Utilization of Biocompatible Adhesive/Sealant Materials for Securing Surgical Devices

Utilization of Biocompatible Adhesive/Sealant Materials for Securing Surgical Devices

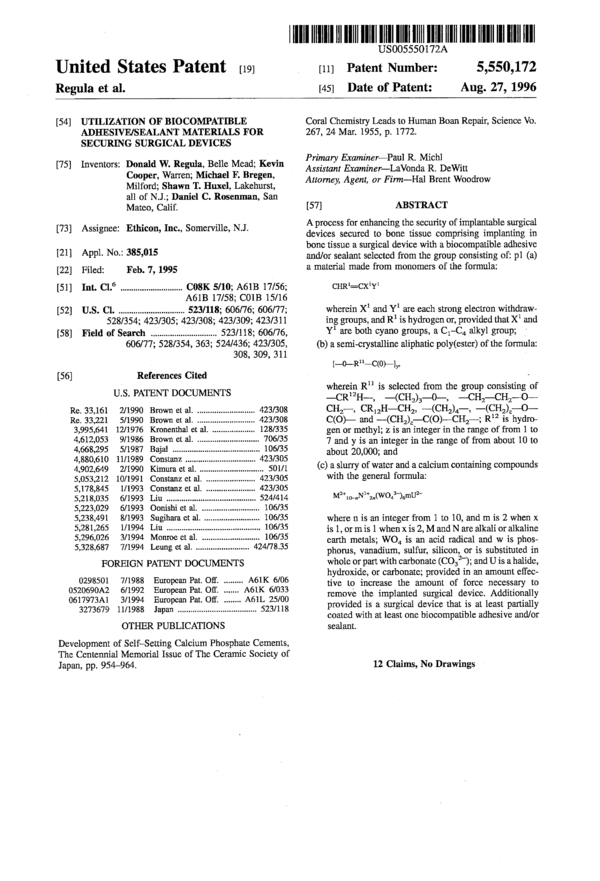

US5550172

Company:

Folder:

Year:

Abstract:

A process for enhancing the security of implantable surgical devices secured to bone tissue comprising implanting in bone tissue a surgical device with a biocompatible adhesive and/or sealant selected from the group consisting of: p1 (a) a material made from monomers of the formula:

Type of document:

Language:

United States Patent [191

Regula et al.

ll|I||||||||l|Ill|||||||l||||||||||||Illll||l||llllll||||||||||||||||l|l||l

US005550172A

Patent Number:

5,550,172

Aug. 27, 1996

[111

[45] Date of Patent:

[54] UTILIZATION OF BIOCOMPATIBLE

ADI-IESIVE/SEALANT MATERIALS FOR

SECURING SURGICAL DEVICES

[75] Inventors: Donald W. Regula, Belle Mead; Kevin

Cooper, Warren; Michael F. Bregen,

Milford; Shawn T. Huxel, Lakehurst,

all of N.J.; Daniel C. Rosenman, San

Mateo, Calif.

[73] Assignee: Ethicon, Inc., Somerville, N.J.

[21] Appl. No.: 385,015

[22] Filed: Feb. 7, 1995

[51] Int. C1.° ........................... .. C08K 5/10; A61B 17/56;

A6lB 17/58; C01B 15/16

[52] U.S. Cl. ............................. .. 523/118; 606/76; 606/77;

528/354; 423/305; 423/308; 423/309; 423/311

[58] Field of Search ............................. .. 523/118; 606/76,

606/77; 528/354, 363; 524/436; 423/305,

308, 309, 311

[56] References Cited

U.S. PATENT DOCUMENTS

Re. 33,161 2/1990 Brown et al. 423/308

Re. 33,221 5/1990 Brown et al. 423/308

3,995,641 12/1976 Kronenthal et al. . .. 128/335

4,612,053 9/1986 Brown et al. . . . . . . . . . . . . .. 706/35

4,668,295 5/1987 Bajal . . . . . . . . . . . . . . . . . . . .. 106/35

4,880,610 11/1989 Constanz ....... .. 423/305

4,902,649 2/1990 Kimura et al. .. ...... .. 501/1

5,053,212 10/1991 Constanz et al. 423/305

5,178,845 1/1993 Constanz et al. 423/305

5,218,035 6/1993 Liu ................ .. 524/414

5,223,029 6/1993 Oonishiet al. . .... .. 106/35

5,238,491 8/1993 Sugihaxa et al. .... .. 106/35

5,281,265 1/1994 Liu . . . . . . . . . . . . . . . . . . . . . . .. 106/35

5,296,026 3/1994 Monroe et al. . ........ .. 106/35

5,328,687 7/1994 Leung et al. ....................... .. 424/78.35

FOREIGN PATENT DOCUMENTS

0298501 7/1988 European Pat. Off. ....... .. A61K 6/06

0520690A2 6/1992 European Pat. Off. ..... .. A6lK 6/033

0617973Al 3/1994 European Pat. Off. ...... .. A6lL 25/00

3273679 11/1988 Japan ................................... .. 523/118

OTHER PUBLICATIONS

Development of Self—Setting Calcium Phosphate Cements,

The Centennial Memorial Issue of The Ceramic Society of

Japan, pp. 954-964.

