Absorbable Tissue Adhesives

Absorbable Tissue Adhesives

US5350798

Folder:

Year:

Abstract:

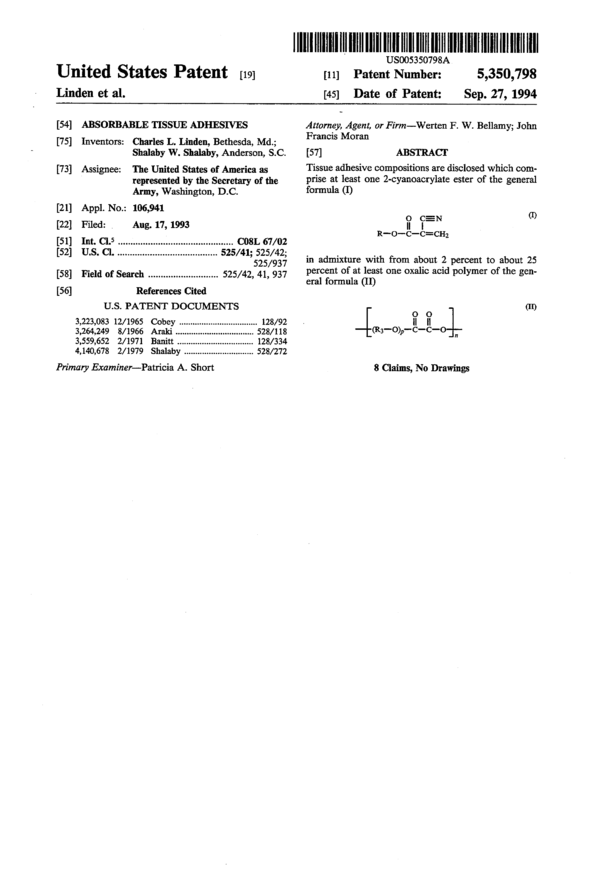

Tissue adhesive compostions are disclosed which comprise at least one 2-cyanoacrylate ester of the general formula (I) in admixture with from about 2 percent to about 25 percent of at least one oxalic acid polymer of the general formula (II).

Type of document:

Language:

United States Patent [19]

Linden et al.

USO05350798A

[11] Patent Number:

[45] Date of Patent:

5,350,798

Sep. 27, 1994

[54] ABSORBABLE TISSUE ADHESIVES

Charles L. Linden, Bethesda, Md.;

Shalaby W. Shalaby, Anderson, S.C.

The United States of America as

represented by the Secretary of the

Army, Washington, D.C.

[21] Appl. No.: 106,941

[7 5] Inventors:

[7 3] Assignee:

[22] Filed: , Aug. 17, 1993

[51] Int. Cl.5 ............................................ .. C08L 67/02

[52] U.S. Cl. ...................................... .. 525/41; 525/42;

525/937

[58] Field of Search .......................... .. 525/42, 41, 937

[56] References Cited

U.S. PATENT DOCUMENTS

3,223,083 12/1965 Cobey ................................. .. 128/92

3,264,249 8/1966 Araki 528/118

3,559,652 2/1971 Banitt ..... .. 128/334

4,140,678 2/1979 Shalaby ............................. .. 528/272

Primary Examiner—Patricia A. Short

Attorney, Agent, or Firm——Werten F. W. Bellamy; John

Francis Moran

[57] ABSTRACI‘

Tissue adhesive compositions are disclosed which com-

prise at least one 2-cyanoacrylate ester of the general

formula (I)

‘.1 15“ “’

R-O-C—C=CH2

in admixture with from about 2 percent to about 25

percent of at least one oxalic acid polymer of the gen-

eral formula (II)

(II)

0 0

II II

(R3—o),,—-c—c—o n

8 Claims, No Drawings

5,350,798

1

ABSORBABLE TISSUE ADHESIVES

FIELD OF THE INVENTION

This invention relates to improvements in the surgical

repair of mammalian body tissues. More particularly the

invention relates to improved surgical repair systems

comprising fast-polymerizing 2-cyanoacrylate mono-

mers modified by the addition of certain polymeric

oxalates.

