Novel alpha-cyanoacrylate compound, method of preparing same and adhesive comprising same

Novel alpha-cyanoacrylate compound, method of preparing same and adhesive comprising same

EP127855

Company:

Year:

Abstract:

a-cyanoacrylate compounds expressed by the following general formula: wherein R' desianates- and R2 designates alkyl groups, alkenyl groups or alkynyl groups of C1 to C4. These compounds are preferably synthesized by the reaction of the compounds expressed by the following general formula: wherein R' and R2 are same as the above described, with formaldehyde products and then the depolymerization of the resulting dehydrating condensation polymers. These compounds are effectively used as fast-setting adhesives.

Type of document:

Language:

EP 0 127 855 A1

Européisches Patentamt

0’ European Patent Office

Office européen des brevets

O 1 27» 855

A1

® Publication number:

® EUROPEAN PATENT APPLICATION

@ Application number: 841059827 @ Int. CL“: C 07 C 121/413

A 61 L 15/O6

® Date offilingz 25.05.34

@ Priority: 3o.o5.s3 JP 95735133

@ Applicant: Kabushiki Kaisha Alpha Giken

1-3-4-, Kasuga

lbaraki-shi Osaka-fu(JP)

@ Date of publication of application:

12.12.84 Bulletin 34/5o @1nventor: l-lirakawa,Eisuke

11-7, Nagaycshi-Rokutan 2-chome

Designated Contracting States: Hirano-ku Osaka-shi(JP)

DEFRGB

Representative: Tfirk, Dietmar, Dr. rer. nat. et al,

Redies, Redies, Turk & Gille Patentanwilte

Brucknerstrasse 20

D-4000 Dusseldorf 13(DE)

@ Novel alpha-cyanoacrylate compound, method of preparing same and adhesive comprising same.

oz-cyanoacrylate compounds expressed by the following

general formula:

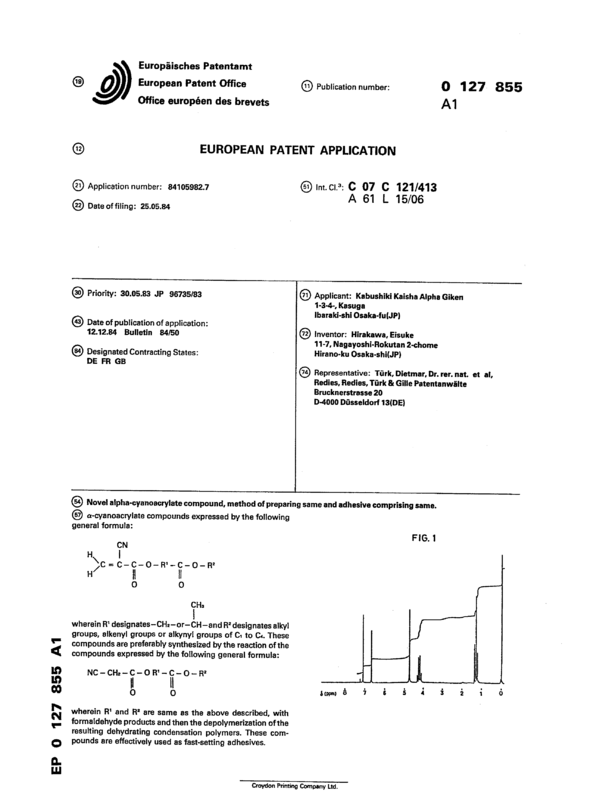

FIG. 1

CN

CH:

wherein R‘ designates-CHz—or— CH—and R’ designates alkyl

groups, alkenyl groups or alkynyl groups of C1 to C4. These

compounds are preferably synthesized by the reaction of the

compounds expressed by the following general formula:

NC—CHz—C—OR‘—C—O—R’

O!

p.

3

@-

~l

O

U!

.0

on.

N

..a

0

II N

o 0

wherein R‘ and R‘ are same as the above described, with

formaldehyde products and then the depolymerization ofthe

resulting dehydrating condensation polymers. These com-

pounds are effectively used as fast-setting adhesives.

Croydon Printing Company Ltd.

