PREPARATION OF MONOMERIC ALKYL

Year:

Type of document:

Language:

Patented Apr. 19, 1949

UNITED

2,467,926

S;TA.TE.;S‘j PATENT OFFICE).

2,467,926

PREPARATION OF MONOMERIC ALKYL

ALPI-IA- CYANO —ACRYLATES

A1an.E. Ardis, Akron, Ohio, assignor to The B. F.

Goodrich Company, New York, N. .Y., a corpo-

ration of New York

No Drawing. Application March 1, 1947,‘

Serial‘No. 731,863‘

9 Claims.

I

This invention relates to alkyl esters of alpha-

cyano acrylic acid and to a method of preparing

them.

Alkyl esters ;of alpha-cyano acrylic acid h9«Ve':

heretofore -been ob»tained»in=the polymeric form

by pyrolysis of-the cyanhydrinracetates of’ acetyl

fattyiacidi esters. It has now been found that

alkyl: esters of. alphacyanoacrylic acid may be

obtained :by reacting an I alkyl -cyanoeacetate first

with-an.a1kali'meta1.a1coho1ate and thenwwith.

a compound of’ the general structure:

R——O——CH2—X

in which Rt‘ is an organic radical having. its..con-,

nectingvalence on a carbon.atom.and.contain-

ing.no reactive hydrogen atoms: (1. e.‘, havingall

its hydrogen attached-. to carbon),.and-X: iS"‘«‘al1‘

halogen- atom. .

Compounds illustrative » of. the. above general

structure include the halo-methyl esters- of -mono-

carboxylic acids (wherein R is an- acyl group):

such. as chloro—methy-1- acetate, chloro-methyl .

propi-onate, bromo-methyl acetate, chloro-methyl‘

benzoate, chloro-methyl chloroacetate, and other

halo-Vmethylsesters of substituted orfunsubstituted ‘

aliphatic or cyclic monocarboxgylic acids; the

halo-methylethers (Wherein.R, is ahydrocarbon»

radical) such as chloro-methyl ether, chloro-~

methyl ethyl ether; chloro-methyl propyl ether,

chloro-methyl triphenylmethyl ether andvothers,»

as well as- any other compoundof the above gen‘-

eral_ structure in-which Ruhas vario.us inertsube»

stituent. groups such as halogen atoms, ether

groups» and hydrocarbon groups.’ Preferably R

is an -:alkyl; ar»y1’or. acyl radical containing from

1 tov»8 carbon-atoms-...

According. tothe present invention an alkyl

cyanoacetate -is reacted firstwith analkali metal.

a1co.holate"and; then with; a; compound of the,-

above structure, the reaction proceeding asuin-»

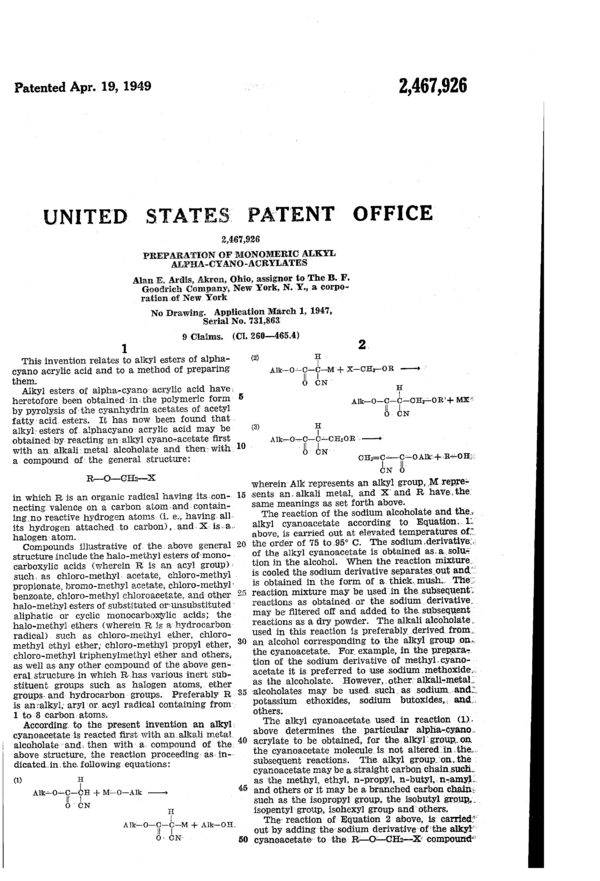

dicatedin .the.. following equations:

(1) H

I

A‘1k'—‘—0—-(!'T‘—(EH + M'—O——A]k ‘-——>

O ' CN

H

I

Alk——-0—C—C——M + Alk—OH..