BACKGROUND OF THE INVENTION

For many years surgical tissue closure has been ac-

complished by a variety of fundamental techniques such

as the use of clamps, staples or a variety of sutures.

Disadvantages associated with use of those techniques

has led to the development of new techniques for join-

ing damaged mammalian tissues and reducing or pre-

venting the loss of blood or other bodily fluids as well.

One approach has been the development of tissue

adhesives for joining tissues, derived from either natural

or synthetic products. Adhesive bonding with natural

products such as fibrin or glues derived from mollusks

such as mussels and barnacles has shown promise. Fi-

brin glue has been prepared by reacting a cryoprecipi-

tate of fibrinogen and thrombin in the presence of cal-

cium ion to produce fibrin monomer. This monomer

reacts in the presence of a factor found in the patient’s

blood (Factor XIII) to form a polymer. These fibrin

glues have found use in topical and spray applications as

a hemostatic agent on bleeding anastomoses, bleed

points caused by needle holes or suture lines, and on the

heart surface to control bleeding. The fibrin glues have

only a modest tensile strength and therefore have not

found significant use for repairing tissues which are

subjected to load.

Barnacle glue has shown promise since its polymeri-

zation is rapid and occurs under conditions which are

similar to the environment in which they would be

used. It also maintains its adhesive properties under

adverse chemical conditions. However under typical

use conditions the resulting adhesive joint has unaccept-

able tensile strength. Preparation of glues from mollusks

is difficult however, and large quantities of material

5

10

15

20

25

30

35

40

must be processed to obtain a significant amount of 45

adhesive. To prepare 1 milligram of adhesive from bar-

nacles requires the harvest and treatment of at least 150

barnacles.

For these reasons a great deal of attention has been

given to the development of synthetic adhesive systems.

Especially prominent has been the development of ad-

hesive and hemostasis-inducing compositions compris-

ing fast curing monomers such as dialkyl methylene

malonates (U .S. Pat. No. 3,221,745) and monomeric

lower alkyl 2-cyanoacrylates (US. Pat. Nos. 3,223,083

and 3,264,249). Because the lower alkyl 2-cyanoacry-

lates did not appear to combine the desired, if not neces-

sary, properties of low toxicity and adequate adsorption

by tissues, the use of alkoxyalkyl 2-cyanoacrylates was

developed (U.S. Pat. No. 3,559,652). Other polymers

presently under investigation include polyurethanes and

epoxy resins. The latter two polymer systems suffer

disadvantages of limited “pot life” or “open time”, have

significant exotherms when polymerized and exhibit

toxicity to surrounding tissues.

It is advantageous for tissue adhesives to able to be

absorbed or degraded in the body, otherwise known as

bioabsorption or biodegradation. Among the advan-

50

55

60

65

2

tages are that it has been shown that long-term implants

of nondegradable films and disks in rodents will induce

neoplasms, and although there are no studies to show

this will occur in primates, it is a matter for concern.

Second, it is obviously more desirable that a device used

in vivo should only remain as long as necessary to en-

sure proper healing. This should reduce or prevent

adverse tissue reactions and/or foreign body responses.

In orthopedic applications absorbable pins and plates

that could perform in place of metal implants would

require only a single surgical procedure. Absorbable

polymers would also be useful for use with implantable

systems for long-term drug delivery. The absorption

ability of current materials ranges from the least degrad-

able materials such as ceramics and carbon fibers

through metallic alloys to the most degradable, organic

polymers having reactive chains.

Shalaby in Encyclopedia of Pharmaceutical Technol-

ogy, Swarbrick and Boylan, eds., Marcel Dekker Inc.,

New York, 1988, pp. 465-476 has classified bioabsorba-

ble polymers into three groups; soluble, solublizable and

depolymerizable. Soluble polymers are water-soluble

and have hydrogen-bonding polar groups, the solubility

being determined by the type and frequency of the polar

group(s). Solublizable polymers are usually insoluble

salts such as calcium or magnesium salts of carboxylic

or sulfonic acid-functional materials which can dissolve

by cation exchange with monovalent metal salts. Depo-

lymerizable systems have chains that dissociate to sim-

ple organic compounds in vivo under the influence of

enzymes or chemical catalysis.

