�������United States Patent [19]

Kimura et al.

[1 1] 4,364,876

[45] Dec. 21, 1982

[54] NOVEL 2-CYANOACRYLATE, PROCESS

FOR PRODUCING SAME AND CURABLE

COMPOSITION COMPRISING SAME

[75] Inventors: Kaoru Kirnura, Kuroishi; Kazuyuki

Sakabe, Tokai, both of Japan

[73] Assignee: Toagosei Chemical Industry Co., Ltd.,

Tokyo, Japan

[21] Appl. No.: 244,276

[22] Filed: Mar. 16, 1981

[30] Foreign Application Priority Data

Mar. 27, 1980 [JP] Japan .............................. 55-38174

[51] Int. Cl.3 .......................................... .. C07C 121/30

[52] U.S. Cl. ............................... .. 260/465.4; 260/464;

- 26o/465 D; 526/312

[53] Field of Search .................................... .. 260/465.4

[56] References Cited

U.S. PATENT DOCUMENTS

2,784,215 3/1957 Joyner ............................ .. 260/465.4

3,142,698 7/1964 Halpem et al. 260/465.4

3,465,027 9/1969 Hawkins . . . . . . . . . . . . . . . .. 260/464

3,540,126 11/1970 Chang et al. .... .. .. 260/465.4 X

3,564,078 2/ I971 Wicker, Jr. et al. ..'. ..... .. 260/ 881

3,577,394 5/ 1971 Harrington ..... .. . 260/78.4

3,699,127 10/1972 O’Sullivan et al. . 260/33.2

3,975,422 8/1976 Buck ............................... .. 260/465.4

OTHER PUBLICATIONS

Kulkarn; et al., Journal of Applied Polymer Science,

vol. 17, pp. 3509-3514, (1973).

Primary Examiner—Joseph Paul Brust

Attorney, Agent, or Firm—Cooper, Dunham, Clark,

Griffin & Moran

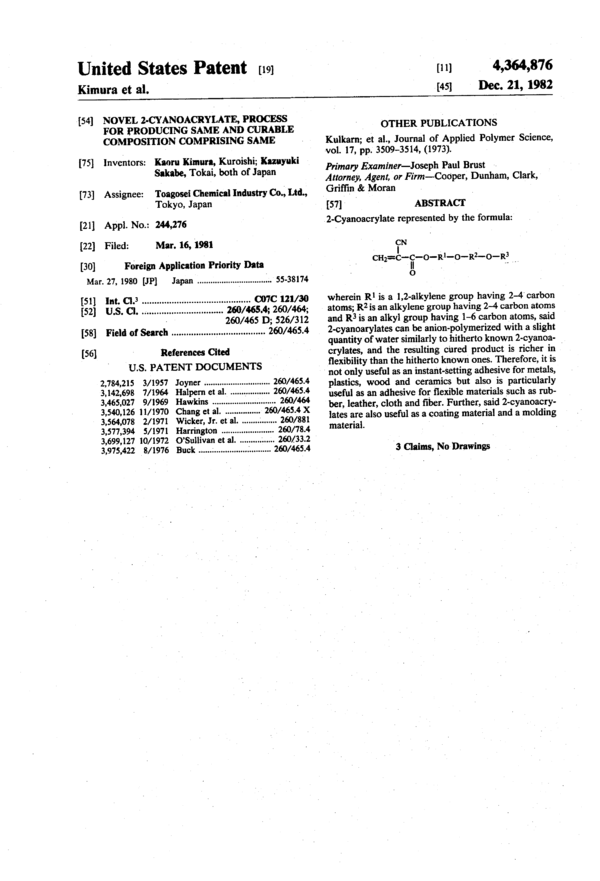

[57] ABSTRACI‘

2-Cyanoacrylate represented by the formula:

CN

cH2=c—c—o—R1-o-R2—o—R§

II

0

wherein R‘ is a 1,2-alkylene group having 2-4’ carbon

atoms; R2 is an alkylene group having 2-4 carbon atoms

and R3 is an alkyl group having 1-6 carbon atoms, said

2-cyanoarylates can be anion-polymerized with a slight

quantity of water similarly to hitherto known 2-cyanoa-

crylates, and the resulting cured product is richer in

flexibility than the hitherto known ones. Therefore, it is

not only useful as an instant-setting adhesive for metals,

plastics, wood and ceramics but also is particularly

useful as an adhesive for flexible materials such as rub-

ber, leather, cloth and fiber. Further, said 2-cyanoacry-

lates are also useful as a coating material and a molding

material. -

.3 Claims, No Drawings

4,364,876

1

NOVEL 2-CYANOACRYLATE, PROCESS FOR

PRODUCING SAME AND CURABLE

COMPOSITION COMPRISING SAME

This invention relates to a novel 2—cyanoacrylate, a

process for producing the same and a curable composi-

tion comprising it. . .

Hitherto, alkyl 2-cyanoacrylate monomers have

widely been utilized for bonding metals, plastics, rub-

bers, wood, ceramics and the like as a cold-setting one-

pack type instant-setting. adhesive anion-polymerizable

with the very small quantity of water adsorbed on the

surface of an adherend.

