Cyanoacrylate-based Liquid Microbial Sealant Drape

Folder:

Year:

Abstract:

The invention relates to methods of using compositions for forming microbial sealant drapes. In particular, the invention relates to the use of compositions of combinations of cyanoacrylates for the in situ formation of drapes that can be used in surgery to protect patients from surgical site infections.

Type of document:

Language:

US 20100l12036A1

(19) United States

(12) Patent Application Publication (10) Pub. No.: US 2010/0112036 A1

Zhang et al. (43) Pub. Date: May 6, 2010

(54) CYANOACRYLATE-BASED LIQUID Related U.S. Application Data

MICROBIAL SEALANT DRAPE

(60) Provisional application No. 61/197,954, filed on Oct.

(75) Inventors: Sheng Zhang, Lenoir, NC (US); 31’ 2008'

Rafael R1111, H11dS011: NC (US) Publication Classification

Correspondence Address: (51) Int‘ Cl‘

STRADLEY RONON STEVENS & YOUNG, LLP ‘WK 9/7” (200601)

30 VALLEY STREAM PARKWAY, GREAT VAL- ‘WK 31/215 (200601)

LEY CORPORATE CENTER (52) U.S. Cl. ....................................... .. 424/443; 514/526

MALVERN, PA 19355-1481 (US) (57) ABSTRACT

(73) Assignee: Adhezion Biomedical, LLC., The invention relates to methods of using compositions for

Hudson, NC (U S) forming microbial sealant drapes. In particular, the invention

relates to the use of compositions of combinations of

(21) Appl. No.: 12/378,277 cyanoacrylates for the in situ formation of drapes that can be

used in surgery to protect patients from surgical site infec-

(22) Filed: Feb. 12, 2009 ti0I1S-

Breakl i ne

Opening

channel ‘

'“’¢i',.u-v;"v*‘**’«2'(4"/ "

./4|-.. ‘ll’; 1 ._ S

0|!’ ‘V ' ' ponge

,|J M f

. i I oam

-A _ R . --I-—-

A

Liquid

Sealant

inside

Reservoir

Patent Application Publication May 6, 2010 US 2010/0112036 A1

FIGURE 1

Breakline

Opening

channel I

-—

.,

-« .y - Sponge

. foam

Liquid

Sealant

inside

Reservoir

US 2010/0112036 A1

CYANOACRYLATE-BASED LIQUID

MICROBIAL SEALANT DRAPE

CROSS REFERENCE TO RELATED

APPLICATIONS

[0001] This application claims priority to the filing date of

U.S. Provisional Application No. 61/197954 filed Oct. 31,

2008; the disclosure of which is herein incorporated by ref-

erence.

BACKGROUND OF THE INVENTION

[0002] 1. Field of the invention

[0003] The invention relates to methods of using composi-

tions for forming microbial sealant drapes. In particular, the

invention relates to the use of compositions of combinations

of cyanoacrylates for the in situ formation of microbial seal-

ant drapes that can be used in surgery to protect patients from

surgical site infections.

[0004] 2. Description of the PriorArt

[0005] Surgical site infections (SSIs) can be classified into

two categories: (1) incisional and (2) organ, which includes

organs and spaces manipulated during an operation. Inci-

sional infections are further divided into superficial infections

and deep soft tissue-muscle and fascia infections. The Cen-

ters for Disease Control and Prevention estimates that

approximately 500,000 surgical site infections occur among

an estimated 27 million surgical procedures conducted every

year in the United States. Surgical site infections (SSI) are

listed as the second most common cause of nosocomial infec-

tion after urinary tract infections, which accounts for 40% of

hospital-acquired infections among surgical patients. Twenty

five to thirty-eight percent of all nosocomial infections

among surgical patients are estimated to be incisional surgical

site infections. SSI is a significant cause of surgical morbidity

and mortality, occurring in 2-5% of patients having clean

extra-abdominal operations and up to 20% of patients under-

going intra-abdominal procedures. Patients with SSI are

twice as likely to die, 60% more likely to be admitted to an

Intensive Care Unit, and more than 5 times more likely to be

readmitted to the hospital than patients who are not infected.

Surgical site infections result in longer hospitalization and

have large economic impact on patients and the health care

system. Patients with surgical site infections are hospitalized

an additional 7 days on average. The longer hospital stay cost

an additional $3,152 on average. The average total cost for

medical care during the eight weeks after hospital discharge is

$5,155 for patients with surgical site infections compared

with $1,773 for patients without SSIs. The total cost includes

out patient visits, pharmacy, radiology services, re-hospital-

ization, skill-nursing facility, home health aids, and durable

equipment.

[0006] The frequency of surgical site infections in patients

varies from surgeon to surgeon, hospital to hospital, surgical

procedure to surgical procedure and patient to patient. Surgi-

cal site infections can be caused by extemal sources of con-

tamination including surgical personnel, surgical environ-

ment, and surgical instruments. Most SSIs are, however,

caused by patient’s own normal skin flora which can enter the

body through the surgical incision. The patient’s skin flora is

considered as the first and foremost pathogenic source

because the transmission of bacteria from skin to the incision

is very eflicient. Innocuous bacterial flora on the skin may

also be colonized by pathogenic organisms. The bacteria of

May 6, 2010

normal skin flora can cause wound infection in the presence

of foreign materials that greatly enhance the pathogenic

potential of these bacteria. Therefore, bacterial contamina-

tion occurs predominantly during and following surgical pro-

cedures.

[0007] Different methods of preventing SSIs have been

developed to reduce patients’ surgical site infections.

Advanced surgical techniques and skillful surgeons can

reduce the duration of surgery. Operation personnel and

operation room hygiene management can lower the probabil-

ity of exogenous pathogens. Operations that are conducted

when patients have healthy physical and psychological states

may enhance patients’ immune system so that the chance of

surgical infections may be considerably reduced. Thoughtful

plans and careful selection of effective antibiotics can also

help reduce the chance of contamination of bacteria.

[0008] Topical bactericidally active or antimicrobial agents

such as iodophors, chlorhexidine, and alcohol-containing

products have been applied to the surgical site before surgery

to kill bacteria. These agents are preoperative skin prepara-

tion products, washes, surgical scrub tissues, wound cleaners,

lotions and ointments.As early as 1960s, the successful use of

prophylactic antibiotics was reported in a randomized, pro-

spective, placebo-controlled clinical study of abdominal

operations on the gastrointestinal tract. The success of anti-

biotic prophylaxis was due to the appropriate patient selec-

tion and wise choice of available agents.

[0009] U.S. Pat. No. 4,542,012 teaches the application of

antimicrobial agents by depositing antimicrobial composi-

tions onto human skin to form an antiseptic film. The antimi-

crobial composition is applied to the skin as a liquid solution

in a fugitive solvent. After the solvent evaporates, a thin film

containing antimicrobial agent is formed on the skin.

[0010] U.S. Pat. No. 5,916,882 discloses a providone-io-

dine alcohol gel antimicrobial skin-preparation formulation

which is used to disinfect a surgical site. The pre-operative

skin-preparation formulation quickly kills bacteria when

applied to the surgical site. The skin-preparation formulation

continues to effectively inhibit microorganism growth in the

applied area for a relatively long period of time. Application

of the skin-preparation formulation is controllable because

the formulation does not run when applied to a patient. The

antimicrobial skin-preparation formula includes iodine, alco-

hol and gel.

[0011] U.S. Pat. No. 6,228,354 provides a skin-preparation

composition which does not harm the skin yet promotes asep-

sis on the skin. The skin-preparation composition disclosed

has a rapid antimicrobial activity when in a liquid form and a

sustained antimicrobial activity when dry. The skin prepara-

tion composition forms a water-resistant film on skin and is

not readily removed when a wound or surgical site is sponged

or irrigated. The antimicrobial film can be removed by rub-

bing an aqueous solution having the proper pH onto the skin.

This patent describes a film-forming topical antimicrobial

composition that includes a broad spectrum antimicrobial

agent, a water-resistant polymer system, a neutralizer, a pH

sensitive polymer, and an alcohol.

[0012] U.S. Pat. No. 6,488,665 discloses an antimicrobial

skin-preparation delivery system used to disinfect a surgical

site. The antimicrobial skin-preparation formula consists of

iodine, alcohol and gel. The delivery system is composed of

an antimicrobial alcohol gel formulation contained within a

sealed, flexible container and a gel formulation dispenser

connected to the container. A porous applicator pad with

US 2010/0112036 A1

enlarged holes for passage of the gel formulation is described.

