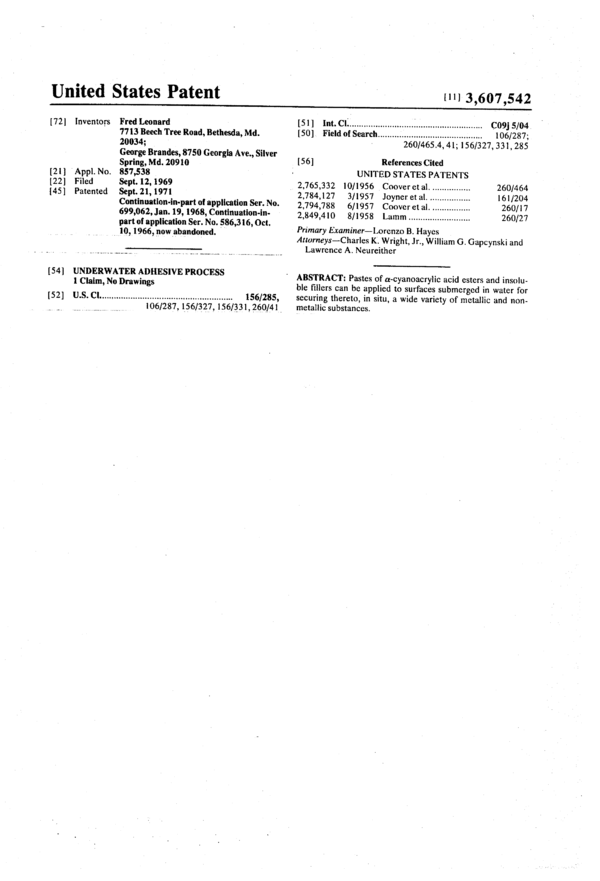

Underwater Adhesive Process

Underwater Adhesive Process

US3607542

Year:

Abstract:

Pastes of alpha-cyanoacrylic acid esters and insolluble fillers can be applied to surfaces submerged in water for securing thereto, in situ, a wide variety of metallic and non. metallic substances.

Type of document:

Language:

3,607,542

5

6

Monomer'

a~cyano-

Filler l

Paste

gramsFlow

Example

acrylate

I'

oetyl

CaCO,

2'

heptyl

fair

SiO. 0.3

CaCO, 2.7 excellent

heptyl

3.4

heptyl

CaCO, 2.6

sio, 0.1 to

0.2

CaCO, 3.4

heptyl

CaCO, 2.7

hexyl

CaC0.:s

amyl

CaCO,

3.5 fair

butyl

CaCO,

201'

110'

187'

100'

175'

25t1'

2.5 good

2.0 very thin

nonyl

l'

Surfaces··

Average

Bond

Strength in

Tension

(p .s. i.)

8'

CaC0.:s 2.7

SiO, 0.05

CaCO, 2.7

Si0 2

0.05

CaCO, 2.7

0.05

SiO,

CaCO, 2.7

10

475"

410'

609'

710 11

rubber/steel 74'

rubber/wood 3 If

glasS/glass

7'

5

15

d

225'

135'

112'

253'

80'

150'

420'

20

and fluid

10

deeyl

II

cyclohexyl

12

ethoxy-

210

885

270

ethyl

13

isobutyl

14

isopropyl

15

2-ethyl-

SiO,

CaCO,

SiO,

CaCO,

SiD,

CaCO,

0.1

2.7

0.05

2.7

0.05

2.7

30

260

360

310

hcxyl

16

propyl'

17

ethyl'

18

methyl"

19

hexyl

20

2-ethyl-

0.05

SiD"

CaCO, 2.6

sio, 0.1

CaCO, 2.7

0.1

Si0 1

CaCO, 2.7

sio, 0.1

BaCO, 2.7

0.1

SiO!

CaSO. 2H,0 2.0

25

200

35

200

75

75

40

750

210

hexyl

21

butyl

22

allyl

n-hcxyl and

n-arn yl

24

trifluoroisopropyl

0.1

SiDI

CaSO, I>H,O 3.0

5i0 2

0.1

CaCO, 2.7

SiD,

0.1

BaCO, 2.7

400

SiO, 0.1

CaC0 3

2.7

155

SiD,!

80

45

250

50

0.1

**AII examples adhere two stainless steel surfuces under fresh water. unless

otherwise specified.

'"Salt water used in this sample.

'I Immediate sealing.

r. Sealing after a J -minute immersion.