However, in bonding rubbers, leathers, papers,

cloths, fibers and the like, they have had a fault that the

cured product (polymer) of the alkyl 2-cyanoacrylate is

very hard, and therefore, the bonded part becomes hard

and lacks flexibility. _ . .

Thus, in order to make the cured product of an alkyl

2—cyanoacrylate type adhesive flexible, the addition of

fine rubber particles, the addition of a plasticizer or a

thickening agent, or the like have been proposed. How-

ever, a bonded part rich in flexibility is not obtainable

by these methods. . ,

Improving the flexibility of cured product of an adhe-

sive-by changing the kind of the alcohol moiety of 2-

cyanoacrylate can be predicted from the case of alkyl

acrylate polymer. That is, it is» known that the higher

the alcohol moiety of the alkyl acrylate, the more flexi-

ble the polymer formed becomes, and the most flexible

polymer among the alkyl acrylate! polymers is an n-

octyl acrylate polymer. If this idea is applied to alkyl

2-cyanoacrylatesto investigate the properties of higher.

alkyl 2—cyanoacrylate polymers, they are not flexible

polymers but rather brittle polymers. That is, since the

alkyl 2—cyanoacrylate polymers are polymers of 1,1-

disubstituted vinyl compounds and the . substituents

thereof are a nitrile group and a carboxyl group, both

having a very high polarity, the polymers are very

rigid, linear polymers and it is inferred that a mere intro-

duction of a higher alkyl group into the side chain of the

polymer cannot render the polymer flexible. The same

is also applicable to the case where the polymer is used

as a paint, a coating material, a resist, a binder or the

like. V ' . .

The present inventorshave conducted extensive re-

search on a modification of such conventional ‘rigid

2-cyanoacrylates to obtain a flexible cured product. As

a result, they have succeeded in obtaining a 2—cyanoa-

crylate which can be cured to give a flexible product,

by introducing a -group having an affinity to the main

chain structure of the cured product of 2—cyanoacrylate

which is a rigid, l,l-disubstituted vinyl polymer and

having a plasticizing effect, into the side chain of the

polymer. .

According to this invention, there is also provided a .

2—cyanoacrylate represented by the formula (I):

i” ‘

CHz=C—C—O—R‘—O—R2—O—R

(1)

ll

0

wherein R1 is a—1,2-alkylene group—having 2-4 carbon

atoms, R2 isan alkylene group having 24 carbon atoms

and R3 is an alkyl group having 1-6 carbon atoms.

10'

15

20

25

30

35

.45

50

55

60

65

2

According to this invention, there is also provided a

curable composition comprising a stabilizer and the

2—cyanoacrylate represented by the above-mentioned

formula (I) or a mixture of said 2—cyanoacrylate and

other 2—cyanoacrylate monomer represented by the

formula (II):

CN

I

cH2=C—C—o—R4

II

0

(11)

wherein R4 is an alkyl group having 'l—l2 carbon atoms,

an a_lkenyl group, an alkinyl group, a cycloalkyl A group,

an aryl group, an aralkyl group or an alkoxyalkyl group;

said alkyl, alkenyl, alkinyl, cycloalkyl, aryland aralkyl

groups may optionally have a halogen substituentor an

ether linkage; and said alkoxyalkyl group may have a

halogen substituent. Examples of the group R4 include

methyl, ethyl, n-propyl, isopropyl, n-butyl, isobutyl,

pentyl, hexyl, methoxyethyl, ethoxyethyl, buty1ox-

yethyl, methoxypropyl, methoxybutyl, tetrahydrofurfu-

ryl, allyl, propargyl, cyclohexyl, benzyl, 2-chlorethyl,

trifluorethyl and the like. As the above-mentioned other

2—cyanoacrylate monomer, all the usually known 2-

cyanoacrylates may be used. g .

When it is intended that the curable composition of

this invention be cured by anionic polymerization with

moisture, itcan serve as an adhesive. .When it is in-

tended that an anion-polymerization initiator or a radi-

cal polymerization initiator be allowed tobepresent in

the composition, the composition can be applied as

paints, -various coating materials and molding materials.

In these cases, the following polymer is formed to

cause curing:

C|3N Polyrnerization .

C1-x;=c-if-o—1't.1—o—1z2v—o—1z3 L)

0

. I CN

MA—CHz—(:3—Nv , - (111)

.o=c-—o—R1—o—R2—o—R3

Hitherto, 2-cyanoacrylates have been produced by

reacting a cyanoacetate with formaldehyde in the pres-

ence‘ of a basic catalyst such as a secondary amine, a

sodium alkoxide or the like to preparea condensate

having a degree of condensation of 5-50, andthermally

depolymerizing the condensate at l50°—200°'.C._ in the

presence of P205 or the like. The novel 2—cyanoacrylate

represented by the formula (I) of this invention can also

be produced by a processs similar to the hitherto known

one. .