The response of tissues to biodegradable materials is

dependent on the rate of absorption, but more impor-

tantly it is regulated by the toxicity of the degradation

products. Thus it is important to have controlled ab-

sorption to decrease the toxicity and reaction of sur-

rounding tissue to products that do elicit a response. It

also is important to ensure that the mechanical proper-

ties of the polymer are maintained for sufficient time to

allow proper healing. Thus absorbable polymeric adhe-

sives and the products of their bioabsorption must be

compatible with the surrounding tissues.

2-cyanoacrylates bond rapidly and form strong adhe-

sive joints. Their properties may be modified easily by

modification of their substituent groups. They are well-

suited for biological applications since, unlike other

adhesives such as epoxy resins and polyurethanes, 2-

cyanoacrylates may be used as pure monofunctional

monomers having well-defined properties. They

homopolymerize rapidly at room temperature in the

presence of weakly basic moieties such as water and

other weakly basic species present in bodily fluids.

Since their introduction in 1958 they have found use in

many surgical applications such as hemostasis, as seal-

ants, for retrofilling and as general tissue adhesives. A

2-cyanoacrylate suitable for use as a tissue adhesive

should be non-toxic and biodegradable, should wet and

spread on tissue substrates and polymerize quickly to a

thin. polymeric film. The polymeric adhesive should

have a degree of flexibility, especially when bonding

soft tissues. Biodegradability is especially important

because the adhesive should be replaced by the body’s

tissues and not slow or bar complete healing.

In the homologous series of poly(alkyl 2-cyanoacry-

lates) the lower homologs such as the methyl ester ex-

hibit the highest rate of bioabsorption but also elicit the

greatest tissue response. They also do not wet, spread or

5,350,798

3

polymerize on biological substrates as rapidly as the

higher homologs. On the other hand, the higher alkyl

esters such as the isobutyl ester elicit minimal tissue

reaction but degrade slowly if at all. Therefore the main

drawbacks for use of the alkyl 2-cyanoacrylates has 5

been their histotoxicity and/or lack of biodegradability.

Despite those deficiencies, the n-butyl and isobutyl and

other higher esters have been found acceptable as tissue

adhesives. In an effort to combine the higher biodegrad-

ability of the lower alkyl esters with the lower toxicity

of the higher esters Banitt and Nelson (U.S. Pat. No.

3,559,652) developed alkoxyalkyl 2-cyanoacrylate ad-

hesives which were stated to be bioabsorbable and to

exhibit minimal toxicity and inflammation. Kronenthal

and Schipper (U.S. Pat. No. 3,995,641) developed a

carboxyalkyl 2-cyanoacrylate which was stated to be

useful as an adhesive or a wound dressing.

Other problems which have been observed with alkyl

2-cyanoacrylate adhesives are their low monomer vis-

cosities and the formation of a high modulus crust on

soft tissues. Due to their low molecular weight and

rapid polymerization times 2-cyanoacrylates may be

formulated with biologically acceptable modifiers. Be-

cause the monomer initiates with any anionic or free

radical source, formulations with modifiers are not eas-

ily made. Control of the viscosity of the monomeric

adhesive may be obtained by adding a biologically ac-

ceptable thickening agent. Millet has reported that

polylactic acid is an effective thickening agent (Struc-

tural Adhesives: Chemistry and Technology, S.R. Harts-

horn ed., Plenum Press, New York, 1986, pp.249—303)

Plasticizers are commonly used to decrease the brit-

tleness of polymers. Plasticizers function by lowering

the glass transition temperature and the modulus of the

polymer. Plasticizers may be internal or external. Inter- 35

nal plasticization is accomplished by using mixtures of

compatible monomers to form a copolymer having

segments of varying hardness. External plasticization

may be obtained by the addition of esters such as cyan-

oacetates, malonates, adipates, sebacates and the like 40

(Millet, op. cit.).