Coral Chemistry Leads to Human Boan Repair, Science V0.

267, 24 Mar. 1955, p. 1772.

Primary Examiner—Pau1 R. Michl

Assistant Examiner—LaV0nda R. DeWitt

Attomey, Agent, or Firm—Hal Brent Woodrow

[57] ABSTRACT

A process for enhancing the security of implantable surgical

devices secured to bone tissue comprising implanting in

bone tissue a surgical device with a biocompatible adhesive

and/or sealant selected from the group consisting of: pl (a)

a material made from monomers of the formula:

Cl-IR‘=CX‘lY‘

wherein X‘ and Y1 are each strong electron withdraw-

ing groups, and R‘ is hydrogen or, provided that X‘ and

Y1 are both cyano groups, a C1-C4 alkyl group; _

(b) a serni-crystalline aliphatic poly(ester) of the formula:

1—o—R“—c(o>—1,.

wherein R” is selected from the group consisting of

—CR‘2H——, —(CH2)3—0—, ——CH2—CH2-—O——

CH2——, CR12H—CH2, ——(CH2)4—, —(CH2)z—-O-—

C(O)— and ——(CH2)z—C(O)—CH2——; R” is hydro-

gen or methyl; z is an integer in the range of from 1 to

7 and y is an integer in the range of from about 10 to

about 20,000; and

(c) a slurry of water and a calcium containing compounds

with the general formula:

Ml+1o—nN1+2n(wO43_)amU27

where n is an integer from 1 to 10, and m is 2 when x

is 1, or m is 1 when x is 2, M and N are alkali or alkaline

earth metals; W04 is an acid radical and w is phos-

phorus, vanadium, sulfur, silicon, or is substituted in

whole or part with carbonate (CO32'); and U is a halide,

hydroxide, or carbonate; provided in an amount effec-

tive to increase the amount of force necessary to

remove the implanted surgical device. Additionally

provided is a surgical device that is at least partially

coated with at least one biocompatible adhesive and/or

sealant.

12 Claims, No Drawings

5,550,172

1

UTILIZATION OF BIOCOMPATIBLE

ADHESIVE/SEALANT MATERIALS FOR

SECURING SURGICAL DEVICES

FIELD OF THE INVENTION

This invention relates to securing surgical repair devices

to tissue, more specifically this invention relates to securing

surgical devices such as screws, plates, bone pins and

anchors to bone tissue.

BACKGROUND OF THE INVENTION

In orthopedic surgery it is often necessary to reattach

cartilage and ligaments to skeletal bones with surgical pins,

screws or anchors. For example, metallic suture anchors are

currently used to facilitate cartilage or ligament reattach-

ment. In these procedures a hole is drilled into the skeletal

bone. A suture anchor, attached to a suture, is then inserted

into the hole in a manner that allows the anchor to engage

the sides of the hole and be held in place. The suture is then

used to secure the torn cartilage or ligament to the bone.

However, sometimes during or after the healing process

these anchors fail to remain in place and must be removed

to avoid harm to the patient.

Recently, absorbable suture anchors have been proposed

as a replacement for metallic suture anchors. The perceived

advantage of an absorbable anchor over the metallic anchor

is that after the healing process for the cartilage or ligament

is complete the anchor will be absorbed by the patient’s

body and disappear. However, most bioabsorbable materials

are not strong enough to dig into bone tissue. Therefore,

bioabsorbable bone anchors tend to have less resistance to

being pulled out of the location in which it is secured.

Thus, it would be a significant contribution to the art to

provide a method to enhance the secure placement of

implantable surgical devices in patients. Additionally, it

would be advantageous if a method could be developed to

enhance the resistance to removal of bioabsorbable surgical

implantable devices.

SUMMARY OF THE INVENTION

We have discovered a process for enhancing the security

of implantable surgical devices secured to bone tissue com-

prising implanting a surgical device with a biocompatible

adhesive and/or sealant provided in an amount effective to

increase the security of the implanted surgical device.

In another embodiment of the present invention we have

also provided an implantable surgical device comprising an

implantable surgical device coated with a biocompatible

adhesive or sealant.

DETAILED DESCRIPTION OF THE

INVENTION

The present invention provides a process for using a

surgical device that improves the security and placement of

the surgical device in a mammalian body. Also described is

an implantable surgical device which has been coated with

a biocompatible adhesive or sealant in an amount sufficient

to facilitate the placement of the surgical device in the

desired location in a patient. Suitable surgical devices which

may benefit from having an adhesive or sealant coating

include but are not limited to surgical screws, pins, plates,

anchors, rods, clamps, clips, staples, rivets, hooks, buttons,

snaps and the like.