The cyanoacetate used in this invention as a starting

material is obtained by esterification of cyanoacetic acid

with an alcohol or by transesterification between an

alkyl cyanoacetate and an alcohol, as shown in the

following schemes:

NC—Cl~l2C0Ol-I + Ho—R*—o——R2—o—R3

Nc—cH2—coo—R1—o—R2—o—R3 + H20

4,364,876

3

-continued

' L ' ‘ ' Trans-

estrifi—

NC—’Cl-I2-—CO0-R + Ho—R1—o—R2-—o—R3

NC-CH2—COO--R1-0-R2-0-R3 + non

Concrete examples of the alcohol represented by

H0—R1-—0—R2—O—R3 used in this invention in-

clude diethylene glycol monomethyl ether, diethylene

glycol monoethyl ether, diethylene glycol monopropyl

ether, diethylene glycol monopentyl ether, diethylene

glycol. monohexyl ether, dipropylene glycol‘ mono-

methyl ether, dipropylene glycol monoethyl ether, di-

propylene glycol monopropyl ether, dipropylene glycol

monobutyl ether, dipropylene glycol monopentyl ether,

dipropylene glycol monohexyl ether, dibutylene glycol

monomethyl ether, dibutylene glycol monoethyl ether,

dibutylene glycol monobutyl ether, mono(3-methoxy-

propyl)-ethylene glycol, mono(3-methoxybutyl)-ethy-

lene glycol, mono(3-methoxypropyl)-propylene-1,2-

glycol, mono(3-methoxybuty1)-propylene-l,2—glycol,

mono(methoxyethyl)-propylene-l,2-glycol, mono(me-

thoxyethyl)-butylene-1,2-glycol and the like.

A cyanoacetate of the above-mentioned alcohol and

formaldehyde or paraforrnaldehyde are condensed in

the presence of a catalyst at amolar ratio of O.S—l.5:l,

preferably O.8—1.2:1,-to obtain a condensate. The cata-

lyst is a base or an amine such as piperidine, diethylam-

ine, dibutylamine,‘morpholine, KOH, NaOH, sodium

alkoxide, secondary amine salt or the -like, which is used

in an amount of O.'00l—10 mole%, preferably 0.0l—l

mole%, based on the cyanoacetate. As the solvent for

the reaction, there may be used benzene, toluene, xy- _

lene, trichloroethylene, methylchloroform, tetrahydro-

furan, ethanol, butanol, water or the like. When the

reaction is carried out at a temperature of 20°-150° C.,

preferably 50°—l30" C., a condensate having a degree of

condensation of about 5-50 is obtained with formation

of condensation water. .

Then, this condensation reaction mixture is depolym-

erized either directly or after removal of the condensa-

tion catalyst. The depolymerization is carried out at a

reaction temperature of l4_0°—250° C. at a pressure of

0.1—50 mmHg in the presence of 0.01—l0% by weight of

phosphorus pentoxide, phosphoric acid, condensed

phosphoric acid or the like. The crude cyanoacrylate

formed by the depolymerization reaction is again dis-

tilled, whereby the cyanoacrylate of this invention hav-

ing, a high purity is obtained. , .

The above-mentioned condensation reaction and the

depolymerization reaction can be expressed by the fol-

lowing schemes:

1

nNC—CI-lg-COOR‘—0--R2—0-R3+ nC!-I20 -9 U

CN

I

“‘('CH2"?"3r

=c—o—R1—o—R2—o—R3

CN

I

—('CH2—$—)7:-

o=c-o—R1—o—R2—o—R3 --9

(2)

l0

15

20

25

30

35

45

50

55

65

4

_ -continued

("IN

-,nCH2=C _

O=C-0-R‘-0-R2-O--R3

The novel 2-cyanoacrylate of this invention thus

obtained is a monomer having a high purity and a low"

or medium viscosity which isrepresented by the for-

mula (I). ’ t ~ .

The 2-cyanoacrylate of this invention is ‘a novel com-

pound which can be anion-polymerized with a slight

quantity of water, an amine, an alkali or the like or can

be radical-polymerized with a peroxide or an azo com-

pound similarly to the hitherto" known alkyl 2-cyanoa-

crylates. - ' ‘ '

Typical concrete examples of the 2-cyanoacrylate

represented by the formula (I) are as follows:

2-(2'-methoxy)-ethoxyethyl-2"-cyanoacrylate,

2-(2’-ethoxy)-ethoxyethyl-2"-cyanoacrylate,

2-(2’-propyloxy)-ethoxyethyl-2"-cyanoacrylate, -V

2-(2’-butoxy)-ethoxyethyl-27-cyanoacrylate, —

2-(2'—pentyloxy)-ethoxyethyl-2"-cyanoacrylate,

2-(2’-hexyloxy)-ethoxyethyl-2"-cyanoacrylate,

2-(2’-methoxy)-propyloxypropyl-2"-cyanoacrylate,

2-(2'-ethoxy)-propyloxypropy1-2"-cyanoacrylate,

2-(2'-propyloxy)-propyloxypropyl-2"-cyanoacrylate,

2-(2'-butyloxy)-propyloxypropyl-2"-cyanoacrylate,

2-(2’-pentyloxy)-propyloxypropyl-2"-cyanoacrylate,

2-(2’-hexyloxy)-propyloxypropyl-2"-cyanoacrylate,

2-(2'-methoxy)-butyloxybutyl-2”-cyanoacrylate, .