Therefore it is clear that there is a need for tissue

adhesives which have been modified by plasticizers/-

modifiers which exhibit biodegradability, an acceptable

histotoxicity and reasonably match the modulus of the 45

tissues being joined by the adhesive.

SUMMARY OF THE INVENTION

2-cyanoacrylate-based tissue adhesives have been

developed which employ biocompatible oxalate poly-

mers as reactive plasticizers and thickening agents. The

adhesives are capable of being formulated to allow

modulus matching of the adhesive and the substrate.

DETAILED DESCRIPTION OF THE

INVENTION

The 2-cyanoacrylate-based tissue adhesive systems of

the present invention comprise at least one 2-cyanoa-

crylate ester of the general formula (I)

10

15

20

25

30

50

55

60

o CEN (I)

II I

R-O-C—C=CHz

wherein R is selected from the group consisting of alkyl 65

groups having from 1 to about 8 carbon atoms and,

preferably, alkoxyalkyl groups having the formula

R1—O——R2— wherein R1 is an alkyl group having from

4

1 to about 8, preferably 1 to 3 carbon atoms and R2 is an

alkylene group having from 3 to about 6, preferably 3 or

4 carbon atoms, in admixture with from about 2 percent

to about 25 percent, preferably about 5 to 10 percent, of

at least one oxalic acid polymer of the general formula

(11)

o 0

4 II II J7

(R3-o),,—c—c--o H

wherein each R3 is an alkylene group having from 2 to

about 4 carbon atoms, each p is an integer from 1 to

about 4, with the proviso that not more than about 1 of

each 20 p’s is 1, and n is the degree of polymerization

which results in a polymer which does not initiate poly-

merization upon mixing with the 2-cyanoacrylate mon-

omer and standing for about 12 hours. Suitable alkylene

groups include but are not limited to ethylene, propy-

lene, trimethylene, butylene, isobutylene, and tetra-

methylene. It is preferred that p have a value of 3 and

R3 is ethylene. Where p is 1 it is preferred that R3 is

trimethylene.

General methods for the preparation of polyalkylene

oxalates have been described by Shalaby and Jamiolk-

owski (US. Pat. No. 4,140,678). A two step process is

used in which first a monomeric oxalic acid ester such

as diethyl oxalate is transesterified with an alkylene

glycol by heating in an inert atmosphere in the presence

of a catalyst such as sta.nnous octanoate and removing

and collecting the ethanol as it is formed. When the

calculated amount of ethanol has been recovered the

mixture is then heated under reduced pressure to in-

crease the molecular weight of the polymer. The

progress of the reaction may be followed by observing

the infrared hydroxyl peak at 3200-3600 cm“ 1 .

It has been found that the poly(alkylene oxalates) of

U.S. Pat. No. 4,140,678 are not compatible with me-

thoxypropyl 2-cyanoacrylate, a preferred 2-cyanoacry-

late of the class of monomers disclosed in U.S. Pat. No.

3,559,652, even after intensive mixing (sonication) for

24 hours. A more polar oxalate polymer prepared from

triethylene glycol, a polyoxyalkylene glycol, was found

to be completely miscible with the cyanoacrylate mono-

mer. It has been found advantageous to include in the

reaction mixture a small amount (about 5 mol %) of a

low molecular weight, and thus more volatile, glycol

such as trimethylene glycol, which can be stripped

more easily from the reaction mixture to advance the

molecular weight in the second step of the po1yconden-

sation reaction. The infra-red spectra of polymers pre-

pared in this manner did not show evidence that any

signfiicant amount of the glycol was incorporated into

the polymer.

Since the polymer-modified 2-cyanoacrylate compo-

sitions of the invention may polymerize upon heating, to

prepare sterile compositions for clinical use the individ-

ual components should be prepared under sterile condi-

tions and then mixed under sterile conditions and then

placed in sealed microbially impervious containers

made of materials such as polyethylene, polypropylene

and the like which will not initiate premature polymeri-

zation of the composition.

