Article containing a Thixotropic Additive and Cyanoacrylate Monomer employed for developing Latent Fingerprints

Article containing a Thixotropic Additive and Cyanoacrylate Monomer employed for developing Latent Fingerprints

US4550041

Company:

Folder:

Year:

Abstract:

Latent fingerprints are developed by exposing them to vapours generated from a thin film of a storage stable cyanoacrylate monomer and a thixotropic additive in sufficient amount to render the composition substantially non-flowable. The monomer film should have a surface area at least 129 sq. cm.

An envelope package for the monomer composition has inner polyethylene surfaces. The envelope may be peeled open to expose the inner surfaces coated with a film of the composition.

Type of document:

Language:

United States Patent [19]

Thompson et al.

[54] ARTICLE CONTAINING A THIXOTROPIC

ADDITIVE AND CY ANOACRYLATE

MONOMER EMPLOYED FOR

DEVELOPING LATENT FINGERPRINTS

[75]

[73]

[21]

[22]

[60]

[51]

[52]

[53]

[56]

Inventors: Richard T. Thompson, Haddam View

Heights; Philip Hinkle, West

Hartford, both of Conn.; Robert B.

Carroll, South Paris, Me.

Assignee: Loctite Corporation, Newington,

' Conn.

App]. No.: 681,961

Fi1ed- Dec. 14, 1984

Division of Ser. No. 743,585 filed as PCT US 84/01354,

Aug. 24, 1984, published as WO 85/00963, Mar. 14,

1985, § 102(e) date Oct. 7, 1984.

Int. Cl.4 ..................... .. A61B 5/10; B41K 1/00

U.S. Cl. ................................... .. 428/35; 118/31.5;

356/71; 427/1; 428/419; 428/516

Field of Search ................. .. 427/1, 145; 118/315;

356/71; 428/35, 419, 516

References Cited

U.S. PATENT DOCUMENTS

3,380,646 4/1968 Dogen et al. ....................... .. 229/57

3,502,521 3/ 1970 Dogen et al. .. 156/69

3,523,628 1/1968 Colvin et al. .. 222/107

3,524,537 8/1970 Winter . . . . . . . . . . . . . . . . .. 206/47

3,663,501 5/1972 Adams et al. .... .. .. 260/41 R

3,839,065 10/1974 Overhults et al. .. 106/308 N

3,935,993 2/1976 Dogen et al . . . . . . . . . . . .. 229/53

3,940,362 2/ 1976 Overhults ..... .. 260/42.16

4,102,945 7/1978 Gleave .......... .. 260/879

4,180,913 1/1980 Takeuchi et al. 433/228

4,297,383 10/1981 Bourdon . . . . . . . . . . . .. 427/1

4,363,286 12/1982 Leavitt .............................. .. 427/ 1

4,379,178 4/1983 Meadows et al. ................ .. 427/ 1

4,407,842 10/1983 Shepard .................... .. 427/ 1

4,461,235 7/1984 Morton ................................. .. 427/ 1

FOREIGN PATENT DOCUMENTS

56-64933 6/1981 Japan .

OTHER PUBLICATIONS

C.A. 100(26)211222v, Oct. 1983 Takaoka Chem.

C. Abs. 100(16)122406r, Sep. 1983 Taoka Chem. Co.

lox‘

. 4,550,041

Oct. 29, 1985

Patent Number:

Date of Patent:

[11]

[45]

Chem. Abs. 100(2)8087n, Jun. 1983 Kowa K.K., JP No.

58/108135.

Chem. Abs. 99(24)196228s, Mar. 1983 Taoka Chem.

Co., JP No. 58/41068.

Chem. Abs. 96(26)218971w Taoka, Feb. 1982, JP No.

57/23666.

Chem. Abs. 96(12)80693v, Nov. 1981 Taoka, JP No.

56/142169.

Chem. Abs. 96(12)86692u, Nov. 1981 T aoka, JP No.

56/142168.

Chem. Abs. 95(18)151873z, Jun. 1981 Toagose, JP No.

56/64933.

Chem. Abs. 92(4)23838t,

Seiyaku, JP No. 54/106426.