The flow rate of the gel formulation is controlled by the

external pressure applied to the flexible container.

[0013] US Patent Publication Nos. 20040126355 and

20080102053 disclose antimicrobial skin compositions com-

prised of an antimicrobial agent, water, an alcohol, and one or

more pH sensitive viscosity builders. The composition’s vis-

cosity is from 100 cp to 1,000 cp and the formulation com-

bines the advantages of an antimicrobial agent and an alcohol.

The viscosity of the formulation permits dispensing from the

applicator, while preventing the solution from flowing away

from the wound area. pH sensitive methacrylic polymers are

used as viscosity modifiers. The preparation forms a water-

resistant film that is diflicult to remove during wound irriga-

tion, but can be easily removed upon completion of the pro-

cedure.

[0014] One of the disadvantages associated with topical

application of skin preparation products is that the antimicro-

bial agents are only effective for a short period of time.

Bacteria that may have survived the initial application of skin

preparation products can proliferate and produce a large

pathogen population. In addition, appropriate antimicrobial

prophylaxis is determined by many factors such as proper

case selection, anti-microbial agent selection, dosing and

route of administration and duration of therapy. Inappropriate

use of antimicrobial agents not only increases the cost of

medical health care, but also exposes the patient to potential

toxicity and other risks. Moreover, many gram-positive

organisms isolated from patients with surgical site infections

are resistant to multiple antimicrobial agents. The problem of

antimicrobial resistance in gram-positive nosocomial patho-

gens has been a growing concem.

[0015] In addition to the use of antimicrobial skin prepara-

tion products, surgical incise drapes have also been used to

help reduce the migration of germs and bacteria into the

incision site. The surgical incise drape is usually a clear

polymeric film with an adhesive backing on one side which is

in turn covered with a release liner. Generally, the incise drape

is used in conjunction with towels or surgical drapes to main-

tain the surgical site as sterile and clean as possible in order to

inhibit surgical site infections. A continuous or longer lasting

antimicrobial effect may be obtained by combining the anti-

microbial agent with a surgical incise drape.

[0016] U.S. Pat. No. 3,579,628 discloses a hydrophilic

acrylic film dressing which contains a composition which

reacts with water to generate a bacteriostatic substance. The

hydrophilic acrylic films are particularly suitable for use as

occlusive dressings and for reducing bacteria.

[0017] U.S. Pat. Nos. 4,310,509 and 4,323,557 disclose

dermatologically acceptable compositions made of a pres-

sure-sensitive surgical incise drape and a broad-spectrum

antimicrobial agent which can be released from the drape

placed in contact with the skin. The active broad-spectrum

antimicrobial agent is polyvinylpyrrolidone-iodine complex

or chlorhexidine. The antimicrobial agents are applied onto

the surgical drape which is made of polymeric materials such

as polyurethane, polyvinyl ethers, polyesters, or polyethyl-

ene.

[0018] U.S. Pat. No. 4,340,043 discloses an adhesive-

coated incise drape material incorporating uniform amounts

of silver sulfadiazine as an antimicrobial agent. The incise

drape is made of polyurethane sheets with an adhesive layer.

[0019] U.S. Pat. No. 4,643,181 discloses a surgical dress-

ing or incise drape material comprising a substrate coated

May 6, 2010

with an antimicrobial containing adhesive. The substrate may

be a woven or knitted fabric, a nonwoven fabric, a plastic or a

polymeric film. The preferred substrate in the invention is a

polyurethane film. The antimicrobial is polyhexarnethylene

biguanide hydrochloride, which is distributed in the adhesive

as particles with a size in the range of 20 to 300 microns.

[0020] U.S. Pat. No. 5,069,907 discloses a synthetic poly-

meric film or fabric surgical drape having incorporated

therein a broad spectrum antimicrobial agent. The drape may

have an adhesive layer attached to one of its external surfaces.

The preferred antimicrobial agent used is 5-chloro-2-(2,4-

dichloro-phenyl)phenol. Suitable adhesives utilized include

polyacrylate adhesives.

[0021] U.S. Pat. No. 5,803,086 discloses adhesive coated

incise drapes useful in surgical procedures. The incise drapes

comprise a flexible film backed coating on one side with a

dermatologically acceptable pressure sensitive adhesive

(PSA) on the other side. The incise drape can be applied by

two people wherein one person holds the core and a second

person ur1rolls the drape by pulling on the handle protruding

from the opposite end of the drape.

[0022] U.S. Pat. Nos. 5,979,450; 5,985,395 and 6,742,522

provide surgical incise drapes comprising a flexible film hav-

ing a major portion thereof coated with an adhesive. The

incise drape has a leading edge and a trailing edge and further

includes a film handle at the leading edge. Methods described

include providing a drape, grasping the film handle of the

drape, pulling upon the liner to remove at least a portion of the

liner exposing at least a portion of the adhesive coating the

major portion of the flexible film, holding the surgical incise

drape in a position such that at least a portion of the adhesive

is contacting the patient, and then removing portions of the

liner remaining.

[0023] US Patent Publication Nos. 20020002223,

20040115274 and 20080078413 disclose adhesive composi-

tions containing acrylic polymers, tackifiers and a broad spec-

trum antimicrobial agent. The adhesive composition is an

essentially solventless composition. The antimicrobial agent

utilized is diiodomethyl-p-tolylsulfone with a preferred con-

centration of antimicrobial agents in the adhesive of about

0.1% to about 2% loading by weight. The antimicrobial adhe-

sive composition is included in a polymeric substrate to form

a surgical drape. The polymeric substrate is preferably a

polyester or co-polyester sheet material.

[0024] US Patent Publication No. 20050284487 discloses a

draping product, which is coated with adhesive along at least

one edge. The adherence strength of the adhesive is greater

than 0.5 N/25 mm when applied to skin. The damage to

stratum comeum of the skin covered by the adhesive is less

than 30% after removal. The adhesive coating is comprised of

a pressure sensitive adhesive such as silicone elastomer, a

hydrogel or a soft, tacky hot melt adhesive.

[0025] US Patent Publication No. 20070048356 describes

an antimicrobial material composition that can be applied to

material substrates. The antimicrobial composition includes a

first or primary antimicrobial agent, such as polyhexameth-

ylene biguanide (PHMB), a second antimicrobial agent, an

anti-static agent or fluoropolymer and/ or an organic acid. The

substrate may encompass both woven and nonwoven fabrics

made from either natural or synthetic fibers, rubber, plastic,

and other synthetic polymer materials. The composition

exhibits an effective microbe-killing eflicacy within a period

of about 30 minutes.

US 2010/0112036 A1

[0026] In spite of the beneficial properties of conventional

surgical drapes with respect to inhibition bacterial infection,

there are many challenges and problems associated with the

conventional surgical drapes regardless of whether they

incorporate antimicrobial agents. Under certain circum-

stances conventional surgical drapes may actually increase

the risk of surgical site infection. Conventional surgical

drapes can be lifted during surgery which results in entry of

bacteria into the surgical site. The lifting of the conventional

surgical drape is usually caused by failure of the adhesive to

remain in contact with the patient’s skin. Attempts to increase

adhesive strength may also prove disadvantageous because

more force is then required to remove the drape from skin

leading to damage of the skin near the surgical site.

[0027] Conventional surgical drapes are normally large and

difficult to apply to the patient without wrinkling the drape

film. Wrinkling of the surgical drape at the surgical site may

block visibility, making it difficult for the surgeon to see the

incision site. In addition, the surgical drape will not prevent

microorganisms from entering the incision if the drape is

wrinkled. Wrinkling is especially problematic with applica-

tion of the conventional surgical drapes to a non-flat skin

surface such as the elbow or knee.

[0028] Incorporation of antimicrobial agents into conven-

tional surgical drapes may permit the antimicrobial action of

the agents to last longer. Antimicrobial agents currently avail-

able are, however, not effective at killing and immobilizing

pathogens on the surface to which the agents are applied. The

extensive use of antimicrobial products has raised concems

about antimicrobial resistance to antibiotics. In addition,

most antimicrobial compounds are heat labile and cannot

survive radiation sterilization. This makes it difficult to pre-

pare sterile surgical drapes infused with antimicrobial agents.