EXPERIMENTAL

Care must be taken at all times to avoid contacting

2-cyanoacrylate-containing materials come with glass,

(11)

5,350,798

5

metals, or water, since polymerization will occur imme-

diately on such contact. All cyanoacrylates were stored

in inert containers under nitrogen at 7° C.

Preparation‘ and Testing of Oxalate Esters

Poly(hexarnethylene oxalate) and poly(trimethylene

oxalate) were prepared according to the method of U.S.

Pat. No. 4,140,678. Samples of each were placed in

sterile 15 ml polypropylene centrifuge tubes with suffi-

cient methoxypropyl 2-cyanoacrylate to form a 10%

wt/vol solution and sealed. After approximately 5 min-

utes mixing the sealed tube was sonicated overnight in a

water bath. No dissolution or mixing of the cyanoacry-

late monomer with the respective polymers was seen.

EXAMPLE 1

Preparation and Testing of Poly[tri(oxyethylene)

oxalate]

A mixture of 26 g (0.20 mol) diethyl oxalate, 31 g

(0.23 mol) triethylene glycol, 0.9 g (0.012 mole) 1,3-pro-

pane diol and 0.0002 mol stannous octanoate as a 0.33M

solution in toluene was placed in a flame-dried polymer-

ization flask equipped with a stirrer and a distillation

head and collection apparatus. All reactants were dis-

tilled or dried in a conventional manner before use. The

flask was heated at 150° C. for 0.3 hour, then 120° C. for

2 hours and then 150° C. for four hours, at which time

the theoretical amount of ethanol had been removed.

The flask then was subjected to a vacuum of less than

0.1 mm Hg and heated to 150° C. for one hour, then

160° C. for three hours, 180° C. for one hour and finally

200° C. for five hours. The progress of the reaction was

monitored by periodically removing a small sample of

the reaction mixture and observing the hydroxyl ab-

sorption peak at 3200-3600 cm"1 of the liquid polymer

spread on a KBr plate. At the end of that time the reac-

tion mixture was allowed to cool and the liquid polymer

was stored in vacuum storage containers at a pressure

below 0.1 mm Hg. On long standing the polymer par-

tially crystallized to a low-melting (about 28° C. as

determined by DSC at 10° C./min heating rate of a

liquid nitrogen quenched sample) solid which reliqui-

fied readily under ambient conditions. The viscosity of

an 0.1% wt/vol solution in chloroform in an Ostwald

viscometer at 31° C. was used to determine the inherent

viscosity '11,-,,;,0.059 (Preparation A).

The compatibility of the polymer with methoxypro-

pyl 2-cyanoacrylate was tested in the same marmer as

the poly(alkylene oxalates) above. Complete miscibility

was observed. In some preparations the molecular

weight was not advanced sufficiently and polymeriza-

tion of the cyanoacrylate occurred on standing. Heating

such polymers for an additional period under vacuum to

increase the molecular weight decreased the hydroxyl

content sufficiently that polymerization no longer oc-

curred when a sample was mixed with monomer in an

dry, inert container. One such preparation yielded poly-

mer having an inherent viscosity '1'),-,,;,0.225 (Preparation

B).

EXAMPLE 2

In Vitro Evaluation of Absorption of Modified

Cyanoacrylates

Samples of pure methoxypropyl 2-cyanoacrylate

(MPC) and poly[tri(oxyethylene) oxalate] modifier

(T OEO) (Example 1, Preparation A) were mixed at 5%

and 10% wt/ vol modifier/cyanoacrylate. 10 ul aliquots

of modified cyanoacrylate and of pure cyanoacrylate

10

15

20

25

30

35

40

45

50

55

60

6

were polymerized in small polyethylene coagulation

cups filled in the presence of a 0.5% aqueous solution of

sodium bicarbonate. The samples were allowed to poly-

merize for at least five minutes and then were trans-

ferred to a large basin filled with the bicarbonate solu-

tion. The samples kept in the bath for an additional 30

minutes to ensure complete polymerization. They were

then removed and rinsed with distilled water, blotted

dry on lint-free absorbent paper and place in a vacuum

desiccator. The samples were from 5 to 8 mm in diame-

ter.