20

25

30

35

45

50

55

60

65

l

2

These surgical devices may be made from a biocompat-

ible material using conventional fabrication methods. The

clips can be composed of various biocompatible metals, e.g.

titanium and tantalum, and polymeric materials. Preferred

bioabsorbable polymeric materials include homopolymers

and copolymers of epsilon-caprolactone, glycolide, lactide,

para-dioxanone, and trimethylene carbonate. Preferred non-

absorbable polymers include nylons, polyesters and

polypropylene. All these materials have been demonstrated

to be biologically acceptable when used as sutures or other

implantable "medical devices.

The preferred means for fabricating surgical devices from

polymeric materials is to inject a suitable polymer melt into

an appropriately designed mold at process conditions con-

ventionally employed for such polymer systems. After the

polymer melt cools, the molded polymer shaped in the mold

to meet the design criteria of the device can be readily

released from the mold.

One class of suitable biocompatible adhesives or sealants

that can be used in the practice of the present invention

include materials made from monomers of the formula:

CI-lR‘=CX‘Y‘ (1)

wherein X1 and Y‘ are each strong electron withdrawing

groups, and R1 is hydrogen or, provided that X’ and Y1 are

both cyano groups, a C1-C4 alkyl group. Examples of

monomers within the scope of formula (I) include ot-cy-

anoacrylates, vinylidene cyanides, C1-C4 alkyl homologues

of vinylidene cyanides, dialkyl methylene malonates, acy-

lacrylonitriles, vinyl sulfinates, and vinyl sulfonates of the

formula CH2=CX2Y2 wherein X2 is SOZRZ or —SO3R2

and Y2 is —CN, COOR2, COCH3, —SO2R2 or —SO3R2

and R2 is hydrogen or an alkyl group.

Preferred monomers of formula (I) for use in this inven-

tion are alpha-cyanoacrylates. These monomers are known

in the art and have the formula

CN (11)

CI-IR3=C

COOR4

wherein R3 is hydrogen and R4 is a hydrocarbon or substi-

tuted hydrocarbon group; a group having the formula

—R5—O—R°—O—R7, wherein R5 is a 1,2-alkylene group

having 2-4 carbon atoms, R6 is an alkylene group having

2-4 carbon atoms, and R7 is an alkyl group having 1-6

carbon atoms; or a group having the formula:

—R8—c—o—R9 (111)

I I

0

wherein R8 is

as

—CH—,

.—CH;—-,

or —C(CH3)2—and R9 is an organic radical.

Examples of suitable hydrocarbon and substituted hydro-

carbon groups include straight chain or branched chain alkyl

groups having l—l6 carbon atoms; straight chain or

branched chain C1—C,6 alkyl groups substituted with one or

more biologically compatible substituents such as an acy-

loxy group, an alkoxy group, an aryloxy group, a haloalkyl

group, a halogen atom, a dialkylamino group, an alkylary-

lamino group, or a cyano group; straight chain or branched

chain alkenyl groups having 2 to 16 carbon atoms; straight

chain or branched chain alkynyl groups having 2 to 12

5,550,172

3

carbon atoms; cycloalkyl groups; arylalkyl groups; alkylaryl

groups and aryl groups

In the cyanoacrylate monomer of formula (II), R4 is

preferably an alkyl group having 1-10 carbon atoms or a

group having the formula —AOR1°, wherein A is a divalent

straight or branched chain alkylene or oxyalkylene radical

having 2-8 carbon atoms, and R” is a straight or branched

alkyl radical having 1-8 carbon atoms. Examples of groups

represented by the formula —AOR‘° include 1-methoxy-2-

propyl, 2-butoxy ethyl, isopropoxy-ethyl, and 2-ethoxy

ethyl.

The most preferred alpha-cyanoacrylate monomers used

in this invention are methyl alpha-cyanoacrylate, butyl

alpha-cyanoacrylate, octyl alpha-cyanoacrylate, 1-methoxy—

2-propyl cyanoacrylate, 2-butoxy ethyl cyanoacrylate, and

isopropoxy-ethyl cyanoacrylate.

The alpha—cyanoacrylates of formula (11) wherein R4 is a

hydrocarbon or substituted hydrocarbon group can be pre-

pared according to methods known in the art. Reference is

made, for example, to U.S. Pat. Nos. 2,721,858 and 3,254,

111, each of which is hereby incorporated by reference

herein. For example, the alpha-cyanoacrylates can be pre-

pared by reacting an alkyl cyanoacetate with formaldehyde

in a non-aqueous organic solvent and in the presence of a

basic catalyst, followed by pyrolysis of the anhydrous inter-

mediate polymer in the presence of a polymerization inhibi-

tor. The alpha-cyanoacrylate monomers prepared with low

moisture content and essentially free of impurities are pre-

ferred for biomedical use.

The alpha-cyanoacrylates of formula (II) wherein R4 is a

group having the formula R5——O—R“—O—R7 can be pre-

pared according to the method disclosed in U.S. Pat. No.