10

15

2O

25

0127855

NOVEL a—CYANOACRYLATE COMPOUND, METHOD OF PREPARING

SAME AND ADHESIVE COMPRISING SAME

BACKGROUND OF THE INVENTION

The present invention relates to the novel a-

cyanoacrylate compounds, a method of preparing same

and adhesives comprising same.

a-cyanoacrylate compounds expressed by the

following general formula have been well known as

instant adhesives:

H CN

\ /

[C = C‘\

H C - O - R

H

0

Such adhesives are fast set time and put together

the substrates made of various kinds of material with

each other strongly. a—cyanoacry1ate compounds

expressed by the above described general formula, in

which R is alkoxyalkyl group, halogenated alkyl group,

alkenyl group, alkynyl group or the like in addition to

alkyl group, have been known. However, almost of them

have such disadvantageous that they have an irritating

odor whereby being disadvantageous in handling, the cir-

cumference of the surfaces bonded being whitened, and

the polymerization set products being fragile whereby

having lower impact resistance and bending resistance.

10

15

20

25

0127855

It is an object of the present invention to pro-

vide novel 0-cyanoacrylate compounds.

It is another object of the present invention

to provide a novel method of preparing said¢z-

cyanoacrylate compounds.

It is further an object of the present invention

to provide novel adhesives comprising same a-cyano-

acrylate compounds.

SUMMARY OF THE INVENTION

The inventor of the present invention synthesized

various kinds of u-cyanoacrylate compound and investi-

gated their properties and bonding performance to

various kinds of substrate (including living bodies).

As a result, it was found that the novel a-cyanoacry-

late compounds expressed by the following general

formula solved the above described disadvantages and

had a superior bonding performance.

cm

H I

‘c=c—c-0-121-c—o—R2

/

H I? II

0 oc

H3

wherein R1 designates — CH2 - or - éfi - and R2 desig-

nates alkyl groups, alkenyl groups or alkynyl groups

0

of C1 to C4.

Said urcyanoacrylate compounds are preferably

prepared by the reaction of the compounds expressed

10

15

20

25

0127855

by the following general formula with formaldehyde

products and then the thermal depolymerization of the

resulting dehydrating condensation polymers:

2

NC - CH2 — c — 0 — R1 — c — o — R

H H

O 0

1 and R2 are same as the above described.

wherein R

BRIEF DESCRIPTION OF THE DRAWINGS

____________________________________

1

Fig. 1 shows a H—NMR spectrum of the compound

1 (ethoxycarbonylmethyl a—cyanoacrylate) of the com-

pounds according to the present invention:

Fig. 2 shows a mass spectrum of said compound 1;

Fig. 3 shows an IR-spectrum of said compound 1;

1

Fig. 4 shows a H-NMR spectrum of the compound 2

(methoxycarbonylmethyl a—cyanoacrylate) of the com-

pounds according to the present invention:

Fig. 5 shows a mass spectrum of said compound 2;

Fig. 6 shows an IR-spectrum of said compound 2;

1

Fig. 7 shows a H—NMR spectrum of the compound 4

(allyloxycarbonylmethyl a—cyanoacrylate) of the com-

pounds according to the present invention;

Fig. 8 shows a mass spectrum of said compound 4;

Fig. 9 shows an IR-spectrum of said compound 4;

Fig. 10 shows a 1H—NMR spectrum of the compound

6 (1-ethoxycarbonylethyl a-cyanoacrylate) of the com-

pounds according to the present invention;

0127855

Fig. 11 shows a mass spectrum of said compound 6;

and

Fig. 12 shows an IR-spectrum of said compound 6.

DESCRIPTION OF THE INVENTION

5 The novel u-cyanoacrylate compounds according to

the present invention are expressed by the following

general formula:

CN

H I 2

\C=C-C-0-R1"C"‘0"R

H’ u H

0

1° 0 CH3

I

wherein R1 designates - CH2 - or - CH - and R2 desi-

gnates alkyl groups, alkenyl groups or alkynyl groups

of C to C4.