2-(2’-ethoxy)-butyloxybuty1-2"—cyanoacrylate,

2-(2’-butyloxy)-butyloxybutyl-2”-cyanoacrylate,

2-(3'-methoxy)-propyloxyethyl-2"-cyanoacrylate,

-2-(3’—methoxy)-butyloxyethyl-2"-cyanoacrylate,

2-(3’-methoxy)-propyloxypropyb2"-cyanoacrylate,

2-(3’-methoxy)-butyloxypropyl-2”-cyanoacrylate,

2-(2’-methoxy)-ethoxypropyl-2"-cyanoacrylate,

2-(2’-methoxy)-ethoxybutyl-2"-cyanoacrylate.

The novel 2-cyanoacrylate represented by the for-

mula (I) of this invention has two ether linkages

(—‘—C—O—C—) in the alcohol moiety of the ester and is

characterized in that the alkylene group.(Rl.of formula

(I)) to which the 2-cyanoacryloyl group is directly

bonded in an ethylene group, a propylene group or a

butylene group connected to the adjacent ether linkage

at the 1,2-position. Such a 2-cyanoacrylate is easy to

synthesize, high in purity, excellent in storage stability

and very effective as an adhesive. From the viewpoint

of production and practical value, 2-cyanoacrylates

wherein R2 of the formula (I) is an alkylene group hav-

ing 2-4 carbon atoms (in this case, -the alkylene group

may be 1,2-, 1,3- or 1,4-one) and R3 of the formula (I) is

an alkyl group having 1-6 carbon atoms arepreferred.

When the novel 2-cyanoacrylate represented by the

formula (I) of this invention is used to form a curable

composition which is used as an adhesive or the like, at

least one member selected from the group consisting of

hydroquinone, hydroquinone monomethyl ether, cate-

chol, pyrogallol, phenol, Bisphenol A, anisole, 2,6-di-t-

butylphenol (BI-IT), sulfurous acid (S02), p-toluenesul-

fonic acid, methanesulfonic acid, benzenesulfonic acid,

trifluoromethanesulfonic acid, trifluoroacetic acid, car-

bon dioxide gas, thionyl chloride, propane sultone and

the like is added as a stabilizer in an amount of 1-10,000

ppm (by weight) and preferably, 10-l,0()0 ppm (by

weight); ‘ ’

4,364,876

5

When the curable composition of this invention is

used as a composition having a high viscosity, an adhe-

sive having the desired viscosity can be obtained by

dissolving a polymer such as alkyl acrylate polymer, for

example, polyalkyl acrylates and copolymers of alkyl

acrylate and vinyl acetate, styrene, butadiene, acrylic

acid, methacrylic acid, acrylonitrile, methacrylonitrile,

glycidyl methacrylate and the like; alkyl methacrylate

polymer, for example, polyalkyl methacrylates and

copolymers of alkyl methacrylate and vinyl acetate,

styrene, butadiene, acrylic acid, methacrylic acid, acry-

lonitrile, methacrylonitrile, glycidyl methacrylate, and

the like; alkyl cyanoacrylate polymer; acetylcellulose,

polystyrene or the like into the composition. Usually, an

adhesive composition having a viscosity of l—l0,000 cps

is used effectively. ' ' ‘

Further, a plasticizer may be added if it is necessary.

For example, a flexible cured product can be obtained

by adding dioctyl‘ phthalate, dibutyl phthalate, trioctyl

trimellitate, dioctyl adipate, dioctyl glutarate or the like

in an amount of 0-50% by weight based on the weight

of the 2-cyanoacrylate. _ _

Further, fine particles of, for example, silica, alumina,

silica-alumina, boron nitride, polyethylene, Teflon or

the like may be added as a filler to improve the bonding

strength and adhesion. For this purpose, a fine particle

having a size of 0.00l—100p. is added in an amount of

1—30% by weight based on the weight of the 2-cyanoa-

crylate.

If necessary, a dye or a pigment may be added some-

times. A perfume may also be added for the sake of

aromatization.

When an adhesive in the form of a curable composi-

tion comprising the 2-cyanoacrylate of the formula (I)

of this invention is applied to the surface of an adher-

end, it is anion-polymerized and cured by the slight

quantity of water adsorbed on said surface similarly to

the hitherto known alkyl 2-cyanoacrylates, to .effect

bonding. Unlike the hitherto known 2-cyanoacrylate

adhesives, however, this adhesive gives a very flexible

cured adhesive so that it is effective for bonding flexible

materials such as leather, vinyl sheet, rubber, fiber,

paper and the like. That is, there is an advantage that the

cured adhesive and the neighborhood of the bonded

part become as flexible as the bonded material.

Further, a hitherto known 2-cyanoacrylate repre-

sented by the formula (II) may be added to the 2-

cyanoacrylate of this invention represented by the for-

mula (I) to_improve the strength. In general, a higher

blending ratio of the nove1.2-cyanoacrylate (I) of this

invention gives a higher flexibility, and a higher blend-

ing ratio of the hitherto known 2-cyanoacrylate (II)

gives a higher hardness to the cured product. The

blending ratio of the novel 2-cyanoacrylate (I) of this

invention to the hitherto known 2-cyanoacrylate (II) is

in the range of 1-100:99-0, preferably 30—100:70-0 by

weight. .