4,364,876 (Kimura et al.), which is hereby incorporated by

reference herein. In the Kimura et al. method, the alpha-

cyanoacrylates are prepared by producing a cyanoacetate by

esterifying cyanoacetic acid with an alcohol or by transes-

terifying an alkyl cyanoacetate and an alcohol; condensing

the cyanoacetate and formaldehyde or para-forrnaldehyde in

the presence of a catalyst at a molar ratio of 0.5—1.5:1,

preferably 0.8-1.211, to obtain a condensate; depolymeriz-

ing the condensation reaction mixture either directly or after

removal of the condensation catalyst to yield crude

cyanoacrylate; and distilling the crude cyanoacrylate to form

a high purity cyanoacrylate.

The alpha-cyanoacrylates of formula (11) wherein R4 is a

group having the formula

_..R8.._fi_0_R9

O

can be prepared according to the procedure described in

U.S. Pat. No. 3,995,641 (Kronenthal et al.), which is

hereby incorporated by reference herein. In the Kronenthal

et al. method, such alpha-cyanoacrylate monomers are pre-

pared by reacting an alkyl ester of an alpha-cyanoacrylic

acid with a cyclic 1,3-diene to form a Diels-Alder adduct

which is then subjected to alkaline hydrolysis followed by

acidification to form the corresponding alpha-cyanoacrylic

acid adduct. The alpha-cyanoacrylic acid adduct is prefer-

ably esterified by an alkyl bromoacetate to yield the corre-

sponding carbalkoxymethyl alpha-cyanoacrylate adduct.

Altematively, the alpha-cyanoacrylic acid adduct may be

converted to the alpha-cyanoacrylyl halide adduct by reac-

tion with thionyl chloride. The alpha-cyanoacrylyl halide

adduct is then reacted with an alkyl hydroxyacetate or a

methyl substituted alkyl hydroxyacetate to yield the corre-

sponding carbalkoxymethyl alpha-cyanoacrylate adduct or

20

25

30

35

40

45

50

55

60

65

4

carbalkoxy alkyl alpha-cyanoacrylate adduct, respectively.

The cyclic 1,3-diene blocking group is finally removed and

the carbalkoxy methyl alpha-cyanoacrylate adduct or the

carbalkoxy alkyl alpha-cyanoacrylate adduct is converted

into the corresponding carbalkoxy alkyl alpha-cyanoacrylate

by heating the adduct in the presence of a slight deficit of

malcic anhydride.

Another type of biocompatible adhesives or sealant that

may be used in the practice of the present invention are

copolymers of formula (I) or one monomer of formula (I)

and a monomer of the formula:

Cl-lZ=CX‘Y‘ (IV)

wherein X‘ and Y1 are as described for formula (I) and Z is

——CH=CH2. Examples of monomers of formula (IV)

include cyanopentadienoates and alpha-cyanoacrylates of

the formula:

CN

/

Cl-IZ=C

(V)

COOR4

wherein Z is —CH=CH2 and R4 is as defined above. The

monomers of formula (IV) wherein R4 is an alkyl group of

1-10 carbon atoms, i.e., the 2-cyanopenta-2,4-dienoic acid

esters, can be prepared by reacting an appropriate 2-cy-

anoacetate with acrolein in the presence of a catalyst such as

zinc chloride. This method of preparing 2-cyanopenta-2,4,

4-dienoic acid esters is disclosed, for example, in U.S. Pat.

No. 3,554,990, which is hereby incorporated by reference

herein.

Optionally, a biocompatibilizing agent may be added to

the cyanoacrylate adhesive such as are disclosed in U.S. Pat.

No. 5,328,687, hereby incorporated by reference.

Suitable bioabsorbable sealants include semi-crystalline

aliphatic ester homopolymers, and copolymers made from

polymers of the formula:

[—0—R“—C(0)-ly. (V1)

wherein R“ is selected from the group consisting of

——CR‘2H—, —(CH2)3——O—, —CH2—CH2——-O—CH2——,

CR‘2H-—CH2, —(CH2)4—, —(CH2)z—O—C(O)—-and

—(CH2)z——C(O)——CH2—; R12 is hydrogen or methyl; z is

an integer in the range of from 1 to 7; and y is an integer in

the range of from about 10 to about 20,000.

Many nontoxic bioabsorbable aliphatic ester polymers

that are semi-crystalline solids at room temperature, may be

used in the present invention. The polymers of this invention

are generally characterized as being solids at body tempera-

ture (37° C.) and preferably will be melt at temperatures of

less than 60° C. Suitable bioabsorbable polymers include

solid poly(e-caprolactone), poly(p-dioxanone), or poly(tri-

methylene carbonate) homopolymers and copolymers of

e-caprolactone and trimethylene carbonate. Copolymers of

e-caprolactone should be composed of from about 100 mole

percent to about 70 mole percent and preferably from 95

mole percent to 85 mole percent of e-caprolactone repeating

units with the remainder of the polymer being a plurality of

second lactone repeating units. The second lactone repeating

units will be selected from the group consisting of glycolide

repeating units, lactide repeating units, 1,4-dioxanone

repeating units, 1,4-dioxepan—2-one repeating units, 1,5-

dioxepan-2-one repeating units, trimethylene carbonate

repeating units, and combinations thereof. Preferred are

copolymers of e-caprolactone that are semicrystalline solids

at body temperature. The solid polymers of trimethylene

5,550,172

5

carbonate should be composed of from in the range of from

about 1 to about 20 mole percent or from about 100 to about

80 mole percent of trimethylene carbonate with the remain-

der of the copolymer being composed of a plurality of '

lactone repeating units selected from the group consisting of

glycolide repeating units, lactide repeating units, p-diox-

anone repeating units, e-caprolactone repeating units, and

combinations thereof.