1

Said compounds are diesters containing two ester

15 parts in one molecule. Concretely speaking, they

include

methoxycarbonylmethyl a-cyanoacrylate,

ethoxycarbonylmethyl u-cyanoacrylate,

butoxycarbonylmethyl u-cyanoacrylate,

20 allyloxycarbonylmethyl a-cyanoacrylate,

propargyloxycarbonylmethyl u—cyanoacrylate,

1-methoxycarbonylethyl u—c¥anoacry1ate,

1-ethoxycarbonylethyl u-cyanoacrylate,

.l—butoxycarbonylethy1 u—cyanoacrylate,

25 l-allyloxycarbonylethyl a—cyanoacrylate and the

10

15

20

25

0127855

like.

Olefinic protons of a-cyanoacrylate were common-

compounds expressed by the above described general

formula, respectively. Protons of - CH2 - put between

two ester parts were observed in the form of single

signal at 6==4.77 and protons of - g:3~ were observed

in the form of quartet signal at 6==5.16 and in the

form of doublet signal at 6==1.56. Protons of the end

ester part were observed similarly as in usual esters.

Chemical shifts, splitting mode and integral ratio of

each signal satisfied those for each compound.

The strongest base peak was commonly observed at

m/e = 80 in their mass spectra. This strongest base

peak at m/e = 80 was resulted from an ion expressed by

the following formula:

H\C _ C /CN

H./ "‘ \.C+

H

O

In addition, a molecular ion peak M+ of each com-

pound was observed though it was weak. Also fragment

ion peaks of each compound, which could be guessed

from the splitting mode of the above described struc—’

ture, were observed.

5

10

15

20

25

0127855

The absorption of 2240 cm-1 resulting from VC EN:

the absorption of 1740 cm_1 resulting from VC==O, the

absorption of 3135 cm-'1 resulting from “c -H (olefin)

1 resulting from “C =C

and the absorption of 1620 cm-

were commonly observed in IR-spectra.

a-cyanoacrylate compounds according to the present

invention is preferably synthesized by the reaction of

the compounds expressed by the following general

formula with formaldehyde products and then the thermal

depolymerization of the resulting dehydrating conden-

sation polymers: V

NC-CH —c-0-121-c-0-122

2 H u

0 0

wherein R1 and R2 are same as the above described.

Said compounds as raw materials expressed by the

above described general formula are obtained by for

example the dehydrochloric condensation reaction

between cyanoacetic acid and chloroacetates or the

dehydrating condensation reaction between cyanoacetic

acid and lactates. Said formaldehyde products include

formaldehyde and the substances producing formaldehyde

in the reaction. However, paraformaldehyde is indust-

rially important. - ;

The reaction of said compounds as raw materials

expressed by the above described formula with said

10

15

20

25

01 27855

formaldehyde products is carried out at a molar ratio

of the latter calculated as formaldehyde to the former

of for example 0.9 to 1.1 : l in the presence of suit-

able basic catalysts, for example amines such as

piperydine, ethanolamine and diethylamine or basic

compounds such as alkaline metal hydroxide and alka-

line metal alkoxide in suitable solvents; for example

inactive solvents such as benzene, toluene, chloroform

and trichloroethylene at 50 to 150°C, preferably 70 to

130°C to obtain dehydrating condensation polymers. The

thermal depolymerization is carried out by washing the

resulting compounds as raw materials with water or

diluted aqueous solutions of acids and then heating under

vacuum at 130 to 250°C, preferably 150 to 220°C in the

presence of suitable depolymerization catalysts such

as phosphorus pentoxide, phosphoric acid and condensed

phosphoric acid.