I I

o CN“

«10 ,

15

20

NJ

in

30

35

40

45

50

(Cl. 260—465.4)

2.

(2) Fl! ~

AIk——0'—(|'|)—-(|J—M'+ X—CH2—OR ——-) '

0 ON‘ H

Alk-—O—?—(]2'—O‘EI7—‘-OR‘+ MK???

6. in

(3) H.

A1k+O—.C——-+‘—.CH20’R ' u —->

to cN

CH2=Cé——C—0Alk‘=+. »R—“.‘—OH‘;r.

éN m'a'i-n -fraction *dis£ti1:ling "over -at -150 to

17'il°- ‘was. ~colleet.ed ‘a receiver immersed in

liquid nitrogen. The boiling rpoint ~'ran=ge~'of 4:50

to '1!70.r° C. is not a true boiling point because a

higher temperature. is: necessary to vdepolymerize

the ester. The resulting monomeric. 'eth.yl~‘a~l.°pha-

cyano acrylate polymerized easily when warmed

to .50?’ ‘C. ‘or higher.

The monomeric ethyl alpha-cyano =ac‘r;yla;te

prepared in =Exampl'e= i had a ‘freezing point or

—20 to 4-25“ G. -and '-upon "analysis was found to

contain 11.21% nitrogen, 57.40% carbon, and

5.64% hydrogen ‘(theoretical for ethyl alpha-

cyano acrylate is 11.20% nitrogen, 57.59% car-

bon and 5.64% 5h.y'd»roge‘n=)-. "The hard polymer

prepared frorn. the monomer --had a softening

point or 1iob'c., a'm’e‘1ting p‘o"int.oIf .150 to 160° C.

and was soluble in acetone but insoluble in alco-

hol and ether.

It was -fz0U.!.’1d that a considerable portion of -the

dis-t_illa‘t’e in -the distillation -of Example I stuck

to ‘thewalls. of-.. the distilling side arm and -in the

ad'a"pterfand..»it. was found that this material had

polymerized. .-It was -further -found that if a

stream ‘of nitric oxide gas was introduced to the

distillation ‘flask just above the surface of the

distilland the polymerization of the distillate in

the side arm and receiver was eliminated and

the ester obtained in the monomeric form.

Example I I

Methyl alpha-cyano acrylate was prepared by

a procedure similar to that of Example I using

23 grams of metallic sodium and 500 ml. of abso-

lute methanol in the preparation of the sodium

alcoholate. 100 grams of methyl cyanoacetate

were then added to the sodium-methanol reac-

tion mixture and the resulting mixture was

heated on a steam bath for an hour and a half.

The entire mixture of sodium derivative of

methyl cyanoacetate in alcohol was then added

to a fiaskcontaining 114 grams of chloro-methyl

acetate. The temperature of the reaction mix-

ture was maintained below 35° C. by means of

an ice-saltbath. The resultant reaction mixture

was poured into 700 “ml. of cold water and stirred.

5

-10

15'

20‘

25

30»

so

in

45

-50

55

60

65

70

6

The water‘ and -on .,1aye‘rs were _«‘ei':‘traote‘¢1

acetoner. 'U'}'g3oi1«;s’t‘ahdin‘g-, a ‘water layer separated

from" ‘the acetone solution was discarded.

The acetone solution was then ‘dried and "the

acetone *eva"p‘oratea ‘under

The acetone extras , was dis “lied “under ‘vac-

uum in the preseirce of nitric ='oxi'd'e gas 'an'd the

distillate was -collected -in a "receiver imrnersed

in a liquid nitrogen bath. The main fraction ‘dis-

tillirfg ’

Coments go here:

- Log in to post comments