It is preferred for the trimethylene carbonate copolymers

to have crystalline regions formed by the second lactone

repeating units wherein the crystalline regions provide at

least 5 percent crystallinity to the final copolymer. The solid

polymers may be linear, branched, or star branched; block

copolymers or terpolymers; segmented block copolymers or

terpolymers. These polymers will also be purified to sub-

stantially remove unreacted monomers which may cause an

inflammatory reaction in tissue. The most preferred poly-

mers for use as the adhesive/sealant are semicrystalline

polymers selected from the group consisting of poly(e-

caprolactone), poly(e-caprolactone-co-trimethylene carbon-

ate), poly(e-caprolactone-co-lactide), po1y(e-caprolactone-

co-p-dioxanone), and poly(e-caprolactone-co-glycolide).

The mole percent of e-caprolactone repeating units in these

polymers should be in the range of from 100 to about 80

mole percent and preferably in the range of from 95 to 85

mole percent. Most preferably these polymers will be sta-

tistically random copolymers.

The polymers used as the adhesive/sealant should have an

inherent viscosity as determined in a 0.1 g/dL solution of

hexafluoroisopropanol (HFIP) at 25° C. ranging from about

0.1 dL/g to about 2.0 dIJg, preferably from about 0.15 dL/g

to about 1.5 dL/g, and most preferably from 0.2 dL/g to 1.0

dL/g. A polymer with an inherent viscosity below 0.1 dL/g

may fail to crystallize at room temperature, and a polymer

with an inherent viscosity above 2.0 dL/g may make the

polymer have too high of a melting point.

The aliphatic poly(ester)s-are generally prepared by a ring

opening polymerization of the desired proportions of one or

more lactone monomers in the presence of an organometal-

lic catalyst and an initiator at elevated temperatures. The

organometallic catalyst is preferably a tin-based catalyst,

e.g. stannous octoate, and is present in the monomer mixture

at a molar ratio of 10 monomer to catalyst ranging from

about 15,000/1 to about 80,000/ 1. The initiator is typically

an alkanol (such as 1-dodecanol), a polyol (such as 1,2-

propanediol, 1,3-propanediol, diethylene glycol, or glycerol,

poly(ethylene glycol)s, poly(propylene glycol)s and poly-

(ethylene-co-propylene glycol)s), a hydroxyacid, or an

amine, and is present in the monomer mixture at a molar

ratio of monomer to initiator ranging from about 100/1 to

about 5000/1. The polymerization is typically carried out at

a temperature range from about 80° to about 220° C.,

preferably 160° to 190° C., until the desired molecular

weight and viscosity are achieved.

The aliphatic polyesters described above will be solids at

room temperature but may be heated to provide a putty like

or liquid material that may be applied as a sealant to support

surgical devices or to secure a surgical device. In one

embodiment of the present invention, the aliphatic polyester

would be heated to its melting point and applied to the

desired location before it resolidified. In this embodiment, if

a bone pin were inserted in a hole drilled in bone tissue,

melted polyester would be poured into the hole before or

after the pin was inserted to help secure the bone pin in the

bone tissue. Alternatively, the aliphatic polyester could be

heated until it softens and then used as a putty and placed at

the desired location and act as a filler.

20

25

30

35

40

45

50

55

60

65

6

Other suitable bioabsorbable sealants include calcium

containing compounds with the general formula:

M2+1o—nN1+2n(wO43_)6mUx-

where n is an integer from 1 to 10, and m is 2 when X is 1,

or m is 1 when x is 2, M and N are alkali or alkaline earth

metals, preferably calcium, magnesium, sodium, zinc, and

potassium. W04 is an acid radical, where W is preferably

phosphorus, vanadium, sulfur or silicon, or is substituted in

whole or part with carbonate (CO32‘). U is an anion,

preferably halide, hydroxide, or carbonate.

Most preferred are calcium containing sealants selected

from the group consisting of mono-, di-, octa-, on-tri-, B-tri-,

or tetra-calcium phosphate, hydroxyapatite, fluorapatite, cal-

cium sulfate, calcium fluoride and mixtures thereof.

The calcium containing sealants can also contain a bio-

active glass comprising metal oxides such as calcium oxide,

silicon dioxide, sodium oxide, phosphorus pentoxide, and

mixtures thereof, and the like. The calcium containing

sealants will preferably have a particle size of about 10

microns to about 1000 microns, and more preferably about

100 microns to about 500 microns.