[0029] Even though many different procedures have been

applied to reduce surgical site infections, the risk of such

infections still exists because of the continuing survival of

skin bacteria after these treatments. Since endogenous flora

on patient’s skin plays a key role in the development of

surgical site infections, a simple and comprehensive solution

to the problem would be to minimize endogenous bacteria at

and around the surgical site. It is known that cyanoacrylate

polymer film can act as a mechanical barrier to penetration by

bacteria while maintaining a natural healing environment.

Cyanoacrylate monomers, which polymerize on contact with

tissue surface to provide a thin and flexible polymer film, have

been used as tissue adhesives for several decades. Cyanoacry-

late adhesives also exhibit strong bond strength and very rapid

cure time.

[0030] Cyanoacrylate’ properties as adhesives may also

make them desirable candidates as microbial sealant drapes.

Cyanoacrylate microbial sealant drapes could prevent surgi-

cal site infections by overcoming the difficulties experienced

by the conventional surgical drapes. U.S. Pat. No. 7,255,874

discloses that modified cyanoacrylate monomers can be used

in various medical applications including wound closure,

treatment of burns and abrasion and as surgical drapes. U.S.

Pat. No. 5,730,994 describes methods for draping a surgical

site by the in situ formation of cyanoacrylate polymer drape

over skin surface. While the specification describes various

cyanoacrylate monomers that can be used as surgical drapes,

the preferred compositions contained only n-butyl

cyanoacrylate. Furthermore, only n-butyl cyanoacrylate

compositions were tested as surgical drapes.

May 6, 2010

[0031] There are several shortcomings associated with

using n-butyl cyanoacrylate as a surgical drape. Compared to

longer chain alkyl cyanoacrylates, n-butyl cyanoacrylate is

less flexible and cracks more easily after forming a polymer

film. Thus a plasticizer is usually needed in the n-butyl

cyanoacrylate formulation to improve flexibility. In addition,

short-chain cyanoacrylates polymerize quickly and then

degrade rapidly into formaldehyde and the corresponding

alkyl cyanoacetate, which can cause significant histotoxicity.

Polymer films of n-butyl cyanoacrylate sloughs off from skin

faster than that of long alkyl chain cyanoacrylates. Skin irri-

tation also occurs with the use of n-butyl cyanoacrylate.

[0032] Hence, development of a cyanoacrylate-based

microbial sealant drape which can immobilize the infectious

microorganisms and effectively seal out the bacteria from a

surgical site is desired. It is desirable to have a cyanoacrylate-

based microbial sealantdrape product that can provide a um-

form and flexible film. It is also desirable to develop a

cyanoacrylate microbial sealant drape with significantly less

tissue toxicity. Additionally, it is also desirable to develop an

easy to use cyanoacrylate-based microbial sealant drape that

will last a long time after the surgery to inhibit the postopera-

tive surgical site infections.

SUMMARY OF THE INVENTION

[0033] The present invention provides cyanoacrylate-

based liquid microbial sealant drape compositions compris-

ing mixtures of cyanoacrylates to inhibit the surgical site

infections. The liquid sealant film formed upon polymeriza-

tion of the cyanoacrylate mixture prevents the spread of bac-

teria by trapping and immobilizing the microorganisms on

the surgical sites. The compositions of the present invention

provide flexible microbial sealant drapes without the addition

of plasticizers and/ or antimicrobial agents.

[0034] The present invention provides a method of per-

forming surgery with a lowered risk of contamination includ-

ing the steps of applying a preoperative skin preparation to a

surgical site, applying the microbial sealant drape composi-

tion based on liquid cyanoacrylates to the surgical site, form-

ing the microbial sealant film on the surgical site, making an

incision through the microbial sealant film, and performing

surgery.

[0035] The present invention provides liquid microbial

sealant drape compositions which can effectively reduce the

amount of microorganisms in the surgical site. Effective

immobilization of microorganisms, by liquid microbial seal-

ants of the present invention, were confirmed by both in vitro

and in vivo bacteria immobilization test. In vitro immobili-

zation test on sterile pig skin confirms that the microbial

sealant compositions of the present invention are at least 95%

effective in preventing the spread of the clinically relevant

bacteria on the surgical sites under a variety of usage condi-

tions. In preferred embodiments of the microbial sealant com-

positions of the present invention the compositions are at least

99.5% effective in preventing the spread of the clinically

relevant bacteria on the surgical sites under a variety of usage

conditions. In more preferred embodiments of the microbial

sealant compositions of the present invention the composi-

tions are at least 99.9% effective in preventing the spread of

the clinically relevant bacteria on the surgical sites under a

variety of usage conditions. The microbial sealant composi-

tions of the present invention do not need to be used in

combination with an antimicrobial surgical incise drape and

may be used as a substitute for an antimicrobial surgical

US 2010/0112036 A1

incise drape. The in vivo bacteria immobilization on 60

human subjects indicates that the microbial sealant composi-

tions of the present invention can reduce microbial coloniza-

tion by at least 99.9% within 15 minutes and maintain at least

a 99.9% reduction throughout the 24 hours post treatment.

[0036] The present invention provides microbial sealant

drape compositions which are resistant to the passage of

blood-borne pathogens using viral penetration as a test sys-

tem. No viral penetration was detected for the disclosed

microbial sealant film.

[0037] The present invention provides a method of inhibit-

ing the surgical site infections during and post the surgery. It

takes days for the microbial sealant film to slough off. The

disclosed cyanoacrylate liquid drape compositions are thus

providing the post-surgical infection protection based on the

anti-microbial property of cyanoacrylates.

[0038] The present invention provides microbial sealant

drape compositions which provide a desirable degradation

profile.

[0039] The present invention provides microbial sealant

drape compositions including at least one cyanoacrylate

monomer with longer alkyl chain and at least one cyanoacry-

late monomer with shorter alkyl chain. The desired

cyanoacrylate properties can thus be fine-tuned by combining

the longer chain and shorter chain cyanoacrylates in specific

ratios. Properties such as bonding strength, setting time, vis-

cosity, degradability and biocompatibility can be altered

depending on the specific combination of cyanoacrylates.

Mixed cyanoacrylate compositions with about 60% to about

90% or more of 2-octyl cyanoacrylate are preferred for use as

microbial sealants to prevent the surgical site infections.

[0040] The present invention provides sterile microbial

sealant drape compositions which may be sterilized by the

combination of ethylene oxide exposure and E-beam irradia-

tion. Sterile microbial sealant compositions sterilized in this

manner provide at least a two year shelf life.

[0041] The present invention provides microbial sealant

drape compositions based on mixed cyanoacrylate mono-

mers, which are packaged in a single use applicator. The

applicator includes a compartment containing the microbial

sealant composition as well as a sponge applicator tip.

Cyanoacrylate-based microbial sealant composition can be

readily dispensed onto the sponge applicator tip. A uniform

sealing film can be formed by applying the cyanoacrylate-

saturated sponge tip onto the surgical sites.

[0042] The present invention provides microbial sealant

drape compositions which are compatible with currently

available skin preparation products, surgical incise drapes

and wound closure products.

[0043] The present invention provides microbial sealant

drape compositions, which form flexible and tight films on

the substrates so that little or no detectable cyanoacrylate

residue is transferred into the incision wound by the surgical

blade.

[0044] The present invention provides microbial sealant

drape compositions which generate less heat during the appli-

cation compared to commercially available drape products

comprised of 100% butyl cyanoacrylate. The average tem-

perature increase of the skin after applying microbial sealant

composition of the present invention is no more than about

0.25° C.

[0045] The present invention provides microbial sealant

drape compositions which provide a high flashpoint for safe

use in the operating room or clinical surgery suite. The flash-

May 6, 2010

point for the disclosed microbial sealant composition is

greater than 240° F. which is greater than 100% butyl

cyanoacrylate drape products.

[0046] The present invention provides cyanoacrylate-

based microbial sealant drape compositions which form a

thin and uniform drape film on the surgical sites. The film

thickness of the disclosed cyanoacrylate liquid drape compo-

sitions was evaluated using optical microscope, which is less

than 500 pm.

[0047] The present invention provides cyanoacrylate-

based microbial sealant drape compositions which has a

desirable surface coverage. The average surface coverage of

the drape composition disclosed in the present invention

device was approximately 222.0 inch2. The average surface

coverage of the drape composition disclosed in the present

invention device is much larger than that of the commercial

applicators with the same amount of the liquid sealant.

