, and H.N. Dunning, Ibid.

64:1175 (1960).

16. Becher, P., Ibid. 63:1615 (1959).

17. Ross, S., and J.P. Olivier, Ibid. 63:1671 (1959).

18. Schmolka, I.P., and A.J. Raymond, JAOCS 42:1088 (1965).

19. Saski, W., and S.G. Shah, J. Pharm. Sci. 54:71 (1965).

20. Sheth, P.B., Diss. Abstr. 28:974 (1967).

21. Anderson, R.A., Pharm. Acta Helv. 47(5):304 (1972).

22. Jacobs, J., R.A. Anderson, and T.R. Watson, J. Pharm.

Pharmacol. 24:586 (1972).

23. Cowie, J.M.G., and A.F. Sirianni, JAOCS 43:572 (1966).

24. Willix, R.L.S., J. Pharm. Sci. 59:1439 (1970).

25. McDonald, C., and C.K. Wong, J. Pharm. Pharmacol. 26:556

(1974).

26. Zinner, D.D., L.F. Duany, and H.J. Lutz, IADR Abstract L340,

London (1975).

27. Januszewski, J.P., U.S. Pat. 3,639,563 (1972).

28. Unilever NV, Neth. Pat. 7,103,689 (1971).

29. Curry, K.B., and A.I. Sahir, Ger. Pat. 2,140,321 (1972).

30. Garcia, L.A., U.S. Pat. 3,880,989 (1975).

31. Green, J., ICH. Baggaley and B. Morgan, U.S. Pat. 3,916,008

(1975).

32. Arambulo, A.S., M.S. Lie, A.L. Rosen, G. Dobben, and D.M.

Long, Drug Dev. Commun. 1:73 (1974).

33. Geyer, P.P., Fed. Prec. 34:1499 (1975).

34. Barnes, M., M.P. Billany, and A.J. Sandoe, Mfg. Chem. and

Aerosol News 44(10):29 (1973).

35. Miskel, J.J., and F.S. Hem, U.S. Pat. 3,867,521 (1975).

36. Meyer, P.M., and E.E. Bartley, U.S. Pat. 3,686,416 (1972).

37. Silk, M., and E. Sigman, Cancer 29(1):171 (1972).

38. Rizner, J.S., U.S. Pat. 3,446,647 (1969).

39. Wennergren, J.J., and L.G. Samuelson, U.S. Pat. 3,674,632

(1972).

40. Lofquist, P.A., and B.T. Hayes, U.S. Pat. 3,655,821 (1972).

41. Weedon, G.C., and L. Crescentini, U.S. Pat. 3,755,497 (1973).

42. Crescentini, L., and R.L. Wells, U.S. Pat. 3,287,524 (1974).

43. Hewitt, G.T., and A.S. Giordano, U.S. Pat. 3,676,199 (1972).

44. Papay, A.G., B.W. Matthews, and A.S. Thomas, U.S. Pat.

3,928,219 (1975).

[ Received August 18, 1976]