I' Sealing after a 2-minute immersion.

" G lass slides broke. precluding reading,

,. Bond strengths as high as 580 p.s.i. obtained in individual tests.

r Peel strength; rubber peeled from steel and wood substrates.

" Held together for only I minute under water.

hexyl-o-cyanoarcylate (pH 3.7), 3.6 parts by weight of calcium carbonate and 0.2 part by weight of "Cab-O-Sil," additional bonds are prepared under water as set forth in examples

25 to 32. In these examples all test specimens (except those

with corroded or painted surfaces) are prepared for adhesive

bonding by vapor degreasing for 5 minutes with

trichloroethylene. This is followed by a hoI water rinse and

then a final wash in methyl ethyl ketone.

The procedure for each test (run) in examples 25 to 32 is as

follows:

a. Water in a container is regulated at the indicated temperature;

b. Test specimens are submerged in the water;

c. Adhesive is applied to bonding surfaee of one submerged

test specimen;

d. Adhesive is spread over entire bonding area by sliding

test specimens over one another;

e. Moderate hand pressure (approximately I pound) is applied between bonding surfaces for a time interval A;

f. Bonded test specimens removed from water and placed in

Dillon Dynamometer for pull tests;

g. Load applied between test specimens; time interval B is

the interval between conclusion of time interval A and

application of load.

The adhesive cure begins immediately upon contaet with

water. Up to 2 minutes are available following application to

spread the adhesive and bring the bonding surfaces together.

All ingredients are stored in closed containers. The hcxyl-ocyanoacrylate is packaged in a polyethylene bottle. Cardboard

cans are used to package the amorphous silica and the calcium

carbonate.

The mixed adhesive paste can be readily applied from its

collapsible squeeze tube container for a period up to 4 hours.

The following portions of Federal Test Standard 175, Adhesive Methods of Testing, are used for performing the physical

tests:

Method 1011.1 - Tensile Properties of Adhesives

Method 1033.1-T - Shear Strength Properties of Adhesives

by Tensile Loading.

All tests for each example are performed on the same day

with the same adhesive batch. The bond area for each test is

one square inch. 7.8 grams of mixed adhesive composition is

adequate for approximately 20 thin film tests.

The aluminum alloy employed in each of examples 25

through 32 is aluminum alloy AA6061-T6 anodized per

Mil-A-625 and having a surface roughness of 32, In each of

said examples the steel is steel per Mil-S-16216, Grade

HY-80; in examples 25, 28, 29, 31 and 32 the surface

roughness is 32; in examples 26 and 30 the surface bonded is

badly oxidized to a finish of approximately 125; in example 27

the surface bonded is painted per NAYORD USTD 52,

System No. 48 (antifouling).

55

EXAMPLE 25

Steel is adhered to anodized aluminum alloy submerged in a

3 percent solution of salt (NaCl) water having a temperature

60 of 70° F. Ten repetitions produce the following results:

h Paste delivered as a glob through a polyethylene tube to one of the two steel

surfaces held under water.

i

All silica (5iO,) used in the examples in conjunction with the filler is

amorphous silica.

j In each example 3.0 grams of monomer are used, except in Example 1 where

6.1 grams of monomer are used; in Example 23,1.5 grams of each monomer are

ernptoyed. Eaeh"!~J isE~~f!l~s~?.tJ1~r~is~.~.!'£ifi~d,•..._ ..•_

.

65

A'

B"

45

37

Heptyl-a-cyanoacrylate admixed with calcium carbonate

45

75

(CaC03 ) and amorphous silica (as in the examples) was also

45

48

found to form strong bonds (under water) of aluminum to alud

45

81

minum. In the same manner wood/wood and rubber/rubber 70

45

55

44

45

bonds were formed. Although there may be some variation in

J

45

57

K

maximum tensile or shear strengths and the optimum pH may

h

45

42

differ, strong bonds are likewise formed under water for

45

62

glass/glass, plastic/plastic (phenol/formaldehyde thermoset 75

47

45

plastic) and combinations of the noted substrates, e.g.

~topl/~h1fT1i"l1m nl~~ti£"l,:"b~~ ~nn'W()O:{\(f1~inted 'steel,

.. Tim" I., ""f·ntHI,!, In of/man: seccirnen bond H

Tensile Strengths

[p.s.i.}

90

375

190

325

425

275

450

125

475

Average 61.5

Time in seconds (unlc,,'( otherwise

Coments go here:

- Log in to post comments