[0048] The present invention provides cyanoacrylate-

based microbial sealant drape compositions which are com-

patible with lasers. The microbial sealant films do not ignite,

crack, blister or peel under the intense thermal energy of the

lasers so that the microbial sealant film maintains its integrity

and effectiveness as a sealant on the surgical site.

[0049] The present invention provides microbial sealant

drape compositions which are compatible with defibrillators

and electrocautery. The combined use of the disclosed micro-

bial sealant composition with defibrillator and electrocautery

does not affect the effectiveness of these devices. The dis-

closed microbial sealant composition demonstrates desirable

performance with regard to charring, plume discoloration and

cleaning of the blade upon completion of the incision and

coagulation procedures. No signs of ignition, blistering,

cracking or peeling were observed.

[0050] The present invention provides cyanoacrylate-

based microbial sealant drape films which provides more

resistance to water penetration by impact than the commer-

cial cyanoacrylate films. The microbial sealant composition

of the present invention elicited a mean value of 0.03 grams

from penetration of water by impact compared to a mean

value of 0.07 grams for butyl cyanoacrylate microbial sealant

drapes.

[0051] The present invention provides microbial sealant

drape compositions which are less irritating to the skin of a

patient than prior art compositions. Based on the skin irrita-

tion study, the primary irritation index for the disclosed

microbial sealant composition was calculated to be 0.7, while

the primary irritation index for butyl cyanoacrylate drapes

was calculated to be 1.4.

[0052] The present invention provides microbial sealant

drape compositions which are safe and biocompatible. Cyto-

toxicity, genotoxicity, local irritation after implantation, and

delay-type hypersensitivity of the disclosed microbial sealant

compositions were evaluated based on ISO 10993, which

confirmed the disclosed compositions are safe to be used as

microbial sealant to inhibit the surgical site infections.

BRIEF DESCRIPTION OF THE FIGURES

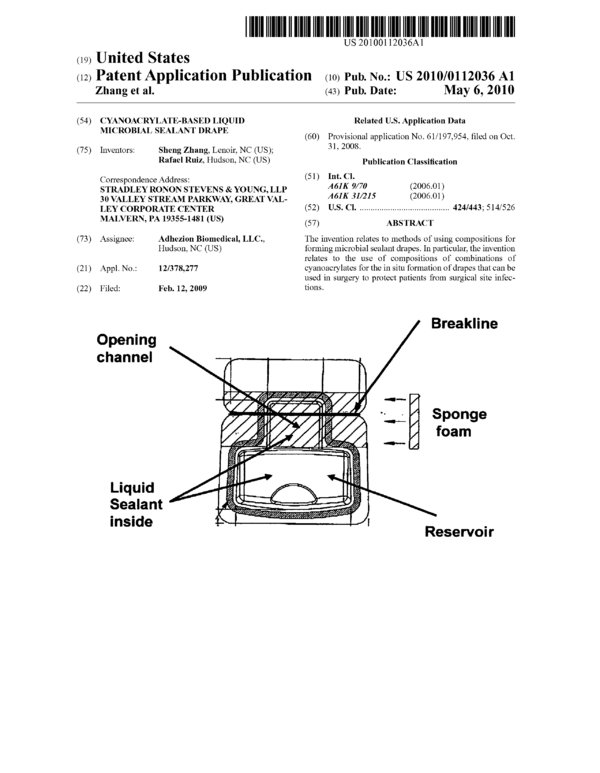

[0053] FIG. 1 is an illustration of a preferred embodiment

of the applicator for the cyanoacrylate microbial sealant

drape compositions.

DETAILED DESCRIPTION OF THE INVENTION

[0054] The present invention provides compositions com-

prising sterile mixtures of cyanoacrylates with different

US 2010/0112036 A1

length alkyl chains for use as a liquid microbial sealant drape

that can inhibit the surgical site infections. The drape film

formed upon polymerization of the mixture of cyanoacrylates

prevents the spread of microorganisms by trapping or immo-

bilizing bacteria that survive on patient’s skin after common

skin preparation procedures.

[0055] Preferred microbial sealant drape compositions dis-

closed herein include at least one cyanoacrylate with longer

alkyl chain and at least one cyanocrylate with shorter alkyl

chain. The longer alkyl chain cyanoacrylates are those con-

taining 5 or more carbon atoms in the alkyl group, which

include but are not limited to n-pentyl cyanoacrylate, iso-

pentyl cyanoacrylate, n-hexyl cyanoacrylate, iso-hexyl

cyanoacrylate, n-heptyl cyanoacrylate, 2-ethylhexyl

cyanoacrylate, n-octyl cyanoacrylate, 2-octyl cyanoacrylate,

nonyl cyanoacrylate, and decyl cyanoacrylate. The shorter

alkyl chain cyanoacrylates are those containing 4 or less

carbon atoms in the alkyl group, which include but are not

limited to methyl cyanoacrylate, ethyl cyanoacrylate, n-pro-

pyl cyanoacrylate, isopropyl cyanoacrylate, n-butyl

cyanoacrylate, isobutyl cyanoacrylate, 3-acetoxypropyl

cyanoacrylate, 2-methoxypropyl cyanoacrylate, and 3-chlo-

ropropyl cyanoacrylate.

[0056] Varying the composition ratio of cyanoacrylate with

different alkyl chains allows modification of the properties of

cyanoacrylate compositions so that bonding strength, flex-

ibility, cure time, degradability and biocompatibility can be

controlled. Cyanoacrylates with long alkyl chains lacking

oxygen-containing functional groups tend to form polymers

that degrade slowly. Compared to longer chain cyanoacry-

lates, the shorter cyanoacrylate monomers have a higher

degree of tissue toxicity due to their rapid degradation into

formaldehyde and the corresponding cyanoacetate. Polymer

films comprising longer alkyl chain cyanoacrylate tend to be

more flexible than those made of shorter alkyl chain

cyanoacrylates. Shorter alkyl chain cyanoacrylates have

advantageous properties as tissue adhesives. For example,

shorter alkyl chain cyanoacrylates provide faster curing speed

and stronger bond strength as compared to longer alkyl chain

cyanoacrylates.

[0057] In a preferred embodiment of compositions of the

present invention, liquid microbial sealant drape composi-

tions comprise 2-octylcyanoacrylate (OCA) in combination

with n-butyl cyanoacrylate (BCA). In order to investigate the

stability of the mixture of 2-octyl cyanoacrylate and n-butyl

cyanoacrylate, a series of mixed cyanoacrylate compositions

with different ratio of OCA/BCA were prepared and sub-

jected to sterilization. Sterilization of the compositions is a

requirement for their use as microbial sealants. Therefore it is

important that the compositions can be sterilized without

significant viscosity change. The compositions tested were

composed of cyanoacrylates having the following ratios of

n-butyl cyanoacrylate to 2-octyl cyanoacrylate: 10:90, 20:80,

30:70, 40:60, 50:50, 60:40, 70:30, 80:20 and 90:10. Table 1

shows the viscosity of the 2-octyl cyanoacrylate and n-butyl

cyanoacrylate mixtures before and after the E-beam steriliza-

tion. The compositions were sterilized in HDPE bottles (1

ounce). Viscosity change correlates with the stability of

cyanoacrylate monomers, stability being an important crite-

rion for selecting the appropriate cyanoacrylate mixture com-

positions for use as microbial sealants. As shown in Table 1,

E-beam sterilization has different effects on different mix-

tures of 2-octyl cyanoacrylate and n-butyl cyanoacrylate

depending on the ratio of the two cyanoacrylates. The viscos-

May 6, 2010

ity of the different compositions before the sterilization

ranges from 3.68 to 3.88 cps and the difference is within the

measurement accuracy of the viscometer. Mixed cyanoacry-

late compositions having approximately 60% to about 90%

2-octyl cyanoacrylate demonstrate slight viscosity increases

after E-beam sterilization. The preferred range of viscosity

change is approximately 0% to 200%. The viscosity of the

mixed cyanoacrylate compositions having about 50% or less

of 2-octyl cyanoacrylate increases dramatically after the

E-beam sterilization. This is indicative of instability of those

compositions after undergoing E-beam sterilization. Mixed

cyanoacrylate compositions having about 20% or less of

2-octyl cyanoacrylate cured after the E-beam sterilization and

are unsuitable for microbial sealant compositions. In a more

preferred embodiment of compositions of the present inven-

tion, compositions with about 60% to about 90% of 2-octyl

cyanoacrylate are used as the liquid microbial sealant to pre-

vent the surgical site infections. More preferably, composi-

tions with about 70% to about 90% of 2-octyl cyanoacrylate

are used. Even more preferably, compositions with about

80% of 2-octyl cyanoacrylate and about 20% of n-butyl

cyanoacrylate is used as the liquid microbial sealant to pre-

vent the surgical site infections.