Chem. Abs. 91(22)176339k, May 1979 Koatsu Gas, No.

54/ 57539.

Chem. Abs. 88(6)38738g, Sep. 1977 Ashiwara, JP No.

52/ 105939.

Chem. Abs. 82(8)44562g, Feb. 1974 Toagose, JP No.

74/5728.

Chem. Abs. 71(16)71543(f) 1969 Korshak et al.

Identification News: May ’82, pp. 3-5; Jun. ’82, pp. 3-4;

Jan. ’83, pp. 9-10; Feb. ’83, pp. 3-4; Feb. ’83, pp. 12, 13,

15; May ’83, p. 10.

Duraprint Investigators Report, Mar./Apr. ’83.

Police Chronicle, May ’83, “New Method of Finger-

printing . . . ”.

Payton Scientific, Undated, Visuprint Advertisment.

Police Chief, Feb. ’83, p. 9, Superprint TM ad.

Primary Examiner—I-Ierbert J. Lilling

Attorney, Agent, or Firm—Wa1ter J. Steinkraus; Eugene

F. Miller

[57] ABSTRACT

Latent fingerprints are developed by exposing them to

vapors generated from a thin film of a storage stable

cyanoacrylate monomer and a thixotropic additive in

sufficient amount to render the composition substan-

tially non-flowable. The monomer film should have a

surface area of at least 129 sq. cm.

An envelope package for the monomer composition has

inner polyethylene surfaces. The envelope may be

peeled open to expose the inner surfaces coated with a

film of the composition.

Aug. 1979 Matsumoto

8 Claims, 3 Drawing Figures

‘*7?

_\ -s

....-,

15""

;\"

/Er

U.S. Patent

Oct. 29, 1985

I20

20

‘§xu“mvL\un1“1

23

K

.\

26

4,550,041

1

ARTICLE CONTAINING A THIXOTROPIC

ADDITIVE AND CY ANOACRYLATE MONOMER

EMPLOYED FOR DEVELOPING LATENT

FINGERPRINT S

BACKGROUND OF THE INVENTION

* This is a division of Ser. No. 743,585 filed as PCT US

84/01354, Aug. 24, 1984, published as W0 85/00963,

Mar. 14, 1985, § I02(e) date Oct. 7, 1984.

To those familiar with instant adhesives, it’s no sur-

prise that their vapors can expose fingerprints with the

white residue caused by monomer “blooming”. In fact,

efforts to reduce this undesirable behavior date from the

early days of cyanoacrylate technology.

However, it was left until much later to discover that

this same process could be tumed to the noble task of

apprehending criminals through fingerprint identifica-

tion. In 1978 the Tokyo Metropolitan Police are re-

ported to have hosted a demonstration of cyanoacrylate

fuming for development of fmgerprints by criminolo-

gists of the Japanese National Police Agency. In May of

1979, Detective Inspector N. Edmunds and L. Wood of

N orthamptonshire (England) Police are reported to

have observed that fingerprints were developed when

they repaired a black plastic developing tank with Loc-

tite Super Glue TM . Within a month, they reported

their findings to a regional police conference.

Constable Paul Bourdon of the North Bay Ontario:

Police Force was an early practitioner of the method

and invented a fuming system which generates vapor in

one chamber and pumps it into another which contains

the evidence under investigation. His system has been

patented in the U.S. and Canada (U.S. Pat. No.

4,297,383, incorporated herein by reference).

Frank Kendall of the U.S. Bureau of Alcohol, To-

bacco and Firearms, developed an improvement in the

method which uses cotton treated sodium hydroxide to

accelerate the generation of vapors. A description of

this technique is given in Identification News, June

1982, page 3.

The use of heat to accelerate generation of cyanoac-

rylate vapors for fingerprint development use has also

been reported. Identification News, January 1983, page

9, and May 1983, page 10.

The cyanoacrylate vapor technique has become an

accepted method for fingerprint development. In sev-

eral cases, identifications have been made on evidence

for which no previous methods had been workable.

Recently, evidence provided by this method has been

accepted in a Kansas court leading to criminal convic-

tion. Abele, Identification News, February 1983, page

12.