The novel a-cyanoacrylate compounds according to

the present invention show a bonding performance to a

substrate made of various kinds of material in the

same manner as the known a-cyanoacrylate such as ethyl

u-cyanoacylate and are effectively used as fast set-

ting adhesives. The adhesives comprising the novel

a-cyanoacrylate compounds according to the present

invention are odorless or slightly give out fragrance

0127855

whereby being remarkably easy to handle in the prepar-

ing process and the bonding process, producing

no whitening in the bonding process, and improving the

polymerization set products in brittleness. In addi-

5 tion, they are superior to the conventional u-

cyanoacrylate in bonding strength to various kinds of

substrate, for example metals, plastics, rubber, glass,

wood and the like, particularly plated articles. It is

perhaps owing to the chelate effect. Furthermore, the

10 adhesives comprising u-cyanoacrylate, in which R2 is

allyl group (CHZCH = CH2), of the novel a-cyanoacrylate

compounds according to the present invention have such

an advantage that the substrate bonded therewith does

not show a large reduction in bonding strength.even

15 when kept in a long time under the high temperature

condition (for example one month at 150°C). In addi-

tion, the adhesives according to the present invention

are superior in bonding (i.e. joining, bleed—stopping)

strength to tissues of living bodies such as skin, gum,

20 blood vessel and various kinds of organ and absorptivity

into tissues after bonding.

Additives such as radical polymerization inhibi-

tors, anion polymerization inhibitors, plasticizers,

tackifiers, coloring agents, fillers, diluents, water,

25 perfumes, carhoxylic acids, carboxylic anhydrides

10

15

20

25

0127855

and polyisocyanates may be added to the adhesives

according to circumstances.

The present invention is more particularly

described and explained by means of the following

Examples, in which "parts" and "%" are all by weight.

EXAMPLE 1

325 parts of ethyl cyanoacetoxyacetate was added

drop by drop to the mixture of 65 parts of paraform-

aldehyde, 350 parts of toluene and 0.4 parts of pipery-

dine put in a four—necked flask provided with a stirrer,

a thermometer, a water-separating means and a dropping

funnel with heating at 95 to 110°C and stirring. The

reaction was continued with reflux-condensing to drive

out the produced water. The stoichiometric amount of

water was driven out within two hours and then the

reaction mixture was cooled. After cooling the reac-

tion mixture (condensation polymers) was washed with

diluted aqueous solutions of acids and then toluene

and water contained in the reaction mixture were

distilled away under vacuum. Then the depolymerization

was carried out by adding 4 parts of phosphorus pentoxide

and 2 parts of hydroquinone and heating the resulting

mixture under vacuum at l§0 to 200‘b to obtain 125 parts

of the crude monomer. 82 parts of the purified monomer

having a boiling point of 91 to 93°C/O.5mmHg was

0127855

-10..

obtained by distilling the mixture of the resulting

crude monomer, a small amount of phosphorus pentoxide

and a small amount of hydroquinone (0.3 %, respectively)

under vacuum. According to a gas chromatography of its

5 solution diluted with nitromethane, the purity of the

resulting purified monomer was 99 %. The yield was

23.4 %.

The characteristics of the resulting monomer were

as follows:

10 Thus it was confirmed that the resulting monomer

was ethoxycarbonylmethyl a—cyanoacrylate (hereinafter

reffered to as compound 1) expressed by the following

formula:

cm

I-I\ I

C=C—C-O—CH-C-0-CH -cu

H’ a 2 u 2 3

o o

15

(molecular weight: 183)

(1) 1H-NM spectrum is as shown in Fig. 1 (100

M2, CDC1 solvent, TMS internal standard).

3

20 Olefinic protons of'a—cyanoacrylate were observed

in the form of single signal at 0 = 7.15 and 6 = 6.65.

Protons of — CH2 — put between two ester parts

were observed in the form of single signal at.6 = 4.77.

(2) Mass spectrum is as shown in Fig. 2.

25 iThe strong peak resulting from a cation expressed

10

15

20

25

01 27855

_ 11 -

by the following formula was observed at m/e = 80.

H CN

\C::C/

/

H

A molecular ion peak M+ was observed at m/e = 183.

(3) IR-spectrum is as shown in Fig. 3.

C EN Expansion and contraction vibration 2240 cm-1

C =0 Expansion and contraction vibration 1740 cm-1

C —H (olefin) Expansion and contraction vibration

3135 cm-1

1

C =C Expansion and contraction vibration 1620 cm-

(4) Elementary analysis

Measured value Theoretical value

C (%) 52.66 52.46

H (%) 5.06 4.95

N (%) 8.06 7.65

(5) Boiling point

91 to 93°C/0.5 mmHg

EXAMPLES 2 to 5

The compounds 2 to 5 as shown in Table 1 were obtain~

ed from paraformaldehyde and methyl cyanoacetoxyacetate,

n-butyl cyanoacetoxyacetate, allyl cyanoacetoxyacetate or

propargyl cyanoacetoxyacetate, which were the starting

materials, in the same manner as in EXAMPLE 1.