TABLE 1

Viscosity ofmixed OCNBCA compositions before and after E-beam

sterilization.

Average viscosity cps

Formulation Composition Before Sterilization After Sterilization

la 1:9 BCNOCA 3.68 5.11

1b 2:8 BCNOCA 3.68 5.71

1c 3:7 BCNOCA 3.68 5.11

1d 4:6 BCNOCA 3.88 6.95

le 5:5 BCNOCA 3.88 15.77

1f 6:4 BCNOCA 3.88 68.03

lg 7:3 BCNOCA 3.68 505.63

1h 8:2 BCNOCA 3.68 Cured

11 9:1 BCNOCA 3.68 Cured

[0058] In preferred embodiments of the present invention

the liquid microbial sealant drape compositions provide at

least two-year shelf life. The stability of the sterile cyanoacry-

late adhesive compositions has evaluated by the accelerated

aging. The accelerated aging test of the mixed cyanoacrylate

microbial sealant composition was performed in an oven at

80° C. for a period of 12 days. The investigated compositions

were tested for viscosity at intervals of 3, 6, 9 and 12 days.

Based onASTM F1980-2, 12 days accelerated aging at 80° C.

correlates to 2 years of shelf life at ambient temperatures.

Table 2 shows the viscosity of a sterile microbial sealant

composition in an applicator containing 80% of 2-octyl

cyanoacrylate and 20% of n-butyl cyanaocrylate at day 0, 3, 6,

9 and 12 of the accelerated aging at 80° C. The viscosity of the

cyanoacrylate-based microbial sealant compositions

increases as the accelerated aging proceeds but the increased

viscosity of the aged samples at day 12 does not affect the

performance of liquid drape compositions nor the dispensing

of the compositions from the applicator.

US 2010/0112036 A1

TABLE 2

Viscosity of the sterile microbial sealant drape composition before

and after the accelerated aging at 80° C. for 12 days.

Viscosi c s

Test 1 Test 2 Test 3 Average

Day 0 4.29 3.68 3.06 3.68

Day 3 4.29 3.68 4.90 4.29

Day 6 4.90 4.90 5.52 5.11

Day 9 6.13 6.13 6.74 6.33

Day 12 27.0 25.7 30.6 27.8

[0059] In preferred embodiments of the present invention

the microbial sealant drape composition is packaged in a

user-friendly, single use applicator. As shown in FIG. 1, the

applicator comprises a compartment containing the mixed

cyanoacrylate compositions and a sponge applicator tip

through which the liquid drape compositions may be applied

to the surgical site. The applicator compartment is preferably

air and water tight with a sealing mechanism to prevent con-

tamination to the mixed cyanoacrylate monomers inside.

When the compartment is opened, the mixed cyanoacrylate

liquid sealant is evenly distributed onto the sponge applicator

tip. Cyanoacrylate liquid drape compositions can be easily

dispensed onto the sponge from an applicator once the sponge

connection is folded. A uniform sealing film is formed by

applying the cyanoacrylate-saturated sponge tip onto surgical

sites.

[0060] According to the present invention, the microbial

sealant drape compositions of the present invention can effec-

tively reduce the amount of microorganisms in the surgical

site. In preferred embodiments the microbial sealant compo-

sitions are at least 99.9% effective in preventing the spread of

the clinically relevant bacteria on the surgical sites under a

variety of usage conditions. The in vitro immobilization of

microorganisms by the microbial sealant compositions was

evaluated using sterile pig skin incised with a sterile surgical

scalpel. Microorganisms used to challenge the surgical site

may include without limitation pathogenic gram negative

bacteria, gram positive bacteria, yeast and Corynebaczerium

sp. The immobilization of microorganisms by the microbial

sealant compositions of the present invention was evaluated

under different conditions which included without limitation

using the microbial sealant composition without incision,

using the microbial sealant composition with incision, using

the microbial sealant composition with incision and skin sur-

gical preps, and using the microbial sealant composition with

incision and surgical incise drapes.

[0061] The microbial sealant drape compositions of the

present invention were effective in preventing the mitigation

in the test organism on the surgical site. Complete effective-

ness was manifest as greater than 3 .9 log 10 mitigation in the

case of S. epidermidis, MRSA, Corynebaczerium species,

Pseudomonas aeruginosa and greater than 4 log 10 mitiga-

tion for Candida albicans. The microbial sealant composi-

tions do not have an adverse effect on the effectiveness of

surgical preps. The microbial sealant compositions do not

need to be used in combination with an antimicrobial surgical

incise drape. Instead the microbial sealant compositions of

the present invention may be used as a substitute for an

antimicrobial surgical incise drape.

May 6, 2010

[0062] According to the present invention, the preferred

microbial sealant drape compositions can reduce microbial

colonization by at least 99.9% within 15 minutes of applica-

tion and maintain at least a 99. 9% reduction throughout the 24

hours post treatment

[0063] According to the present invention, the microbial

sealant drape compositions are resistant to the passage of

blood-borne pathogens. Testing based on ASTM F1671 “Test

Method for Resistance of Materials Used in Protective Cloth-

ing to Penetration by Blood-Bome Pathogens Using Phi-

X174 Bacteriophage Penetration as a Test System” was con-

ducted to demonstrate the pathogen resistance. The test

results indicated that the disclosed microbial sealant film is

resistant to the passage of blood-borne pathogens using a

viral penetration as a test system.

[0064] Preferred microbial sealant drape compositions of

the present invention generate less heat during the application

compared to commercially available drape products. Poly-

merization of cyanoacrylate is an exothermic process. The

amount of heat released during polymerization is related to

the length of the alkyl chain of the cyanoacrylate. Cyanoacry-

lates with shorter length chains release more heat. Too much

heat generated from the application of cyanoacrylates onto

human skin makes the patient uncomfortable. The exother-

mic effect of microbial sealant product of the present inven-

tion and a commercially available product was evaluated

using an Infrared Thermometer to measure the temperature

change on human skin. The skin temperature of patients was

measured before and after the application of the drape prod-

ucts onto human skin. The average temperature increase after

applying microbial sealant composition disclosed in the

present invention and a commercially available product were

0.25 and 0.41 ° C., respectively. The test results indicate that

less heat is released from the application of the preferred

composition disclosed in the present invention than that of a

commercially available product.

[0065] According to the present invention, the microbial

sealant drape compositions of the present invention have a

high flashpoint for safe use in the operating room or clinical

surgery suite. The test was performed in accordance with

ASTM D56-05, ISO 3679:2004 determination of flashpoint-

rapid equilibrium closed cup method. The flashpoint for the

microbial sealant compositions of the present invention is

greater than 240° F. The flashpoint of the 100% butyl

cyanoacrylate microbial sealant compositions is about 227°

F

[0066] According to the present invention, no cyanoacry-

late residue was detected on a surgical blade through which an

incision was made on a substrate covered with a microbial

sealant drape compositions disclosed herein. The detection

limit of the test was 5 ppm. The residue analysis on a surgical

blade confirmed that no detectable cyanoacrylate sealants

were transferred into the incision wound site.

[0067] According to the present invention, the preferred

microbial sealant drape compositions of the present invention

provide a desirable degradation profile. The integrity (degra-

dation over time) of the disclosed microbial sealant film was

evaluated following topical application to the skin of three

pigs and comparisons were made to commercially available

drapes. The microbial sealant films applied at each applica-

tion site were evaluated for degradation at approximately 8

hours after application, and 1, 2, 3, 4, 6, 8, 10, 12, 14, and 16

days after application. Degradation of both the disclosed

microbial sealant film and the commercial product was evi-

US 2010/0112036 A1

dent by the first observation interval (8 hours after applica-

tion). At this time, 2 out of 12 test sites with the disclosed

microbial sealant film remained intact and 5 out of 12 sites

with the predicate device were intact. When the study ended

on day 16, the microbial sealant film of the present invention

was partially present in 2 of the 12 sites, while the commercial

product was absent from all 12 sites.