10

l5

20

25

30

35

45

50

55

As mentioned above, the novel 2-cyanoacrylate (I) of 60

this invention or its mixture with a hitherto known

2-cyanoacrylate (II) is anion-polymerized by a slight

quantity of water. Similarly to the hitherto known alkyl

2-cyanoacrylates, it can also be anion-polymerized by a

base or a weak base such as amines, alkalis, phosphines,

sulfides, mercaptans, quatemary ammonium salts, wa-

—ter, alcohols or the like to form a polymer having the

following skeleton:

65

(‘IN

-Cl-I2—C—

I

o=c—o—R1—o—R2—o—R3

Usually, such a polymer has a molecular weight of

about l0,000—1,000,000. .

As the initiator for the anionic polymerization, N,N-

dimethylaniline, N,N-dimethyl-p-toluidine, sodium

ethoxide, triethylbenzylammonium chloride and the

like are particularly effective.

If the novel 2-cyanoacrylate (I) of this invention is

radical-polymerized with a radical initiator, a cured

product having the same skeleton as above is obtained.

' As the radical initiator, peroxides and azo compounds

such as benzoyl peroxide, azobisisobutyronitrile and the

like are effective for the radical polymerization of this

invention. ‘

Also, it can be polymerized by ultraviolet rays and

sunlight rays. In this case, the addition of a photosensi-

tizer such as benzophenone, benzoin monomethyl ether

or the like facilitates the photopolymerization.

The novel 2-cyanoacrylate (I) of this invention can

also be radical-copolymerized with almost‘ all kinds of

vinyl monomers. - ' .

The curable composition of this invention comprising

the novel 2-cyanoacrylate is useful not only as an adhe-

sive but also as a paint and various coating materials. It

can also be used as a molding ‘material or a potting

material.

The homopolymer and copolymers of the 2-cyanoa-

crylate of this invention are also applicable to paints,

various coating materials, resists, binders, and the like.

This invention is concretely explained below with

reference to Examples which are byway of illustration

and not by way of limitation. In the Examples, parts and

% are by weight unless otherwise specified.

EXAMPLE 1

Under reflux, 85 parts of cyanoacetic acid, 161 parts

of diethylene glycol monoethyl’ ether, 100 parts of tolu-

ene and 1 part of sulfuric acid were subjected to reac-

tion, and the resulting water was removed as an azeo-

tropic mixture with toluene. After completion of the

reaction, the unreacted acid was neutralized with so-

dium hydroxide and the oily phase was distilled to ob-

tain 2-(2'-ethoxy)-ethoxyethyl cyanoacetate. The char-

acteristic properties thereof were as follows: bp= 120°

C./2 mmHg, d41°=1.098, np2°:—-1.4448. The yield of

the 2-cyanoacetate was 170 parts.

Then, 166 parts of 2-(2’-ethoxy)-ethoxyethyl -cyano-

acetate, 24 parts of paraformaldehyde, 80 parts of tolu-

ene and 0.2 parts of piperidine were subjected to con-

densation under reflux for 7 hours while removing the

water formed. After washing the reaction mixture with

an aqueous solution of p-toluenesulfonic acid, the oily

phase was separated, mixed with 0.75 part of P205 and

0.5 part of hydroquinone and depolymerized under

vacuum at l65°—205° C. Thus, 95 parts of a depolymer-

ized fraction having a boiling point of l20°—l46° C./2-3

mmHg was obtained. By distilling it again, 65_ parts of

2-(2’-ethoxy)-ethoxyethyl-2"-cyanoacrylate having a

boiling point of l07°—l 10° C./2 mmHg was obtained. It

was a light yellow liquid having a viscosity of 20-30

cps. After adding 21 ppm of S02 thereto, the perfor-»

4,364,876

7

mances of the product as adhesive were investigated.

The results obtained were as follows:

Setting time as measured according to J IS K

6861-1977:

Iron/Iron: 15 seconds 5

Rigid PVC/Riding PVC: 10 seconds

ABS/ABS: 5 seconds

This monomer was anion-polymerized with’ N,N-

dimethyl-p-toluidine to obtain a polymer. The polymer

was transparent and had a flexible nature. Its glass tran-

sition temperature (Tg) was —5°.C.

EXAMPLE 2

Under reflux, 85 parts of cyanoacetic acid, 144 parts

of diethylene glycol monomethyl ether, 1 part of sulfu-

ric acid and 100 parts of toluene were subjected to

esterification while removing the water formed. Then,

10

15

the unreacted acid was neutralized and the mixture was ‘

distilled to obtain 160 parts of 2-(2’-methoxy)-ethox-

yethyl cyanoacetate. The characteristic properties

thereof were as follows: bp=120°—l22° C./3 mmHg,

d42°=1.132, nD20= 1.4426. , V .