10

15

20

25

0127855

_ 12 _

In addition, H-NMR spectrum, a mass spectrum and an

IR-spectrum of the compound 2 of compounds shown in Table

1, that is to say methoxycarbonylmethyl a-cyanoacrylate

(molecular weight : 169) is shown in Fig. 4, Fig. 5 and

Fig. 6, respectively. Furthermore, 1H—NMR spectrum, a

mass spectrum and an IR-spectrum of the compound 4 of

compounds shown in Table 1, that is to say al1yloxy-

carbonylmethyl a-cyanoacrylate (molecular weight : 195)

is shown in Fig. 7, Fig. 8 and Fig. 9, respectively.

Table 1

CN

H I

‘c =:c — C — 0 — CH2 — C — 0 — R2

}{’ I! H

0 O

Elementary analysis (%)

C : H N

-——n--

a9m 91°C/0.5 mm!-lg i 23:3:

Com-

pound

2 CH3

ll3'Vl15°C/0.5 mHg

101'U1O3°C/0.5 mHg

wwx:-.c-a\o\.t>.t>

III!

O‘mO\\llUO|-‘N

U'|DU'|\DOLAJ-vJkO

98 m1oo°c/0. 5 mmHg

(Note)

The upper numerical value shows the measured

value while the lower numerical value shows

the theoretical value in the results of element-

ary analysis.

10

15

20

25

01 27855

_ 13 _

EXAMPLE 6

372 parts of ethyl 2—cyanoacetoxypropionate was

added drop by drop to the mixture of 75 parts of para-

formaldehyde, 350 parts of toluene and 0.5 parts of

piperydine put in a four—necked flask provided with a stir-

rer, a thermometer, a water-separating means and a dropping

funnel with heating at 95 to 110°C and stirring. The reac—

tion was continued with reflux-condensing to drive out

the produced water. The stoichiometric amount of water

was driven out within two hours and then the reaction

mixture was cooled. After cooling the reaction mixture

(condensation polymers) was washed with diluted aqueous

solutions of acids and then toluene and water contained

in the reaction mixture were distilled off under vacuum.

Then the depolymerization was carried out by adding

5 parts of phosphorus pentoxide and 3 parts of hydroquinone

and heating the resulting mixture under vacuum of 2 to

4 mmHg at 150 to 190°C to obtain 163 parts of the crude

monomer. 122 parts of the purified monomer having a

boiling point of 98 to 99°C/1 mmHg was obtained by distil-

ling the mixture of the crude monomer, a small amount

of phosphorus pentoxide and a small amount of hydroquinone

(0.3 %, respectively) under vacuum. The purity of the

resulting purified monomer was 98.6 %. The yield was

31.7 %.

10

15

20

25

0127855

-14-

The characteristics of the resulting monomer were

as follows:

Thus it was confirmed that the resulting monomer

was l-ethoxycarbonylethyl a—cyanoacrylate (hereinafter

referred to as compound 6) expressed by the following

formula:

— C — O — CH -CH

H u H

O 0

(molecular weight: 197)

(1) 1H-NMR spectrum is as shown in Fig. 10 (100

MHZ, CDCl3 solvent, TMS internal standard).

Olefinic protons of a-cyanoacrylate were observed

in the form of single signal at 6 = 7.15 and & = 6.65.

in the form of doublet signal at 6 = 1.56.

(2) Mass spectrum is as shown in Fig. 11.

The strong peak resulting from a cation expressed

by the following formula was observed at m/e = 80.

H /CN

:C:C\ +

H C

H

O

A molecular ion peak M+ was observed at m/e = 197.

(3) IR—spectrum is as shown in Fig. 12.