[0068] According to the present invention, the liquid

microbial sealant compositions are compatible with currently

available skin preparation products, surgical incise drape

products and wound closure products. Compatibility with

current products means that the application of the disclosed

microbial sealant drape composition does not adversely

affect the performance of wound closure products and surgi-

cal incise drapes. Skin preparation products that may be used

in concert with the compositions of the present invention

include without limitation Chloraprep, Duroprep, 10% Povi-

done iodine and Betadine. Duraprep is preoperative skin

preparation product comprising iodine povacrylex and iso-

propyl alcohol. ChloraPrep is a rapid-acting, persistent, and

broad- spectrum preoperative skin preparation product, which

consists of 2% Chlorhexidine Gluconate in 70% isopropyl

alcohol. Betadine is a consumer-available topical antiseptics

containing 10% of povidone-iodine. Surgical incise drapes

may also be used with the cyanoacrylate compositions of the

present invention including without limitation 3M Steri-strip

and loban 2. Steri-Strip is an antimicrobial skin closure prod-

uct that is made of a porous, non-woven backing coated with

a pressure-sensitive adhesive which contains iodophor and is

reinforced with polyester filaments for improved strength.

loban 2 is an antimicrobial surgical incise drape with an

iodophor impregnated adhesive providing a sterile surface

and antimicrobial activity throughout the procedure. The

compatibility of the preferred liquid microbial sealant com-

positions with current commercial products used for prevent-

ing surgical site infections was investigated by observing the

effect of the disclosed liquid drape product on the adhesion

property of surgical incise drape in the absence and presence

of different skin preparation products.

[0069] The liquid cyanoacrylate sealant compositions of

the present invention are also compatible with currently avail-

able wound closure products. The wound closure products

may include SurgiSeal, Dermabond and Steri-Strip. Derrna-

bond is a liquid bonding adhesive that holds cuts, incisions

and wounds together. SurgiSeal is cyanoacrylate-based topi-

cal skin adhesive for the closure of wound and incisions to

provide a flexible, water-resistant, antimicrobial protective

coating, which provides the optimal balance between bond

strength and flexibility.

[0070] According to the present invention, the preferred

liquid cyanoacrylate sealant drape composition is compatible

with lasers. The lasers that may be used in concert with the

compositions of the present invention include without limi-

tation CO2, Nd:YAG, and Diode. The disclosed microbial

sealant is intended to be used after typical operative skin

preparation prior to a surgical incision. Lasers may be

required to be used for skin incision, ablation, or coagulation

for a surgical procedure. The in vitro study was conducted to

evaluate the effect of both free beam and contact use of the

lasers on the disclosed microbial sealant film formed on pig

skin. The combined use of a skin prep such as Betadine with

the disclosed microbial sealant composition was also inves-

tigated using a Diode laser. The integrity of the disclosed

microbial sealant film was evaluated by macroscopic obser-

May 6, 2010

vations for cracking, blistering and peeling. The intense ther-

mal energy of the lasers was used to determine if the disclosed

microbial sealant film would ignite. The results showed that

the disclosed microbial sealant film did not ignite, crack,

blister or peel for all three laser types when used with either

free beam or contact thermal energy applications so that the

microbial sealant maintains its integrity and effectiveness as a

sealant for the surgical procedure. These same results were

obtained when combined with the surgical skin preparation

product when the Diode laser was used with either free beam

or contact laser.

[0071] According to the present invention, the cyanoacry-

late-based microbial sealant compositions are compatible

with defibrillators and an electrocautery. The in vitro study

was conducted on porcine skin to evaluate the effect of the

microbial sealant compositions of the present invention on

the performance of the defibrillator and electrocautery. The

microbial sealant composition was applied onto porcine skin.

A metal plate or probe was attached on the underneath side of

the porcine skin to measure the voltage of the defibrillator. In

order to evaluate the compatibility with Electrocautery, a

commercially available Electrocautery device was used to

make incisions and coagulations on the porcine skins covered

with the disclosed microbial sealant film. The Electrocautery

settings were made at 70 watts for both incision and coagu-

lation. The single coat application of the microbial sealant

compositions of the present invention did not significantly

decrease the conductance of the energy being discharged

from the defibrillator. There was no observation of ignition,

blistering, cracking or peeling. When used with the electro-

cautery, the microbial sealant compositions demonstrated

desirable performance with regard to charring, plume discol-

oration and cleaning of the blade upon completion of the

incision and coagulation.

[0072] According to the present invention, the cyanoacry-

late liquid drape compositions provide a thin and uniform film

on the surgical sites. In preferred embodiments of the present

invention the drape film has a thickness of from about 5 to

about 400 pm. More preferably, the drape film provides a

thickness of about 10 to 200 pm, more preferably from about

30 to 80 um and still more preferably from about 50 to 60 pm.

The film thickness study indicates the formation of thin and

uniform films of the disclosed liquid drape compositions.

[0073] According to the present invention, the liquid

microbial sealant drape compositions provide greater resis-

tance to penetration of water by impact than the commercially

available liquid drapes. The resistance of the microbial seal-

ant compositions of the present invention to the penetration of

water by impact was investigated according to the American

Association of Textile Chemists and Colorists (AATCC) test

method. A volume of water is allowed to spray against the taut

surface of the disclosed microbial sealant film backed by a

weighted blotter. The blotter was then reweighed to determine

water penetration. The microbial sealant compositions of the

present invention have an average value of 0.03 grams from

penetration of water by impact compared to an average value

of 0.07 grams for a commercial drape composition. The test

results indicate that the disclosed microbial sealant composi-

tion provides twice more resistance to water penetration by

impact than the commercial product.

[0074] According to the present invention, the cyanoacry-

late liquid sealant drape compositions are safe and effective as

a surgical sealant product useful for inhibiting surgical site

infections. The safety and biocompatibility of the disclosed

US 2010/0112036 A1

liquid drape composition has been evaluated based on the

International Organization for Standardization (ISO) 10993,

Biological Evaluation of Medical Devices. Cytotoxicity was

measured on the preferred liquid microbial sealant composi-

tion using an in vitro biocompatibility study. The liquid

microbial sealant compositions of the present invention are

not cytotoxic. For comparison, the in vitro cytotoxicity of

prior art device was also evaluated, which showed no evi-

dence of causing cell lysis or toxicity.

[0075] According to the present invention, the preferred

liquid cyanoacrylate-based microbial sealant drape composi-

tion is less irritating than the prior art device, which was

confirmed by the primary skin irritation study and ISO intra-

cutaneous study.

[0076] According to the present invention, the preferred

liquid microbial sealant drape composition is not genotoxic.

Bacterial reverse mutation test, mouse peripheral blood

micronucleus study and in vitro chromosomal aberration

study in mammalian cells confirmed that the compositions

are not genotoxic.

[0077] The mixed cyanoacrylate compositions may be sta-

bilized with a combination of free radical stabilizer and

anionic stabilizer. In embodiments of the present invention,

the preferred primary free radical stabilizer is butylated

hydroxyl anisole (BHA). BHA is used in an amount of about

200 to about 15000 ppm, preferably about 1000 to about

10000 ppm, more preferably about 2000 to about 8000 ppm.

Other free radical stabilizers that may be used include without

limitation, hydroquinone; catechol; hydroquinone monom-

ethyl ether and hindered phenols such as butylated hydroxya-

nisol; 4-ethoxyphenol; butylated hydroxytoluene (BHT, 2,6-

di-tert-butyl butylphenol), 4-methoxyphenol (MP);

3-methoxyphenol; 2-tert-butyl-4methoxyphenol; 2,2-meth-

ylene-bis-(4-methyl-6-tert-butylphenol).

[0078] In embodiments of the present invention, the pre-

ferred primary anionic stabilizer is sulfur dioxide in an

amount of about 2 to about 500 ppm, preferably from about

10 ppm to about 200 ppm. The anionic stabilizer may be a

very strong acid including without limitation perchloric acid,

hydrochloric acid, hydrobromic acid, toluenesulfonic acid,

fluorosulfonic acid, phosphoric acid, ortho, meta, or para-

phosphoric acid, trichloroacetic acid, and sulfuric acid. The

very strong acid may be used in an amount of 0 to about 250

ppm, preferably from about 5ppm to 50 ppm. Preferably, the

very strong acid stabilizer is sulfuric acid, phosphoric acid or

perchloric acid.