Recognized benefits of using cyanoacrylate mono-

mers to develop fmgerprints which have been discov-

ered to date are as follows:

(a) Development of latent prints on objects where other

methods have failed;

(b) development of prints on difficult surfaces such as

polyethylene bags or electrical tapes;

(c) print images produced are easier to handle than

powder-dusted prints which may blow away;

(d) large enclosed areas, such as automobile interiors

can be fumed for prints.

The significant benefits of the cyanoacrylate finger-

print development technique, however, have been ac-

companied by other notable disadvantages. These dis-

advantages include the instant bonding of cyanoacry-

late adhesives to skin and clothing when contacted by

l0

15

20

25

30

35

40

45

50

55

60

65

2

evidence technicians. Also, the typical low viscosity

cyanoacrylate adhesive used in the prior techniques is

easily spilled or dripped. This not only contributes to

inadvertent bonding of clothes and skin but can also

result in damage to the evidence. Initially, without ac-

celeration of vapor generation, it has been reported that

full development of a print takes at least about five

hours and can take as long as 90 days.

With acceleration of vapor generation, other disad-

vantages have been identified as follows:

Disadvantages of Sodium Hydroxide Acceleration:

1. Sodium hydroxide is a poison and corrosive, and can

cause damage to skin if not mixed wearing gloves.

2. Preparation time is substantial.

3. The technique provides a small amount of fumes for

the amount of adhesive used. Most of the adhesive

polymerizes, within the saturated pad or as visible

white smoke, rather than being evaporated into the

atmosphere within the chamber. The polymerized

white smoke does not react with the latent print.

. Fumes from the pads rise to the top of the chamber,

then filter down, failing to provide uniform exposure

of the objects being processed to the vapors.

Disadvantages of Heat Acceleration:

1. Temperature setting can be critical. Too hot may

result in overdevelopment of the print and failure of

the adhesive to polymerize within the print. Too cool

may result in failure of the adhesive to be absorbed

into the chamber as quickly as desired, requiring

longer processing.

2. Use in smaller chambers, even in small amounts, may

result in overdevelopment if the items being pro-

cessed are not closely monitored.

3. Various methods of using heat as an accelerant also

heat the entire chamber, affecting vinyls and plastics

(especially black vinyl tapes).

4. Minor accidents involving the use of heated objects

may result in bums or damage to the chamber.

SUMMARY OF THE INVENTION

The present invention is an improvement of develop-

ing latent fmgerprints with cyanoacrylate vapors. The

method comprises subjecting an article suspected of

containing a latent fingerprint to cyanoacrylate vapors

generated from a thin film of a storage-stable composi-

tion comprising a cyanoacrylate monomer and a thixo-

tropic additive in an amount effective to render the

composition substantially nonflowable on a vertical

surface. This thixotropic composition is preferably also

stabilized against polymerization to a degree where the

adhesiveness of the composition is substantially re-

duced.

In a preferred embodiment of the invention, the gel

composition is contained in a thin envelope or pouch

which is peeled open to expose two inner surfaces

coated with a thin layer of the gel. The resulting large

surface area generates vapor rapidly and evenly pro-

longed periods of time. This rapid and sustained vapor

generation can result in development of latent fmger-

prints which are not developed by prior art methods.

The following advantages have been identified for

the inventive process over the prior art methods of

generating vapors.

1. No poisons or corrosives.

2. No preparation time.

4,550,041

3

3. Produces an even amount of exposure to the adhesive

evaporated within the chamber over a 20-minute plus

time period.

4. Provides evaporation from a larger surface area than

previous methods.

5. Room temperature operation. No critical effects of

minor variations in the temperature.

No heat to destroy vinyls or plastics.

. Overdevelopment does not occur in a short period of

time. Items can be left in the chamber up to one hour

over the amount of time required without loss of

ridge detail (items, as in previous methods, should not

be placed closer than 3 inches to the envelope).

8. No burns or damaged chambers.

9. No spillage of adhesive or contamination of evidence.

10. Substantially reduces complexity of cyanoacrylate

use making it feasible for use in the field by minimally

trained technicians.