The calcium containing sealants will generally be applied

in an aqueous slurry. The amount of calcium containing

material in the slurry will generally be in the range from

about 10 weight percent to about 90 weight percent. The

slurry will preferably be retained in place at the desired

location until it solidifies or develops a putty like consis-

tency.

The adhesive and/or sealant may be applied to at least one

surface of the medical device that is to be contacted with the

bone tissue or applied to the site where the surgical device

is to be secured. For example, when a bone pin or anchor is

placed in a hole drilled in bone tissue the pin or anchor

surfaces that will contact the bone tissue will be coated with

adhesive and placed in intimate contact with the bone tissue.

The adhesive will then adhere to the device and the bone and

enhance the security of the pin or anchor in the hole.

Alternatively, the adhesive may be applied to the site where

the surgical device is to be secured and the surgical device

applied thereafter in an appropriate time so that the adhesive

or sealant can set. If a sealant is used the sealant may serve

as a filling and support agent for the medical device. For

example, when using a bone plate with multiple openings for

fasteners (such as screws), the sealant would be applied to

the surface to contact the bone to provide a putty like base

on which to mount the bone plate on to simplify installation

of the bone plate.

Those skilled in the art will readily be able to determine

the appropriate amount of adhesive and/or sealant to apply

in a given surgical application. Similarly, the amount of an

adhesive and/or sealant to be applied to a surgical device

before implantation will be a discretionary matter depending

on the operation and the specific circumstances of the

operation.

The adhesives and/or sealants of the present invention

will generally be applied in a liquid form. The adhesive

and/or sealant will generally be applied through a small

diameter delivery device such as a syringe, with or without

mechanical assistance, a caulking gun, a soft-sided tube, and

the like.

The following nonlimiting examples are provided to

illustrate the practice of the present invention.

EXAMPLE 1

Synthesis of the Anthracene Adduct of Dimethyl Meth-

ylidene Malonate. 178.0 grams (1.00 mol) of powdered

5,550,172

7

anthracene, 60.0 grams (2.00 mol) of powdered paraforrn-

aldehyde, 132.0 grams (1.00 mol) of dimethyl malonate,

10.0 grams (50 mmol) of cupric acetate monohydrate, 225

mL of glacial acetic acid, and 450 mL of xylene were added

to a two liter, three necked, round bottom flask. In the

exhaust hood, the flask was immersed into an oil bath and

secured with a clamp. A mechanical stirrer, a stainless steel

thermocouple connected to a therrnowatch which controlled

the immersion heater, and a water cooled distillation appa-

ratus were then installed. The still was connected to a dry

nitrogen gas line via a Firestone valve. The contents of the

reaction flask were heated to 100° C. for 18 hours; then, the

pot temperature was raised until the azeotropic mixture of

acetic acid, water, and xylene started to distill out. The oil

bath temperature ranged 125° C. to 145° C. during the

distillation. The still head temperature varied from 95° 1 C.

to 110° C. When most of the solvents were removed, the

resulting suspension was allowed to cool down to room

temperature. The residue was dissolved in chloroform, and

in portions, transferred into a separatory funnel, washed with

an equal volume of saturated ammonium chloride solution,

washed with saturated sodium chloride solution, dried over

anhydrous magnesium sulfate, and suction filtered. The

filtrate was transferred into a round bottom flask and the

chloroform removed by evaporation. The crude product

[305 grams; 95% yield, but impure] was then recrystallized

from xylene [1 grarn/2 mL] using activated charcoal at —5°

C. 228 grams of recrystallized adduct were collected [75%

recovery; 71% yield overall, although the material is still

contaminated with small amounts of anthracene]. The mate-

rial was recrystallized again to produce about 188 grams of

doubly recrystallized adduct [82% recovery; 58% yield

overall; still contained some anthracene]. The material was

recrystallized again yielding 158 grams of triply recrystal-

lized material [84% recovery; 49% overall yield]. The

crystals were isolated by suction filtration, washed with

methanol, and vacuumed dried at 50° C. after each recrys-

tallization.

EXAMPLE 2

Synthesis of Dimethyl Methylidene Malonate (DMMM).

500 grams of mineral oil, 120.0 grams (373 mmol) of the

anthracene adduct of dimethyl methylidene malonate, 64.9

grams (375 mmol) of N-phenylmaleimide, and 050 grams

(3.5 mmol) of phosphorous pentoxide were added to a

silanized, flame dried, one liter round bottom flask contain-

ing a magnetic stirring bar. This mixture was degassed on a

vacuum manifold overnight. Then, a silanized distillation

head and fraction cutter were installed, and the flask

immersed in an oil bath already set at 225° C. under a

nitrogen atmosphere. After fifteen minutes, a yellow solution

was obtained. One hour later, the oil bath was removed and

the contents of the flask were allowed to cool down to 50°

C. High vacuum was then applied to the reaction system. A

pressure of around 450 microns was typical in the beginning

of the distillation, and the pressure fell to around 300

microns by the end of the distillation. Once the system

stabilized at low pressure, the dimethyl methylidene mal-

onate distilled over between 50° C. and 55° C. [the oil bath

temperature ranged from 50° C. to around 70° C.]. 31.0

grams of dimethyl methylidene malonate were collected in

the middle fraction [58% yield;>99 mole % pure by NMR

spectroscopy].