[0079] According to the present invention, the cyanoacry-

late-based microbial sealant drape compositions are sterilized

for medical use. The sterilization can be accomplished by

common techniques, and is preferably accomplished by

methods including, but not limited to, chemical, physical, and

irradiation methods. An example of a chemical method

includes, but is not limited to, exposure to ethylene oxide.

Examples of irradiation methods include, but are not limited

to, gamma irradiation, electron beam irradiation (E-beam),

and microwave irradiation.

[0080] In preferred embodiments of the present invention,

E-beam is used to sterilize the cyanoacrylate-based microbial

sealant compositions. The dose of E-beam irradiation applied

should be sufficient enough to sterilize both the package and

the adhesive inside. The E-beam irradiation may be in a

dosage of from about 5 to 50 kGy, and more preferably from

about 12 to about 25 kGy. E-beam irradiation is preferably

conducted at ambient atmosphere conditions and the expo-

May 6, 2010

sure time to the irradiation is preferably from about 1 to about

60 seconds, more preferably from about 10 seconds to 60

seconds.

[0081] In preferred embodiments of the present invention,

the viscosity of the preferred cyanoacrylate-based microbial

sealant composition changes upon the E-beam sterilization.

The average viscosity of the preferred microbial sealant drape

composition comprising 20% butyl cyanoacrylate and 80%

octyl cyanoacrylate before sterilization is 3.68 cps. After the

sealant composition is subjected to E-beam sterilization the

viscosity was measured to be 5.71 cps. The prior art refer-

ences indicate that E-beam sterilization can induce serious

partial polymerization of cyanoacrylate, which would lead to

a large increase in viscosity.

[0082] In order to reduce the bioburden, the cyanoacrylate-

based microbial sealant drape compositions may be filtered

through a 0.2 pm filter. The applicators with the overpack may

also be sterilized with heat, ethylene oxide prior to the final

E-beam irradiation.

[0083] The sterility of the cyanoacrylate-based microbial

sealant drape compositions may be analyzed by Bacteriosta-

sis and Fungistasis tests. In embodiments of the present

invention, a Sterility Assurance Level (SAL) should be

obtained at a minimum of 10‘3 , which means that the prob-

ability of a single unit being non-sterile after sterilization is 1

in 1000. In more preferred embodiments, the Sterility Assur-

ance Level may be at least 10‘6.

[0084] The following non-limiting examples are intended

to further illustrate the present invention.

EXAMPLE 1

Setting Time Measurement

[0085] Pig skin (4>< MEM) with 5% serum and 2% antibi-

otics. The test extract was placed onto three separate mono-

US 2010/0112036 A1

layers of L-929 mouse fibroblast cells propagated in 5% CO2.

High density polyethylene was used as the negative control

and tin stabilized polyvinylchloride was used as the positive

control. All monolayers were incubated at 37° C. in the pres-

ence of 5% CO2 for 48 hours, which was then examined

microscopically to determine any change in cell morphology.

The liquid microbial sealant compositions of the present

invention did not cause cell lysis or toxicity.

EXAMPLE 8

Genotoxicity Study 1

[0092] A glass rod was cleaned with 70% isopropyl alcohol

and allowed to air dry. The rod was then coated with a micro-

bial sealant drape composition comprising 80% of 2-octyl

cyanoacrylate and 20% of n-butyl cyanoacrylate up to 4 cm

and allowed to dry for at least 1 minute prior to extraction with

dimethyl sulfoxide (DMSO) and 0.9% sodium chloride at 37°

C. for 72 hours. Another glass rod without cyanoacrylate

liquid drape was similarly subjected to the extraction condi-

tions for use as a negative control. Known mutagens, benzo

[a]pyrene and 2-nitrofluorene, were used as positive control

to demonstrate that tester strain TA 98 was sensitive to muta-

tion reversion to wild type. For tester strains TA100 and TA

1535, sodium azide and 2-aminoanthracene were used as

positive controls. For tester 1537, 2-aminoanthracene and

ICR-191 were used as positive controls. For tester strain

WP2uvrA, 2-aminoanthracene and methylmethane-sul-

fonate were used as positive controls.

[0093] Tubes containing molten top agar supplemented

with tryptophan for the Escherichia coli or with histidine-

biotin solution for the Salmonella zyphimurium were inocu-

lated with culture for each of the five tester strains and with

the DMSO and saline extracts of the disclosed cyanoacrylate

liquid drape film. Sterile water for injection (SW1) or S9

homogenate simulating metabolic activation was added as

necessary. Trytophan-free media plates (for E. coli) and his-

tidine-free media plates (for S. zyphimurium) were prepared

in triplicate as follows: 1) DMSO and saline extracts of the

cyanoacrylate liquid drape film with and without S9 activa-

tion; 2) negative controls with and without S9 activation; and

3) positive controls with different tester strains in the absence

and presence of S9 activation.

[0094] The plates were incubated at 37° C. for 2 to 3 days.

Following the incubation period, the revertant colonies on

each plate were recorded. The mean number of revertants and

standard deviation was determined. The mean number of

revertants of the test plates was compared to the mean number

of revertants of the negative control for each of the five tester

strains. It was concluded that, under the study conditions, the

disclosed liquid microbial sealant compositions in both

DMSO and saline extracts were not mutagenic to Salmonella

Zjzphimurium strains (TA98, TA100, TA1535, and TA1537),

and were not mutagenic to tryptophan-dependent Escheri-

chia coli strain WP2uvrA.

EXAMPLE 9

Genotoxicity Study 11

[0095] A glass rod was cleaned with 70% isopropyl alcohol

and allowed to air dry, and then coated with the microbial

sealant drape compositions comprising 80% of 2-octyl

cyanoacrylate and 20% of n-butyl cyanoacrylate up to 4 cm.

The drape was allowed to dry for at least 1 minute prior to

May 6, 2010

extraction with dimethyl sulfoxide (DMSO) and 0.9%

sodium chloride at 37° C. for 72 hours. Additional test rods

without cyanoacrylate microbial sealant were subjected to the

same extraction conditions as the test article and were used as

negative controls. Methyl methanesulfonate (MMS) in saline,

an antineoplastic drug known to have mutagenic properties,

was used as a positive control.

[0096] Five groups of mice, each of which consisted of 6

male and 6 female, were injected with cyanoacrylate liquid

drape in SC extract, cyanoacrylate liquid drape in SO extract,

negative control in SC, negative control in SO, and positive

control with methyl methanesulfonate, respectively. Each

mouse received an intraperitoneal injection at a dose of 20

ml/kg of the appropriate extract accordingly for consecutive

three days.All animals were observed immediately following

injection and on a daily basis to access general health. On day

4, blood was collected from the tail veins of each mouse and

solutions were prepared. The normochromatic erythrocytes

were evaluated for the presence of micronuclei. The fre-

quency of micronucleated reticulocytes (MN-RETs) was

determined and used as an index of genotoxicity. The fre-

quency of reticulocytes relative to total erythrocytes was cal-

culated as an indication of stem cell toxicity. Both SC and SO

extracts of the cyanoacrylate liquid drapes of the present

invention did not show statistically significant increases in the

frequency of MN-RETs. Cyanoacrylate liquid microbial

sealant compositions of the present invention are not geno-

toxic under the study conditions. Also, there was no evidence

of cellular toxicity from extracts of the disclosed cyanoacry-

late liquid drape composition.

EXAMPLE 10

Local Irritation and Toxicity Study

[0097] Local irritation or toxicity effect after implantation

of the microbial sealant drape compositions comprising 80%

of 2-octyl cyanoacrylate and 20% of n-butyl cyanoacrylate

was conducted to evaluate the potential for a local irritant or

toxic response to the drape implanted in direct contact with

muscle tissue. High density polyethylene was used as the

negative control. Three Albino New Zealand rabbits were

used for the test. One incision was made on each side of the

rabbit back. The fascia was cut to expose the paravertebral

muscle. A pocket was formed with a hemostat between the

muscle fibers into which the implant material was introduced.