DESCRIPTION OF THE DRAWINGS

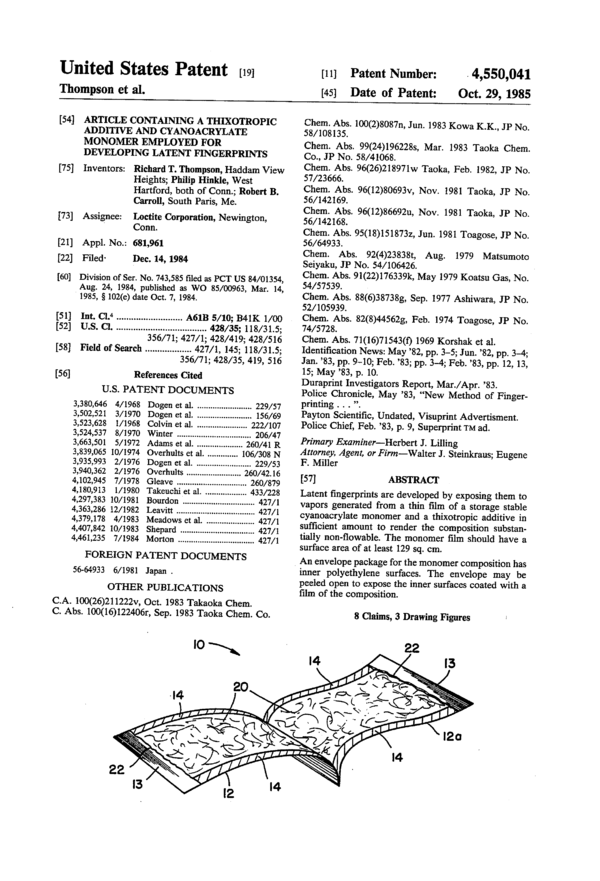

FIG. It is a side sectional view of a cyanoacrylate gel

containing package preferred for use in the inventive

method.

FIG. 2 is a bottom plan view of the package of FIG.

\-.°~

1.

FIG. 3 is a pictorial view of the opened package

showing cyanoacrylate coated inner surfaces exposed

to the air for vapor generation.

DETAILED DESCRIPTION OF THE

INVENTION

Cyanoacrylate Gel Formulation

A high vapor pressure cyanoacrylate monomer must

be utilized in order to give adequate monomer vaporiza-

tion. Methyl cyanoacrylate and ethyl cyanoacrylate are

the preferred monomers. Allyl cyanoacrylate and iso-

propyl cyanoacrylate are suitable monomers which

may also be utilized alone or in a mixture.

The formulation of a storage-stable nonflowable cya-

noacrylate gel has long been a difficult problem because

of the ease of polymerization of the monomer. Thus,

while many formulations employing typical silica thixo-

tropes have been reported in the art, such compositions

typically are intended to be utilized immediately or

have been subsequently shown to have poor shelf stabil-

ity. While it has been discovered that storage stable

formulations of certain silicas highly treated with di-

methyldichlorosilane can be made, the high degree of

surface treatment so dramatically affects the thixotropic

capability of the silica that nonflowable gels cannot be

prepared. More recently, it has been discovered that

certain uniquely treated silicas produce storage-stable

nonflowable gel compositions. Compositions of cyano-

acrylate monomers with these silicas, are described

more fully in co-pending application U.S. Ser. No.

528,275, filed Aug. 31, 1983, now U.S. Pat. No.

4,477,607, the disclosure of which is incorporated

herein by reference. The compositions of U.S. Ser. No.

528,275 are suitable for use in the inventive method and

provided the initial embodiments of the gel used in the

inventive method.

Working with the initial gel formulations, it was dis-

covered that the stabilizer level could be substantially

increased over that typically used in cyanoacrylate

adhesive formulations. Since the fingerprints are devel-

oped by polymerization of monomer vapors, the level

of stabilizer in the base composition was not critical.