In vitro absorption was studied by measuring weight

loss of samples in a synthetic medium at 5, 15, 25, 50, 75,

100 and 125 days. Test sets of five samples of each com-

position for each test interval were prepared in the

following manner. A phosphate buffer was prepared

using 4.54 g potassium hydrogen phosphate and 14.21 g

sodium dihydrogen phosphate in 2,000 ml distilled wa-

ter. Preweighed 50 ml polypropylene centrifuge tubes

were filled with 50 ml of buffer and a weighed sample of

the modified polymer or homopolymer was placed in

each tube. The tubes were placed in a 37° C. water bath

and agitated for the entire test period.

After each period of time all samples for that period

were evaluated to determine if they had fragmented.

For samples which had not fragmented the buffer solu-

tion was removed and reduced to about 3 ml. The sam-

ple was rinsed with about 50 ml of ultrapure water. The

rinse water was decanted until about 3 ml remained and

the tube was placed in a vacuum desiccator until the

weight of the tube plus sample became constant. The

sample was then removed and the tube was rinsed to

remove any sample fragments and the tube was then

dried in the same marmer. The weight of sample was

then determined by the difference between the weight

of tube plus sample and the weight of the tube. If any

one of a set of samples showed particulate matter all of

the set was treated by a modified procedure, centrifug-

ing at 1,000 rpm for five minutes before decanting the

buffer and after rinsing to ensure capture of all particu-

late matter. The analysis showed that there was a statis-

tically significant difference between the absorbability

of the samples containing 5% modifierand those con-

taining 10%. None of the samples fragmented or broke

up into small pieces, many had the same outward ap-

pearance as at the beginning of the run. This phenome-

non is not unusual, and has been discussed by Kronen-

thal (Polymer Science and Technology, pp.1l3—133, Ple-

num Press, New York 1975). Electron Dispersive Anal-

ysis (EDAX) was carried out to be certain that buffer

residues did not contribute to the sample weights. Only

trace amounts of contaminating species were observed.

The data were treated statistically using the General

Linear Models Procedure of SAS Institute and are pres-

ented in Table 1.

TABLEI

Days

5 15 25 50 75 100 150

%loss — — 5.77 12.26 12.14 7.82 8.97

MPC

» %loss 13.36 35.74 51.12 74.53 37.34 93.15 94.83

5% TOEO

%loss 24.85 32.40 47.84 45.24 57.87 53.02 56.07

10% TOEO

65

The adhesive performance of isobutyl cyanoacrylate

(IBC), methoxypropyl cyanoacrylate (MPC) and MPC

5,350,798

7

containing 10% poly[(trioxyethylene) oxalate] (TOEO)

from Example 1, Preparation B were compared in vitro

using goat skin as the substrate.

After closely clipping the hair, skin was harvested

from the sides of a goat carcass as three marked and

measured 3" by 12" strips. The skin had been frozen for

eleven days and was removed from the carcass on the

twelfth day. The skin patches were pinned to pans

which had been coated with paraffin to simplify pinning

and covered with normal saline and stored in a refriger-

ator overnight. The following day the saline was

drained and excess moisture blotted off with lint-free

paper. A 28 mm incision was made down the middle of

each patch along the long axis with a #10 scalpel, being

certain not to sever the skin at either end of the cut.

Taking care that the skin was in its original cut size, the

cross-sectional areas of the incisions were determined

by measuring across the cut site and multiplying by the

width of each of the sample cuts (2.5 cm). The incision

was dabbed with a gauze sponge to remove excess mois-

ture and a 1 ml aliquot of the test adhesive was intro-

duced along the incision line. The incision was quickly

opposed using finger pressure to hold the sides together

for about 30 seconds. The samples were allowed to

polymerize for at least 3§hours. The IBC polymerized

the most rapidly, the MPC more slowly, and the modi-

fied adhesive slightly more slowly than the MPC. The

IBC formed a stiff crust at the incision site as has been

reported in the literature, but neither the MPC nor the

modified polymer appeared to do so. Then Zlcm strips

were cut transversely to the incision line by first plung-

ing the scalpel into the glued incision and then making

a standard cut from that point to complete the sample.