After four weeks, the rabbits were weighed and then eutha-

nized by an intravenous injection of a sodium pentobarbital

based drug. The paravertebral muscles were dissected free

and fixed in 10% neutral buffered formalin to facilitate cut-

ting. The tissue was macroscopically examined using low

magnification to look for capsule formation or other signs of

irritation. The excised sections were also histologically pro-

cessed for microscopic evaluations. The disclosed microbial

sealant drapes of the present invention caused no macro-

scopic reaction under the study conditions, while micro-

scopic examination indicated the disclosed composition was

moderately irritating to the tissue.

EXAMPLE 11

ISO lntracutaneous Study

[0098] lntracutaneous study of microbial sealant drape

compositions comprising 80% of 2-octyl cyanoacrylate and

20% of n-butyl cyanoacrylate was conducted to determine

US 2010/0112036 A1

whether leachables extracted from the disclosed microbial

sealant composition wound cause local dermal irritant effects

following injection into rabbit skin. The glass rods were

wiped clean with 70% isopropyl alcohol and allowed to air

dry. The glass rod was coated with the disclosed microbial

sealant compositions up to 4 cm and allowed to air dry for at

least one minute prior to placing in the extraction container.

The test article was extracted in 0.9% sodium chloride USP

solution (SC) and sesame oil, NF 9 (S0) at 37° C. for 72

hours. A 0.2 ml dose of the test article extract was injected by

the intracutaneous route into five separate sites on the right

side of the back of each rabbit. Injections were spaced

approximately 2 cm apart. The appearance of each injection

site was noted immediately after injection. Observations for

erythema and edema were conducted at 24, 48, and 72 hours

after injection. Under the conditions of this study, there was

no erythema and no edema from the SC extract injected

intracutaneously into rabbits. There was very slight erythema

and very slight edema from the SO extracts injected intracu-

taneously into rabbits.

EXAMPLE 12

ISO Skin Irritation Study

[0099] Skin irritation study of cyanoacrylate-based micro-

bial sealant drape compositions comprising 80% of 2-octyl

cyanoacrylate and 20% of n-butyl cyanoacrylate was con-

ducted to evaluate the potential for a single topical application

of the disclosed microbial sealant composition to irritate skin.

New Zealand white male rabbits were used for this study. On

the day of treatment, four sites, two on each side of the back

cranially and caudally, were designated on each rabbit. A 0.5

ml portion of the disclosed microbial sealant composition

was applied topically to each cranial site by introduction

under a 4 ply gauze layer to an area of skin approximately 25

mm>99% effective in preventing the

spread of the microorganisms into the wound site.

EXAMPLE 19

In vivo Bacteria Immobilization

[0109] A total of 60 healthy volunteers (29 females and 31

males) were recruited to evaluate the in vivo bacteria immo-

bilization of a microbial sealant composition comprising 20%

butyl cyanoacrylate and 80% octyl cyanoacrylate. The study

included a 14-day pretreatment washout period for stabiliza-

tion of skin bacteria flora. During the washout period, sub-

jects refrained from using any topical antimicrobials, sys-

temic antibiotics, medical soaps, lotions, shampoos, etc, for at

least two weeks before the evaluation and throughout the

study. The tested area consisted of the right inguinal region.

May 6, 2010

Mean difference

score (test — control)

Very slight edema (barely perceptible)

Well-defined edema (edges ofarea

well-defined by definite raising)

Severe edema (raised more than 1 mm,

and extending beyond exposure area)

Hair was removed using a sterile disposable clipper device. A

sterile drape was used to isolate the inguinal area from the rest

of the body and then a surgical marker was used to draw four

different 1 inch squares separated by 1 inch of normal skin in

which the microbial sealant composition was applied. Using

sterile gloves the products were applied onto the skin in its

designated areas and allowed to dry. Sterile gauze was placed

over the test area to avoid sub sequent contamination.

Swabbed samples from skin were collected at 15 minutes, 4

hours and 24 hours after the initial application of the micro-

bial sealant composition. The sample collection procedure

was performed using a sterile technique including sterile

gloves, sterile microbial sealants, surgical masks and hats.

After the sampling was completed the entire contents of the

tube was poured carefully onto a 1 mL Petrifilm aerobic plate

(plate count agar) and the plates were incubated for 48 hours

at 30° C. 3MTM PetrifilmTM plate was used to quantify colony

counts. At 15 minutes, the absolute log reduction was 5.568

for the disclosed microbial sealant composition. The absolute

log reduction of bacteria for the disclosed microbial sealant

composition is 4.299 and 3 .33 at 4 hours and 24 hours, respec-

tively.

EXAMPLE 20

In vitro Chromosomal Aberration Study in Mamma-

lian Cells

[0110] A chromosomal aberratioin study was conducted to

determine whether an extract of the microbial sealant drape

composition wound cause clastogenic changes in Chinese

Hamster Ovary (CHO). A glass rod was sterilized with 70%

isopropyl alcohol and allowed to air dry. The glass rod was

then coated (4 cm) with a microbial sealant composition

comprising 20% butyl cyanoacrylate and 80% octyl

cyanoacrylate and allowed to air dry for at least 1 minute prior

to placing the coated rod in the extraction container. A single

preparation was extracted with DMSO with agitation at 37°

C. for 72 hours. Following extraction, the DMSO extract was

diluted with McCoy’s 5A medium to a final concentration of

25% prior to testing. Aveclor 1254:induced rat liver (S9

homogenate) was used as metabolic activation. The S9 homo-

genate is prepared from male, Sprague Dawley rats. An

US 2010/0112036 A1

uncoated glass rod was subjected to the same extraction con-

ditions to serve as a negative control. A known direct acting

genotoxic compound, Mitomycin C (MMC), was used as a

positive control to demonstrate that CHO cells were sensitive

to mutagens in the absence of metabolic activation. The

microbial sealant composition extract, negative control, and

positive control were tested in triplicate. For the assays con-

ducted without metabolic activation, the growth medium in

each of three test culture flasks was replaced with 10 ml of the

prepared extracts. For the assay conducted with metabolic

activation, the test samples were supplemented with isocitrate

dehydrogenase (NADP+) at 60 111/ ml and S9 at 20 p.l/ml.After

18 hours of incubation at 37° C. in the presence of CO2, the

medium was decanted and the cultures were rinsed twice with

4-6 ml of calcium magnesium free phosphate buffered saline

(CMF-PBS). The flasks were incubated for an additional 2

hours at 37° C. After harvesting, slides of the cells were

prepared, stained with Giemsa, and examined microscopi-

cally for chromosomal aberrations at 100>< magnification.

Under the conditions of this assay, the DMSO test extract of

the disclosed microbial sealant composition was not consid-

ered genotoxic to Chinese Hamster Ovary cells in the absence

of S9 metabolic activation. The prepared McCoy’s extract

was not considered genotoxic to Chinese Hamster Ovary cells

in the presence or absence of S9 metabolic activation. The

positive and negative controls performed as expected.

EXAMPLE 21

Resistance to Impact Penetration

[0111] The resistance of a microbial sealant drape compo-

sition comprising 20% butyl cyanoacrylate and 80% octyl

cyanoacrylate to the penetration of water by impact was

evaluated by following the American Association of Textile

Chemists and Colorists (AATCC) test method. Test sample

films of the microbial sealant composition were made that

measured 178x230 mm. The samples and the blotting paper

were conditioned in an atmosphere of 65:2% relative humid-

ity (RH) at 21:1° C. for 4 hours before testing. After clamping

the film onto an inclined stand, a standard blotter 152x230

mm was weighed and inserted beneath the test sample. A

500110 ml volume of distilled water at 27:1° C. was poured

into a funnel of the tester and allowed to spray onto the test

sample of the microbial sealant composition. After the spray-

ing, the test sample was carefully lifted, the blotter removed

and reweighed to determine the amount of water that pen-

etrated the film during the test. The mean value for the micro-

bial sealant composition was 0.03 grams. Under the same

conditions a commercial microbial sealant film comprised of

100% butyl cyanoacrylate displayed a mean value of 0.07

grams.

EXAMPLE 22

Sealant Film Integrity Over Time

[0112] The integrity (degradation over time) of a microbial

sealant composition comprising 20% butyl cyanoacrylate and

80% octyl cyanoacrylate was evaluated following topical

application to the skin of three pigs and compared to another

microbial sealant product. The pigs were restrained in a sling

for up to 30 minutes during the application procedures. To

reduce possible stress at being restrained in the sling, the pigs

were initially conditioned to the sling over the course of 3