10

15

20

25

0127855

- 15 _

C EN Expansion and contraction vibration 2240 cmul

C =0 Expansion and contraction vibration 1740 cm_l

C -H (olefin) Expansion and contraction vibration

3135 cm'1

1

C =C Expansion and contraction vibration 1620 cm-

(4) Elementary analysis

Measured value Theoretical value

C (%) 54.92 54.82

H (%) 5.69 5.62

N (%) 7.17

7.10

(5) Boiling point

98 to 99°C/0.5 mmHg

EXAMPLES 7 to 9

The compounds as shown in Table 2 were obtained

from paraformaldehyde and methyl 2-cyanoacetoxypropio-

hate, n—buty1 2—cyanoacetoxypropionate or allyl 2-

cyanoacetoxypropionate, which were the starting

materials, in the same manner as in EXAMPLE 6.

10

15

20

25

0127855

_ 15 _

Table 2

CN CH3

}{\ I I 2

C = C — C - 0 - CH ‘- C — O — R

/

H H H

O 0

96 W 98°C/1 mmflg

1l4'V116°C/1 mmfig

105 "'l06°C/l mml-Ig

(Note) The upper numerical value shows the measured

value while the lower numerical value shows

the theoretical value in the results of element-

ary analysis.

EXAMPLE 10

The compounds obtained in the above described

EXAMPLE 1 and EXAMPLE 6 were tested on the performance

as adhesives. Also ethyl a-cyanoacrylate was tested on

the performance as adhesives for COMPARATIVE EXAMPLE.

The results are shown in Table’3.

0127855

_ 17 _

Table 3

' Ethyl 0-

V Compound 1 Compound 6 Cyanoacr late

F—-—-—-------—-—~———--—‘~*'"——-""-‘““"“‘-‘T‘“‘““‘”JL“““"

Odor odorless Slightly giv— gciving out

’ing out frag- strong irritat-

grance ing odor I

whitening ‘ whitened all

over the surface

of Petri dish

Set time (sec)

Fe/Fe

NBR/NBR

Tensile shear 2

strength (kg/cm ) ; E

Fe/Fe 153 3

sus/sus 162 I

A1/Al 146 E

Ni-plating/Ni- 152 ; 90 4o

plating §

Zn-p1ating/Zn- 173 § 130 120 ,

plating A ? §

: ' I

z ABS/ABS Adherend g Adherend Adherend E

| failure . fa11UP€ failure §

5 - I

3 NBR/NBR Adhepend ? Adherend Adherend I

' failure ‘ failure failure

Joining of liv-

ing body ? ' E

. 3 K

Note 1. The odor was tested on the basis of sensual

test by five panelers.

Note 2. The Whitening of a drop of adhesives fallen

in a Clean Petri dish was investigated after

leaving for twenty-four hours at room tem-

perature.

_18_ 0127355

Note 3. The set time was measured in accordance

with JIS K 6861.

Note 4. The tensile shear strength was measured

in accordance with JIS K 6850.

Also the compounds 2 to 5 and 7 to 9 obtained in

the above described EXAMPLES 2 to 5 and 7 to 9 were

tested on the performance in the same manner as in the

above described. The compounds 2 to 5 all were odor-

10 less while the compounds 7 to 9 all slightly gave out

fragrance. The compounds 2 to 5 and 7 to 9 all did

not produce the whitening. The compounds 2 to 5 and

7 to 9 all had the tensile shear strength of the same

degree as the compound 1 or 6. They showed also the

15 desirable jointability to living bodies.

In addition, an iron-piece/iron-piece bonded with

the compound 4 (allyloxycarbonylmethyl u-cyanoacrylate)

as adhesives was tested on tensile shear strength at

higher temperature of 150'. The results are shown

20 in Table 4.

However, COMPARATIVE EXAMPLE in Table 4 shows the

adhesive of heat-resisting grade on the market which

is obtained by adding aromatic carboxylic acids to

ethyl u—cyanoacrylate.

25 It is found from this Table also that the com-

01 27855

_ 19 _

pound 4 is very effectively used as heat-resisting

adhesives.

Table 4

; Compound 4

Tensile shear 2

strength (kg/Cm )

COMPARATIVE

EXAMPLE

At first

After leaving for.