Therefore, the stabilizer level in the base composition

5

10

15

20

25

30

35

40

45

50

55

60

65

4}-

could be increased to the point where adhesive bonding

is significantly reduced without affecting fingerprint

development performance. This is especially advanta-

geous in fingerprint development since the possibilities

of monomer contact are substantial. The monomer con-

tainers are open and have substantial surface areas (typi-

cally 2”>< 103)

Thixotropic Ratio 2.5 RPM/

20 RPM

92 92 92 60 94 88

88

%

I

I

8|‘5||

O\

a

~°o I

O\O'\O\

lolalll

801

3.0 3.0 5.7 5.3 7.3 5.7

'Aerosil is L! trademark of DeGussa Corp. R972, R976, R805, and 200 are fumed

silicas with respective treatments: dimethyldichlorosilane, octyltrimethoxysilane.

and untreated.

lCabosil is a trademark of Cabot Corp. N70-TS is fumed silica treated with polydi-

methylsiloxane.

-‘see US. Pat. No. 4.105.775.

The various formulations have different monomer

evaporation characteristics depending on thixotrope

and level. Formulations such as C and E are preferred

4,550,041

5

for evaporation charactertistics because they give faster

evaporation rates and almost total evaporation at room

temperature before polymerization from thin films on

polyethylene. Composition D had the slowest evapora-

tion and lowest total evaporation, presumably because

of the high polymer content.

Generating The Vapors

In order to obtain rapid and uniform vapor genera-

tion at room temperature, it is desirable that the mono-

mer be distributed over a large surface area. Whereas

development techniques using pourable liquid mono-

mers must contain the monomer in a bowl on a horizon-

tal surface, the nonflowable formulations used in the

inventive method do not have to be contained. They

may be thinly spread on vertical surfaces, e.g., on a

sheet of paper or plastic film hung on a wall, without

fear of damage to evidence or personnel.

A preferred package for the fingerprint developing

gels is shown in FIGS. 1-3. The package generally

designated by the numeral 10 is an envelope con-

structed from three sheets, 12, 12a and 13 of a laminate

material having a polyethylene inner surface. The lami-

nate is preferably a paper/polyethylene/aluminum/-

polyethylene laminate material. A bonding primer be-

tween the various layers is preferably included so that

the material does not delaminate when the envelope is

peeled open. Three heat sealed edges 14 bond sheets 12

and 12a together. Sheet 13 is heat sealed between the

end flaps 16 and 160 at the fourth end of sheets 12 and

12a, thereby forming a closed envelope structure with

separable but sealed end flaps 16 and 160. Inside the

envelope is a thin layer of the gel cyanoacrylate formu-

lation 20. To open and use, flap 16 and 16a are pulled

apart as shown in FIG. 1 and sheet 13 is tom along the

fold line 22. To facilitate substrate failure along the side

edges 14, the central outer portions of sheets 12 and 12a

may be reinforced by an additional layer of tape or label

material 23. Sheets 12 and 12a are then peeled back as

shown in FIG. 3 to open the package 10 and expose the

cyanoacrylate gel 20 to the air. The gel sticks to the

’ inner surfaces of both sheets 12 and 12a so that a maxi-

mum surface area of cyanoacrylate monomer is ex-

posed. It is recommended that the package when

opened provide a monomer coated surface area of at

least 20 sq. in. (129 sq. cm.), preferably 40 sq. in. (258 sq.

cm.) or more.

Optionally package 10 may also be supplied with a

strip 24 pressure sensitive adhesive located on the outer

surface of flap 16a. Strip 24 is covered with a release

paper 26 which may be pulled off when the package is

to be used. The exposed adhesive layer 24 may then be

used to adhere the open package to a desired surface

such as a wall or window. Since the cyanoacrylate

monomer is in gelled form it does not run off sheets 12

and 12a even when the open package is hung vertically

or upside down.

Although the seal is broken when the package is first

opened, the package may be closed after use and reused

over several weeks before the monomer is completely

polymerized or vaporized.

Developing The Fingerprints

For small portable evidence items a fuming chamber

such as an aquarium fitted with a lid may be used. The

lid contains a hanging device such as a clothes hanger

or alligator clips from which the evidence is suspended.

A preferred envelope 10 contains about 3-4 grams of a

l0

15

20

25

30

35

45

50

55

60

65

6

gel such as in formulation F in a 6£;”>

Coments go here:

- Log in to post comments