To condensation were subjected 154 parts of 2-(2'-

methoxy)-ethoxyethyl cyanoacetate, 24 parts of para-

formaldehyde, 80 parts of toluene and 0.2 part of piperi-

dine under reflux while azeotropically removing the

resulting water. -After washing the condensation mix-

ture with water, the oily phase was mixed with 0.5 part

of P205 and 0.5 part of hydroquinone and depolymer-.

ized to obtain 50 parts of a fraction having a boiling

point of 100°—l48° C./5 mmHg. By distilling it again,

2-(2’-methoxy)-ethoxyethyl-2"-cyanoacrylate having a

boiling point of l00°—1 12° C./ 3 mmHg was obtained. It

was a liquid having a viscosity of 20-30 cps. After add-

ing 21 ppm of S02 thereto, the performances of the

product as adhesive were investigated. The setting time

A was 10 seconds on rigid polyvinyl chloride and 15 sec-

onds on iron.

.20

25

30

35

'40

EXAMPLE 3

To esterification were subjected 85 parts’ of cyano-

acetic acid, 194 parts of diethylene glycol mono-n-butyl

ether, 100 parts of toluene and 2 parts of p-toluenesul-

fonic acid under reflux while azeotropically removing

the waterformed, to obtain 195 parts of 2-(2'-n-butylox-

y)-ethoxyethyl cyanoacetate. The characteristic prop-

erties thereof were as follows: bp=131°—133° C./2

mmHg; d42°= 1.053, nD2°= 1.4442.

Then, 189 parts of 2-(2'-n-butyloxy)-ethoxyethyl cya-

noacetate, 24 parts of paraformaldehyde, 80 parts of

toluene and 0.2 parts of piperidine were subjected to

reaction under reflux while removing the water formed

for 7 hours. After washing the condensation reaction

mixture with 5% aqueous solution of p-toluenesulfonic

acid, the oily phase was separated, mixed with 0.5 part

of P205 and 0.5 part of hydroquinone, and depolymer-

ized under vacuum at l50°—200° C. to.obtain 88 parts of

a fraction having a boiling point of 130°—152° C./3

mmHg. By distilling the fraction again, 2-(2'-n-butylox-

y)-ethoxyethyl-2"-cyanoacrylate having a boiling point

of 120°—l24° C./3 mmHg was obtained. It was a light

yellow liquid having a viscosity of 20-30 cps. After

adding 53 ppm of S02 thereto, the performances of the

product as adhesive were investigated. The ‘setting time

was 45 seconds on rigid polyvinyl .chloride and 60 sec-

onds on iron. , 5 . v -

45

50

55

60

65

8

EXAMPLE 4

To reaction were subjected 85 parts of cyanoacetic

acid, 228 parts of diethylene glycol mono-n-hexyl ether,

1 part of p-toluenesulfonic acid and 150 parts of benzene

under, reflux while azeotropically removing the water

formed. Then, the reaction mixture was neutralized and

distilled to obtain 220 parts of 2-(2’-n-hexyloxy)-ethox-

yethyl cyanoacetate. The characteristic properties

thereof were as follows: bp=l52°—145° C./2 mmHg,

d420= 1.022, IIDZO 1.4465. _ ‘

Then, 212 parts of 2-(2’-n-hexyloxy)-ethoxyethyl cya-

noacetate, 24 parts of paraformaldehyde, 80 parts of

_toluene and 0.2 part of piperidine were subjected to

reaction under reflux while removing the resulting con-

densation water azeotropically. Then, the reaction

product was depolymerized under vacuum at 150°—200°

,C. in the presence of 0.5 part of P205 and 0.5 part of

hydroquinone to obtain 40 parts of a fraction having a

boiling point of l43°—160° C./3 mmHg. By distilling the

fraction again, 2-(2’-n-hexyloxy)-ethoxyethyl-2"-

cyanoacrylate having a boiling point of 130°—135° C./3

mmHg was obtained.

After adding thereto 50 ppm of sulfurous acid gas, the

performances of the product as adhesive were investi-

gated. On rigid polyvinyl chloride, the setting time was

30 seconds and the tensile shear strength of bond was 75

kgf/cmz.

EXAMPLE 5

To esterification were subjected 85 parts of cyano-

acetic acid, 178 parts of dipropylene glycol mono-

methyl ether, 1 part of sulfuric acid and 100 parts of

toluene under reflux while azeotropically removing the

water formed. Then, the reaction mixture was distilled

to obtain 185 parts 2-(2'-methoxy)-propyloxypropyl

cyanoacetate. The characteristic properties of the cya-

noacetate were as follows: bp=115”—118° ’C./2.5

mmHg, d42°= 1.060, 11020: 1.4368.

Then, 177 parts of 2-(2’-methoxy)-propyloxypropyl

cyanoacetate, 24 parts of paraformaldehyde, 80 parts of

toluene and 0.2 part of piperidine were subjected to

reaction under reflux while azeotropically removing the

resulting water. Then, 0.5 part of ‘P205 and 0.5 part of

hydroquinone were added to the reaction product thus

obtained, and the reaction product was depolymerized

in vacuum at 150°—200° C. to obtain 100 parts of a frac-

tion having a boiling point of 110°—130° C./ 3 mmHg. By

distilling the fraction again, 2-(2’-methoxy)-propyloxy-

propyl-2"-cyanoacrylate having a boiling point of

l03°—105° C./3 mmHg was obtained. .