10 hours at 150°C

After leaving for

7 days at l50°C__

After leaving for

15 days at 150°C

After leaving for

29 days at 150°C

_ 20 _ 0127855

what is claimed is:

1. a-cyanoacrylate compounds expressed by the follow-

ing general formula:

cu

H I

5 ‘c=c—c-o-R‘-C-0-R2

H’ it ll

0 °cH

.3 2

wherein R1 designates - CH2 - or - CH — and R desig-

nates alkyl groups, alkenyl groups or alkynyl groups

of C1 to C4.

10 2. A method of preparing a-cyanoacrylate compounds

expressed by the following general formula:

cm

H I

:c=-.c—c-0-R1-c-0-R2

H u u

0 OCH

.3

15 wherein R1 designates - CH2 - or - CH - and R2 desig-

nates alkyl groups, alkenyl groups or alkynyl groups

of C to C4, comprising

1

a step for reacting the compounds expressed by

the following genral formula:

20 NC-CH-C-Co—R1-C-O-R2

2 u .1

0 0

wherein R1 and R2 are same as the above described,

with formaldehyde products; and

a step for depolymerizing the resulting dehydrat-

25 ing condensation polymers.

O1 2 7-8 55

-21..

3. Adhesives comprising a—cyanoacrylate compounds

expressed by the following general formula:

H II ll

0

‘EH3

wherein R1 designates - CH — or - CH - and R2 des1g-

2

nates alkyl groups. alkenyl groups or alkynyl groups

of C1 to C4.

I/Q 0127855

F|G.1

3(ppm>53 7 5 5 4 3 2 1 .0

2% 0127855

F|G.3

4000 3000 2(0) I500 IZW 8(1) (00

cm

FlG.4

01 27855

2/e

F|G.5

‘Vlrlv !vt..$I. lt|u1.lD..v.!sr!.l.......%\n1tcs.|n :..2!6.tl.o.I.lIn1¢a..v..I\.||.Vn.....o». ..l§l. .. :

F|G.6

400

1200

4000

7/5 0127855?’

FlG.7

FIG. 8

5'/é W ' 0127355

F|G.9

4000 3000 2000 1600 1200 . 800 400

FlG.1O

40(1)

3000

2000

FIG. 12

I600

[ZN

BID

o127855”“

mo -,

EPO Form 1503. 03.82

E"',°°°a" Pam“ EUROPEAN SEARCH REPORT o1“‘%‘°Z""8"'§’-’”§°'

FR-A-2 308 360 (ETHICON INC.) A 61 L 15/O6

* Page 20, lines 27-38; page 21,

lines 1-10 *

CHEMICAL ABSTRACTS, vol. 91, no.

7, 13th August 1979, page 646,

no. 56325f, Columbus, Ohio, US;

D.A. ARONOVICH et al.:

"Carbalkoxymethyl esters of

cyanoacetic and cyanoacrylic

acids" & ZH. PRIKL. KHIM.

(LENINGRAD) 1979, 52(4), 939-42

* Abstract *

CHEMICAL ABSTRACTS SERVICE

REGISTRY HANDBOOK, number

section, part 1, 1978

supplement, page 958RG,American

Chemical Society, Columbus, sEAHCHED(Int-CL’)

Ohio, US;

* Abstract 66470-71-1,

"2-Propenoic acid, C 07 C 121/00

2-cyano-,2-methoxy-1-methyl—2-oxo

ethyl ester, (S)-C8H9NO4" *

FR-A-2 017 157 (MINNESOTA

MINING AND MANUFACTURING CO.)

* Pages 13-14 *

Place of search Date of corn letion of the search Examiner

THE HAGUE 07- 9-1984 VERHULST W.

pl

CATEGORY OF CITED DOCUMENTS : theory or princi e underlying the invention

: earlier patent document. but published on, or

: particularly relevant if taken alone after the filing date .

: particularly relevant if combined with another : document cited in the application

document of the same category : document cited for other reasons

: technological background

: non—written disclosure : member of the same patent family. corresponding

: intermediate document document

Coments go here:

- Log in to post comments