Samples were then tested on an Instron at a stroke rate

of 0.6 in/sec, using a 500 lb load cell at 10% of full

range. The results are shown below.

IBC 19 samples 31.25 i 5.99 psi (95% conf. level)

MPC 18 samples 33.47 1‘ 6.25 psi "

10% TOEO/MPC 19 43.86 i 7.05 psi "

samples

It is clear that the tensile strength of the adhesive made

with the modified polymer is significantly greater than

either of the homo polymers, which in turn showed no

significant difference between one another.

Tests were also made joining bone, where MPC and

the composition of the present invention were both

observed to be less effective than IBC.

EXAMPLE 4

Cytotoxicity testing was performed on IBC, MPC

and MPC containing 10% TOEO (Example 1, Prepara-

tion B) using a modification of ASTM F 895-84 “Stan-

dard Test Method for Agar Diffusion Cell Culture for

Cytotoxicity”. The actual test method was changed by

placing 10 pl aliquots of MPC and 10% TOEO/MPC

monomers directly on confluent monolayers of mouse

fibroblasts from which most of the culture medium had

been removed, rather than on an agar diffusion barrier.

The negative control was medium and a monolayer to

which no additive was introduced. The positive control

was a copper penny placed directly on the center of the

5

10

15

20

25

30

35

40

45

50

55

60

65

8

monolayer. The monomers were allowed to polymerize

for at least one minute and then 2.0 ml of the culture

medium was pipetted back into the 35 mm culture plate.

The plates were incubated for at least 24 hours and then

qualitatively evaluated. The results were taken from

photographs taken at 200x magnification about 1 cm

from the polymerized sample or penny, and the middle

of the plate of the negative control. The negative con-

trol showed a crowded confluent monolayer. The posi-

tive control showed signs of total cellular lysis, only

cellular debris being observed. The plates of the MPC

and the 10% TOEO/MPC both appeared to have

clumping of detached cells with little or no discernible

lysis. The MPC plate appeared to have some cells that

were just in the process of detaching. It is unclear

whether the reaction observed was the result of fast-

absorbing monomeric byproducts causing cellular de-

tachment or was due to a toxic response associated with

the high initial dose of monomeric adhesive which was

used to ensure a response within a short time period.

We claim:

1. A composition of matter which comprises at least

one 2-cyanoacrylate ester of the general formula (I)

0 CEN

H I

R—O—C—C::CHz

(1)

wherein R is selected from the group consisting of alkyl

groups having from 1 to about 8 carbon atoms and

alkoxyalkyl groups having the formula R1-O—R2—

wherein R1 is an alkyl group having from 1 to about 8

carbon atoms and R2 is an alkylene group having from

3 to about 6 carbon atoms, in admixture with from about

2 percent to about 25 percent of at least one oxalic acid

polymer of the general formula (II)

o 0 (11)

II 11

{.01-.—o),.-—c—c—o ..

wherein each R3 is an alkylene group having from 2 to

about 4 carbon atoms, each p is an integer from 1 to

about 4, with the proviso that not more than about 1 of

each 20 p’s is 1, and n is the degree of polymerization

which results in a polymer which does not initiate poly-

merization upon mixing with the 2-cyanoacrylate

monomer and standing for about 12 hours.

2. The composition of claim 1 wherein the 2-cyanoa-

crylate is 2-methoxypropyl 2-cyanoacrylate.

3. The composition of claim 1 wherein the oxalic acid

polymer is a copolymer of oxalic acid with triethylene

glycol and a minor amount of 1,3-propanediol.

4. A composition of matter which comprises 2-

methoxypropyl 2-cyanoacrylate and a copolymer of

oxalic acid with triethylene glycol.

5. The composition of claim 4 which further com-

prises a minor amount of 1,3—propanediol in the oxalate

copolymer.

6. The cured composition of claim 1.

7. The cured composition of claim 4.

8. A sterile preparation which comprises the compo-

sition of claim 1.

* * * * *

Coments go here:

- Log in to post comments