It was a colorless liquid. After adding thereto 34 pp

of sulfurous acid gas, the performances of the product

as adhesive were investigated. The setting‘ time was 30

seconds on rigid polyvinyl chloride and 45 seconds on

iron.

EXAMPLE 6

To a 2-cyanoacrylate monomer as shown in Table 1

was added 2% of N,N-dimethylformamide to prepare a

uniform solution. The monomer was anion-polymerized

and cured at 40°—60° C. for 12 hours or more to obtain

a .- cured product having a molecular weight of

100,000-300,000 or so as measured by a high speed

liquid chromatography (HLC) in tetrahydrofuran.

Other properties of the cured products are shown in

Table 1.

4,364,876

9

TABLE 1 . :

(EN . V . -

CHg=C-C—'0—R‘-Oz-R2-0-4-V-_l‘{~‘i _‘* ‘, A ,

H =' ' - «' Properties of. I 5

O - H :4 cured productsc .

Appear; V _

R1 R2 ‘ ‘R3 ance ~ Tg

-CH2CH2— -Cl-igCH2— ‘-‘CH3 Tra'ns- ‘ —"

- V ‘' ~ V ’ parent and . ' 10-

- . flexible : .. V

-CH2CH2- -Cl-i2CH;— _ . -C2!-I5 _Trans- ,—5‘? C.

parent and

' flexible‘ '

-CH2CH2— "'CH2CH2— -n-C4H9 Trans- ,_ ‘—20° C.

— ' parent and . < 15

. g , flexible _

-CH2CH2— —CH2CH2- -n-C61-I13 Trans- 4-

V 2* parent and- " v 2-

flexible

CH3 CH3 _-CH3 Trans-M . x—3l)° C. 20

I I . parent and

-CH2CH- -CHzCH— flexible

For comparison, ethyl 2-cyanoacrylate was anion-

polymerized in the same manner as above to obtain a 25

cured product. It was hard and had a T3 of 100° C.

Further, a cured product of n-hexyl 2-cyanoacrylate

was also examined. It was hard and brittle.

EXAMPLE 7 30

To each of the 2-cyanoacrylate monomers shown in

Table 1 was added 0.1% of azobisisobutyronitrile. After

deaeration, the monomer was radical-polymerized at

60° C. for 24 hours to obtain a cured product. All the

cured products obtained were transparent and flexible. 35

_ EXAMPLE 8

In 2-(2’-ethoxy)-ethoxyethyl-2"-cyanoacrylate was

dissolved 0.2% of benzophenone, and the solution was

irradiated with ultraviolet rays from a high pressure~4o

mercury lamp in an intert gas atmosphere, such as nitro-

gen gas. Thus, a transparent cured product rich in flexi-

bility was obtained. - .

Further, 20 g of 2-(2'-ethoxy)-ethoxyethyl-2"-

cyanoacrylate was placed in a polyethylene vessel hav-.._45

ing a capacity of 20 g and irradiated with sunlight rays.

Thus, a transparent and flexible block of 2-(2’-ethoxy)-

ethoxyethyl-2"-cyanoacrylate polymer was obtained.

The properties thereof were the same as the results of

Example 7. 50

EXAMPLE 9

» The 2-(2’-ethoxy)-ethoxyethyl-2"-cyanoacrylate (I)

obtained in Example 2 was mixed with ethyl 2-cyanoa-

crylate (II) in a proportion as shown in Table 2, and 50_ 55

ppm of sulfurous acid gas and 1,000 ppm of hydroqui-

none were added thereto to prepare an adhesive. The

bonding performances of the adhesives were measured

to obtain the results shown in Table 2.

60

TABLE 2 ‘

Bonding strength (iron/iron}

Mixing ratio Tensile shear Impact peel

(by weight) strength‘ Tensile strength“ strength

(1)/(11) (kgr/cm?) (kgr/c-ml) (kgf/cm/cmz)

100/0‘ 50 40 11

70/30 120 200 12

50/50 150 260 12

30/70 _ 140 250 9

' tained were a's’sho'wn in Table 3. '

10

TABLE 2-continued

Bonding strength (iron/iron}

Mixing ratio Tensile shear . . . Impact peel

(by weight) strength‘ Tensile stren th“ strength

(I)/(ll) (kgf/cmz) (kgf/cm ) (kgf/cm/cmz)

0/ I00 l50 3l0 7

:= (Control) ‘ - v . '

xNote': ’

‘Measured according to MS K 6tl6l-l977:_- ‘

"Measured according to_.llS K_ 6855 '

V . EXAMPLE 10 -

Neoprene rubberwas selected as a flexible material.

Twoepieces of neoprene rubber we're bonded to each

other with a 2—cyanoac‘rylate_' adhesive as ‘shown in

Table 3 and the tensileshear strength of bond was mea-

sured according to JIS Kg’ 6861-19077. Theresults ob-

. Test piece’: neoprene rubber: 3X25>< 100 mm "

Area of bonded surface: 3.125 em2 ’ “

Bonding conditions: 23:1” C., 60i2% RH, aging

for 24 hours.

