The Preparation of Thiocyanoacrylates

The Preparation of Thiocyanoacrylates

Folder:

Journal:

Year:

DOI:

10.1002/pol.1981.170191025

Type of document:

Language:

The Preparation of Thiocyanoacrylates

In this note we report the preparation of hitherto unknown thiocyanoacrylates. These compounds

are conveniently prepared by displacement from their readily synthesized anthracene adducts by

treatment with relatively strong dienophilessuch as maleic anhydride’ or even, as we have discovered,

ethyl cyanoacrylate. Utilization of the latter material in excess provides a very convenient method

for the preparation of thiocyanoacrylate-containing ethyl cyanoacrylate solutions with improved

moisture-resistant properties when polymerized between metals.

The thiocyanoacrylate-anthraceneadducts were prepared in high yield by reacting cyanoacrylyl

chloride-anthracene adduct with the appropriate lead mercaptide in dry ether.2 The S-dodecyl

thiocyanoacrylate-anthracene

adduct was thus obtained as a colorless crystalline solid with melting

point 62-64°C (IR v C(S) = 0.1683 s cm-’). Reacting together equimolar quantities of maleic anhydride, the ,displacing dienophile,’ and the thio anthracene adduct in refluxing xylene for 42 h*

gave the near-theoretical yield of maleic anhydride-anthracene adduct, which came out of solution

on cooling to room temperature as colorless crystals which were filtered off. The last traces of this

material were similarly removed following the addition of a large volume of pentane to give the

thiocyanoacrylate as a very pale brown heavy oil after removal of volatiles. Methyl acetylene dicarboxylate was also found to displace the thiocyanoacrylate from its anthracene adduct.

A thiocyanoacrylate-containing ethyl cyanoacrylate solution was obtained by reacting together

excess ethyl cyanoacrylate with the thiocyanoacrylate-anthraceneadduct in refluxing xylene for

5 h* (SO2 bleed). The high reactivity of the ethyl cyanoacrylate dienophile in the Diels Alder displacement would appear to reside in the higher electron withdrawing capacity of C(0) OCHzCH3

f

solution (ca. 10%level of additive)

over that o C(0)SR. The S-dodecylthiocyanoacrylate-containing

possessed significantly improved moisture resistance over ethyl cyanoacrylate with no additive’

after polymerization between grit-blasted mild steel lapshears exposed to humid aging.

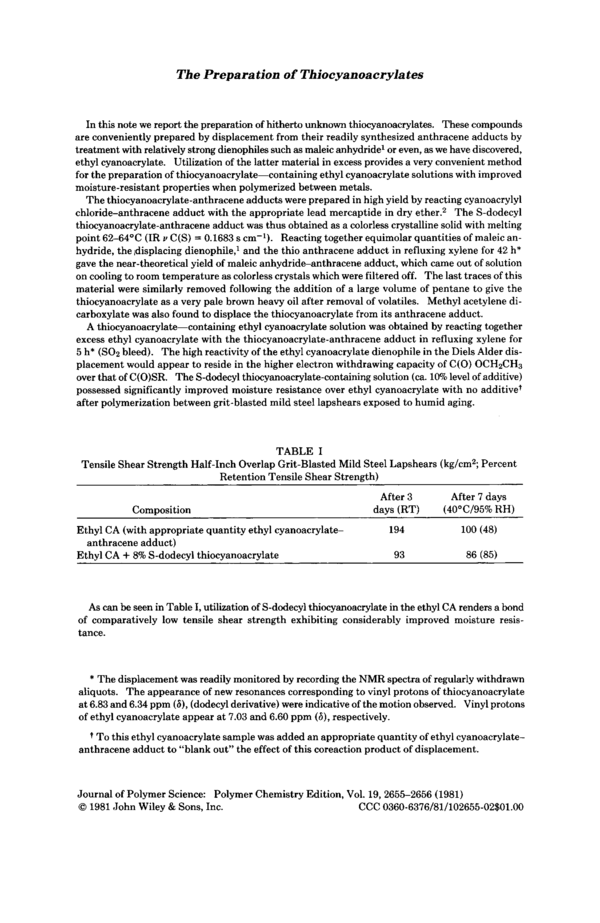

TABLE I

Tensile Shear Strength Half-Inch Overlap Grit-Blasted Mild Steel Lapshears (kg/cm2;Percent

Retention Tensile Shear Strength)

Composition

Ethyl CA (with appropriate quantity ethyl cyanoacrylateanthracene adduct)

Ethyl CA 8% S-dodecyl thiocyanoacrylate

+

After 3

days (RT)

After 7 days

(4OoC/95%

RH)

194

100 (48)

93

86 (85)

As can be seen in Table I, utilization of S-dodecylthiocyanoacrylatein the ethyl CA renders a bond

of comparatively low tensile shear strength exhibiting considerably improved moisture resistance.

* The displacement was readily monitored by recording the NMR spectra of regularly withdrawn

aliquots. The appearance of new resonances corresponding to vinyl protons of thiocyanoacrylate

a t 6.83 and 6.34 ppm (a), (dodecyl derivative) were indicative of the motion observed. Vinyl protons

of ethyl cyanoacrylate appear a t 7.03 and 6.60 ppm (a), respectively.

+ To this ethyl cyanoacrylate sample was added an appropriate quantity of ethyl cyanoacrylateanthracene adduct to “blank out” the effect of this coreaction product of displacement.

Journal of Polymer Science: Polymer Chemistry Edition, Vol. 19,2655-2656 (1981)

0 1981 John Wiley & Sons, Inc.

CCC 0360-6376/81/102655-02$01.00

2656

NOTES

References

1. C. J. Buck, US.Patent 4,013,703,1977.

2. G. Braude, J. Org. Chern., 22,1675 (1957).

S. HARRIS

Research & Development

Loctite Ltd.

Dublin, Ireland

Received March 4,1981

Accepted May 15,1981

Coments go here:

- Log in to post comments