EXAMPLE 3

synthesis of Poly[e-caprolactone] (PCL). In the glove

box, l°uL (40 umol) of a 0.33M stannous octoate solution in

10

20

25

30

35

45

50

55

60

65

8

toluene, 2.3 mL (24 mmol) of distilled diethylene glycol,

and 205.3 grams (1.8 mol) of distilled e-caprolactone were

transferred into a silanized, flame dried, 500 mL, round

bottom flask equipped with a stainless steel mechanical

stirrer and a nitrogen gas blanket. The reaction flask was

immersed in an oil bath already set at 75° C. After fifteen

minutes, a clear solution was obtained and then the oil bath

temperature was raised to 190° C. for 19 hours. The stirrer

blade was removed, and the polymer melt was allowed to

cool down to room temperature in an inert atmosphere. After

about two hours, the polymer started to crystallize and

became opaque. The polymer was isolated by wrapping the

flask in aluminum foil, freezing the flask in liquid nitrogen,

and removing the broken glass. Then, the frozen polymer

was ground on a Wiley mill and sieved through a screen.

35.2 grams of a fine powder were saved; 161.8 grams of the

coarse grounds were vacuum dried at 40° C. for 12 hours.

160.9 grams of devolatized PCL were collected. The PCL

was vacuum dried again under the same conditions without

any weight loss. The inherent viscosity was measured in

chloroform at 25° C. and found to be 0.3 dL/g [c=0.10 g/dL].

The number average molecular weight was 9,000 glmol and

the weight average molecular weight was 16,000 glmol as

determined by gel permeation chromatography in HFIP

using PMMA standards. The monomer conversion was 97.6

mole percent as determined by 300 MHZ ‘H NMR spectrum

in HFAD/CGDE; 2.4 mole percent unreacted monomer was

also detected. The polymer melted between 60° C. and 65°

C. using a Fisher-Johns apparatus.

In the glove box, 25 grams of PCL and 0.25 grams of

sucrose [a nucleating agent] were added to a silanized, flame

dried, 100 mL, round bottom flask equipped with a stainless

steel mechanical stirrer and a nitrogen gas blanket. The

reaction flask was immersed in an oil bath set at 125°C.

After the PCL had melted, the mixture was blended for one

hour and then allowed to cool down to room temperature

under .an inert atmosphere. The polymer was isolated by

wrapping the flask in aluminum foil, freezing the flask in

liquid nitrogen, and removing the broken glass. The frozen

polymer was crushed and vacuum dried at room temperature

overnight and then stored under nitrogen gas until used in

the bone pin study described below.

EXAMPLE 4

Bone Pin Pullout Force Measurements. Materials and

Methods: Rabbit femurs were cleaned and frozen. They

were defrosted before testing and allowed to warm up to 37°

C. A hole was drilled in the femoral condyle with a 2.7 mm

drill bit. Bone pins made of poly[glycolie acid] having a

nominal diameter of 2.8 mm were roughened with sand

paper to improve adhesion and were inserted into the

femoral condyle with no adhesive, with Vetbond (n-butyl

cyanoacrylate), dimethyl methylene malonate (DMMM)

from Example 2 and with low molecular weight poly[e-

caprolactone] (PCL) from Example 3. The cure time was

one minute for the Vetbond and DMMM and thirty minutes

for the low molecular weight PCL. Mechanical testing was

conducted on an Instron model 1122 tensile tester at a cross

head speed of 0.5 inches per minute. The femur was held in

the bottom fixture, and the bone pin was pulled out by the

upper fixture. The force was measured and the maximum

force recorded.

Results: The pullout force data are summarized in Table

1. These data clearly show that the average pullout force

increased significantly when an adhesive was used; the

increase in pullout strength varied from 4 to 11 times that of

5,550,172

9

the force needed to remove the bone pin without any glue

being applied.

TABLE 1

Pullout Strengths

Pullout Strengths (kg)

Bone Pin

Test Only Vetbond DMMM PCL

1 ‘ 0.661 6.95 3.43 2.3

2 0.765 8.35 7.41 2.94

3 — 9.82 6.79 2.19

4 — 5.66 2.27 3.41

Average 0.71 7.70 4.98 2.71

We claim:

1. A process for enhancing the security of implantable

surgical devices secured to bone tissue consisting essentially

of securing a surgical device with a biocompatible adhesive

and/or sealant selected from the group consisting of:

(a) a bioabsorbable semi-crystalline aliphatic poly(ester)

of the formula:

[-0-—R“-C(0)-ly,

wherein R” is selected from the group consisting of

—CR‘2H—, —(CH2)3—O—, —CH2—CH2 —

CH2—, CR‘2H—CH2, —(CH2)4—, —(CH2)z—O—

C(O)— and —(CH2)Z—C(O)—CH2—; R12 is hydro-

gen or methyl; z is an integer in the range of from 1 to

7 and y is an integer in the range of from about 10 to

about 20,000; and

(b) a slurry of water and a calcium containing compound

with the general formula:

M2+t.HN‘+2...mU*-

where n is an integer form 1 to 10, and m is 2 when x

is l, or In is 1 when x is 2, M and N are alkali or alkaline

earth metals; W04 is an acid radical and W is phos—

phorus, vanadium, sulfur, silicon, or is substituted in

whole or part with carbonate (CO32_); and U is a

halide hydroxide, or carbonate; provided in an amount

eifective to increase the amount of force necessary to

remove the implanted surgical device.

2. The process of claim 1 wherein the sealant and/or

adhesive is applied to the site where the implantable surgical

device is to be secured. -

3. The process of claim 1 wherein the surgical device is

selected from the group consisting of screws, pins, plates,

anchors, rods, clamps, clips, staples, rivets, hooks, buttons

and snaps.

4. The process of claim 1 wherein the surgical device is

made of a bioabsorbable polymeric material.

5. The process of claim 1 wherein the adhesive and/or

sealant is a bioabsorbable serni-crystalline aliphatic poly-

(ester) homopolymer selected from the group consisting of

poly(e-caprolactone), poly(p-dioxanone), and poly(trimeth—

ylene carbonate).

6. A process for enhancing the security of implantable

surgical devices secured to bone tissue comprising securing

a surgical device to bone with a bioabsorbable semi-crys-

talline aliphatic poly(ester) copolymer composed of from

about 100 mole percent to about 70 mole percent of e-ca-

prolactone repeating units with the remainder of the polymer

being a plurality of second lactone repeating unit selected

10

20

25

30

35

45

50

55

60

65

10

from the group consisting of glycolide repeating units,

lactide repeating units, 1,4-dioxanone repeating units, 1,4-

dioxepan-2-one repeating units, 1,5-dioxepan-2-one repeat-

ing units, trimethylene carbonate repeating units, and com-

binations thereof provided in an amount effective to increase

the amount of force necessary to remove the implanted

surgical device.

7. The process of claim 1 wherein the adhesive and/or

sealant is applied to the implantable surgical device and the

surgical device is then secured to the bone tissue.

8. An implantable surgical device consisting essential of

an implantable surgical device that is at least partially coated

with a biocompatible adhesive and/or sealant selected from

the group consisting of:

(a) a bioabsorbable semi-crystalline aliphatic poly(ester)

of the formula:

[—0—R”—C(0)—]y,

wherein R“ is selected from the group consisting of

—CR‘_2H——, —(CH2)3-—O—, —CH2——CH2—O—

CH2—, CR‘2H—CH2, —(CH2)4—, —(CH2)Z

—O—C(O)— and —(CH2)z—C(0)—CH2—; R12 is

hydrogen or methyl; 2 is an integer in the range of from

1 to 7 and y is an integer in the range of from about 10

to about 20,000; and

(b) a slurry of water and a calcium containing compound

with the general formula:

M2+ro_,.N”;..(W043“)smU"- '

where n is an integer from 1 to 10, and m is 2 when x

is 1, or m is 1 when x is 2, M and N are alkali or alkaline

earth metals; W04 is an acid radical and W is phos-

phorus, vanadium, sulfur, silicon, or is substituted in

whole or part with carbonate (CO32“); and U is a halide,

hydroxide, or carbonate; provided in an amount effec-

tive to increase the amount of force necessary to

remove the implanted surgical device.

9. The surgical devices of claim 8 wherein the surgical

device is selected from the group consisting of screws, pins,

plates, anchors, rods, clamps, clips, staples, rivets, hooks,

buttons and snaps.

10. The surgical device of claim 8 wherein the surgical

device is made of a bioabsorbable polymeric material.

11. The surgical device of claim 8 wherein the adhesive

and/orsealant that at least partially coats the surgical device

is a bioabsorbable semi-crystalline aliphatic poly(ester)

homopolymer selected from the group consisting of poly(e-

caprolactone), poly(p-dioxanone), and poly(trimethylene

carbonate).

12. An implantable surgical device comprising an

implantable surgical device that is at least partially coated

with a bioabsorbable semi-crystalline aliphatic poly(ester)

copolymer composed of from about 100 mole percent to

about 70 mole percent of e-caprolactone repeating units with

the remainder of the polymer being a plurality of second

lactone repeating units selected from the group consisting of

glycolide repeating units, lactide repeating units, 1,4-diox-

anone repeating units, 1,4-dioxepan-2-one repeating units,

1,5-dioxepan-2-one repeating units, trimethylene carbonate

repeating units, and combinations thereof provided in an

amount efl"'ective to increase the amount of force necessary

to remove the implanted surgical device.

* * * * *

Coments go here:

- Log in to post comments