TABLE 3

Adhesive

$N Tensile

CH2=C-C-O—R‘—0-R2-0-R3 Shear

|| » . strength of State of

0 bond bonded

‘ R1 R2 R3 (kgf/cmz) part

-CH2CH2— -CHzCH2— —CH3 4‘ Rich in

. flexibility

—CH2CH2- -CHzCH2- -C2H5 4‘ Rich in

flexibility

""CHzCH2— —CH2CH2'— -n-C4H9 4‘ ' Rich in

flexibility

CH CH

1 3 i 3 Rich in

—CHzCH— —CH2CH— —CH3 4‘ flexibility

CN

CH2=C—C0OC2H5 (Control) 4‘ Hard

. fl“

CH2=C—CO0-n-C4H9 (Control) 4' Hard

Note:

‘A material failure occurred.

EXAMPLE 1 l

2-(2’-Ethoxy)-ethoxybutyl cyanoacetate was synthe-

sized in the same manner as in Example 1 by the esterif1-

cation between cyanoacetic acid and 2-(2’-ethoxy)-

ethoxybutanol. It had the following characteristic prop-

erties: bp=130°-135° C./2.5 mmHg, d,.2°= 1.05.

Then, 189 parts of 2-(2’-ethyoxy)-ethoxybutyl cyano-

acetate, 24 parts of paraformaldehyde, 80 parts of tolu-

ene and 0.2 parts of piperidine were condensed in the

same manner as in Example 1, and subsequently, the

reaction product was depolymerized to obtain 70 parts

of a fraction having a boiling point of l35°—150° C./ 3

mmHg. By distilling the fraction again, 2-(2’-ethoxy)-

ethoxybutyl-2”-cyanoacrylate having a boiling point-of

122°-125-° C./3 mmHg was obtained.

An adhesive obtained by adding 50 ppm of S02

thereto had a setting time of 45 seconds on rigid polyvi-

nyl chloride and gave a flexible cured product.

What is claimed is:

1. A 2-cyanoaicrylate represented by the formula:

ll

(|ZN

cH2=c-fi—o—n'—o—R2-so-"R3

0

(1)

wherein R‘ is a 1,2-alkylene group having 2-4 carbon

atoms, R2 is an alkylene group having 21-4‘c2i1‘bon atoms

and R3 is an alkyl group ha’ving‘1='-6' 'carbon_atoms; ,

2. A 2-cyanoacrylate according" to claim I selected

from the group consisting of 2-(2’-methoxy)-ethoxyeth-

yl-2"-cyanoacrylate; 2 ' 2-(2’-ethoxy)—ethoxyethyl-2"-

cyanoacrylate, 1 2-(2’-propyloxy)-ethoxyethyl-2”-

cyanoacrylate; 2-(2'-Butyloxyyéthoxyethy1-2”gcyanoa-

crylate, 2-(2'-penityloxy)-eihoxyethyl-2”-cyanoacrylaie,

2-(2’-hexyloxy)-ethoxyethyl-2"-cyginogcgylate, . 2-(2’-

methoxy)-propyloxypropyb2"-cyanoacrxlgte, 2~(2'-

ethoxy)-propyloxypropyls2"~cyanoacrylate, ' . 2-(_2'.

propyloxy)-propyloxypropyl-2"-cyanoacrylate, 2-(2'-

butyloxy)-propyloxypropyl:2"¢cyanoac;ylatei ‘2-(2’-

I0

15

20

25

4,364,876

12

pentyloxy)-propyloxypropyl-2"-cyanoacrylate, 2-(2'-

hexyloxy)-propyloxypropyl-2"Lcyanoacrylate, 2-(2'-

methoxy)-butyloxybutyl-2"-cyanoacrylate, 2-(2'-ethox-

y)-butyloxybutyl-2"-cyanoacrylate, 2-(2’-butyloxy)-

butyloxybutyl-2"-cyanoacrylate, 2—(3'-methoxy)-

propyloxyethyh2”—cyanoaci'ylate, 2-(3’-n1ethoxy)-

butyioxyethyl-2”~cyanoacrylate, 2-(3'-methoxy)-

propyloxypropyl-2Wcyanoacrylatc, 2-(3’-m_ethoxy)-

butyloxypropyl-2"-cyanoacrylate, 2-(2'-methoxy)-

elhoxypropyl-'2"-cyanoacrylate and 2-(2'-xnethoxy)-

ethoxybutyl-2_"-cyanoacrylate. '

3. A 2-cyanoacrylate according to claim 1 selected

from the group consisting of 2-(2’-ethoxy)-ethoxyethyb

2”-cyanoacrylate, < 2-(2'-methoxy)-ethoxyethyl-2"-

cyanoacrylate, 2-(2’-n-butyloxy)-ethoxyethyl—2”-

cyanoacrylate, 2-(2’-n-hexyloxy)-ethokyethyl-2"-

cyanoacrylate and 2-(2’-methoxy)-propyloxypropyb2"-

cyanoacrylate.

O I O I ‘ O

30»

35"

45 "

55‘

i65